1. Introduction

In recent years, organic light-emitting-diode (OLED) displays have become an increasingly important part of the overall display market. In particular, thanks to their superior display quality, specifically their true black state and fast response time compared with liquid crystal displays (LCDs) (see, for example, Chen et al. Reference Chen, Lee, Lin, Chen and Wu2018), OLED displays are now preferred to LCDs for mobile and high-end television applications (see, for example, Lee et al. Reference Lee2018). Currently, the vast majority of OLED displays are manufactured using a vacuum-coating method with a fine metal mask. However, a number of issues, notably the difficulty of precisely controlling the distance between the mask and the display (see, for example, Zhu et al. Reference Zhu, Wang, Zhang, Jin, Li, Wang, Zhang and Yuan2018), limit the size of displays that can be mass-produced using this technique. As a result, there has been considerable interest in avoiding the difficulties associated with the mask by inkjet printing the active materials (dissolved in one or more carrier solvents) directly into small cavities, hereafter referred to as ‘wells’, in the substrate, the solvent thereafter evaporating to leave the desired deposit of active material in the well (see, for example, Shimoda et al. Reference Shimoda, Morii, Seki and Kiguchi2003; Halls Reference Halls2005; Singh et al. Reference Singh, Haverinen, Dhagat and Jabbour2010; Madigan et al. Reference Madigan, Hauf, Barkley, Harjee, Vronsky and Van Slyke2014; Levermore et al. Reference Levermore, Schenk, Tseng, Wang, Heil, Jatsch, Buchholz and Böhm2016; Walker et al. Reference Walker, Leith, Duff, Tan, Tseng, Schenk and Levermore2016). While there is a substantial body of work on the inkjet printing process and, in particular, on the ejection of the droplets from the printheads and the subsequent dynamics of the detached droplets (see, for example, Hoath Reference Hoath2016), far less work has been done on the evolution of the droplets once they have been deposited into the wells. Of particular industrial interest is the period of time between printing taking place and the printed substrate being placed into a drier, during which the solvents evaporate in a diffusion-limited regime. Inkjet printing of droplets into wells also arises in other contexts (such as, for example, the applications in biotechnology described by Marizza, Keller & Boisen Reference Marizza, Keller and Boisen2013).

While there is a large and rapidly growing literature on the dynamics of evaporating droplets on planar substrates (see, for example, the review articles by Larson (Reference Larson2014); Lohse & Zhang (Reference Lohse and Zhang2015); Brutin & Starov (Reference Brutin and Starov2018) and Giorgiutti-Dauphiné & Pauchard (Reference Giorgiutti-Dauphiné and Pauchard2018), and the many references therein), there has been relatively little work on the evaporation of and/or the deposition from a droplet in a well. Not only is this problem directly relevant to the industrial manufacture of OLED displays, but it is also of interest in its own right as a fundamental scientific problem that is key to understanding the many other situations in which evaporating droplets on non-planar substrates occur (such as, for example, the agrochemical spraying of plants that motivated the work of Tredenick et al. Reference Tredenick, Forster, Pethiyagoda, van Leeuwen and McCue2021).

Experimental studies have been undertaken to investigate the evolution of an evaporating droplet in a cuboidal well by van den Doel & van Vliet (Reference van den Doel and van Vliet2001), and in a cylindrical well by Rieger, van den Doel & van Vliet (Reference Rieger, van den Doel and van Vliet2003), Chen, Tseng & Chieng (Reference Chen, Tseng and Chieng2006); Chen, Chieng & Tseng (Reference Chen, Chieng and Tseng2007), Jung et al. (Reference Jung, Kajiya, Yamaue and Doi2009), Kajiya et al. (Reference Kajiya, Kobayashi, Okuzono and Doi2009) and Vlasko-Vlasov et al. (Reference Vlasko-Vlasov, Sulwer, Shevchenko, Parker and Kwok2020). van den Doel & van Vliet (Reference van den Doel and van Vliet2001) and Rieger et al. (Reference Rieger, van den Doel and van Vliet2003) studied the evolution of the free-surface profile of the droplet before it touches the bottom of the well, hereafter referred to as ‘touchdown’, and showed that the volume of the droplet decreases at a rate that is approximately constant in time and proportional to the length of the contact line (rather than the surface area) of the droplet (both of which behaviours are consistent with predictions of a diffusion-limited model such as that presented in the present work). Chen et al. (Reference Chen, Tseng and Chieng2006) investigated evolution after touchdown and found that, at least for the situations they investigated, the new inner contact line that appears at the centre of the well at touchdown recedes at an approximately constant speed (behaviour that is not, in general, either predicted by the mathematical model or seen in the experimental results presented in the present work). Chen et al. (Reference Chen, Chieng and Tseng2007) showed that the wettability properties of the well can have a strong effect on the evolution of the free surface, and hence on the spatial distribution of the final deposit left in the well after a droplet containing suspended particles has completely evaporated. Jung et al. (Reference Jung, Kajiya, Yamaue and Doi2009) studied the evolution of and the final deposit from a droplet of a polymer solution whose contact line is pinned at the lip of the well, and Kajiya et al. (Reference Kajiya, Kobayashi, Okuzono and Doi2009) extended this work to investigate the effect of adding various surfactants to the droplet. More recently, Vlasko-Vlasov et al. (Reference Vlasko-Vlasov, Sulwer, Shevchenko, Parker and Kwok2020) performed a detailed investigation of a final deposit in the form of concentric rings arising from a stick–slip motion of the receding inner contact line.

In addition to these primarily experimental studies, a number of theoretical investigations of the evaporation of a droplet in a well have also been performed. Okuzono, Kobayashi & Doi (Reference Okuzono, Kobayashi and Doi2009) assumed the evaporative flux from the droplet to be spatially uniform and used a thin-film approximation to analyse the evolution of and the final deposit from a two-dimensional droplet in a rectangular well. Subsequently, Eales et al. (Reference Eales, Dartnell, Goddard and Routh2015) used the same approach to investigate the final deposit from an axisymmetric droplet in an axisymmetric (but, in general, non-cylindrical) well. However, both of these works concern droplets of a polymer solution in which gelation (i.e. solidification) effects play a key role, and so touchdown never occurs. Tarasevich et al. (Reference Tarasevich, Vodolazskaya, Isakova and Abdel Latif2009) calculated the radial velocity within an axisymmetric droplet in a cylindrical well for four different evaporative fluxes (slightly confusingly referred to as ‘four different modes of evaporation’). Son (Reference Son2012) and Ahn & Son (Reference Ahn and Son2015) used a sharp-interface level-set method to simulate numerically the impact and evolution of an evaporating droplet in a cylindrical well, and the evolution of an evaporating droplet in both cuboidal and cylindrical wells, respectively. Wang & Fukai (Reference Wang and Fukai2018) used a finite-element method to calculate numerically the evaporative flux from a droplet in a cylindrical well before touchdown. They considered the situation in which the contact line is pinned on the vertical side of the well (rather than at the lip of the well, as it is in the present work), and found that the confining effect of the side of the well can significantly suppress the evaporation in the vicinity of the contact line and lead to a substantial reduction in the total evaporative flux. In related work on non-evaporating droplets, Kant et al. (Reference Kant, Hazel, Dowling, Thompson and Juel2017, Reference Kant, Hazel, Dowling, Thompson and Juel2018) used a combination of experimental and analytical methods to analyse the spreading of both a single droplet and a sequence of partially overlapping droplets in a ‘stadium-shaped’ well, while Zhang et al. (Reference Zhang, Ku, Cheng, Song and Zhang2018) used the lattice Boltzmann method to simulate numerically the impact and evolution of a droplet in a cuboidal well.

Thus, while there have been previous investigations of various aspects of the evaporation of a droplet in a well, there is still neither a complete mathematical model for this problem nor a comprehensive set of experimental results against which the predictions of such a model can be validated. The aim of the present work is to rectify these omissions. Specifically, the outline of the remainder of the present work is as follows. Firstly, in §§ 2–4 we formulate and analyse a mathematical model for the evolution of a thin droplet in a shallow axisymmetric well of rather general shape both before and after touchdown that accounts for the spatially non-uniform evaporation of the fluid. Secondly, in §§ 5 and 6 we perform physical experiments using three cylindrical wells with different small aspect ratios. Thirdly, in §§ 7 and 8 we validate the mathematical model by comparing the present experimental results and experimental results obtained by previous authors, respectively, with the corresponding theoretical predictions for a cylindrical well. Finally, in § 9 we summarise our findings and indicate some possible directions for future work.

