1 Introduction

1.1 Applications of yield stress fluids

Gels are usually particulate dispersions that undergo solid–liquid or sol-gel transition i.e. they yield beyond a critical shear stress (called the yield stress ![]() $\unicode[STIX]{x1D70F}_{y}$); they have many applications in industry (for e.g. in food products like mayonnaise, consumer products like toothpaste and drugs, building materials like concrete and paint, oil and drilling muds, etc. Bird, Dai & Yarusso (Reference Bird, Dai and Yarusso1983)), in biology (for e.g. blood flow Picart et al. (Reference Picart, Piau, Galliard and Carpentier1998)) and the environment (for e.g. clay suspension, debris, snow avalanches, lava flows, etc. Ancey (Reference Ancey2007) and Chambon, Ghemmour & Naaim (Reference Chambon, Ghemmour and Naaim2014)). Before yielding, they have solid-like properties e.g. they can sustain shear stress and deform elastically, whereas after yielding they behave like a fluid. Thus, the yield stress

$\unicode[STIX]{x1D70F}_{y}$); they have many applications in industry (for e.g. in food products like mayonnaise, consumer products like toothpaste and drugs, building materials like concrete and paint, oil and drilling muds, etc. Bird, Dai & Yarusso (Reference Bird, Dai and Yarusso1983)), in biology (for e.g. blood flow Picart et al. (Reference Picart, Piau, Galliard and Carpentier1998)) and the environment (for e.g. clay suspension, debris, snow avalanches, lava flows, etc. Ancey (Reference Ancey2007) and Chambon, Ghemmour & Naaim (Reference Chambon, Ghemmour and Naaim2014)). Before yielding, they have solid-like properties e.g. they can sustain shear stress and deform elastically, whereas after yielding they behave like a fluid. Thus, the yield stress ![]() $\unicode[STIX]{x1D70F}_{y}$ is a practically useful parameter. To give some examples, it is used to assess the shelf life of paints, keep particulate fillers from settling in many consumer products and also dictates whether bubbles remain trapped in cement (Singh & Denn Reference Singh and Denn2008). The latter is an important factor in the structural integrity of buildings.

$\unicode[STIX]{x1D70F}_{y}$ is a practically useful parameter. To give some examples, it is used to assess the shelf life of paints, keep particulate fillers from settling in many consumer products and also dictates whether bubbles remain trapped in cement (Singh & Denn Reference Singh and Denn2008). The latter is an important factor in the structural integrity of buildings.

The yield stress ![]() $\unicode[STIX]{x1D70F}_{y}$ has its origin in the microstructure of the material, which can dynamically adjust under the action of a flow. Hence, thixotropic (time-dependent shear thinning) behaviour is generally observed for many materials (e.g. clay suspension, colloidal gels) and

$\unicode[STIX]{x1D70F}_{y}$ has its origin in the microstructure of the material, which can dynamically adjust under the action of a flow. Hence, thixotropic (time-dependent shear thinning) behaviour is generally observed for many materials (e.g. clay suspension, colloidal gels) and ![]() $\unicode[STIX]{x1D70F}_{y}$ may not exhibit a single invariant value (Bonn & Denn Reference Bonn and Denn2009). Apart from this, yield stress fluids (YSF) may possess complex macroscopic properties because of their different elastic, viscous and plastic characteristics (Piau Reference Piau2007). For a recent comprehensive review describing the properties of YSF, please refer to Bonn et al. (Reference Bonn, Denn, Berthier, Divoux and Manneville2017).

$\unicode[STIX]{x1D70F}_{y}$ may not exhibit a single invariant value (Bonn & Denn Reference Bonn and Denn2009). Apart from this, yield stress fluids (YSF) may possess complex macroscopic properties because of their different elastic, viscous and plastic characteristics (Piau Reference Piau2007). For a recent comprehensive review describing the properties of YSF, please refer to Bonn et al. (Reference Bonn, Denn, Berthier, Divoux and Manneville2017).

1.2 Non-dimensional numbers

The Herschel–Bulkley (HB) constitutive equation (i.e. the relation between stress ![]() $\unicode[STIX]{x1D70F}$ and strain rate

$\unicode[STIX]{x1D70F}$ and strain rate ![]() $\dot{\unicode[STIX]{x1D6FE}}$) is the archetypical form used for YSF, and is given as

$\dot{\unicode[STIX]{x1D6FE}}$) is the archetypical form used for YSF, and is given as ![]() $\dot{\unicode[STIX]{x1D6FE}}=0$ when

$\dot{\unicode[STIX]{x1D6FE}}=0$ when ![]() $\unicode[STIX]{x1D70F}\leqslant \unicode[STIX]{x1D70F}_{y}$, and

$\unicode[STIX]{x1D70F}\leqslant \unicode[STIX]{x1D70F}_{y}$, and ![]() $\unicode[STIX]{x1D70F}=\unicode[STIX]{x1D70F}_{y}+\unicode[STIX]{x1D705}\dot{\unicode[STIX]{x1D6FE}}^{n}$ when

$\unicode[STIX]{x1D70F}=\unicode[STIX]{x1D70F}_{y}+\unicode[STIX]{x1D705}\dot{\unicode[STIX]{x1D6FE}}^{n}$ when ![]() $\unicode[STIX]{x1D70F}\geqslant \unicode[STIX]{x1D70F}_{y}$. Here, the power law exponent

$\unicode[STIX]{x1D70F}\geqslant \unicode[STIX]{x1D70F}_{y}$. Here, the power law exponent ![]() $n$ is the flow behaviour index i.e. it quantifies the degree of non-Newtonian behaviour, and

$n$ is the flow behaviour index i.e. it quantifies the degree of non-Newtonian behaviour, and ![]() $\unicode[STIX]{x1D705}$ is the consistency parameter. For the special case of

$\unicode[STIX]{x1D705}$ is the consistency parameter. For the special case of ![]() $n=1$, known as the Bingham plastic model,

$n=1$, known as the Bingham plastic model, ![]() $\unicode[STIX]{x1D705}$ is called the plastic viscosity.

$\unicode[STIX]{x1D705}$ is called the plastic viscosity.

The generalised Bingham number ![]() $Bi$ or equivalently, Oldroyd

$Bi$ or equivalently, Oldroyd ![]() $Od$ or Herschel–Bulkley number, is the ratio of plastic (yield stress) to viscous (shear stress) effects. The average wall-shear stress

$Od$ or Herschel–Bulkley number, is the ratio of plastic (yield stress) to viscous (shear stress) effects. The average wall-shear stress ![]() $\unicode[STIX]{x1D70F}_{w}$, which is proportional to the streamwise pressure gradient

$\unicode[STIX]{x1D70F}_{w}$, which is proportional to the streamwise pressure gradient ![]() $\unicode[STIX]{x0394}P/\unicode[STIX]{x0394}x$, can be used to define

$\unicode[STIX]{x0394}P/\unicode[STIX]{x0394}x$, can be used to define ![]() $Bi=\unicode[STIX]{x1D70F}_{y}/((H/2)(\unicode[STIX]{x0394}p/\unicode[STIX]{x0394}x))$. Here,

$Bi=\unicode[STIX]{x1D70F}_{y}/((H/2)(\unicode[STIX]{x0394}p/\unicode[STIX]{x0394}x))$. Here, ![]() $H$ is the half-height in the case of a square duct or the radius in the case of a round pipe. Alternately, one can use the nominal shear stress based on the HB model to define

$H$ is the half-height in the case of a square duct or the radius in the case of a round pipe. Alternately, one can use the nominal shear stress based on the HB model to define ![]() $Bi=\unicode[STIX]{x1D70F}_{y}/(\unicode[STIX]{x1D705}(U/L)^{n})$, where

$Bi=\unicode[STIX]{x1D70F}_{y}/(\unicode[STIX]{x1D705}(U/L)^{n})$, where ![]() $U$ and

$U$ and ![]() $L$ are the characteristic velocity and length scale respectively. The former definition is used in this work.

$L$ are the characteristic velocity and length scale respectively. The former definition is used in this work.

The choice of a representative Reynolds number ![]() $Re^{\ast }$ for non-Newtonian fluids is often motivated by its ability to correctly predict the laminar friction factor

$Re^{\ast }$ for non-Newtonian fluids is often motivated by its ability to correctly predict the laminar friction factor ![]() $f=\unicode[STIX]{x1D70F}_{w}/(0.5\unicode[STIX]{x1D70C}U_{Bulk}^{2})$, according to a relationship

$f=\unicode[STIX]{x1D70F}_{w}/(0.5\unicode[STIX]{x1D70C}U_{Bulk}^{2})$, according to a relationship ![]() $f=16/Re^{\ast }$ (see Metzner & Reed Reference Metzner and Reed1955), where

$f=16/Re^{\ast }$ (see Metzner & Reed Reference Metzner and Reed1955), where ![]() $\unicode[STIX]{x1D70C}$ is the density and

$\unicode[STIX]{x1D70C}$ is the density and ![]() $U_{Bulk}$ is the average or bulk velocity of the fluid. Note that we have used the Fanning friction factor in this study. Using the Rabinowitsch–Mooney equation, Kozicki, Chou & Tiu (Reference Kozicki, Chou and Tiu1966) provided a general framework to predict the flow rate as a function of the streamwise pressure gradient for flow of non-Newtonian fluids in ducts of arbitrary cross-section, yielding a

$U_{Bulk}$ is the average or bulk velocity of the fluid. Note that we have used the Fanning friction factor in this study. Using the Rabinowitsch–Mooney equation, Kozicki, Chou & Tiu (Reference Kozicki, Chou and Tiu1966) provided a general framework to predict the flow rate as a function of the streamwise pressure gradient for flow of non-Newtonian fluids in ducts of arbitrary cross-section, yielding a ![]() $Re^{\ast }$ consisting of two shape factors corresponding to the shape of the duct. Later, Liu & Masliyah (Reference Liu and Masliyah1998) improved the accuracy of the above relationship by proposing a three shape-factor approach that is better suited for ducts, where the wall-shear rate has contributions from terms other than only the wall-normal streamwise velocity gradient. The above approach has been used in the present study to define a generalised Reynolds number as

$Re^{\ast }$ consisting of two shape factors corresponding to the shape of the duct. Later, Liu & Masliyah (Reference Liu and Masliyah1998) improved the accuracy of the above relationship by proposing a three shape-factor approach that is better suited for ducts, where the wall-shear rate has contributions from terms other than only the wall-normal streamwise velocity gradient. The above approach has been used in the present study to define a generalised Reynolds number as

$$\begin{eqnarray}Re^{\ast }=\frac{16}{f}=\frac{8\unicode[STIX]{x1D70C}U_{Bulk}^{2}}{\displaystyle \unicode[STIX]{x1D70F}_{y}+\unicode[STIX]{x1D705}\left(\frac{2U_{Bulk}a}{H}\right)^{n}\left(1+\frac{1-n}{bn}\right)^{n}c^{n-1}}.\end{eqnarray}$$

$$\begin{eqnarray}Re^{\ast }=\frac{16}{f}=\frac{8\unicode[STIX]{x1D70C}U_{Bulk}^{2}}{\displaystyle \unicode[STIX]{x1D70F}_{y}+\unicode[STIX]{x1D705}\left(\frac{2U_{Bulk}a}{H}\right)^{n}\left(1+\frac{1-n}{bn}\right)^{n}c^{n-1}}.\end{eqnarray}$$ The constants are ![]() $a=1.778$,

$a=1.778$, ![]() $b=4.382$ and

$b=4.382$ and ![]() $c=1.067$ for a square duct (Liu & Masliyah Reference Liu and Masliyah1998). It should be noted that (1.1) has strictly been evaluated for a generalised Newtonian fluid i.e. purely viscous (including viscoplastic), inelastic and time-independent fluid. However, the laminar friction factor

$c=1.067$ for a square duct (Liu & Masliyah Reference Liu and Masliyah1998). It should be noted that (1.1) has strictly been evaluated for a generalised Newtonian fluid i.e. purely viscous (including viscoplastic), inelastic and time-independent fluid. However, the laminar friction factor ![]() $f$ for even strongly viscoelastic fluid flows has been shown to be the same as that for the generalised Newtonian fluids, provided that an appropriate Reynolds number such as

$f$ for even strongly viscoelastic fluid flows has been shown to be the same as that for the generalised Newtonian fluids, provided that an appropriate Reynolds number such as ![]() $Re^{\ast }$ is used. This is true for laminar viscoelastic fluid flow in a circular pipe (see Cho & Harnett (Reference Cho and Harnett1982), where it is explicitly mentioned that there is no effect of elasticity). In the case of duct flows, viscoelasticity can generate secondary flows in the laminar regime, as will be discussed later. Even for such cases, it is shown that

$Re^{\ast }$ is used. This is true for laminar viscoelastic fluid flow in a circular pipe (see Cho & Harnett (Reference Cho and Harnett1982), where it is explicitly mentioned that there is no effect of elasticity). In the case of duct flows, viscoelasticity can generate secondary flows in the laminar regime, as will be discussed later. Even for such cases, it is shown that ![]() $16/Re^{\ast }$ is a very good estimate of the friction factor (see Hartnett & Kostic (Reference Hartnett and Kostic1985) and Hartnett, Kwack & Rao (Reference Hartnett, Kwack and Rao1986), for a rectangular duct and square duct respectively), thus affirming that the secondary flow has a very small effect on the pressure drop (also shown in Dodson, Townsend & Walters (Reference Dodson, Townsend and Walters1974)).