2. Mathematical model

Consider a droplet of fluid in an axisymmetric well in the otherwise dry planar surface of a substrate undergoing quasi-static diffusion-limited evaporation into a quiescent atmosphere. We refer the description to polar coordinates ![]() $r$,

$r$, ![]() $\phi$,

$\phi$, ![]() $z$ with

$z$ with ![]() $Oz$ along the axis of the well, perpendicular to the surface of the substrate at

$Oz$ along the axis of the well, perpendicular to the surface of the substrate at ![]() $z = 0$, as sketched in figure 1. We denote the maximum depth of the well, which occurs at

$z = 0$, as sketched in figure 1. We denote the maximum depth of the well, which occurs at ![]() $r = 0$, by

$r = 0$, by ![]() $H_0$, and the radius of its lip by

$H_0$, and the radius of its lip by ![]() $R_0$, so that the lip is located at

$R_0$, so that the lip is located at ![]() $r = R_0$,

$r = R_0$, ![]() $z = 0$. We take the droplet to be axisymmetric, and denote its free-surface profile by

$z = 0$. We take the droplet to be axisymmetric, and denote its free-surface profile by ![]() $z = h(r,t)$, where

$z = h(r,t)$, where ![]() $t$ denotes time. The droplet is deposited into the well at

$t$ denotes time. The droplet is deposited into the well at ![]() $t=0$, and thereafter its volume decreases due to evaporation until it has completely evaporated, which occurs at

$t=0$, and thereafter its volume decreases due to evaporation until it has completely evaporated, which occurs at ![]() $t=t_{lifetime}$, where

$t=t_{lifetime}$, where ![]() $t_{lifetime}$ is the lifetime of the droplet.

$t_{lifetime}$ is the lifetime of the droplet.

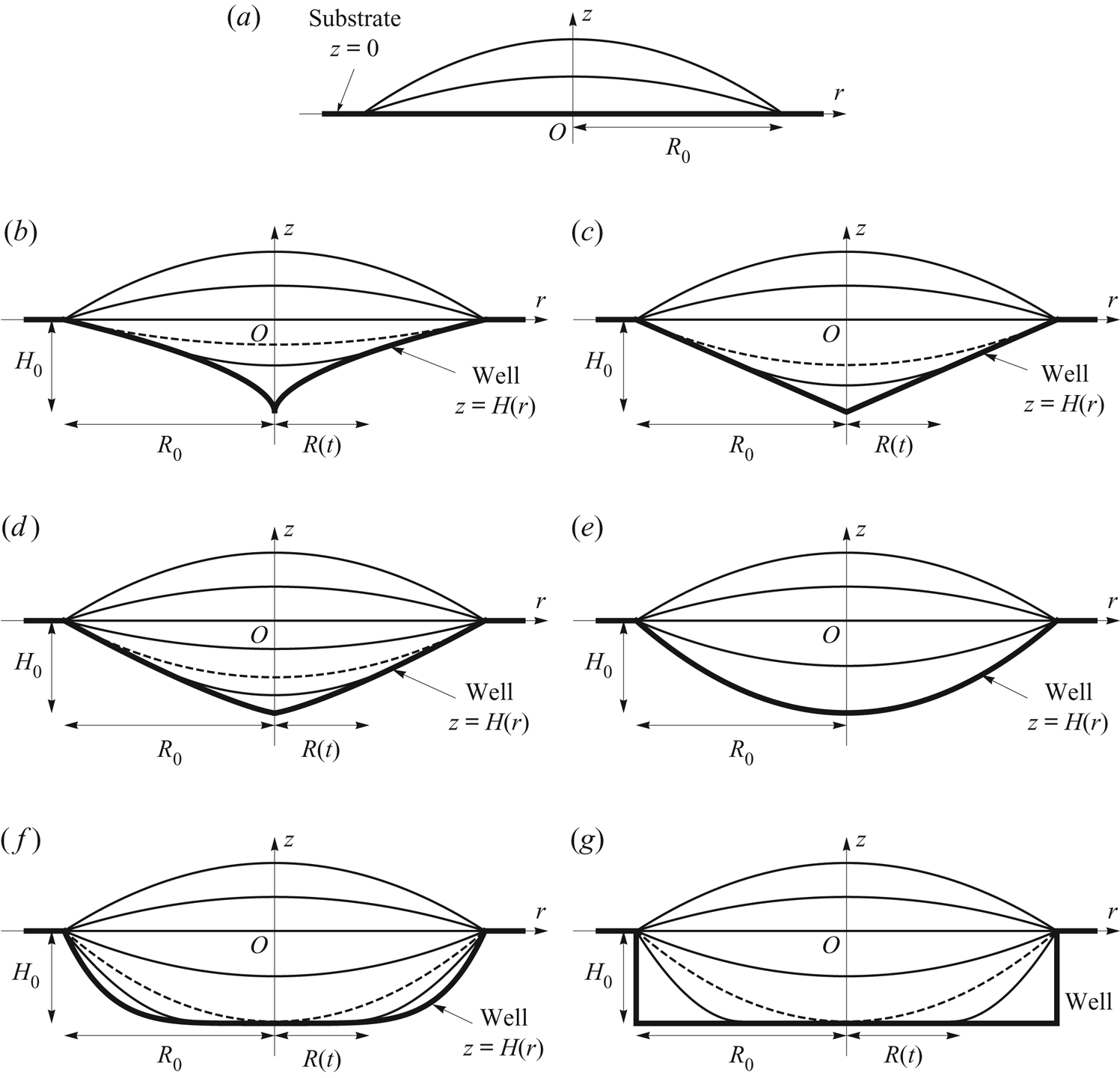

Figure 1. Sketch of snapshots of the free-surface profile ![]() $z=h(r,t)$ of a thin droplet evaporating in a shallow axisymmetric well with profile

$z=h(r,t)$ of a thin droplet evaporating in a shallow axisymmetric well with profile ![]() $z = H(r) = - H_0(1 - (r/R_0)^{n})$ in the otherwise dry planar surface

$z = H(r) = - H_0(1 - (r/R_0)^{n})$ in the otherwise dry planar surface ![]() $z = 0$ of a substrate, for (a) either

$z = 0$ of a substrate, for (a) either ![]() $H_0 = 0$ or

$H_0 = 0$ or ![]() $n = 0$ (i.e. a planar substrate with no well), (b)

$n = 0$ (i.e. a planar substrate with no well), (b) ![]() $0 < n < 1$, (c)

$0 < n < 1$, (c) ![]() $n = 1$ (i.e. a conical well), (d)

$n = 1$ (i.e. a conical well), (d) ![]() $1 < n < 2$, (e)

$1 < n < 2$, (e) ![]() $n = 2$ (i.e. a paraboloidal well), (f)

$n = 2$ (i.e. a paraboloidal well), (f) ![]() $2 < n < \infty$ and (g) in the limit

$2 < n < \infty$ and (g) in the limit ![]() $n \to \infty$ (i.e. a cylindrical well). In (b–g) the free-surface profile at

$n \to \infty$ (i.e. a cylindrical well). In (b–g) the free-surface profile at ![]() $t=t_{touchdown}$ is indicated with a dashed curve. Note that the dashed curve is not visible in (e) as touchdown occurs everywhere simultaneously within the well in the special case

$t=t_{touchdown}$ is indicated with a dashed curve. Note that the dashed curve is not visible in (e) as touchdown occurs everywhere simultaneously within the well in the special case ![]() $n=2$.

$n=2$.

We consider situations in which the droplet is thin and the well is shallow, the droplet is sufficiently small that the effect of gravity is negligible, and the surface tension is sufficiently strong that the free surface of the droplet evolves quasi-statically. More specifically, we consider situations in which the aspect ratio of the droplet and the well, ![]() $\epsilon = H_0/R_0 \ll 1$, is small, as are the appropriately defined Bond number

$\epsilon = H_0/R_0 \ll 1$, is small, as are the appropriately defined Bond number ![]() ${Bo}$ and capillary number

${Bo}$ and capillary number ![]() ${Ca}$, namely

${Ca}$, namely

where ![]() $\rho$,

$\rho$, ![]() $\gamma$ and

$\gamma$ and ![]() $\mu$ are the constant density, surface tension and dynamic viscosity of the fluid, respectively,

$\mu$ are the constant density, surface tension and dynamic viscosity of the fluid, respectively, ![]() $g$ denotes the magnitude of acceleration due to gravity and

$g$ denotes the magnitude of acceleration due to gravity and ![]() $U$ is an appropriate radial velocity scale (defined in § 7).

$U$ is an appropriate radial velocity scale (defined in § 7).

The mean curvature of the free surface of the droplet is spatially constant, and so at leading order in the limit ![]() $\epsilon \to 0$ the free-surface profile

$\epsilon \to 0$ the free-surface profile ![]() $h$ satisfies

$h$ satisfies

and hence takes the general form

where the ![]() $c_i = c_i(t)$ for

$c_i = c_i(t)$ for ![]() $i = 1$,

$i = 1$, ![]() $2$,

$2$, ![]() $3$ are yet to be determined.

$3$ are yet to be determined.