$16/Re^{\ast }$ is a very good estimate of the friction factor (see Hartnett & Kostic (Reference Hartnett and Kostic1985) and Hartnett, Kwack & Rao (Reference Hartnett, Kwack and Rao1986), for a rectangular duct and square duct respectively), thus affirming that the secondary flow has a very small effect on the pressure drop (also shown in Dodson, Townsend & Walters (Reference Dodson, Townsend and Walters1974)).

1.3 YSF in a square duct

Square duct flows of YSF, mostly of the Bingham type, have been a subject of several numerical studies. Following Taylor & Wilson (Reference Taylor and Wilson1997), Van Pham & Mitsoulis (Reference Van Pham and Mitsoulis1998) performed simulations of laminar duct flow using the Bingham model and proposed a master curve relating the flow rate to the pressure drop; useful information in the design of extrusion geometries. Saramito & Roquet (Reference Saramito and Roquet2001) used the augmented Lagrangian method for a Bingham model fluid flow in a square duct at varying ![]() $Bi$ to compute the critical value of

$Bi$ to compute the critical value of ![]() $Bi$ above which the flow stops, known as the stopping criterion (also see Mosolov & Miasnikov (Reference Mosolov and Miasnikov1965)). Huilgol & You (Reference Huilgol and You2005) extended the above method to a HB fluid model and found that, for a fixed

$Bi$ above which the flow stops, known as the stopping criterion (also see Mosolov & Miasnikov (Reference Mosolov and Miasnikov1965)). Huilgol & You (Reference Huilgol and You2005) extended the above method to a HB fluid model and found that, for a fixed ![]() $Bi$ (or

$Bi$ (or ![]() $Od$ in their case), the plug region increases as the power law exponent in the HB model decreases.

$Od$ in their case), the plug region increases as the power law exponent in the HB model decreases.

A YSF may also display elastic properties both below and above yield stress, thus behaving like a viscoelastic solid before yielding and a viscoelastic liquid after yielding. Recently, Fraggedakis, Dimakopoulos & Tsamopoulos (Reference Fraggedakis, Dimakopoulos and Tsamopoulos2016b) compared the prediction from different elastoviscoplastic constitutive models in simple rheometric flows. Letelier, Siginer & González (Reference Letelier, Siginer and González2017) introduced elasticity in their simulations of a Bingham fluid for an approximate square duct geometry and observed that, for a fixed ![]() $Bi$, the flow rate increases with increasing elasticity (quantified using a Weissenberg number

$Bi$, the flow rate increases with increasing elasticity (quantified using a Weissenberg number ![]() $Wi$, which is the ratio of elastic stresses in the form of a normal-stress difference to the viscous stress due to shear forces). In a later work by the same authors, by including higher-order terms in

$Wi$, which is the ratio of elastic stresses in the form of a normal-stress difference to the viscous stress due to shear forces). In a later work by the same authors, by including higher-order terms in ![]() $Wi$, a secondary flow in the form of streamwise vortices is seen (Letelier et al. Reference Letelier, Barrera, Siginer and González2018). Increasing the

$Wi$, a secondary flow in the form of streamwise vortices is seen (Letelier et al. Reference Letelier, Barrera, Siginer and González2018). Increasing the ![]() $Bi$ at the same

$Bi$ at the same ![]() $Wi$ reduced the intensity of the secondary flow, and displaced the vortices further away from the centre of the duct. Similar observations are also reported in this work, the novelty being the HB nature of the experimental fluid against the Bingham numerical model along with a higher

$Wi$ reduced the intensity of the secondary flow, and displaced the vortices further away from the centre of the duct. Similar observations are also reported in this work, the novelty being the HB nature of the experimental fluid against the Bingham numerical model along with a higher ![]() $Bi$ in our case compared to their simulations, as will be described in the following sections. Often a Deborah number

$Bi$ in our case compared to their simulations, as will be described in the following sections. Often a Deborah number ![]() $De$ is defined as the ratio of the relaxation time of the fluid

$De$ is defined as the ratio of the relaxation time of the fluid ![]() $\unicode[STIX]{x1D706}$ to the characteristic observation time scale of the flow

$\unicode[STIX]{x1D706}$ to the characteristic observation time scale of the flow ![]() $T_{f}$. Under certain circumstances,

$T_{f}$. Under certain circumstances, ![]() $De=\unicode[STIX]{x1D706}/T_{f}$ is equivalent to the

$De=\unicode[STIX]{x1D706}/T_{f}$ is equivalent to the ![]() $Wi$ (Poole Reference Poole2012b), which is more appropriately related to the characteristic rate of deformation (Dealy Reference Dealy2010). Since both

$Wi$ (Poole Reference Poole2012b), which is more appropriately related to the characteristic rate of deformation (Dealy Reference Dealy2010). Since both ![]() $Wi$ and

$Wi$ and ![]() $Re^{\ast }$ increase with the flow rate for a given elastoviscoplastic fluid, an elasticity number

$Re^{\ast }$ increase with the flow rate for a given elastoviscoplastic fluid, an elasticity number ![]() $El$ is defined as

$El$ is defined as ![]() $Wi/Re^{\ast }$ to quantify the effects of elastic forces compared to inertial forces.

$Wi/Re^{\ast }$ to quantify the effects of elastic forces compared to inertial forces.

Many researchers since Ericksen (Reference Ericksen1956) have investigated the existence and strength of the aforementioned streamwise vortices in laminar rectangular duct flows. This secondary flow originates from viscoelastic forces in non-circular pipes, specifically the second normal-stress difference (Dodson et al. Reference Dodson, Townsend and Walters1974), and its strength increases with the elasticity (Debbaut & Dooley Reference Debbaut and Dooley1999). Thus, no secondary flow would be observed in a purely viscous or viscoplastic fluid or for a certain special relationship between the second normal-stress difference and the fluid viscosity (Xue, Phan-Thien & Tanner Reference Xue, Phan-Thien and Tanner1995). Despite being very weak (around two orders in magnitude lower than the mean axial velocity), the presence of such a secondary velocity field may have substantial effects on the rate of heat transfer (Kostic Reference Kostic1994; Gao & Hartnett Reference Gao and Hartnett1996). Its weak nature also presents challenges in measuring it experimentally (Schroeder & Jeffrey Reference Schroeder and Jeffrey2011). Yue, Dooley & Feng (Reference Yue, Dooley and Feng2008) provided a general criterion to predict the direction of these secondary flows.

1.4 Studies in particle-laden flow

Dispersed phases like particles, drops or bubbles may appear as desired or undesired components in the final product made using YSF. Hence, their interaction with YSF is of practical importance and this paper partly addresses this problem.

In the case of particle-laden flows, sedimentation of a single spherical particle in a YSF is the most common study on account of its obvious importance in gaining fundamental understanding and as a precursor for multi-particle problems. A heavy isolated particle can settle inside a YSF only when the buoyancy force exceeds the resistance offered by the yield stress. Accordingly, a dimensionless yield–gravity parameter ![]() $Y=\unicode[STIX]{x1D70F}_{y}/((\unicode[STIX]{x1D70C}_{p}-\unicode[STIX]{x1D70C}_{f})gd_{p})$ can be defined such that the particle moves only when

$Y=\unicode[STIX]{x1D70F}_{y}/((\unicode[STIX]{x1D70C}_{p}-\unicode[STIX]{x1D70C}_{f})gd_{p})$ can be defined such that the particle moves only when ![]() $Y$ is lower than a threshold critical value

$Y$ is lower than a threshold critical value ![]() ${\approx}0.2$ while noting that the exact value is still a topic of investigation (Chhabra Reference Chhabra2006). Creeping flow of an ideal yield stress fluid (Bingham or Herschel–Bulkley) around a sphere is reversible and displays fore–aft symmetry (Beaulne & Mitsoulis Reference Beaulne and Mitsoulis1997; Putz & Frigaard Reference Putz and Frigaard2010).

${\approx}0.2$ while noting that the exact value is still a topic of investigation (Chhabra Reference Chhabra2006). Creeping flow of an ideal yield stress fluid (Bingham or Herschel–Bulkley) around a sphere is reversible and displays fore–aft symmetry (Beaulne & Mitsoulis Reference Beaulne and Mitsoulis1997; Putz & Frigaard Reference Putz and Frigaard2010).

1.5 Need for careful preparation of the solution

In contrast to the above observation, when Putz et al. (Reference Putz, Burghelea, Frigaard and Martinez2008) performed particle image velocimetry (PIV) measurements of the flow field around a spherical particle sedimenting in a Carbopol solution at low ![]() $Re<1$, they observed a breaking of the symmetry that is not observed in Newtonian fluids. In particular, the characteristics of the flow regions around the falling sphere were associated with the rheological properties of the fluid, thus calling for numerical models to include both elastic (Fraggedakis, Dimakopoulos & Tsamopoulos Reference Fraggedakis, Dimakopoulos and Tsamopoulos2016a) and hysteresis/thixotropic effects to accurately reproduce experimental observations as well as for experiments to ensure careful preparation of the fluid. On the other hand, Tabuteau, Coussot & de Bruyn (Reference Tabuteau, Coussot and de Bruyn2007) could obtain reproducible results in experiments for the drag on a settling sphere, in agreement with the simulations of Beaulne & Mitsoulis (Reference Beaulne and Mitsoulis1997). The authors attributed this to the careful preparation (homogenising for ten days!) of the yield stress fluid.

$Re<1$, they observed a breaking of the symmetry that is not observed in Newtonian fluids. In particular, the characteristics of the flow regions around the falling sphere were associated with the rheological properties of the fluid, thus calling for numerical models to include both elastic (Fraggedakis, Dimakopoulos & Tsamopoulos Reference Fraggedakis, Dimakopoulos and Tsamopoulos2016a) and hysteresis/thixotropic effects to accurately reproduce experimental observations as well as for experiments to ensure careful preparation of the fluid. On the other hand, Tabuteau, Coussot & de Bruyn (Reference Tabuteau, Coussot and de Bruyn2007) could obtain reproducible results in experiments for the drag on a settling sphere, in agreement with the simulations of Beaulne & Mitsoulis (Reference Beaulne and Mitsoulis1997). The authors attributed this to the careful preparation (homogenising for ten days!) of the yield stress fluid.

Indeed, in the recent work by Dinkgreve et al. (Reference Dinkgreve, Fazilati, Denn and Bonn2018), it was clearly shown that the discrepancy in the simple yield stress behaviour of Carbopol observed in previous studies was most likely due to lack of optimal mixing. At low shear rates, transient shear banding (Divoux et al. Reference Divoux, Tamarii, Barentin and Manneville2010) may occur that can cause apparent hysteresis in the flow curve i.e. the relation between shear stress and shear rate in simple shear, due to a lack of sufficient measurement time. The measurement time required to reach a steady state approaches unrealistically large values in the presence of wall slip, which occurs when a smooth rotating surface is used during rheometry (Poumaere et al. Reference Poumaere, Moyers-González, Castelain and Burghelea2014).

1.6 Particle migration in non-Newtonian fluids

Since the Carbopol gel used in this study exhibits small but measurable elastic effects both below and above the yield stress, the normal stresses and ensuing secondary flows are expected to affect the particle migration and their equilibrium distribution. Hence, a review of particle migration inside a duct flow of viscoelastic fluid is appropriate.

Cross-stream particle migration in viscoelastic fluids is quite different to their migration in a Newtonian fluid (D’Avino & Maffettone Reference D’Avino and Maffettone2015). In the absence of inertia, which is typical of microfluidic applications (e.g. cell focussing and separation), depending on the initial particle position, fluid elasticity drives the particle towards the channel centreline or the closest wall and from there towards the nearest corner in case of a duct geometry (Villone et al. Reference Villone, D’avino, Hulsen, Greco and Maffettone2013). This can be understood by observing the distribution of the first normal-stress difference, which has local minima at the centre and the corners of the duct cross-section (Yang et al. Reference Yang, Kim, Lee, Lee and Kim2011). The shear-thinning effects reduce the first normal-stress difference (Li, McKinley & Ardekani Reference Li, McKinley and Ardekani2015) thus, augmenting particle migration towards the closest wall (D’Avino et al. Reference D’Avino, Romeo, Villone, Greco, Netti and Maffettone2012). When second normal-stress differences are present (e.g. in a duct), the particle migration velocity, proportional to ![]() $De(d_{p}/(2H))^{2}$, may be higher or lower than the ensuing secondary flow velocity, proportional to

$De(d_{p}/(2H))^{2}$, may be higher or lower than the ensuing secondary flow velocity, proportional to ![]() $De^{4}$ (Yue et al. Reference Yue, Dooley and Feng2008). Note that the observation time

$De^{4}$ (Yue et al. Reference Yue, Dooley and Feng2008). Note that the observation time ![]() $T_{f}$ in the definition of

$T_{f}$ in the definition of ![]() $De$ above is taken as the inverse of the nominal shear rate:

$De$ above is taken as the inverse of the nominal shear rate: ![]() $T_{f}=1/(U_{Bulk}/H)$ by Villone et al. (Reference Villone, D’avino, Hulsen, Greco and Maffettone2013). Thus, at larger

$T_{f}=1/(U_{Bulk}/H)$ by Villone et al. (Reference Villone, D’avino, Hulsen, Greco and Maffettone2013). Thus, at larger ![]() $De$ and smaller particle confinement

$De$ and smaller particle confinement ![]() $d_{p}/(2H)$, the secondary flow may overcome the migration velocity and the particle may also find a stable position near the centre of the streamwise vortices that are characteristic of the secondary flow (Villone et al. Reference Villone, D’avino, Hulsen, Greco and Maffettone2013).