We consider a shaped well with profile ![]() $z = H(r)$ (

$z = H(r)$ (![]() $\le 0$), where

$\le 0$), where

in which the exponent ![]() $n$ (

$n$ (![]() $\ge 0$) is a constant. The volume of the well (i.e. its volume below the plane

$\ge 0$) is a constant. The volume of the well (i.e. its volume below the plane ![]() $z = 0$) is given by

$z = 0$) is given by

and any three of the four quantities ![]() $V_{well}$,

$V_{well}$, ![]() $R_0$,

$R_0$, ![]() $H_0$ and

$H_0$ and ![]() $n$ may be prescribed. Cases with either

$n$ may be prescribed. Cases with either ![]() $H_0 = 0$ or

$H_0 = 0$ or ![]() $n = 0$ in (2.4), sketched in figure 1(a), correspond to the familiar case of a droplet on a planar substrate with no well. The cases

$n = 0$ in (2.4), sketched in figure 1(a), correspond to the familiar case of a droplet on a planar substrate with no well. The cases ![]() $n = 1$,

$n = 1$, ![]() $n = 2$ and in the limit

$n = 2$ and in the limit ![]() $n \to \infty$, also included in figure 1, correspond respectively to a conical well, a paraboloidal well (which will turn out to be an important special case), and a cylindrical well with vertical side

$n \to \infty$, also included in figure 1, correspond respectively to a conical well, a paraboloidal well (which will turn out to be an important special case), and a cylindrical well with vertical side ![]() $r = R_0$ and flat bottom

$r = R_0$ and flat bottom ![]() $z = -H_0$. The latter case, which, as we have already seen, is of particular interest from a practical point of view, is the subject of the experimental investigation reported in the present work. At its lowest point located at

$z = -H_0$. The latter case, which, as we have already seen, is of particular interest from a practical point of view, is the subject of the experimental investigation reported in the present work. At its lowest point located at ![]() $r = 0$,

$r = 0$, ![]() $z = -H_0$ the profile of the well (2.4) has a cusp when

$z = -H_0$ the profile of the well (2.4) has a cusp when ![]() $0 < n < 1$, has a corner when

$0 < n < 1$, has a corner when ![]() $n = 1$, and is flat when

$n = 1$, and is flat when ![]() $n > 1$; also its curvature there is infinite when

$n > 1$; also its curvature there is infinite when ![]() $0 < n < 2$, takes the value

$0 < n < 2$, takes the value ![]() $4H_0/R_0^{2}$ when

$4H_0/R_0^{2}$ when ![]() $n = 2$, and is zero when

$n = 2$, and is zero when ![]() $n > 2$. The slope of the well at its lip is

$n > 2$. The slope of the well at its lip is ![]() $nH_0/R_0$.

$nH_0/R_0$.

We assume that, at least in the first stage of the evolution, the contact line is pinned at the lip of the well located at ![]() $r = R_0$,

$r = R_0$, ![]() $z = 0$. The initial volume of the droplet,

$z = 0$. The initial volume of the droplet, ![]() $V_0$, could be greater than, equal to, or less than the volume of the well,

$V_0$, could be greater than, equal to, or less than the volume of the well, ![]() $V_{well}$, in which case the initial free surface of the droplet would be respectively above, at, or below the plane

$V_{well}$, in which case the initial free surface of the droplet would be respectively above, at, or below the plane ![]() $z = 0$. Although all of these cases could be analysed by the present approach, for definiteness we take

$z = 0$. Although all of these cases could be analysed by the present approach, for definiteness we take ![]() $V_0$ to be greater than

$V_0$ to be greater than ![]() $V_{well}$, so that initially the well is completely filled and the free surface is above

$V_{well}$, so that initially the well is completely filled and the free surface is above ![]() $z = 0$.

$z = 0$.

At some time ![]() $t = t_{touchdown}$ (

$t = t_{touchdown}$ (![]() $0 < t_{touchdown} \le t_{lifetime}$) the free surface makes contact tangentially (i.e. at zero contact angle) with the surface of the well. As shown by the dashed curves in figure 1, when

$0 < t_{touchdown} \le t_{lifetime}$) the free surface makes contact tangentially (i.e. at zero contact angle) with the surface of the well. As shown by the dashed curves in figure 1, when ![]() $0 < n < 2$ touchdown occurs at the lip of the well, and when

$0 < n < 2$ touchdown occurs at the lip of the well, and when ![]() $n > 2$ it occurs at the centre of the well. In the special case n = 2 touchdown occurs everywhere simultaneously within the well, and so the dashed curve is not visible in figure 1(e). Before touchdown the behaviour of the droplet is the same in all three cases, which may therefore be analysed together, but after touchdown the behaviour is different, and it is then convenient to consider the three cases separately.

$n > 2$ it occurs at the centre of the well. In the special case n = 2 touchdown occurs everywhere simultaneously within the well, and so the dashed curve is not visible in figure 1(e). Before touchdown the behaviour of the droplet is the same in all three cases, which may therefore be analysed together, but after touchdown the behaviour is different, and it is then convenient to consider the three cases separately.

In the special case ![]() $n = 2$ the droplet has completely evaporated at

$n = 2$ the droplet has completely evaporated at ![]() $t = t_{touchdown}$, and so

$t = t_{touchdown}$, and so ![]() $t_{lifetime} = t_{touchdown}$. However, in the general case

$t_{lifetime} = t_{touchdown}$. However, in the general case ![]() $n \ne 2$ the droplet has not completely evaporated at

$n \ne 2$ the droplet has not completely evaporated at ![]() $t = t_{touchdown}$, and the nature of its subsequent evolution depends on whether

$t = t_{touchdown}$, and the nature of its subsequent evolution depends on whether ![]() $0 < n < 2$ or

$0 < n < 2$ or ![]() $n > 2$. When

$n > 2$. When ![]() $0 < n < 2$ we assume that, as sketched in figure 1(b–d), the contact line de-pins from the lip of the well, and thereafter the contact line recedes (i.e. moves inwards towards the centre of the well) with decreasing radius

$0 < n < 2$ we assume that, as sketched in figure 1(b–d), the contact line de-pins from the lip of the well, and thereafter the contact line recedes (i.e. moves inwards towards the centre of the well) with decreasing radius ![]() $R = R(t)$ until

$R = R(t)$ until ![]() $R(t_{lifetime})=0$, at which time the droplet has completely evaporated. On the other hand, when

$R(t_{lifetime})=0$, at which time the droplet has completely evaporated. On the other hand, when ![]() $n > 2$ we assume that, as sketched in figure 1(f,g), a new inner contact line appears at the centre of the well (i.e. at the centre of the droplet, which then becomes annular), and thereafter the inner contact line recedes (i.e. moves outwards towards the lip of the well, where the outer contact line remains pinned) with increasing radius

$n > 2$ we assume that, as sketched in figure 1(f,g), a new inner contact line appears at the centre of the well (i.e. at the centre of the droplet, which then becomes annular), and thereafter the inner contact line recedes (i.e. moves outwards towards the lip of the well, where the outer contact line remains pinned) with increasing radius ![]() $R = R(t)$ until

$R = R(t)$ until ![]() $R(t_{lifetime})=R_0$, at which time the droplet has completely evaporated.

$R(t_{lifetime})=R_0$, at which time the droplet has completely evaporated.

In the next two sections we analyse the evolution of the droplet before and after touchdown, respectively.

3. Evolution before touchdown, i.e. for  $0 \le t \le t_{touchdown}$

$0 \le t \le t_{touchdown}$

Before touchdown, i.e. for ![]() $0 \le t \le t_{touchdown}$, the contact line is pinned at the lip of the well, and so the free-surface profile given by (2.3) must satisfy

$0 \le t \le t_{touchdown}$, the contact line is pinned at the lip of the well, and so the free-surface profile given by (2.3) must satisfy ![]() $h(R_0,t) = 0$; in addition,

$h(R_0,t) = 0$; in addition, ![]() $h$ must be finite at

$h$ must be finite at ![]() $r = 0$, and is therefore of the familiar paraboloidal form

$r = 0$, and is therefore of the familiar paraboloidal form

where ![]() $h_{m} = h_{m}(t) = h(0,t)$ is the height of the free surface at the centre of the well, and

$h_{m} = h_{m}(t) = h(0,t)$ is the height of the free surface at the centre of the well, and ![]() $\theta = \theta (t) \ll 1$ is the (small) angle that the free surface at the lip of the well makes with the plane

$\theta = \theta (t) \ll 1$ is the (small) angle that the free surface at the lip of the well makes with the plane ![]() $z = 0$, i.e.

$z = 0$, i.e. ![]() $\theta = -\partial h/\partial r$ at

$\theta = -\partial h/\partial r$ at ![]() $r = R_0$. Note that, unlike for a droplet on a planar substrate for which both

$r = R_0$. Note that, unlike for a droplet on a planar substrate for which both ![]() $h_{m}$ and

$h_{m}$ and ![]() $\theta$ must be non-negative, for a droplet in a well they may be positive, zero or negative. The volume

$\theta$ must be non-negative, for a droplet in a well they may be positive, zero or negative. The volume ![]() $V = V(t)$ of the droplet is related to

$V = V(t)$ of the droplet is related to ![]() $V_{well}$,

$V_{well}$, ![]() $R_0$,

$R_0$, ![]() $H_0$,

$H_0$, ![]() $n$ and

$n$ and ![]() $\theta$ by

$\theta$ by

According to the well-known quasi-static diffusion-limited model of the evaporation of a droplet (see, for example, Picknett & Bexon Reference Picknett and Bexon1977; Deegan et al. Reference Deegan, Bakajin, Dupont, Huber, Nagel and Witten1997; Hu & Larson Reference Hu and Larson2002; Popov Reference Popov2005; Dunn et al. Reference Dunn, Wilson, Duffy, David and Sefiane2009; Wray, Duffy & Wilson Reference Wray, Duffy and Wilson2020), the (static) concentration ![]() $c=c(r,z)$ of vapour in the atmosphere satisfies

$c=c(r,z)$ of vapour in the atmosphere satisfies

with

where ![]() $c_{sat}$ is the constant saturation concentration and

$c_{sat}$ is the constant saturation concentration and ![]() $c_{\infty } = RHc_{sat}$ is the constant ambient concentration, where

$c_{\infty } = RHc_{sat}$ is the constant ambient concentration, where ![]() $RH$

$RH$ ![]() $(0 \le RH \le 1)$ is the relative humidity of the vapour in the atmosphere. The local evaporative flux

$(0 \le RH \le 1)$ is the relative humidity of the vapour in the atmosphere. The local evaporative flux ![]() $J=J(r)$ from the free surface of the droplet is given by

$J=J(r)$ from the free surface of the droplet is given by

where ![]() $D$ is the constant diffusion coefficient of vapour in the atmosphere, and the volume

$D$ is the constant diffusion coefficient of vapour in the atmosphere, and the volume ![]() $V=V(t)$ evolves according to the global mass-conservation condition

$V=V(t)$ evolves according to the global mass-conservation condition

Note that, in general, (3.5) and (3.7) apply on the free surface ![]() $z = h$, but for a thin droplet such as that considered in the present work they can be transferred to the plane

$z = h$, but for a thin droplet such as that considered in the present work they can be transferred to the plane ![]() $z = 0$ by Taylor expanding about

$z = 0$ by Taylor expanding about ![]() $z = 0$. We denote the initial values of

$z = 0$. We denote the initial values of ![]() $\theta$,

$\theta$, ![]() $h_{m}$ and

$h_{m}$ and ![]() $V$ by

$V$ by ![]() $\theta _0$,

$\theta _0$, ![]() $h_{{m}0}$ and

$h_{{m}0}$ and ![]() $V_0$, respectively, so that

$V_0$, respectively, so that

Note that for ![]() $0 \le t \le t_{touchdown}$ the concentration

$0 \le t \le t_{touchdown}$ the concentration ![]() $c$ and hence the local flux

$c$ and hence the local flux ![]() $J$ are independent of

$J$ are independent of ![]() $t$, whereas for

$t$, whereas for ![]() $t_{touchdown} < t \le t_{lifetime}$ both of them depend on

$t_{touchdown} < t \le t_{lifetime}$ both of them depend on ![]() $t$ via their dependence on

$t$ via their dependence on ![]() $R=R(t)$.

$R=R(t)$.

The natural time scale for the evaporation of a thin droplet is ![]() $\rho \theta _0 R_0^{2}/[D(c_{sat}-c_{\infty })]$ (see, for example, Dunn et al. Reference Dunn, Wilson, Duffy, David and Sefiane2008; Schofield et al. Reference Schofield, Wilson, Pritchard and Sefiane2018), and so we non-dimensionalise and scale the variables according to

$\rho \theta _0 R_0^{2}/[D(c_{sat}-c_{\infty })]$ (see, for example, Dunn et al. Reference Dunn, Wilson, Duffy, David and Sefiane2008; Schofield et al. Reference Schofield, Wilson, Pritchard and Sefiane2018), and so we non-dimensionalise and scale the variables according to

\begin{align} \left. \begin{gathered} r = R_0 r^{*}, \quad z = \theta_0 R_0 z^{*}, \quad h = \theta_0 R_0 h^{*}, \quad h_{m} = \theta_0 R_0 h_{m}^{*}, \quad t = \frac{\rho\theta_0 R_0^{2}}{D(c_{sat}-c_{\infty})}t^{*},\\ \theta = \theta_0 \theta^{*}, \quad R = R_0 R^{*}, \quad H = \theta_0 R_0 H^{*}, \quad H_0 = \theta_0 R_0 H_0^{*}, \quad V = \theta_0 R_0^{3} V^{*}, \\ c = c_{\infty}+(c_{sat}-c_{\infty})c^{*},\quad J = \frac{D(c_{sat}-c_{\infty})}{R_0}J^{*}\end{gathered} \right\} \end{align}

\begin{align} \left. \begin{gathered} r = R_0 r^{*}, \quad z = \theta_0 R_0 z^{*}, \quad h = \theta_0 R_0 h^{*}, \quad h_{m} = \theta_0 R_0 h_{m}^{*}, \quad t = \frac{\rho\theta_0 R_0^{2}}{D(c_{sat}-c_{\infty})}t^{*},\\ \theta = \theta_0 \theta^{*}, \quad R = R_0 R^{*}, \quad H = \theta_0 R_0 H^{*}, \quad H_0 = \theta_0 R_0 H_0^{*}, \quad V = \theta_0 R_0^{3} V^{*}, \\ c = c_{\infty}+(c_{sat}-c_{\infty})c^{*},\quad J = \frac{D(c_{sat}-c_{\infty})}{R_0}J^{*}\end{gathered} \right\} \end{align}

for the droplet, and similarly for the atmosphere except that ![]() $z = R_0 \hat {z}$. With the stars and the hat immediately dropped for clarity, (3.1a,b) and (3.2) give

$z = R_0 \hat {z}$. With the stars and the hat immediately dropped for clarity, (3.1a,b) and (3.2) give

Laplace's equation (3.3) is unchanged, and (3.4)–(3.9) become

respectively. The solution for the concentration ![]() $c$ may be written in the form (see, for example, Fabrikant Reference Fabrikant1995)

$c$ may be written in the form (see, for example, Fabrikant Reference Fabrikant1995)

which, using (3.15), leads to the solution for the local flux ![]() $J$, namely

$J$, namely

which exhibits the familiar (integrable) square-root singularity in J at the contact line ![]() $r = 1$ even when the free surface is below the plane

$r = 1$ even when the free surface is below the plane ![]() $z = 0$.

$z = 0$.

Substituting the expression for ![]() $V$ given by (3.11c) and the expression for

$V$ given by (3.11c) and the expression for ![]() $J$ given by (3.19) into (3.16) yields

$J$ given by (3.19) into (3.16) yields

and so the evolution of the droplet before touchdown is given by

The free surface is instantaneously flat (i.e. ![]() $\theta = 0$,

$\theta = 0$, ![]() $h_{m} = 0$ and

$h_{m} = 0$ and ![]() $V = V_{well}$) at some time

$V = V_{well}$) at some time ![]() $t = t_{flat}$ given by

$t = t_{flat}$ given by

As well as being of some interest in its own right, the occurrence of a flat free surface is relatively easy to observe experimentally.

When ![]() $0 < n < 2$ touchdown occurs when

$0 < n < 2$ touchdown occurs when ![]() $\theta = -H'(1) = -n H_0$, where a dash denotes differentiation with respect to argument, showing that

$\theta = -H'(1) = -n H_0$, where a dash denotes differentiation with respect to argument, showing that

at touchdown. As we have already seen, in the special case ![]() $n = 2$ touchdown occurs everywhere simultaneously within the well, and so

$n = 2$ touchdown occurs everywhere simultaneously within the well, and so ![]() $t_{lifetime} = t_{touchdown} = {\rm \pi}(1 + 2 H_0)/16$. When

$t_{lifetime} = t_{touchdown} = {\rm \pi}(1 + 2 H_0)/16$. When ![]() $n > 2$ touchdown occurs when

$n > 2$ touchdown occurs when ![]() $h_{m} = -H_0$, showing that

$h_{m} = -H_0$, showing that

at touchdown. Setting either ![]() $H_0 = 0$ or

$H_0 = 0$ or ![]() $n=0$ in (3.23a) or

$n=0$ in (3.23a) or ![]() $H_0=0$ in (3.24a) gives

$H_0=0$ in (3.24a) gives ![]() $t_{lifetime} = t_{touchdown} = t_{flat} = {\rm \pi}/16$, recovering the familiar expression for the lifetime of a pinned droplet on a planar substrate (see, for example, Stauber et al. Reference Stauber, Wilson, Duffy and Sefiane2014, Reference Stauber, Wilson, Duffy and Sefiane2015).

$t_{lifetime} = t_{touchdown} = t_{flat} = {\rm \pi}/16$, recovering the familiar expression for the lifetime of a pinned droplet on a planar substrate (see, for example, Stauber et al. Reference Stauber, Wilson, Duffy and Sefiane2014, Reference Stauber, Wilson, Duffy and Sefiane2015).