$d_{p}/(2H)$, the secondary flow may overcome the migration velocity and the particle may also find a stable position near the centre of the streamwise vortices that are characteristic of the secondary flow (Villone et al. Reference Villone, D’avino, Hulsen, Greco and Maffettone2013).

It is shown by Seo, Kang & Lee (Reference Seo, Kang and Lee2014) that complex interplay between elasticity, inertia, shear thinning and confinement can lead to multiple stable and unstable equilibrium configurations. Lim et al. (Reference Lim, Ober, Edd, Desai, Neal, Bong, Doyle, McKinley and Toner2014a) realised that particles in microfluidic flows can be focussed at a high throughput rate even at very high ![]() $Re\approx 10\,000$ i.e. high inertia, provided that the elastic normal stresses also increase proportionally i.e. the important criterion governing particle focussing is the elasticity number

$Re\approx 10\,000$ i.e. high inertia, provided that the elastic normal stresses also increase proportionally i.e. the important criterion governing particle focussing is the elasticity number ![]() $El$.

$El$.

In the Stokes regime i.e. negligible particle inertia, flow of a particle suspension in a YSF inside a tube has been recently simulated by Siqueira & de Souza Mendes (Reference Siqueira and de Souza Mendes2019) using a regularised viscosity function, with the diffusive flux model (Phillips et al. Reference Phillips, Armstrong, Brown, Graham and Abbott1992) being used to describe the shear-induced particle migration. Particles were found to concentrate at the boundary of the plug and with increasing particle concentration, the maxima shifted towards the tube wall. No particles were found inside the plug due to the high but finite viscosity gradient (due to the regularisation) that slowly pushed them radially outwards. A similar method was used to model the particle migration for a tube flow of a Bingham fluid in Lavrenteva & Nir (Reference Lavrenteva and Nir2016). The maximum particle concentration was found at the interface between the yielded and unyielded regions. On the other hand, in the simulations of Hormozi & Frigaard (Reference Hormozi and Frigaard2017) to model particle-laden flow in a fracture, particles were found to concentrate in the plug.

1.7 Importance of the present study

Most of the above experimental studies concerning particle migration are microfluidic in their treatment i.e. they have a very low fluid and particle inertia. Also, they deal with a very low particle concentration ![]() $(\unicode[STIX]{x1D6F7}\leqslant 0.1\,\%)$ i.e. negligible inter-particle interactions, that is typical of flow-focusing experiments, and to our knowledge there have not been many experimental studies devoted to multi-particle dynamics with the exception of the impressive observations made by Gauthier, Goldsmith & Mason (Reference Gauthier, Goldsmith and Mason1971) and Tehrani (Reference Tehrani1996) a while ago. A noteworthy contribution of this study lies in extending previous scientific investigations beyond the above regimes using a novel set-up with a large flow cross-section where the flow can be resolved at the particle scale, a feature that is very difficult to capture in microfluidic devices. In addition, the presence of yield stress in the suspending fluid and its interaction with the finite-size dispersed phase is expected to complement studies using the continuum-based approaches e.g. Hormozi & Frigaard (Reference Hormozi and Frigaard2017).

$(\unicode[STIX]{x1D6F7}\leqslant 0.1\,\%)$ i.e. negligible inter-particle interactions, that is typical of flow-focusing experiments, and to our knowledge there have not been many experimental studies devoted to multi-particle dynamics with the exception of the impressive observations made by Gauthier, Goldsmith & Mason (Reference Gauthier, Goldsmith and Mason1971) and Tehrani (Reference Tehrani1996) a while ago. A noteworthy contribution of this study lies in extending previous scientific investigations beyond the above regimes using a novel set-up with a large flow cross-section where the flow can be resolved at the particle scale, a feature that is very difficult to capture in microfluidic devices. In addition, the presence of yield stress in the suspending fluid and its interaction with the finite-size dispersed phase is expected to complement studies using the continuum-based approaches e.g. Hormozi & Frigaard (Reference Hormozi and Frigaard2017).

1.8 Outline

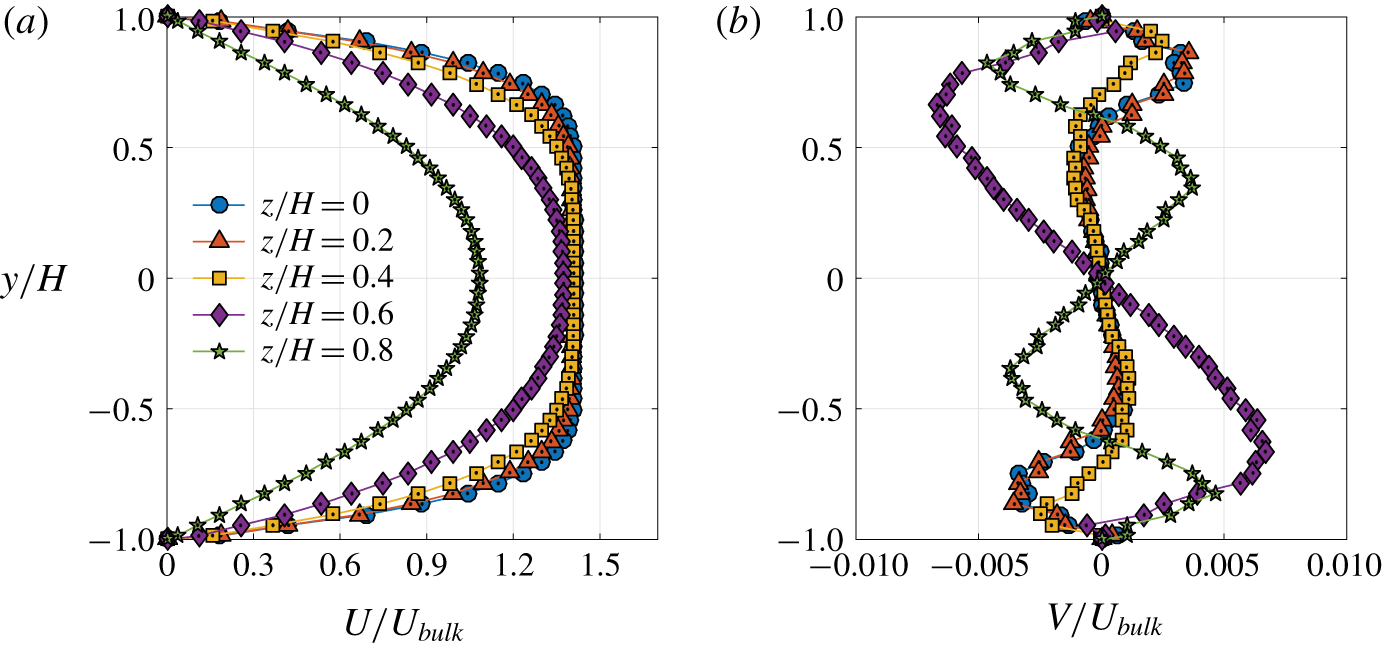

In the following sections, we start by describing the experimental set-up and the PIV–PTV (particle tracking velocimetry) measurement techniques. The fluid rheology and particle properties are also mentioned. Later, in the results section, we first describe the single-phase flow of two YSFs, with high (HYS) and low (LYS) yield stresses, at varying ![]() $Re^{\ast }$ and

$Re^{\ast }$ and ![]() $Bi$. This is then followed by the results concerning the particle-laden cases. Finally, in the discussion section, we try to interpret the above results by supporting our main observations with simple visual images obtained from shadowgraphy experiments, which are described therein. This is followed by a summary of the main conclusions.

$Bi$. This is then followed by the results concerning the particle-laden cases. Finally, in the discussion section, we try to interpret the above results by supporting our main observations with simple visual images obtained from shadowgraphy experiments, which are described therein. This is followed by a summary of the main conclusions.

2 Experimental technique

2.1 Experimental set-up

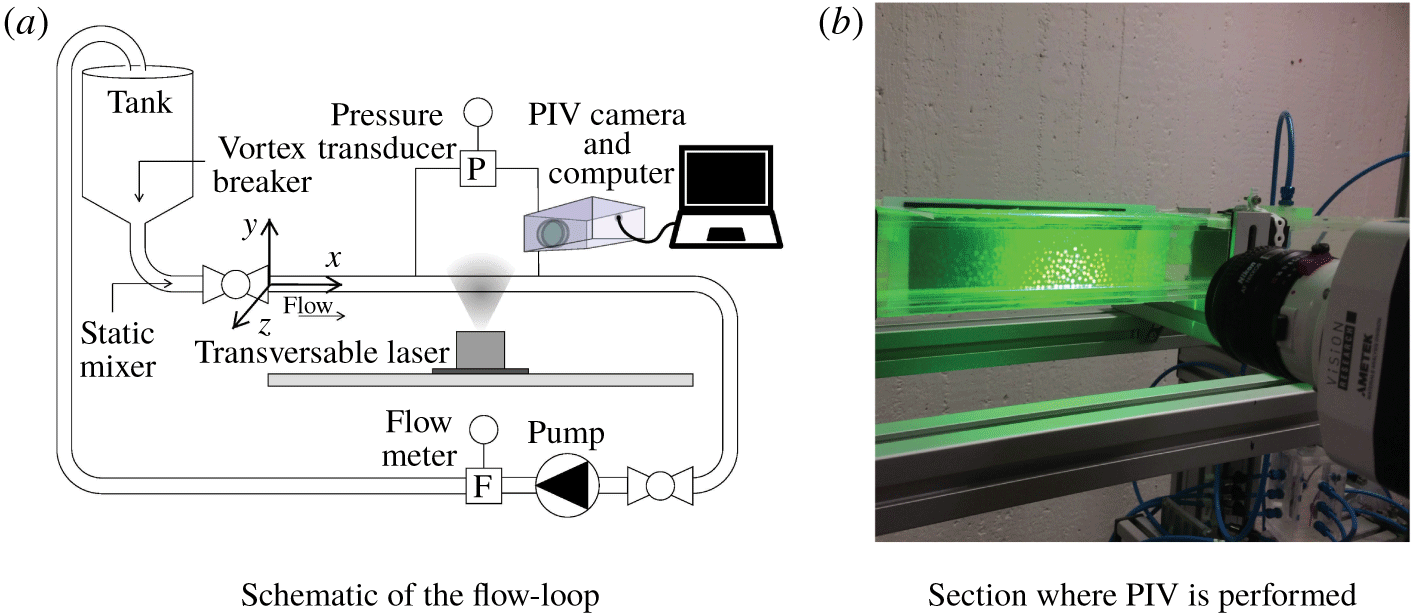

The experimental set-up used in this study has been previously used in Zade et al. (Reference Zade, Costa, Fornari, Lundell and Brandt2018) to investigate particle-laden turbulent flows of Newtonian and non-Newtonian flows up to ![]() $\unicode[STIX]{x1D719}=20\,\%$, and is shown in figure 1. Only the most important features are described here and the interested reader is referred to the previous publications for additional details. The flow loop consists of a 5 m long transparent square duct with

$\unicode[STIX]{x1D719}=20\,\%$, and is shown in figure 1. Only the most important features are described here and the interested reader is referred to the previous publications for additional details. The flow loop consists of a 5 m long transparent square duct with ![]() $50~\text{mm}\times 50~\text{mm}$ cross-section (refer to figure 1a). The particles are introduced in the conical tank and are circulated through the loop for a long enough time before measurements begin, so that they homogeneously disperse in the carrier fluid. A static mixer (Vortab Company, CA, USA) is installed close to the inlet of the duct to neutralise any swirling motions that may arise from the long

$50~\text{mm}\times 50~\text{mm}$ cross-section (refer to figure 1a). The particles are introduced in the conical tank and are circulated through the loop for a long enough time before measurements begin, so that they homogeneously disperse in the carrier fluid. A static mixer (Vortab Company, CA, USA) is installed close to the inlet of the duct to neutralise any swirling motions that may arise from the long ![]() $90^{\circ }$ bend at the exit of the tank. The temperature is maintained at nearly

$90^{\circ }$ bend at the exit of the tank. The temperature is maintained at nearly ![]() $20\,^{\circ }\text{C}$ by means of an immersed-coil heat exchanger in the tank. A very gentle disc pump (Model: 2015-8-2HHD Close coupled, Discflo Corporations, CA, USA) has been chosen, similar to Draad, Kuiken & Nieuwstadt (Reference Draad, Kuiken and Nieuwstadt1998), to minimise the mechanical breakage of the particles and avoid unwanted pulsations in the flow.

$20\,^{\circ }\text{C}$ by means of an immersed-coil heat exchanger in the tank. A very gentle disc pump (Model: 2015-8-2HHD Close coupled, Discflo Corporations, CA, USA) has been chosen, similar to Draad, Kuiken & Nieuwstadt (Reference Draad, Kuiken and Nieuwstadt1998), to minimise the mechanical breakage of the particles and avoid unwanted pulsations in the flow.

Figure 1. Experimental set-up. Reproduced from Zade et al. (Reference Zade, Costa, Fornari, Lundell and Brandt2018).