4. Evolution after touchdown, i.e. for  $t_{touchdown} < t \le t_{lifetime}$

$t_{touchdown} < t \le t_{lifetime}$

4.1. The case  $0 < n < 2$

$0 < n < 2$

When ![]() $0 < n < 2$ the free surface touches down at the lip of the well located at

$0 < n < 2$ the free surface touches down at the lip of the well located at ![]() $r = 1$,

$r = 1$, ![]() $z = 0$ at

$z = 0$ at ![]() $t = t_{touchdown}$, and after touchdown, i.e. for

$t = t_{touchdown}$, and after touchdown, i.e. for ![]() $t_{touchdown} < t \le t_{lifetime}$, the non-annular droplet has a receding circular contact line of radius

$t_{touchdown} < t \le t_{lifetime}$, the non-annular droplet has a receding circular contact line of radius ![]() $R=R(t)$ which satisfies

$R=R(t)$ which satisfies ![]() $R(t_{touchdown}) = 1$ and

$R(t_{touchdown}) = 1$ and ![]() $R(t_{lifetime}) = 0$. We must specify a condition in addition to

$R(t_{lifetime}) = 0$. We must specify a condition in addition to ![]() $h = H$ at the moving contact line. Since the (paraboloidal) free surface (3.21a) for

$h = H$ at the moving contact line. Since the (paraboloidal) free surface (3.21a) for ![]() $0 \le t \le t_{touchdown}$ touches down with zero contact angle at

$0 \le t \le t_{touchdown}$ touches down with zero contact angle at ![]() $r = 1$, we make the natural modelling assumption that the contact angle at the receding contact line remains at the value zero throughout the subsequent evolution. Thus we have the boundary conditions

$r = 1$, we make the natural modelling assumption that the contact angle at the receding contact line remains at the value zero throughout the subsequent evolution. Thus we have the boundary conditions

where again a dash denotes differentiation with respect to argument. The solution (2.3) for ![]() $h$ satisfying (4.1) with

$h$ satisfying (4.1) with ![]() $h$ finite at

$h$ finite at ![]() $r = 0$ takes the form

$r = 0$ takes the form

or, equivalently,

for ![]() $0 \le r \le R$, and

$0 \le r \le R$, and ![]() $V$ is given by

$V$ is given by

The (now quasi-static) concentration ![]() $c=c(r,z,t)$ of vapour in the atmosphere still satisfies Laplace's equation (3.3) and the boundary condition (3.12), but (3.13)–(3.17) must be replaced with

$c=c(r,z,t)$ of vapour in the atmosphere still satisfies Laplace's equation (3.3) and the boundary condition (3.12), but (3.13)–(3.17) must be replaced with

respectively, where ![]() $J=J(r,t)$ is again the local evaporative flux. In addition, we have

$J=J(r,t)$ is again the local evaporative flux. In addition, we have

As in § 3, for a thin droplet (4.5) and (4.7) are applied on ![]() $z=0$ rather than on

$z=0$ rather than on ![]() $z=h$, and similarly for a shallow well (4.6) for

$z=h$, and similarly for a shallow well (4.6) for ![]() $R < r \le 1$ is also applied on

$R < r \le 1$ is also applied on ![]() $z=0$ rather than on

$z=0$ rather than on ![]() $z=H$. The solution for the concentration

$z=H$. The solution for the concentration ![]() $c$ of the problem defined by (3.3), (3.12), (4.5) and (4.6) is analogous to (3.18) and is given by

$c$ of the problem defined by (3.3), (3.12), (4.5) and (4.6) is analogous to (3.18) and is given by

which, using (4.7), leads to the solution for the local flux ![]() $J$ analogous to (3.19), namely

$J$ analogous to (3.19), namely

Substituting (4.4) and (4.12) into (4.8) yields

leading to an explicit solution for ![]() $R$ after touchdown, namely

$R$ after touchdown, namely

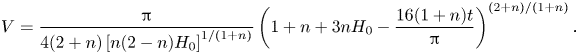

\begin{equation} R = \left[\frac{1}{n(2 - n)H_0}\left(1 + n + 3n H_0 - \frac{16(1 + n)t}{\rm \pi}\right)\right]^{1/(1 + n)}, \end{equation}

\begin{equation} R = \left[\frac{1}{n(2 - n)H_0}\left(1 + n + 3n H_0 - \frac{16(1 + n)t}{\rm \pi}\right)\right]^{1/(1 + n)}, \end{equation}

with ![]() $h$ given by (4.2) and

$h$ given by (4.2) and ![]() $V$ given by (4.4), i.e.

$V$ given by (4.4), i.e.

\begin{equation} V = \frac{\rm \pi}{4(2 + n)\left[n(2 - n)H_0\right]^{1/(1 + n)}} \left(1 + n + 3n H_0 - \frac{16(1 + n)t}{\rm \pi}\right)^{(2 + n)/(1 + n)}. \end{equation}