An electromagnetic flowmeter (Krohne Optiflux 1000 with IFC 300 signal converter, Krohne Messtechnik GmbH, Germany) is used to measure the volume flow rate of the particle–fluid mixture. The pressure loss is measured over a distance of ![]() $54H$ starting at

$54H$ starting at ![]() $140H$ from the inlet using a differential pressure transducer (

$140H$ from the inlet using a differential pressure transducer (![]() $0{-}1~\text{kPa}$, Model: FKC11, Fuji Electric France, S.A.S.). Data acquisition from the camera, flow meter and pressure transducer is performed using a National Instruments NI-6215 DAQ card using Labview™ software. The entry flow problem for YSF has been studied by Ookawara et al. (Reference Ookawara, Ogawa, Dombrowski, Amooie-Foumeny and Riza2000), amongst others, who proposed that the spatial development of the streamwise velocity at the edge of the plug is a suitable indicator for a fully developed flow. The development length was deduced in terms of a modified Reynolds number accounting for the plug radius, and for the maximum

$0{-}1~\text{kPa}$, Model: FKC11, Fuji Electric France, S.A.S.). Data acquisition from the camera, flow meter and pressure transducer is performed using a National Instruments NI-6215 DAQ card using Labview™ software. The entry flow problem for YSF has been studied by Ookawara et al. (Reference Ookawara, Ogawa, Dombrowski, Amooie-Foumeny and Riza2000), amongst others, who proposed that the spatial development of the streamwise velocity at the edge of the plug is a suitable indicator for a fully developed flow. The development length was deduced in terms of a modified Reynolds number accounting for the plug radius, and for the maximum ![]() $Re^{\ast }$ encountered in our case, this development length would be less than

$Re^{\ast }$ encountered in our case, this development length would be less than ![]() $30H$. Thus, at our measurement location

$30H$. Thus, at our measurement location ![]() ${\approx}150H$, the flow can be considered to be fully developed for the single phase cases. For the particle-laden cases, the evolution of the particle concentration is qualitatively observed using shadowgraphy techniques, described later in the discussion section, and it is observed that an equilibrium concentration is established upstream of the measurement location.

${\approx}150H$, the flow can be considered to be fully developed for the single phase cases. For the particle-laden cases, the evolution of the particle concentration is qualitatively observed using shadowgraphy techniques, described later in the discussion section, and it is observed that an equilibrium concentration is established upstream of the measurement location.

2.2 Fluid rheology

An aqueous solution of Carbomer powder supplied as Carbopol® NF 980 (Lubrizol Corporation, USA), a commercial thickener, that is neutralised with sodium hydroxide (NaOH), is used as the model yield stress fluid. It is chosen due to its high transparency, small thixotropy and material stability (very slow ageing).

For each of our Carbopol batches, a weighed amount of Carbopol powder (0.25 % by weight) was first dispersed in 24 kg of water at room temperature ![]() $({\sim}20\,^{\circ }\text{C})$. A high shear mixer (Silverson AX5, Silverson Machines, Inc., USA) was used to disperse the powder at a maximum of

$({\sim}20\,^{\circ }\text{C})$. A high shear mixer (Silverson AX5, Silverson Machines, Inc., USA) was used to disperse the powder at a maximum of ![]() ${\sim}1200~\text{rpm}$ for up to

${\sim}1200~\text{rpm}$ for up to ![]() ${\sim}30~\text{minutes}$. The dispersion was then left stationary for

${\sim}30~\text{minutes}$. The dispersion was then left stationary for ![]() ${\sim}30~\text{minutes}$ to allow for air bubbles to evacuate. Then, a 18 wt./v % of NaOH solution at 2.3 times the mass of Carbomer powder was used to neutralise the dispersion. The NaOH was gradually added with a pipette whilst stirring the solution gently at low rotational speeds

${\sim}30~\text{minutes}$ to allow for air bubbles to evacuate. Then, a 18 wt./v % of NaOH solution at 2.3 times the mass of Carbomer powder was used to neutralise the dispersion. The NaOH was gradually added with a pipette whilst stirring the solution gently at low rotational speeds ![]() $({\sim}135~\text{rpm})$ using a helical mixer (RW 20 DZM-P4, IKA-Labortechnik, IKA-Werke GmbH & Co. KG, Germany). At the end of the neutralisation process, the pH was noted to be ideally within the required range (6.5–7.0) so as to ensure maximum swelling and, hence, a high yield stress. The neutralised solution was further mixed in a large cement mixer (1402 HR, AL-KO, Germany) at a low rotational speed for an

$({\sim}135~\text{rpm})$ using a helical mixer (RW 20 DZM-P4, IKA-Labortechnik, IKA-Werke GmbH & Co. KG, Germany). At the end of the neutralisation process, the pH was noted to be ideally within the required range (6.5–7.0) so as to ensure maximum swelling and, hence, a high yield stress. The neutralised solution was further mixed in a large cement mixer (1402 HR, AL-KO, Germany) at a low rotational speed for an ![]() ${\sim}5$ additional hours to ensure complete homogenisation.

${\sim}5$ additional hours to ensure complete homogenisation.

The whole preparation process led to a concentrated solution with a high yield stress. Experiments had to be performed with a thinner (less viscous) fluid in order to facilitate pumping. Thus, the concentrated solution was gradually diluted in the flow loop by mixing with water and recirculating for ![]() ${\sim}2~\text{hours}$ before measurements began. Since the shear rates in the flow loop are not extremely high, solution degradation and the resulting change in properties can be considered insignificant. Repeatability of the properties of the final solution was ascertained by (i) measuring the flow curves in a rheometer and (ii) by monitoring the pressure drop at a fixed flow rate. It was found that by systematically following the above mixing protocol, solutions with nearly the same pressure drop exhibiting the same flow curve were obtained repeatedly. In order to minimise the occurrence of bubbles arising due to dissolved gases in the water, tap water was heated so as to remove these dissolved gases and then cooled before being used for preparation of the Carbopol solution. Air bubbles entrained during introduction of the hydrogel particles were removed in the conical tank that is open to the atmosphere.

${\sim}2~\text{hours}$ before measurements began. Since the shear rates in the flow loop are not extremely high, solution degradation and the resulting change in properties can be considered insignificant. Repeatability of the properties of the final solution was ascertained by (i) measuring the flow curves in a rheometer and (ii) by monitoring the pressure drop at a fixed flow rate. It was found that by systematically following the above mixing protocol, solutions with nearly the same pressure drop exhibiting the same flow curve were obtained repeatedly. In order to minimise the occurrence of bubbles arising due to dissolved gases in the water, tap water was heated so as to remove these dissolved gases and then cooled before being used for preparation of the Carbopol solution. Air bubbles entrained during introduction of the hydrogel particles were removed in the conical tank that is open to the atmosphere.

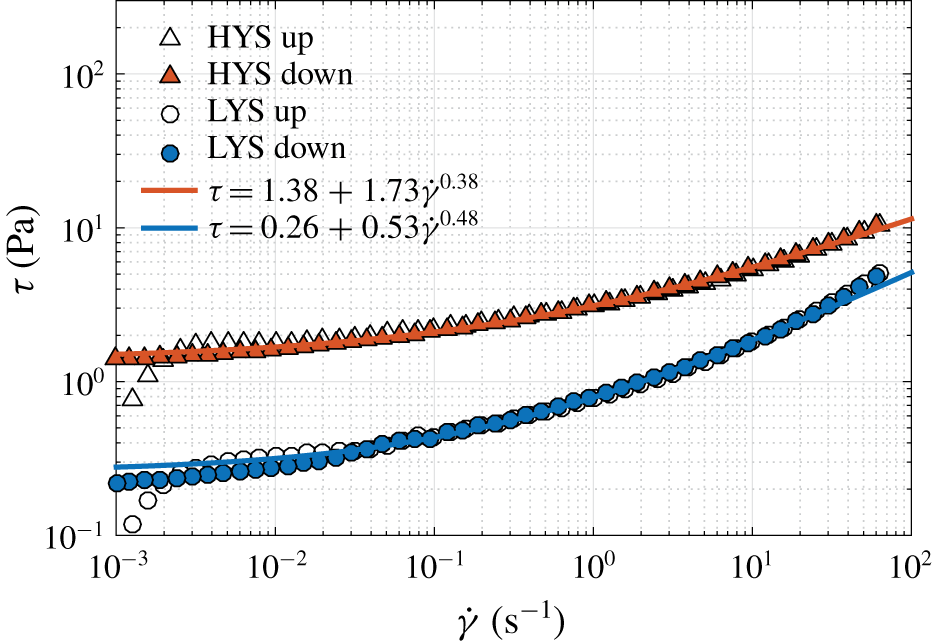

Figure 2. Flow curves (symbols) and the HB model fit (solid lines) for the LYS and HYS yield stress fluids. The open and closed symbols denote measurements during ascending and descending shear rates respectively.

The rheological tests focused on the determination of the steady-state flow curve. They were performed using a TA AR-2000ex rheometer (TA Instruments, Inc., USA) with a vane and cup geometry. A pre-shear of ![]() $300~\text{s}^{-1}$ was applied for 10 s followed by a rest period of 40 s to establish a reproducible state. Flow sweeps in both ascending and descending controlled shear rate were then carried out in a range of shear rates (0.001 to

$300~\text{s}^{-1}$ was applied for 10 s followed by a rest period of 40 s to establish a reproducible state. Flow sweeps in both ascending and descending controlled shear rate were then carried out in a range of shear rates (0.001 to ![]() $80~1~\text{s}^{-1}$ with 10 points per decade) at room temperature to determine the flow curves and to check for thixotropy. This range of shear rates includes the maximum shear rate in the experiments. For each measurement point, the shear rate was held constant for 30 s. Figure 2 shows the flow curve for the two fluids used in this study. Elastic effects on start-up (Dinkgreve, Denn & Bonn Reference Dinkgreve, Denn and Bonn2017) were visible for a few points at low shear rates during the up sweep i.e. the accumulated strain was perhaps insufficient for the material to flow. Hence, the down sweep curve is used to fit the Herschel–Bulkley model, whose parameters are mentioned in the legend of figure 2. The repeatability of the flow curves was ensured by performing the above tests on three separate solutions prepared independently of each other, both before and after adding the particles, and an average curve is used. The working fluids display a shear-thinning behaviour after yielding i.e. they are yield pseudo-plastic fluids. The dynamic yield stress determined above (static yield stress is determined using creep tests) is low compared to other wall-bounded flow studies of YSF (see Güzel et al. (Reference Güzel, Burghelea, Frigaard and Martinez2009) and Escudier & Presti (Reference Escudier and Presti1996) amongst others) but for such flows, the non-dimensional

$80~1~\text{s}^{-1}$ with 10 points per decade) at room temperature to determine the flow curves and to check for thixotropy. This range of shear rates includes the maximum shear rate in the experiments. For each measurement point, the shear rate was held constant for 30 s. Figure 2 shows the flow curve for the two fluids used in this study. Elastic effects on start-up (Dinkgreve, Denn & Bonn Reference Dinkgreve, Denn and Bonn2017) were visible for a few points at low shear rates during the up sweep i.e. the accumulated strain was perhaps insufficient for the material to flow. Hence, the down sweep curve is used to fit the Herschel–Bulkley model, whose parameters are mentioned in the legend of figure 2. The repeatability of the flow curves was ensured by performing the above tests on three separate solutions prepared independently of each other, both before and after adding the particles, and an average curve is used. The working fluids display a shear-thinning behaviour after yielding i.e. they are yield pseudo-plastic fluids. The dynamic yield stress determined above (static yield stress is determined using creep tests) is low compared to other wall-bounded flow studies of YSF (see Güzel et al. (Reference Güzel, Burghelea, Frigaard and Martinez2009) and Escudier & Presti (Reference Escudier and Presti1996) amongst others) but for such flows, the non-dimensional ![]() $Bi$ is the relevant criterion to assess the importance of plasticity on the flow. This point about the relevance of

$Bi$ is the relevant criterion to assess the importance of plasticity on the flow. This point about the relevance of ![]() $Bi$ will be illustrated further by means of velocity profiles that exhibit a solid plug.

$Bi$ will be illustrated further by means of velocity profiles that exhibit a solid plug.