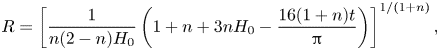

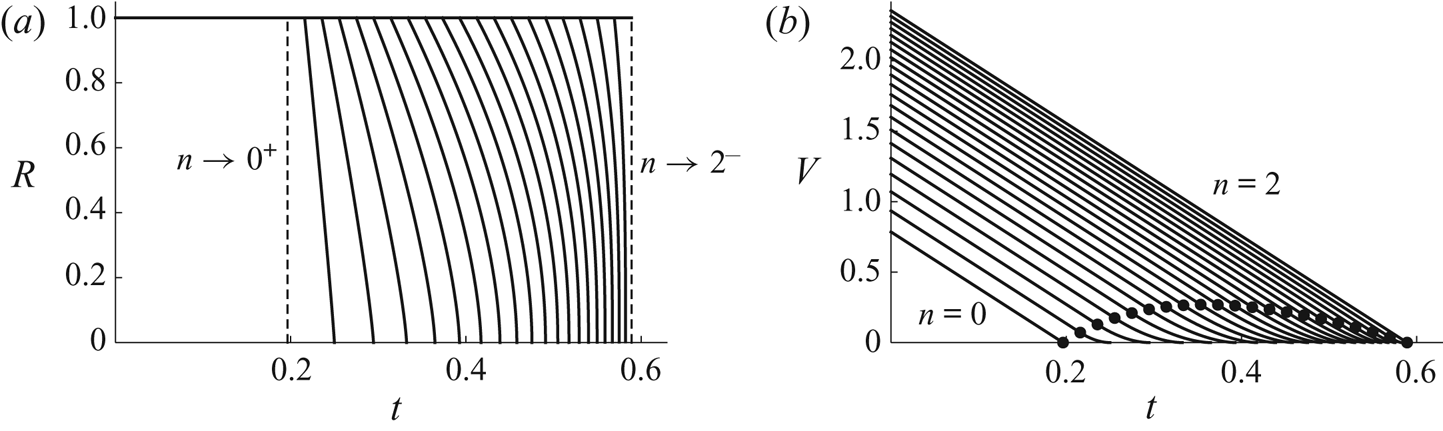

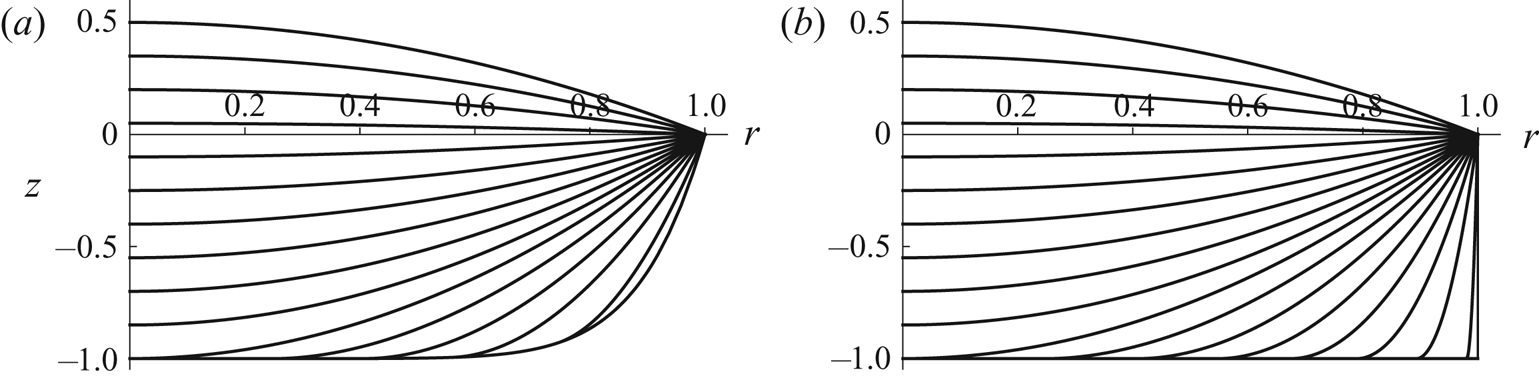

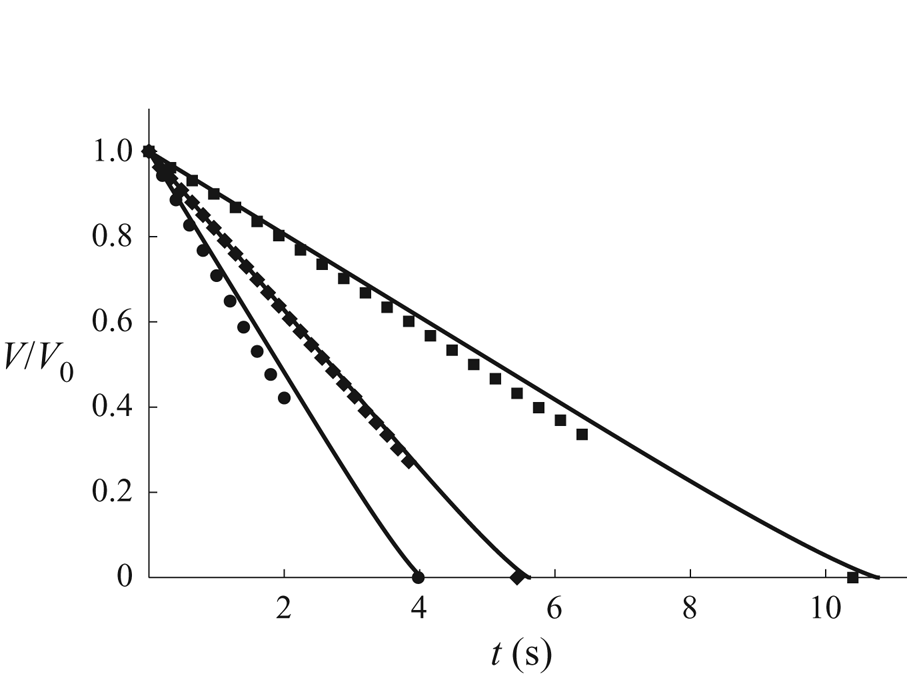

\begin{equation} V = \frac{\rm \pi}{4(2 + n)\left[n(2 - n)H_0\right]^{1/(1 + n)}} \left(1 + n + 3n H_0 - \frac{16(1 + n)t}{\rm \pi}\right)^{(2 + n)/(1 + n)}. \end{equation} Figure 2 shows the evolution of the free-surface profile ![]() $h$ for

$h$ for ![]() $n = 1$ and

$n = 1$ and ![]() $n = 2$ with

$n = 2$ with ![]() $H_0 = 1$. Figure 3 shows plots of

$H_0 = 1$. Figure 3 shows plots of ![]() $R$ and

$R$ and ![]() $V$ as functions of

$V$ as functions of ![]() $t$ for a range of values of

$t$ for a range of values of ![]() $n$, again with

$n$, again with ![]() $H_0 = 1$. Note that

$H_0 = 1$. Note that ![]() $\textrm {d} R/\textrm {d} t \to \infty$ and (although not very easy to see in figure 3b)

$\textrm {d} R/\textrm {d} t \to \infty$ and (although not very easy to see in figure 3b) ![]() $\textrm {d} V/\textrm {d} t \to 0^{+}$ in the limit

$\textrm {d} V/\textrm {d} t \to 0^{+}$ in the limit ![]() $t \to t_{lifetime}^{-}$.

$t \to t_{lifetime}^{-}$.

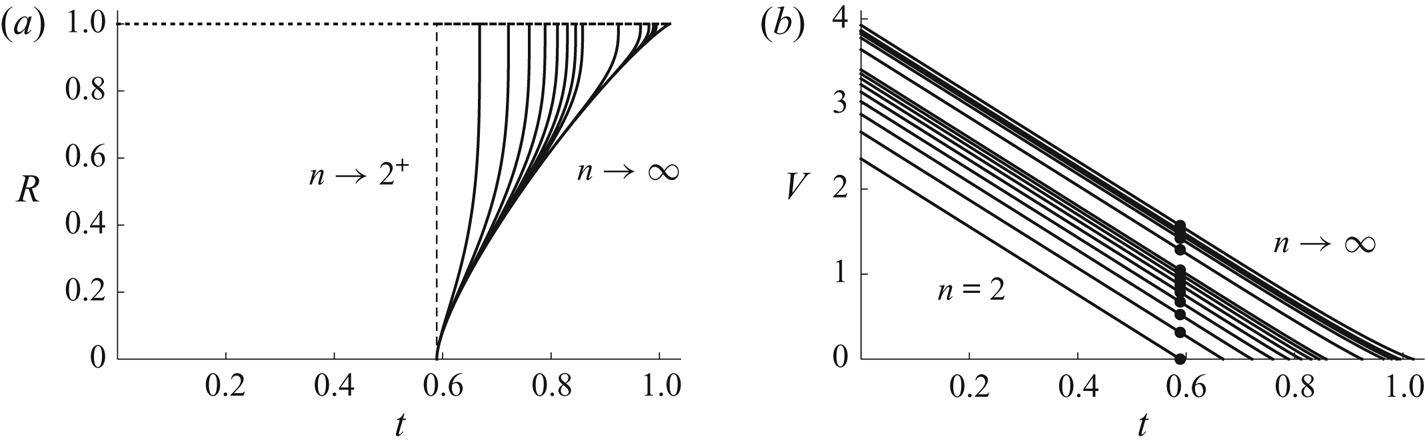

Figure 2. Evolution of the free-surface profile ![]() $h$ given by (3.21a) for

$h$ given by (3.21a) for ![]() $0 \le t \le t_{touchdown}$ and by (4.2) for

$0 \le t \le t_{touchdown}$ and by (4.2) for ![]() $t_{touchdown} < t \le t_{lifetime}$ for (a) a conical well with

$t_{touchdown} < t \le t_{lifetime}$ for (a) a conical well with ![]() $n = 1$ and

$n = 1$ and ![]() $H_0 = 1$, and (b) a paraboloidal well with

$H_0 = 1$, and (b) a paraboloidal well with ![]() $n = 2$ and

$n = 2$ and ![]() $H_0 = 1$. In (a) the curves are drawn at intervals of

$H_0 = 1$. In (a) the curves are drawn at intervals of ![]() $t_{touchdown}/16 = {\rm \pi}/128 \simeq 0.0245$, and the lifetime is

$t_{touchdown}/16 = {\rm \pi}/128 \simeq 0.0245$, and the lifetime is ![]() $t_{lifetime} = 5{\rm \pi} /32 \simeq 0.4909$, while in (b) the curves are drawn at intervals of

$t_{lifetime} = 5{\rm \pi} /32 \simeq 0.4909$, while in (b) the curves are drawn at intervals of ![]() $t_{touchdown}/15 = {\rm \pi}/80 \simeq 0.0393$, and the lifetime is

$t_{touchdown}/15 = {\rm \pi}/80 \simeq 0.0393$, and the lifetime is ![]() $t_{lifetime} = t_{touchdown} = 3{\rm \pi} /16 \simeq 0.5890$.

$t_{lifetime} = t_{touchdown} = 3{\rm \pi} /16 \simeq 0.5890$.

Figure 3. Plots of (a) the radius ![]() $R$ of the receding contact line given by (4.14), and (b) the volume

$R$ of the receding contact line given by (4.14), and (b) the volume ![]() $V$ of the droplet given by (3.21d) for

$V$ of the droplet given by (3.21d) for ![]() $0 \le t \le t_{touchdown}$ and by (4.15) for

$0 \le t \le t_{touchdown}$ and by (4.15) for ![]() $t_{touchdown} < t \le t_{lifetime}$ as functions of

$t_{touchdown} < t \le t_{lifetime}$ as functions of ![]() $t$ for

$t$ for ![]() $n = 0$,

$n = 0$, ![]() $1/10$,

$1/10$, ![]() $1/5$, …,

$1/5$, …, ![]() $2$ in the case

$2$ in the case ![]() $H_0 = 1$. The vertical dashed lines in (a) correspond to the limits

$H_0 = 1$. The vertical dashed lines in (a) correspond to the limits ![]() $n \to 0^{+}$ and

$n \to 0^{+}$ and ![]() $n \to 2^{-}$, and the dots in (b) correspond to touchdown (at the lip of the well) at

$n \to 2^{-}$, and the dots in (b) correspond to touchdown (at the lip of the well) at ![]() $t = t_{touchdown} = {\rm \pi}(1 + nH_0)/16$.

$t = t_{touchdown} = {\rm \pi}(1 + nH_0)/16$.

The lifetime of the droplet, ![]() $t_{lifetime}$, which corresponds to

$t_{lifetime}$, which corresponds to ![]() $R = 0$ and

$R = 0$ and ![]() $V=0$, is given by

$V=0$, is given by

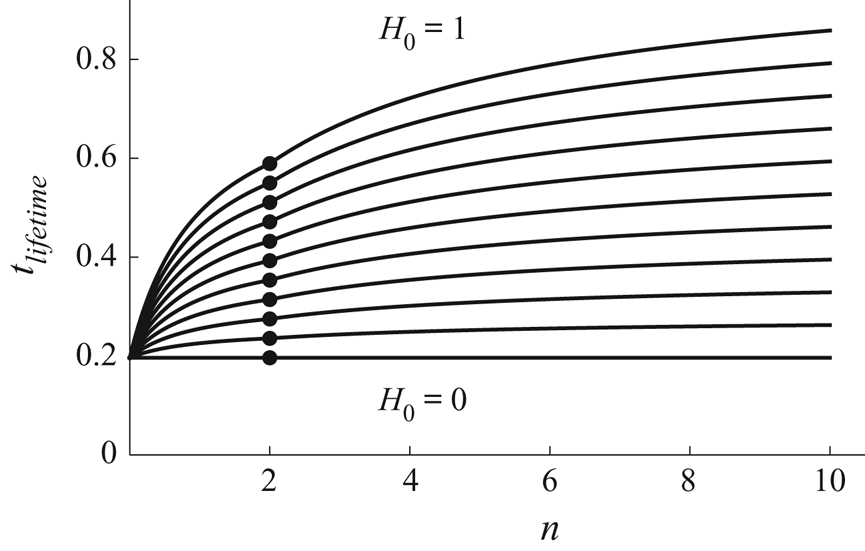

which is linear in ![]() $H_0$. Figure 4 includes a plot of

$H_0$. Figure 4 includes a plot of ![]() $t_{lifetime}$ given by (4.16) as a function of

$t_{lifetime}$ given by (4.16) as a function of ![]() $n$ for

$n$ for ![]() $0 \le n \le 2$ (i.e. to the left of the dots) for a range of values of

$0 \le n \le 2$ (i.e. to the left of the dots) for a range of values of ![]() $H_0$. For a given value of

$H_0$. For a given value of ![]() $H_0$, the shortest lifetime is

$H_0$, the shortest lifetime is ![]() ${\rm \pi} /16$, corresponding to

${\rm \pi} /16$, corresponding to ![]() $n = 0$, and the longest lifetime is

$n = 0$, and the longest lifetime is ![]() ${\rm \pi} (1 + 2H_0)/16$, corresponding to

${\rm \pi} (1 + 2H_0)/16$, corresponding to ![]() $n = 2$; also the longest life after touchdown (i.e. the largest value of

$n = 2$; also the longest life after touchdown (i.e. the largest value of ![]() $t_{lifetime} - t_{touchdown}$) is

$t_{lifetime} - t_{touchdown}$) is ![]() $(2 - \sqrt {3}){\rm \pi} H_0/8 \simeq 0.1052 H_0$, corresponding to a well with

$(2 - \sqrt {3}){\rm \pi} H_0/8 \simeq 0.1052 H_0$, corresponding to a well with ![]() $n = \sqrt {3} - 1 \simeq 0.7321$.

$n = \sqrt {3} - 1 \simeq 0.7321$.

Figure 4. Plot of the lifetime of the droplet, ![]() $t_{lifetime}$, given by (4.16) for

$t_{lifetime}$, given by (4.16) for ![]() $0 \le n \le 2$ and by (4.28) for

$0 \le n \le 2$ and by (4.28) for ![]() $n > 2$, as a function of

$n > 2$, as a function of ![]() $n$ for

$n$ for ![]() $H_0 = 0$,

$H_0 = 0$, ![]() $1/10$,

$1/10$, ![]() $1/5$, …,

$1/5$, …, ![]() $1$. The dots denote the values

$1$. The dots denote the values ![]() $t_{lifetime} = t_{touchdown} = {\rm \pi}(1 + 2 H_0)/16$ for

$t_{lifetime} = t_{touchdown} = {\rm \pi}(1 + 2 H_0)/16$ for ![]() $n=2$. The curves approach the asymptotic values

$n=2$. The curves approach the asymptotic values ![]() $t_{lifetime} = {\rm \pi}[1 + 2(1 + 8\alpha _{\infty })H_0]/16 \simeq 0.1963 + 0.8228H_0$ in the limit

$t_{lifetime} = {\rm \pi}[1 + 2(1 + 8\alpha _{\infty })H_0]/16 \simeq 0.1963 + 0.8228H_0$ in the limit ![]() $n \to \infty$.

$n \to \infty$.

4.2. The case  $n > 2$

$n > 2$

When ![]() $n > 2$ the free surface touches down at the centre of the well located at

$n > 2$ the free surface touches down at the centre of the well located at ![]() $r = 0$,

$r = 0$, ![]() $z = -H_0$ at

$z = -H_0$ at ![]() $t = t_{touchdown}$, and after touchdown, i.e. for

$t = t_{touchdown}$, and after touchdown, i.e. for ![]() $t_{touchdown} < t \le t_{lifetime}$, the annular droplet has a pinned circular outer contact line

$t_{touchdown} < t \le t_{lifetime}$, the annular droplet has a pinned circular outer contact line ![]() $r=1$ and a receding circular inner contact line of radius

$r=1$ and a receding circular inner contact line of radius ![]() $R=R(t)$ which satisfies

$R=R(t)$ which satisfies ![]() $R(t_{touchdown}) = 0$ and

$R(t_{touchdown}) = 0$ and ![]() $R(t_{lifetime}) = 1$. We must again specify a condition in addition to

$R(t_{lifetime}) = 1$. We must again specify a condition in addition to ![]() $h = H$ at the moving contact line. Since the (paraboloidal) free surface (3.21a) for

$h = H$ at the moving contact line. Since the (paraboloidal) free surface (3.21a) for ![]() $0 \le t \le t_{touchdown}$ touches down with zero contact angle at

$0 \le t \le t_{touchdown}$ touches down with zero contact angle at ![]() $r = 0$, we again make the natural modelling assumption that the contact angle at the receding contact line remains at the value zero throughout the subsequent evolution, and so the boundary conditions (4.1) again hold. The solution (2.3) for

$r = 0$, we again make the natural modelling assumption that the contact angle at the receding contact line remains at the value zero throughout the subsequent evolution, and so the boundary conditions (4.1) again hold. The solution (2.3) for ![]() $h$ satisfying (4.1) and

$h$ satisfying (4.1) and ![]() $h=0$ at

$h=0$ at ![]() $r=1$ takes the form

$r=1$ takes the form

for ![]() $R \le r \le 1$, and

$R \le r \le 1$, and ![]() $V$ is given by

$V$ is given by

where we have defined the function ![]() $f = f(R)$ by

$f = f(R)$ by

\begin{equation} f = \frac{n \left[4 -(n + 2)R^{n - 2} + (n - 2)R^{n + 2}\right]}{4(n + 2)} - \frac{\left(1 - R^{2}\right)^{2} \left[(n - 2)R^{n} - n R^{n - 2} + 2\right]}{4 \left(1 - R^{2} + 2 R^{2} \log R\right)}. \end{equation}

\begin{equation} f = \frac{n \left[4 -(n + 2)R^{n - 2} + (n - 2)R^{n + 2}\right]}{4(n + 2)} - \frac{\left(1 - R^{2}\right)^{2} \left[(n - 2)R^{n} - n R^{n - 2} + 2\right]}{4 \left(1 - R^{2} + 2 R^{2} \log R\right)}. \end{equation}

It is useful to note that ![]() $f \to (n - 2)/[2(n + 2)]$ in the limit

$f \to (n - 2)/[2(n + 2)]$ in the limit ![]() $R \to 0^{+}$ (in agreement with the expression for

$R \to 0^{+}$ (in agreement with the expression for ![]() $V$ at touchdown given by (3.24c)), and that

$V$ at touchdown given by (3.24c)), and that ![]() $f \sim n^{2}(n - 2)(1 - R)^{4}/36 \to 0^{+}$ in the limit

$f \sim n^{2}(n - 2)(1 - R)^{4}/36 \to 0^{+}$ in the limit ![]() $R \to 1^{-}$.

$R \to 1^{-}$.

The (again quasi-static) concentration ![]() $c=c(r,z,t)$ of vapour in the atmosphere still satisfies Laplace's equation (3.3) and the boundary condition (3.12), but in this case (3.13)–(3.17) must be replaced with

$c=c(r,z,t)$ of vapour in the atmosphere still satisfies Laplace's equation (3.3) and the boundary condition (3.12), but in this case (3.13)–(3.17) must be replaced with

respectively, where ![]() $J=J(r,t)$ is again the local evaporative flux, and

$J=J(r,t)$ is again the local evaporative flux, and ![]() $F=F(R)$ (which depends on

$F=F(R)$ (which depends on ![]() $t$ via its dependence on

$t$ via its dependence on ![]() $R=R(t)$) is the total evaporative flux from the droplet. In addition, we have

$R=R(t)$) is the total evaporative flux from the droplet. In addition, we have

As in § 4.1, (4.20), (4.22) and (4.21) for ![]() $0 \le r < R$ are applied on

$0 \le r < R$ are applied on ![]() $z = 0$.

$z = 0$.