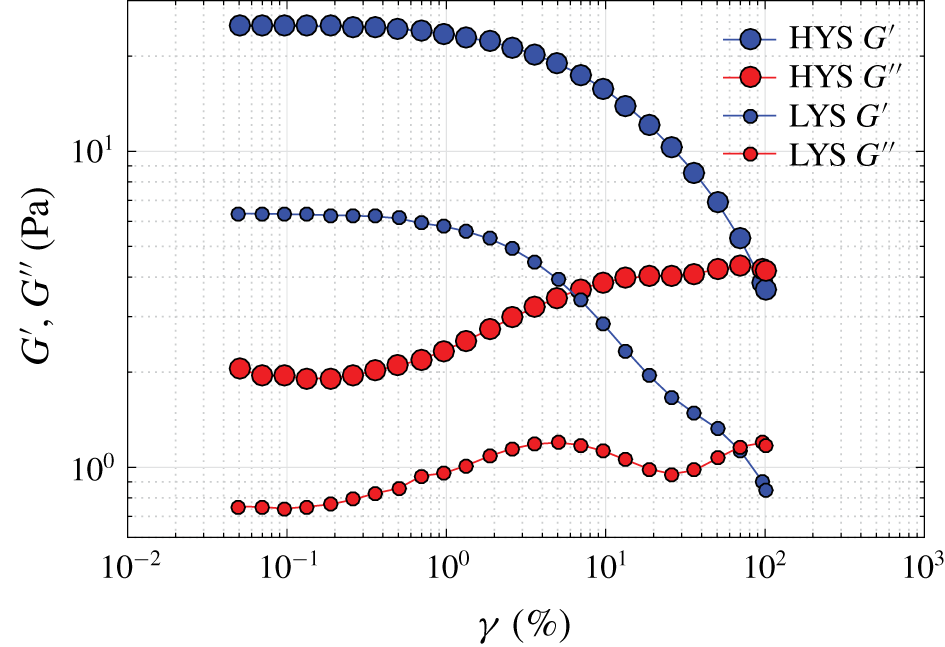

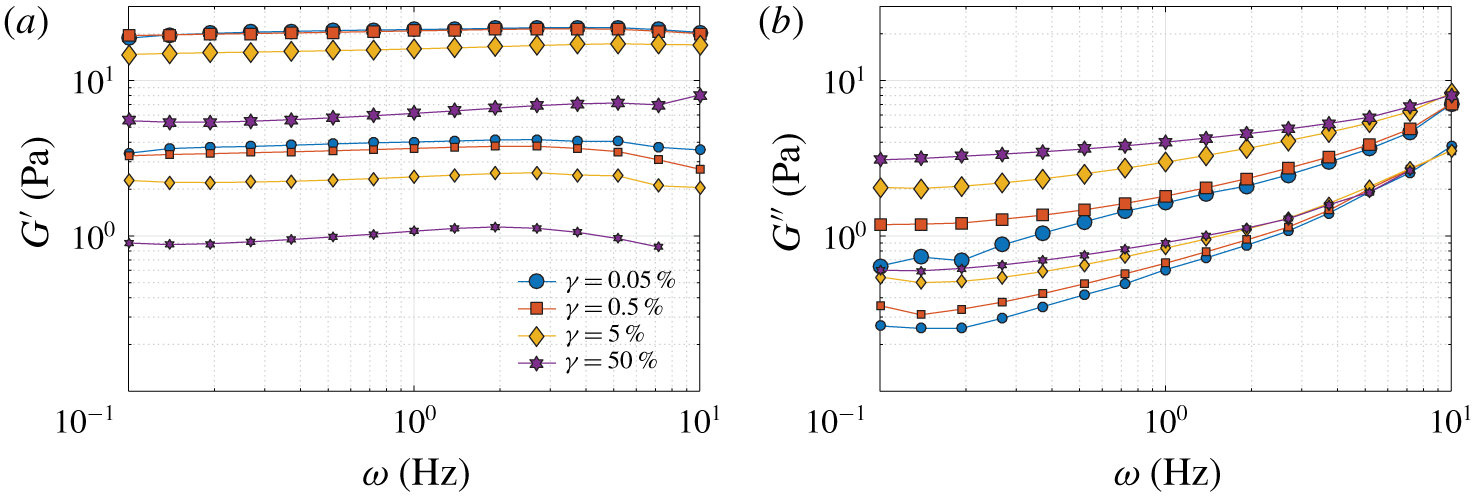

Figure 3. Oscillatory measurements: amplitude of the strain, ![]() $\unicode[STIX]{x1D6FE}$, sweeps at a fixed angular frequency

$\unicode[STIX]{x1D6FE}$, sweeps at a fixed angular frequency ![]() $\unicode[STIX]{x1D714}=1~\text{Hz}$ for the two fluids used in this work.

$\unicode[STIX]{x1D714}=1~\text{Hz}$ for the two fluids used in this work.

The viscoelastic behaviour near the yield limit is measured by oscillatory tests using a splined bob and cub attachment in a Kinexus pro+ rheometer (Malvern Panalytical, UK). The linear viscoelastic region that exists at small strain ![]() $\unicode[STIX]{x1D6FE}$ amplitudes can be identified by nearly constant elastic

$\unicode[STIX]{x1D6FE}$ amplitudes can be identified by nearly constant elastic ![]() $G^{\prime }$ and viscous

$G^{\prime }$ and viscous ![]() $G^{\prime \prime }$ moduli over a wide range of strain amplitudes. This is shown in figure 3 where oscillatory measurements are performed at a frequency

$G^{\prime \prime }$ moduli over a wide range of strain amplitudes. This is shown in figure 3 where oscillatory measurements are performed at a frequency ![]() $\unicode[STIX]{x1D714}$ of 1 Hz. The point of cross-over between

$\unicode[STIX]{x1D714}$ of 1 Hz. The point of cross-over between ![]() $G^{\prime }$ and

$G^{\prime }$ and ![]() $G^{\prime \prime }$ for each of the two fluids at 1 Hz,

$G^{\prime \prime }$ for each of the two fluids at 1 Hz, ![]() $H\unicode[STIX]{x1D70F}_{y}\sim 4~\text{Pa}$ and

$H\unicode[STIX]{x1D70F}_{y}\sim 4~\text{Pa}$ and ![]() $L\unicode[STIX]{x1D70F}_{y}\sim 1~\text{Pa}$, is of a similar order of magnitude as the yield stress, albeit slightly larger. Figure 4 shows the variation of

$L\unicode[STIX]{x1D70F}_{y}\sim 1~\text{Pa}$, is of a similar order of magnitude as the yield stress, albeit slightly larger. Figure 4 shows the variation of ![]() $G^{\prime }$ and

$G^{\prime }$ and ![]() $G^{\prime \prime }$ with the frequency

$G^{\prime \prime }$ with the frequency ![]() $\unicode[STIX]{x1D714}$ at multiple strain amplitudes

$\unicode[STIX]{x1D714}$ at multiple strain amplitudes ![]() $\unicode[STIX]{x1D6FE}$, starting from the linear and extending towards the nonlinear viscoelastic regime associated with yielding. In the linear regime i.e. at lower

$\unicode[STIX]{x1D6FE}$, starting from the linear and extending towards the nonlinear viscoelastic regime associated with yielding. In the linear regime i.e. at lower ![]() $\unicode[STIX]{x1D6FE}$, the elastic modulus

$\unicode[STIX]{x1D6FE}$, the elastic modulus ![]() $G^{\prime }$ (refer to figure 4a) is approximately flat and around one order of magnitude greater than the viscous modulus

$G^{\prime }$ (refer to figure 4a) is approximately flat and around one order of magnitude greater than the viscous modulus ![]() $G^{\prime \prime }$ (refer to figure 4b);

$G^{\prime \prime }$ (refer to figure 4b); ![]() $G^{\prime }$ and

$G^{\prime }$ and ![]() $G^{\prime \prime }$ are nearly independent of

$G^{\prime \prime }$ are nearly independent of ![]() $\unicode[STIX]{x1D6FE}$ in this linear regime

$\unicode[STIX]{x1D6FE}$ in this linear regime ![]() $(\unicode[STIX]{x1D6FE}\leqslant 0.5\,\%)$, as expected. As mentioned in Varges et al. (Reference Varges, Costa, Fonseca, Naccache and de Souza Mendes2019), at these low amplitudes the microgels deform elastically but they do not move significantly relative to each other and hence have a low internal dissipation (also see Piau Reference Piau2007). As the deformation amplitude increases, the microstructure starts breaking, causing elastohydrodynamic friction forces to rise and dissipation to increase, leading to a higher loss modulus. Finally, at higher

$(\unicode[STIX]{x1D6FE}\leqslant 0.5\,\%)$, as expected. As mentioned in Varges et al. (Reference Varges, Costa, Fonseca, Naccache and de Souza Mendes2019), at these low amplitudes the microgels deform elastically but they do not move significantly relative to each other and hence have a low internal dissipation (also see Piau Reference Piau2007). As the deformation amplitude increases, the microstructure starts breaking, causing elastohydrodynamic friction forces to rise and dissipation to increase, leading to a higher loss modulus. Finally, at higher ![]() $\unicode[STIX]{x1D6FE}$, outside the purview of small amplitude oscillatory shear, the elastic components decrease and the viscous components increase. Similar observations have been reported in Piau (Reference Piau2007), Gutowski et al. (Reference Gutowski, Lee, de Bruyn and Frisken2012), Firouznia et al. (Reference Firouznia, Metzger, Ovarlez and Hormozi2018) and Varges et al. (Reference Varges, Costa, Fonseca, Naccache and de Souza Mendes2019) amongst others. The viscoelastic moduli

$\unicode[STIX]{x1D6FE}$, outside the purview of small amplitude oscillatory shear, the elastic components decrease and the viscous components increase. Similar observations have been reported in Piau (Reference Piau2007), Gutowski et al. (Reference Gutowski, Lee, de Bruyn and Frisken2012), Firouznia et al. (Reference Firouznia, Metzger, Ovarlez and Hormozi2018) and Varges et al. (Reference Varges, Costa, Fonseca, Naccache and de Souza Mendes2019) amongst others. The viscoelastic moduli ![]() $G^{\prime }$ and

$G^{\prime }$ and ![]() $G^{\prime \prime }$ are relevant at small shear rates. In order to quantify the viscoelastic effects at higher shear rates, other steady-state viscometric functions namely, the first and second normal-stress differences:

$G^{\prime \prime }$ are relevant at small shear rates. In order to quantify the viscoelastic effects at higher shear rates, other steady-state viscometric functions namely, the first and second normal-stress differences: ![]() $N_{1}$ and

$N_{1}$ and ![]() $N_{2}$ needs to be measured. These measurements are fraught with difficulties in YSF and for

$N_{2}$ needs to be measured. These measurements are fraught with difficulties in YSF and for ![]() $N_{1}$, both positive (Tehrani Reference Tehrani1996; Peixinho et al. Reference Peixinho, Nouar, Desaubry and Théron2005; Piau Reference Piau2007) and negative values (Janmey et al. Reference Janmey, McCormick, Rammensee, Leight, Georges and MacKintosh2007) are reported. In the recent work of De Cagny et al. (Reference De Cagny, Fazilati, Habibi, Denn and Bonn2019), the authors investigated common simple i.e. non-thixotropic YSF, including Carbopol, and found that

$N_{1}$, both positive (Tehrani Reference Tehrani1996; Peixinho et al. Reference Peixinho, Nouar, Desaubry and Théron2005; Piau Reference Piau2007) and negative values (Janmey et al. Reference Janmey, McCormick, Rammensee, Leight, Georges and MacKintosh2007) are reported. In the recent work of De Cagny et al. (Reference De Cagny, Fazilati, Habibi, Denn and Bonn2019), the authors investigated common simple i.e. non-thixotropic YSF, including Carbopol, and found that ![]() $N_{1}>0$ and

$N_{1}>0$ and ![]() $N_{2}<0$ with

$N_{2}<0$ with ![]() $N_{1}>N_{2}$; they increase quadratically with the shear stress, both below and above the yield stress. The above authors proposed that, in the absence of normal-stress measurements,

$N_{1}>N_{2}$; they increase quadratically with the shear stress, both below and above the yield stress. The above authors proposed that, in the absence of normal-stress measurements, ![]() $N_{1}$ can be estimated by using the linear elastic modulus

$N_{1}$ can be estimated by using the linear elastic modulus ![]() $G^{\prime }$ as

$G^{\prime }$ as ![]() $N_{1}\sim \unicode[STIX]{x1D70F}^{2}/G^{\prime }$. Here,

$N_{1}\sim \unicode[STIX]{x1D70F}^{2}/G^{\prime }$. Here, ![]() $\unicode[STIX]{x1D70F}$ is the shear stress and, for our fluids, this implies that

$\unicode[STIX]{x1D70F}$ is the shear stress and, for our fluids, this implies that ![]() $N_{1}<6~\text{Pa}$ (for LYS at the maximum shear rate of figure 2). Such small values are quite difficult to measure, especially due to normal force drift and inertia (Poole Reference Poole2012a). It was hence not possible to accurately measure the normal-stress differences for our weakly elastic fluid. Nevertheless, viscoelasticity of Carbopol after yielding has been observed in many studies (e.g. see Taylor & Bagley Reference Taylor and Bagley1974; Laurencena & Williams Reference Laurencena and Williams1974). Peixinho et al. (Reference Peixinho, Nouar, Desaubry and Théron2005) also observed substantial drag reduction in turbulent flow of Carbopol, a typical viscoelastic effect.

$N_{1}<6~\text{Pa}$ (for LYS at the maximum shear rate of figure 2). Such small values are quite difficult to measure, especially due to normal force drift and inertia (Poole Reference Poole2012a). It was hence not possible to accurately measure the normal-stress differences for our weakly elastic fluid. Nevertheless, viscoelasticity of Carbopol after yielding has been observed in many studies (e.g. see Taylor & Bagley Reference Taylor and Bagley1974; Laurencena & Williams Reference Laurencena and Williams1974). Peixinho et al. (Reference Peixinho, Nouar, Desaubry and Théron2005) also observed substantial drag reduction in turbulent flow of Carbopol, a typical viscoelastic effect.

Figure 4. Oscillatory measurements: frequency ![]() $\unicode[STIX]{x1D714}$ sweeps to determine (a) the elastic modulus

$\unicode[STIX]{x1D714}$ sweeps to determine (a) the elastic modulus ![]() $G^{\prime }$ and (b) the viscous modulus

$G^{\prime }$ and (b) the viscous modulus ![]() $G^{\prime \prime }$ for several strain amplitudes. The larger and smaller symbols refer to the HYS and LYS cases, respectively.

$G^{\prime \prime }$ for several strain amplitudes. The larger and smaller symbols refer to the HYS and LYS cases, respectively.

2.3 Particle properties

As already noted in our previous work (Zade et al. Reference Zade, Costa, Fornari, Lundell and Brandt2018) the particles are commercially procured super-absorbent (polyacrylamide-based) hydrogel spheres which are delivered in dry form. After grading them into different sizes using sieves, one fairly mono-dispersed fraction is used in these experiments. These dry particles are mixed with tap water that has a very small amount of fluorescent rhodamine dye (a few ppm) dissolved in it, and then left submerged for around one day. Ultimately, they grow to an equilibrium size of ![]() $4.2\pm 0.8~\text{mm}$ (3 times standard deviation), thus yielding a duct height to particle diameter ratio

$4.2\pm 0.8~\text{mm}$ (3 times standard deviation), thus yielding a duct height to particle diameter ratio ![]() $2H/d_{p}$ of

$2H/d_{p}$ of ![]() ${\sim}12$. The tiny amount of rhodamine is absorbed by each particle, and makes them glow in the laser sheet, so that they can be detected in the PIV images, as will be shown later. The particle size was determined both by a digital imaging system and from the PIV images of particles in the flow. A small Gaussian-like spread in the particle diameter was observed. The fact that a Gaussian-like particle size distribution has a small effect on the flow statistics has already been shown in Fornari, Picano & Brandt (Reference Fornari, Picano and Brandt2018).

${\sim}12$. The tiny amount of rhodamine is absorbed by each particle, and makes them glow in the laser sheet, so that they can be detected in the PIV images, as will be shown later. The particle size was determined both by a digital imaging system and from the PIV images of particles in the flow. A small Gaussian-like spread in the particle diameter was observed. The fact that a Gaussian-like particle size distribution has a small effect on the flow statistics has already been shown in Fornari, Picano & Brandt (Reference Fornari, Picano and Brandt2018).

The density ratio of the particle to tap water ![]() $\unicode[STIX]{x1D70C}_{p}/\unicode[STIX]{x1D70C}_{f}$ is found to be equal to

$\unicode[STIX]{x1D70C}_{p}/\unicode[STIX]{x1D70C}_{f}$ is found to be equal to ![]() $1.0035\pm 0.0003$. Since the final concentration of Carbomer in the working fluid is less than 0.1 %, the change in density of the fluid from tap water is assumed to be insignificant. Since the typical flow velocities are relatively small

$1.0035\pm 0.0003$. Since the final concentration of Carbomer in the working fluid is less than 0.1 %, the change in density of the fluid from tap water is assumed to be insignificant. Since the typical flow velocities are relatively small ![]() $(U_{Bulk}<0.3~\text{m}~\text{s}^{-1})$ in the present flow configuration, the corresponding dynamical forces are low under these conditions and the hydrogel particles did not exhibit any visible deformation (as also confirmed from the time-resolved movies of the particles in flow). Also, as pointed out by Gondret, Lance & Petit (Reference Gondret, Lance and Petit2002), for the low impact Stokes number, collisions between particles or between a particle and the wall are dominated by viscous effects, and particles do not rebound i.e. the effective coefficient of restitution will be very small. Based on the above arguments, the particles can be considered to behave as rigid spheres. For details about the density measurements and calculations pertaining to the restitution coefficient, the reader is referred to our previous work (Zade et al. Reference Zade, Fornari, Lundell and Brandt2019a).

$(U_{Bulk}<0.3~\text{m}~\text{s}^{-1})$ in the present flow configuration, the corresponding dynamical forces are low under these conditions and the hydrogel particles did not exhibit any visible deformation (as also confirmed from the time-resolved movies of the particles in flow). Also, as pointed out by Gondret, Lance & Petit (Reference Gondret, Lance and Petit2002), for the low impact Stokes number, collisions between particles or between a particle and the wall are dominated by viscous effects, and particles do not rebound i.e. the effective coefficient of restitution will be very small. Based on the above arguments, the particles can be considered to behave as rigid spheres. For details about the density measurements and calculations pertaining to the restitution coefficient, the reader is referred to our previous work (Zade et al. Reference Zade, Fornari, Lundell and Brandt2019a).

2.4 Velocity measurement technique

The coordinate system is sketched in figure 1(a) with ![]() $x$ in the streamwise,

$x$ in the streamwise, ![]() $y$ in the wall-normal and

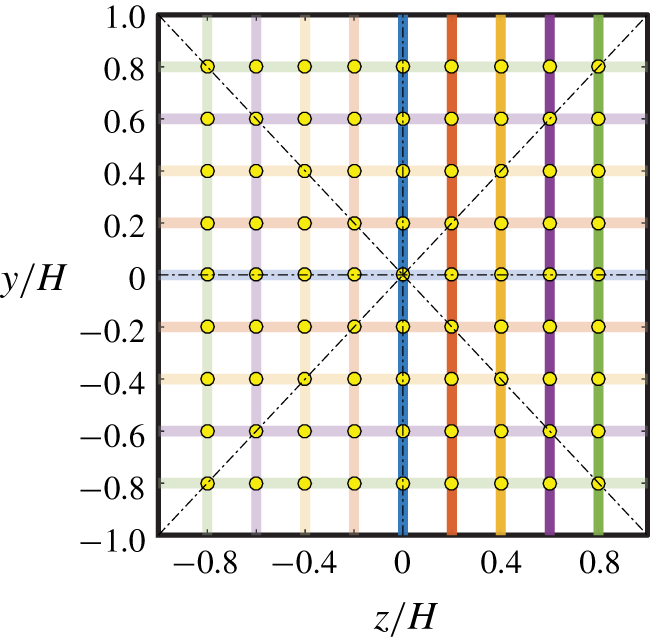

$y$ in the wall-normal and ![]() $z$ in the spanwise directions. The velocity field is measured using two-dimensional PIV (2D-PIV) in multiple spanwise planes (

$z$ in the spanwise directions. The velocity field is measured using two-dimensional PIV (2D-PIV) in multiple spanwise planes (![]() $z/H=0$ to 1) to measure the inhomogeneous velocity field in the square duct. The PIV set-up consists of a continuous wave laser

$z/H=0$ to 1) to measure the inhomogeneous velocity field in the square duct. The PIV set-up consists of a continuous wave laser ![]() $(\text{wavelength}=532~\text{nm},\text{power}=2~\text{W})$ and a high-speed camera (Phantom Miro 120, Vision Research, NJ, USA), as shown in figure 1(b). The thickness of the laser light sheet is 1 mm. The seeding particles are hollow glass microspheres (Sphericel® 110P8, Potters industries Inc.,

$(\text{wavelength}=532~\text{nm},\text{power}=2~\text{W})$ and a high-speed camera (Phantom Miro 120, Vision Research, NJ, USA), as shown in figure 1(b). The thickness of the laser light sheet is 1 mm. The seeding particles are hollow glass microspheres (Sphericel® 110P8, Potters industries Inc., ![]() $d_{p}=9{-}13~\unicode[STIX]{x03BC}\text{m}$,

$d_{p}=9{-}13~\unicode[STIX]{x03BC}\text{m}$, ![]() $\unicode[STIX]{x1D70C}_{p}=1.10\pm 0.05~\text{gm}~\text{cm}^{3}$) and polyamide microspheres (

$\unicode[STIX]{x1D70C}_{p}=1.10\pm 0.05~\text{gm}~\text{cm}^{3}$) and polyamide microspheres (![]() $d_{p}\approx ~55~\unicode[STIX]{x03BC}\text{m}$,

$d_{p}\approx ~55~\unicode[STIX]{x03BC}\text{m}$, ![]() $\unicode[STIX]{x1D70C}_{p}=1.2~\text{gm}~\text{cm}^{-3}$). The following paragraphs are briefer reproductions of the PIV–PTV algorithm already described in Zade et al. (Reference Zade, Fornari, Lundell and Brandt2019a).

$\unicode[STIX]{x1D70C}_{p}=1.2~\text{gm}~\text{cm}^{-3}$). The following paragraphs are briefer reproductions of the PIV–PTV algorithm already described in Zade et al. (Reference Zade, Fornari, Lundell and Brandt2019a).

PIV image pairs are captured at a resolution of approximately ![]() $60~\text{mm}/1024~\text{pixels}$; the size of the measurement section is

$60~\text{mm}/1024~\text{pixels}$; the size of the measurement section is ![]() $50~\text{mm}\times 50~\text{mm}$. For each flow rate, a time delay was chosen so that the maximum pixel displacement, based on the mean velocity, did not exceed a quarter of the size of the final interrogation window (IW) (Raffel et al. Reference Raffel, Willert, Wereley and Kompenhans2013). Thus, it can range from

$50~\text{mm}\times 50~\text{mm}$. For each flow rate, a time delay was chosen so that the maximum pixel displacement, based on the mean velocity, did not exceed a quarter of the size of the final interrogation window (IW) (Raffel et al. Reference Raffel, Willert, Wereley and Kompenhans2013). Thus, it can range from ![]() $36\times 10^{-3}~\text{s}$ for the

$36\times 10^{-3}~\text{s}$ for the ![]() $\text{lowest flow rate}=2~\text{l}~\text{min}^{-1}$ (litres per minute), to approximately

$\text{lowest flow rate}=2~\text{l}~\text{min}^{-1}$ (litres per minute), to approximately ![]() $1.8\times 10^{-3}~\text{s}$ for the

$1.8\times 10^{-3}~\text{s}$ for the ![]() $\text{highest flow rate}=40~\text{l}~\text{min}^{-1}$. The exposure time is kept small enough

$\text{highest flow rate}=40~\text{l}~\text{min}^{-1}$. The exposure time is kept small enough ![]() $({<}0.1\times 10^{-3}~\text{s})$ so that enough light is captured by the camera sensor while pixel displacement within one frame is significantly less than 1 pixel. Images were processed using an in-house, three-step, fast Fourier transform (FFT)-based, cross-correlation algorithm (Kawata & Obi Reference Kawata and Obi2014). The degree of overlap is approximately 47 % and can be estimated from the fact that the corresponding final resolution is

$({<}0.1\times 10^{-3}~\text{s})$ so that enough light is captured by the camera sensor while pixel displacement within one frame is significantly less than 1 pixel. Images were processed using an in-house, three-step, fast Fourier transform (FFT)-based, cross-correlation algorithm (Kawata & Obi Reference Kawata and Obi2014). The degree of overlap is approximately 47 % and can be estimated from the fact that the corresponding final resolution is ![]() $1~\text{mm}\times 1~\text{mm}$ per IW. Between 200 and 400 image pairs have been observed to be sufficient to ensure statistically converged results.

$1~\text{mm}\times 1~\text{mm}$ per IW. Between 200 and 400 image pairs have been observed to be sufficient to ensure statistically converged results.

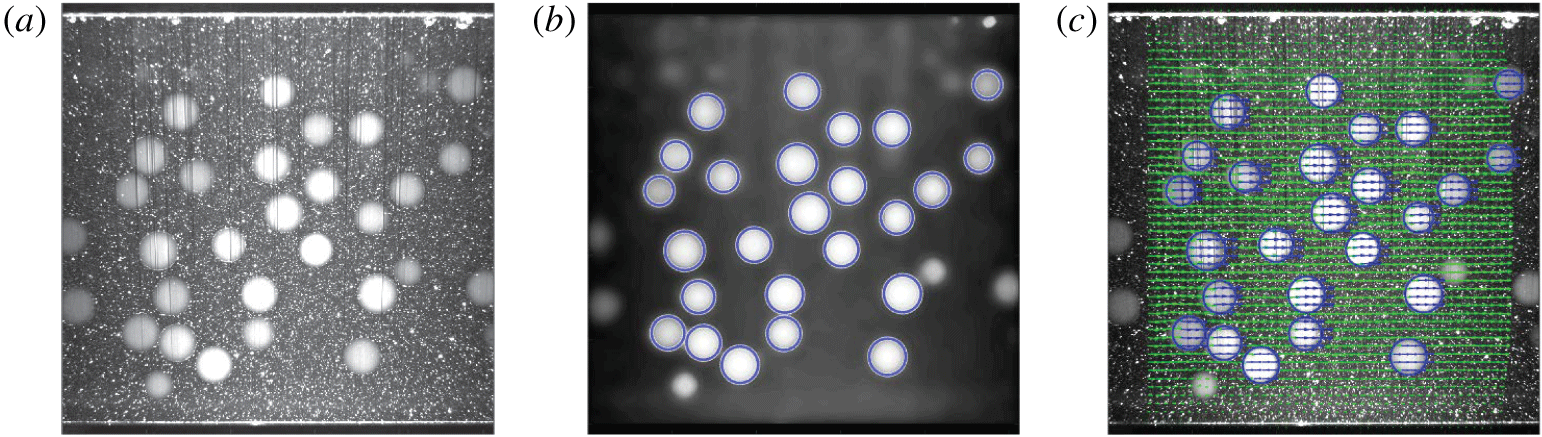

Figure 5. Images involved to calculate the fluid and particle velocity fields. The raw image (a) is used for PIV analysis. The enhanced image (b) is used to detect circles and for the subsequent PTV analysis. The combined PIV (for fluid phase denoted by green arrows) and PTV (for particle phase denoted by blue arrows) velocity field is shown in (c). The detected particles are also shown in (b). The above images correspond to LYS fluid, ![]() $\unicode[STIX]{x1D719}=10\,\%$,

$\unicode[STIX]{x1D719}=10\,\%$, ![]() $z/H=0.9$ and

$z/H=0.9$ and ![]() $Re^{\ast }=156$.

$Re^{\ast }=156$.

Figure 5(a) depicts one image from a typical PIV sequence for particle-laden flow. Raw images captured during the experiment were saved in groups of two different intensity levels. The first group of images, a typical example being figure 5(a), were used for regular PIV processing according to the algorithm mentioned above to find the fluid velocity field. The same first group of images were later contrast enhanced in the post-processing step and constituted the second group of images, an example being figure 5(b). These second group of images were used to detect the particles. Again, the details of the image post-processing and the PTV algorithm are explained at length in Zade et al. (Reference Zade, Fornari, Lundell and Brandt2019a).

The velocity of both the fluid and particle phases is defined on a spatially fixed Eulerian grid. Consequently, a mask matrix is defined, which assumes the value 1 if the point lies inside the particle and 0 if it lies outside the particle. The particle velocity is determined using PTV at its centre, which is assigned to the grid points inside the particle ![]() $(\text{mask}=1)$. The velocity field of the particle phase is now available at the same grid points as that of the fluid and the ensemble averaging, reported later, are phase averaged statistics. Figure 5(c) shows the combined fluid (PIV) and particle (PTV) velocity field. It may be observed that the intensity of the laser sheet is weaker away from the centre of the images and particles are not accurately detected in this region. Hence, PIV and PTV results are extracted from a reduced area neglecting this poorly illuminated region, as shown in figure 5(c).

$(\text{mask}=1)$. The velocity field of the particle phase is now available at the same grid points as that of the fluid and the ensemble averaging, reported later, are phase averaged statistics. Figure 5(c) shows the combined fluid (PIV) and particle (PTV) velocity field. It may be observed that the intensity of the laser sheet is weaker away from the centre of the images and particles are not accurately detected in this region. Hence, PIV and PTV results are extracted from a reduced area neglecting this poorly illuminated region, as shown in figure 5(c).

3 Results

The results are described first in terms of the pressure drop. The velocity field for single-phase flow is described later, before the velocity and concentration profiles for the particle-laden cases are presented.

3.1 Pressure drop

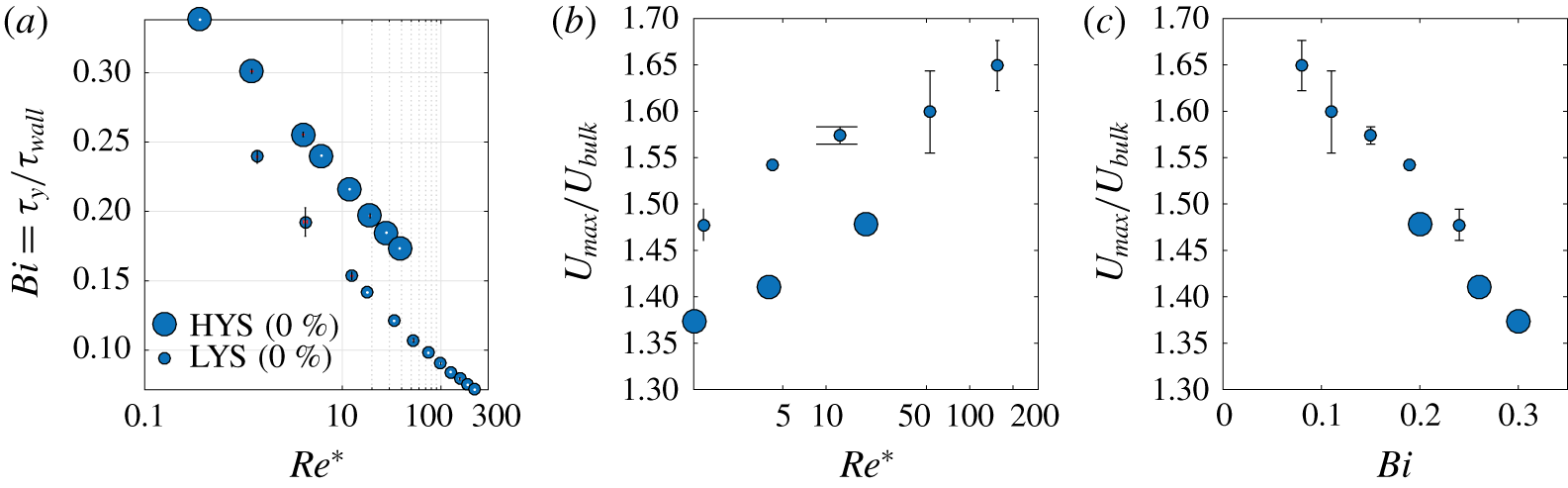

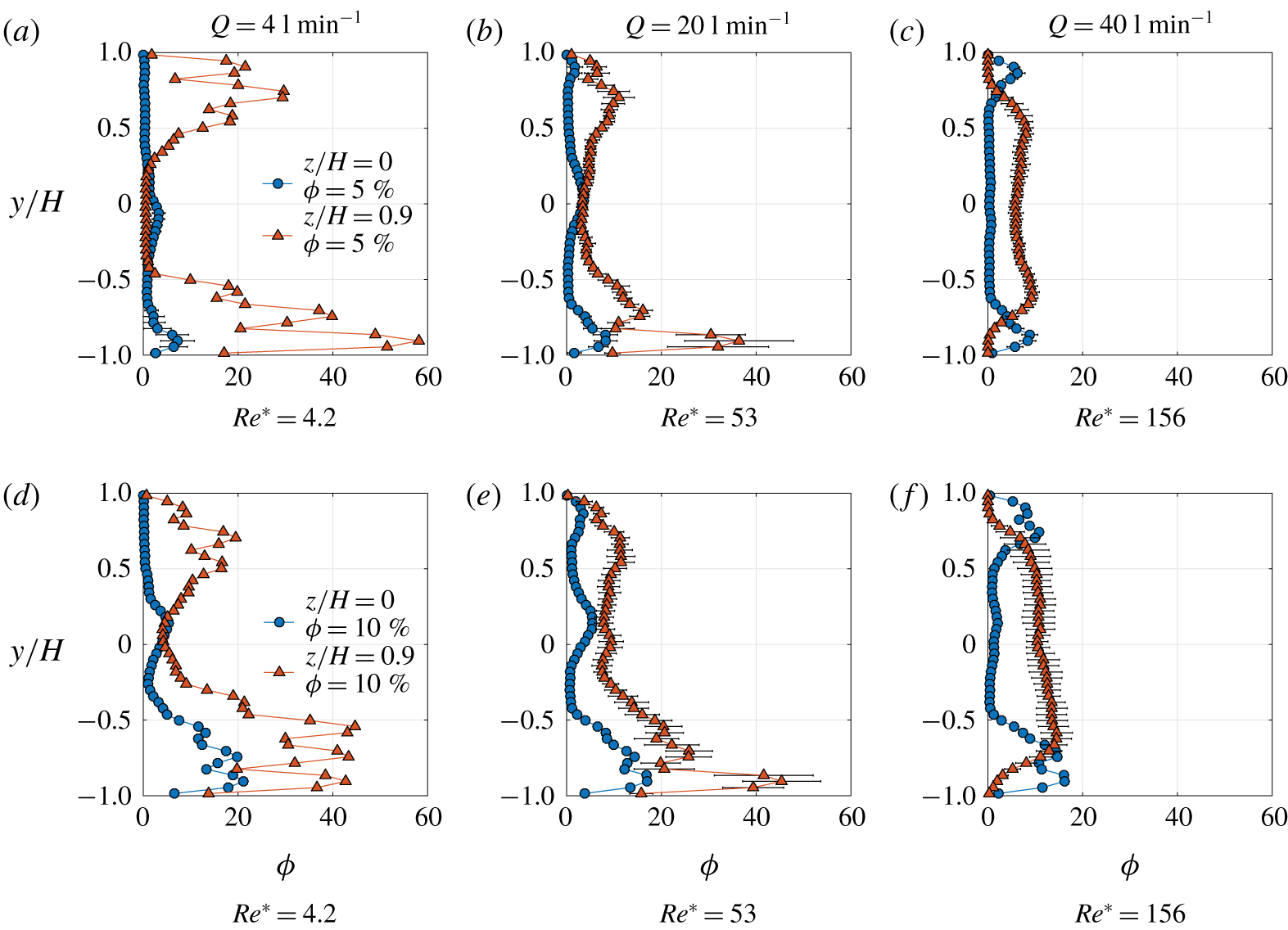

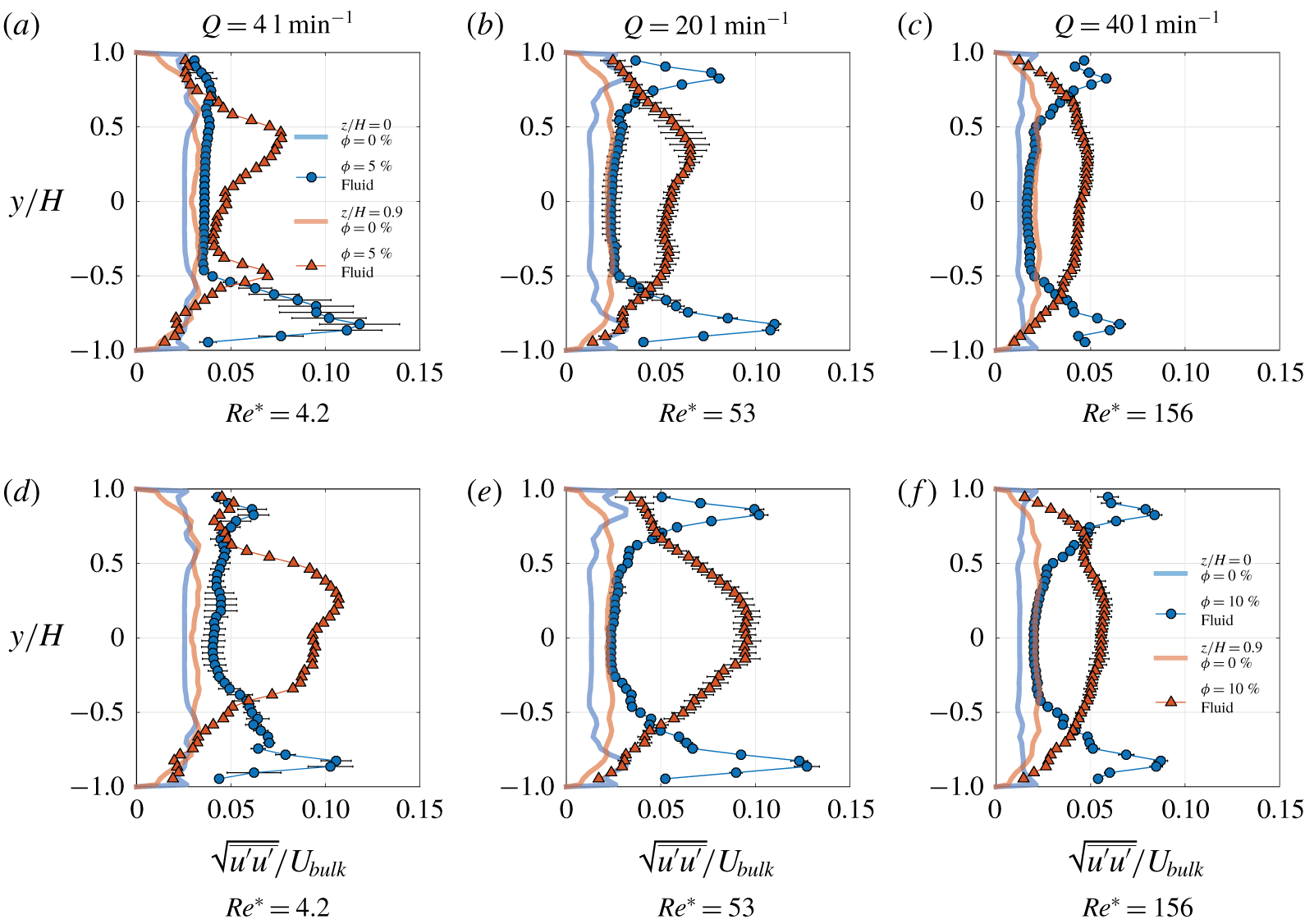

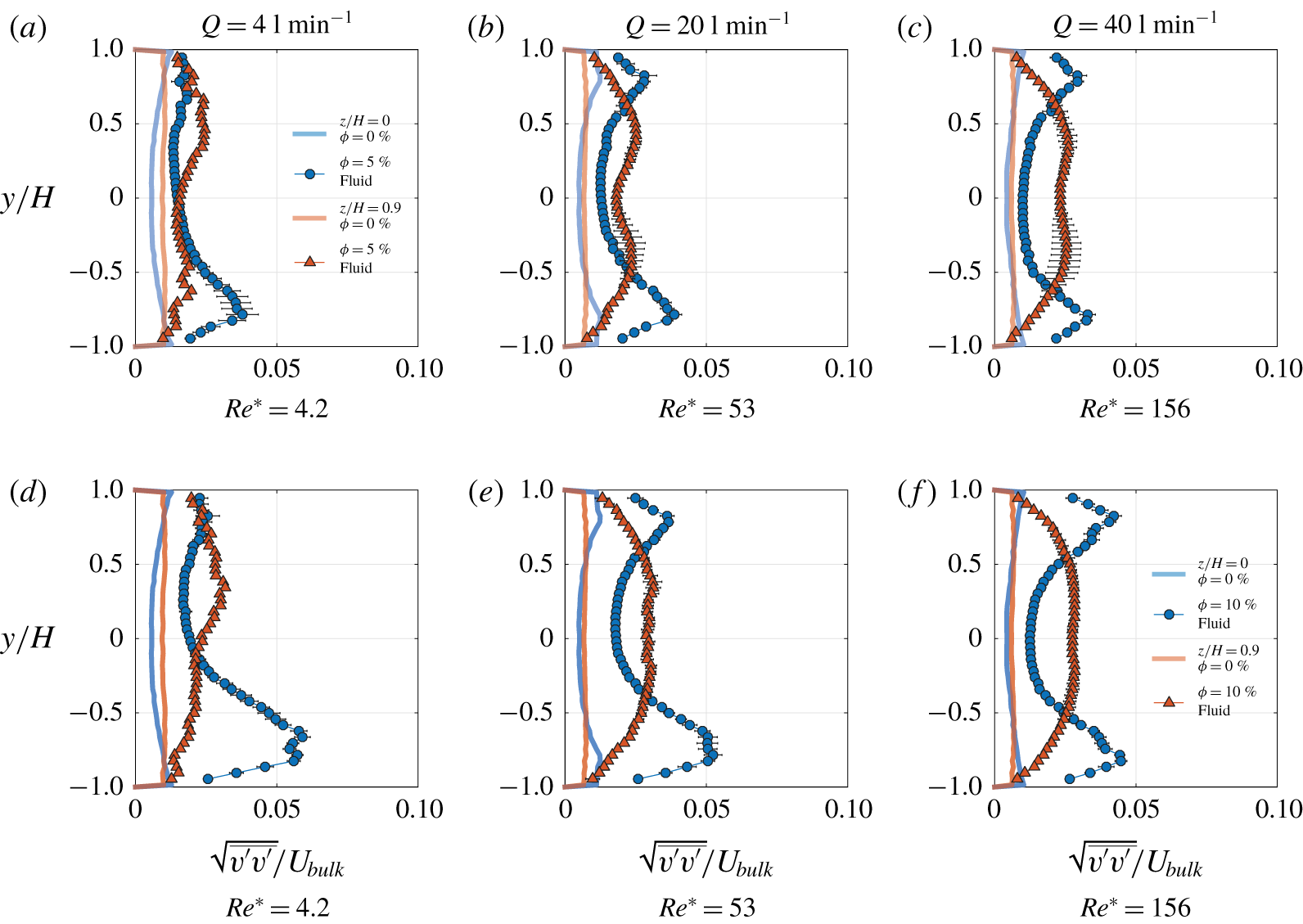

Figure 6(a) displays the friction factor ![]() $f$ as a function of the Reynolds number

$f$ as a function of the Reynolds number ![]() $Re^{\ast }$ for all the cases investigated in this study. The single-phase cases seem to agree reasonably well with the

$Re^{\ast }$ for all the cases investigated in this study. The single-phase cases seem to agree reasonably well with the ![]() $16/Re^{\ast }$ curve, which is the analytical solution for Poiseuille flow of a Newtonian fluid. This is noteworthy considering the fact that a complex expression is used to define

$16/Re^{\ast }$ curve, which is the analytical solution for Poiseuille flow of a Newtonian fluid. This is noteworthy considering the fact that a complex expression is used to define ![]() $Re^{\ast }$, see (1.1). There are measurable changes due to the addition of particles and to better appreciate them, the data in the figure are re-plotted as a percentage change compared to the analytical solution

$Re^{\ast }$, see (1.1). There are measurable changes due to the addition of particles and to better appreciate them, the data in the figure are re-plotted as a percentage change compared to the analytical solution ![]() $16/Re^{\ast }$ in figure 6(b). The deviation for single-phase flow is higher at the lowest

$16/Re^{\ast }$ in figure 6(b). The deviation for single-phase flow is higher at the lowest ![]() $Re^{\ast }$ for HYS fluid but drops to values very close to the analytical solution for higher

$Re^{\ast }$ for HYS fluid but drops to values very close to the analytical solution for higher ![]() $Re^{\ast }$. At particle volume fraction

$Re^{\ast }$. At particle volume fraction ![]() $\unicode[STIX]{x1D719}=5\,\%$, within the extent of the error bars, the increase in pressure drop is independent of the suspending fluid and

$\unicode[STIX]{x1D719}=5\,\%$, within the extent of the error bars, the increase in pressure drop is independent of the suspending fluid and ![]() $Re^{\ast }$. The departure in pressure drop from the single-phase case is more pronounced for

$Re^{\ast }$. The departure in pressure drop from the single-phase case is more pronounced for ![]() $\unicode[STIX]{x1D719}=10\,\%$. Note that for

$\unicode[STIX]{x1D719}=10\,\%$. Note that for ![]() $\unicode[STIX]{x1D719}=10\,\%$, experiments are conducted only in LYS.

$\unicode[STIX]{x1D719}=10\,\%$, experiments are conducted only in LYS.

Figure 6. (a) Variation of friction factor ![]() $f$ with

$f$ with ![]() $Re^{\ast }$ for both single-phase and particle-laden cases. (b) The percentage deviation of the measured

$Re^{\ast }$ for both single-phase and particle-laden cases. (b) The percentage deviation of the measured ![]() $f$ compared to the

$f$ compared to the ![]() $f$ expected for single-phase laminar flow. The inset in (b) shows the same plot but with a Reynolds number

$f$ expected for single-phase laminar flow. The inset in (b) shows the same plot but with a Reynolds number ![]() ${Re_{e}}^{\ast }$ accounting for the additional suspension viscosity due to particles: the filled symbols are based on the Eilers fit and the unfilled symbols are based on a suspension having a modified yield stress and consistency (Chateau, Ovarlez & Trung Reference Chateau, Ovarlez and Trung2008).

${Re_{e}}^{\ast }$ accounting for the additional suspension viscosity due to particles: the filled symbols are based on the Eilers fit and the unfilled symbols are based on a suspension having a modified yield stress and consistency (Chateau, Ovarlez & Trung Reference Chateau, Ovarlez and Trung2008).

The increase in the viscosity of a suspension due to the addition of hard spheres can be semi-empirically described using the Eilers fit (von Eilers Reference von Eilers1941) for a Newtonian suspending fluid under negligible inertia at the particle scale as ![]() $\unicode[STIX]{x1D707}_{e}/\unicode[STIX]{x1D707}=(1+(5/4)\unicode[STIX]{x1D719}/(1-\unicode[STIX]{x1D719}/\unicode[STIX]{x1D719}_{Max}))^{2}$. This effective suspension viscosity

$\unicode[STIX]{x1D707}_{e}/\unicode[STIX]{x1D707}=(1+(5/4)\unicode[STIX]{x1D719}/(1-\unicode[STIX]{x1D719}/\unicode[STIX]{x1D719}_{Max}))^{2}$. This effective suspension viscosity ![]() $\unicode[STIX]{x1D707}_{e}$ is only a function of the nominal particle concentration

$\unicode[STIX]{x1D707}_{e}$ is only a function of the nominal particle concentration ![]() $\unicode[STIX]{x1D719}$ and the maximum packing fraction

$\unicode[STIX]{x1D719}$ and the maximum packing fraction ![]() $\unicode[STIX]{x1D719}_{Max}$, assumed here to be equal to the value for random-close packing

$\unicode[STIX]{x1D719}_{Max}$, assumed here to be equal to the value for random-close packing ![]() ${\approx}65\,\%$. Note that for

${\approx}65\,\%$. Note that for ![]() $\unicode[STIX]{x1D719}\leqslant 10\,\%$, changing

$\unicode[STIX]{x1D719}\leqslant 10\,\%$, changing ![]() $\unicode[STIX]{x1D719}_{Max}$ even by

$\unicode[STIX]{x1D719}_{Max}$ even by ![]() $\pm 10\,\%$ does not produce any substantial change in the estimate of

$\pm 10\,\%$ does not produce any substantial change in the estimate of ![]() $\unicode[STIX]{x1D707}_{e}$. In the limit of low particle inertia and a uniform particle distribution, it may be used to predict the change in the friction factor for a Newtonian suspending fluid. Accordingly, in the inset of figure 6(b), a new effective Reynolds number

$\unicode[STIX]{x1D707}_{e}$. In the limit of low particle inertia and a uniform particle distribution, it may be used to predict the change in the friction factor for a Newtonian suspending fluid. Accordingly, in the inset of figure 6(b), a new effective Reynolds number ![]() ${Re_{e}}^{\ast }$ is defined using

${Re_{e}}^{\ast }$ is defined using ![]() $\unicode[STIX]{x1D707}_{e}$ such that

$\unicode[STIX]{x1D707}_{e}$ such that ![]() ${Re_{e}}^{\ast }=Re^{\ast }\unicode[STIX]{x1D707}/\unicode[STIX]{x1D707}_{e}$ and the experimentally measured friction factor

${Re_{e}}^{\ast }=Re^{\ast }\unicode[STIX]{x1D707}/\unicode[STIX]{x1D707}_{e}$ and the experimentally measured friction factor ![]() $f$ at

$f$ at ![]() $Re^{\ast }$ is compared to the expected friction factor

$Re^{\ast }$ is compared to the expected friction factor ![]() $16/{Re_{e}}^{\ast }$ for an effective fluid (see filled symbols). A good collapse of all the data points within

$16/{Re_{e}}^{\ast }$ for an effective fluid (see filled symbols). A good collapse of all the data points within ![]() $\pm 5\,\%$ of the single-phase results is observed using this approach. A more appropriate rheological description of suspensions in YSF is provided by Chateau et al. (Reference Chateau, Ovarlez and Trung2008) and Mahaut et al. (Reference Mahaut, Chateau, Coussot and Ovarlez2008). Their experiments and theoretical arguments suggest that a particle suspension in YSF behaves like a Herschel–Bulkley fluid with the same flow index

$\pm 5\,\%$ of the single-phase results is observed using this approach. A more appropriate rheological description of suspensions in YSF is provided by Chateau et al. (Reference Chateau, Ovarlez and Trung2008) and Mahaut et al. (Reference Mahaut, Chateau, Coussot and Ovarlez2008). Their experiments and theoretical arguments suggest that a particle suspension in YSF behaves like a Herschel–Bulkley fluid with the same flow index ![]() $n$ as the suspending YSF, but with a different equivalent yield stress

$n$ as the suspending YSF, but with a different equivalent yield stress ![]() $\unicode[STIX]{x1D70F}_{y}\sqrt{(1-\unicode[STIX]{x1D719})g(\unicode[STIX]{x1D719})}$ and consistency

$\unicode[STIX]{x1D70F}_{y}\sqrt{(1-\unicode[STIX]{x1D719})g(\unicode[STIX]{x1D719})}$ and consistency ![]() $\unicode[STIX]{x1D705}\sqrt{(g(\unicode[STIX]{x1D719}))^{n+1}/(1-\unicode[STIX]{x1D719})^{n-1}}$. The function

$\unicode[STIX]{x1D705}\sqrt{(g(\unicode[STIX]{x1D719}))^{n+1}/(1-\unicode[STIX]{x1D719})^{n-1}}$. The function ![]() $g(\unicode[STIX]{x1D719})$ is the Krieger–Dougherty fit for suspension viscosity:

$g(\unicode[STIX]{x1D719})$ is the Krieger–Dougherty fit for suspension viscosity: ![]() $g(\unicode[STIX]{x1D719})=(1-\unicode[STIX]{x1D719}/\unicode[STIX]{x1D719}_{Max})^{-2.5\unicode[STIX]{x1D719}_{Max}}$ (Krieger & Dougherty Reference Krieger and Dougherty1959) and is virtually indistinguishable from the Eilers fit (mentioned above) up to the low

$g(\unicode[STIX]{x1D719})=(1-\unicode[STIX]{x1D719}/\unicode[STIX]{x1D719}_{Max})^{-2.5\unicode[STIX]{x1D719}_{Max}}$ (Krieger & Dougherty Reference Krieger and Dougherty1959) and is virtually indistinguishable from the Eilers fit (mentioned above) up to the low ![]() $\unicode[STIX]{x1D719}=10\,\%$ investigated in the present case. Using the above modification in yield stress and consistency, an equivalent Reynolds number, based on (1.1), can be defined and the corresponding laminar friction factor is (also) plotted in the inset of figure 6(b) (see unfilled symbols). Indeed, there are differences between the predictions using a simple effective viscosity (filled symbols) and the more reasonable modification in viscosity for YSF (unfilled symbols) proposed by Chateau et al. (Reference Chateau, Ovarlez and Trung2008). Both the above fits are based on the assumption of a homogeneous particle distribution and, as will be shown later, this is definitely not the case in our present experiments, where particles migrate to specific regions of the flow domain. Thus, there is no strong reason for an effective viscosity formulation to accurately predict the friction factor in laminar flows for a square duct. A more thorough investigation at multiple