Perhaps surprisingly, no simple closed-form solution of the problem for ![]() $c$ defined by (3.3), (3.12), (4.20) and (4.21) is available (see § 10.1.1 of Popov, Hess & Willert Reference Popov, Heß and Willert2019 for an overview of previous work on this problem in the context of contact mechanics). The problem was reformulated as equivalent integral equations by, for example, Cooke (Reference Cooke1963), Williams (Reference Williams1963) and Fabrikant (Reference Fabrikant1993), and the last-mentioned also gave an iteration-based infinite-series solution to their formulation. Since our primary concern is with the total flux

$c$ defined by (3.3), (3.12), (4.20) and (4.21) is available (see § 10.1.1 of Popov, Hess & Willert Reference Popov, Heß and Willert2019 for an overview of previous work on this problem in the context of contact mechanics). The problem was reformulated as equivalent integral equations by, for example, Cooke (Reference Cooke1963), Williams (Reference Williams1963) and Fabrikant (Reference Fabrikant1993), and the last-mentioned also gave an iteration-based infinite-series solution to their formulation. Since our primary concern is with the total flux ![]() $F$, we obtained this numerically in two independent ways, namely by solving the integral equation of Cooke (Reference Cooke1963) by means of Chebyshev–Gauss quadrature with typically 200 nodes, and by solving Laplace's equation for

$F$, we obtained this numerically in two independent ways, namely by solving the integral equation of Cooke (Reference Cooke1963) by means of Chebyshev–Gauss quadrature with typically 200 nodes, and by solving Laplace's equation for ![]() $c$ using the finite-element package COMSOL Multiphysics 5.3a (COMSOL Inc.), from which

$c$ using the finite-element package COMSOL Multiphysics 5.3a (COMSOL Inc.), from which ![]() $J$ and hence

$J$ and hence ![]() $F$ were obtained; the values of

$F$ were obtained; the values of ![]() $F$ obtained using these two different approaches were found to be in good agreement.

$F$ obtained using these two different approaches were found to be in good agreement.

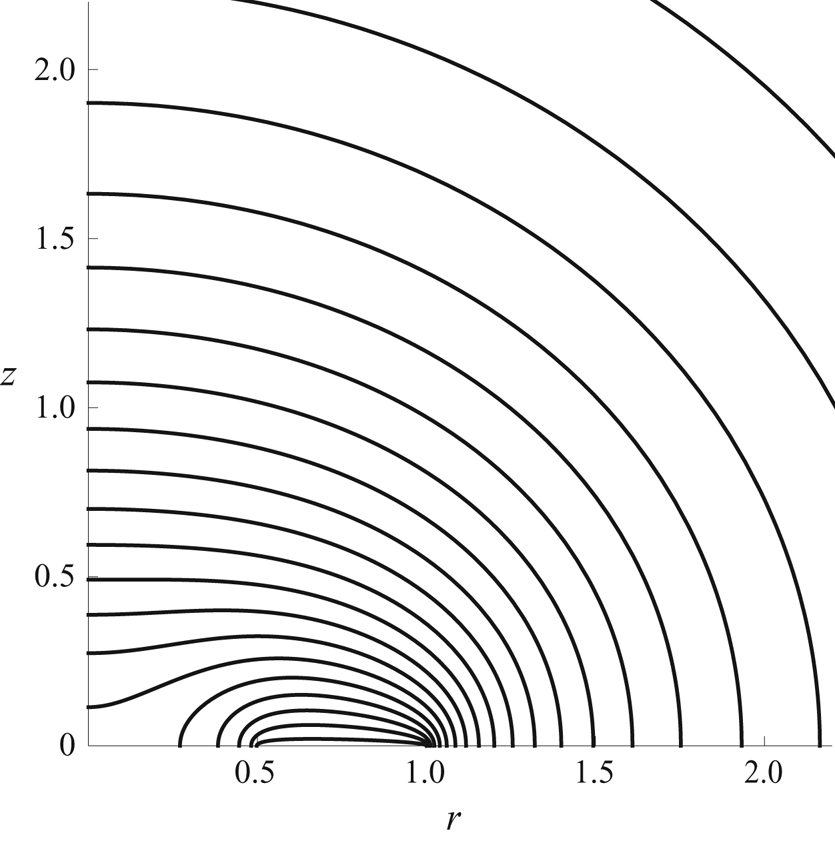

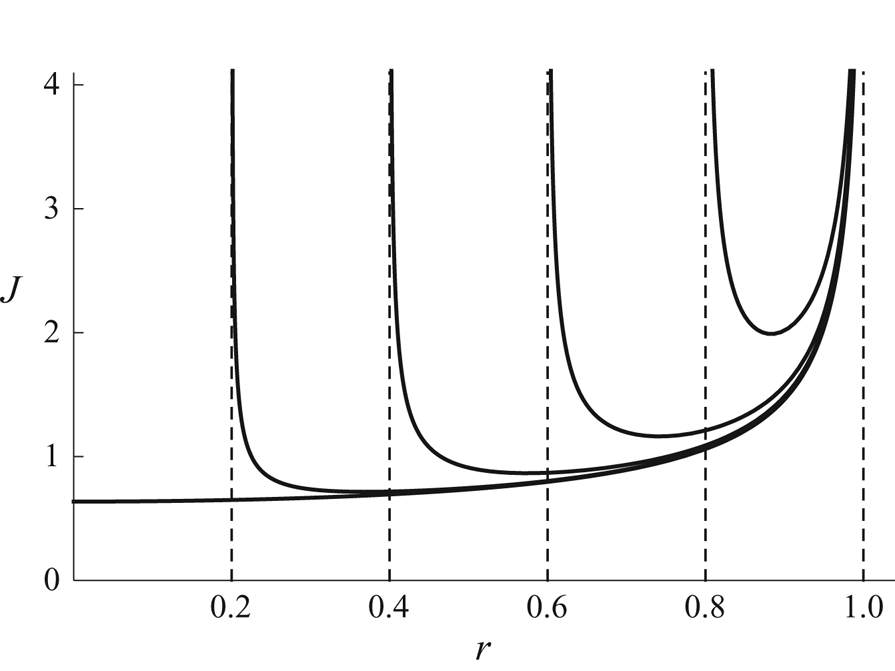

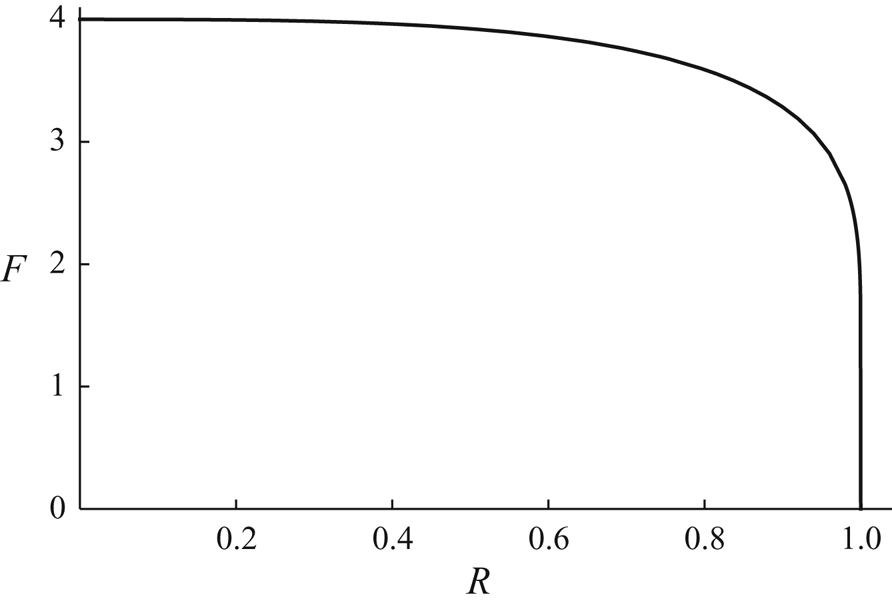

Figure 5 shows an example of contours of ![]() $c$ in the

$c$ in the ![]() $r$–

$r$–![]() $z$ plane for an annular droplet obtained using COMSOL Multiphysics, figure 6 shows a plot of the local flux

$z$ plane for an annular droplet obtained using COMSOL Multiphysics, figure 6 shows a plot of the local flux ![]() $J$ from an annular droplet as a function of

$J$ from an annular droplet as a function of ![]() $r$ (

$r$ (![]() $R \le r \le 1$) for a range of values of

$R \le r \le 1$) for a range of values of ![]() $R$, as well as that from a non-annular droplet given by (3.19), and figure 7 shows the total flux

$R$, as well as that from a non-annular droplet given by (3.19), and figure 7 shows the total flux ![]() $F$ from an annular droplet as a function of

$F$ from an annular droplet as a function of ![]() $R$ (

$R$ (![]() $0 \le R \le 1$). Intriguingly, as figure 6 shows, the local flux

$0 \le R \le 1$). Intriguingly, as figure 6 shows, the local flux ![]() $J$ from a non-annular droplet is smaller than that from an annular droplet with the same outer radius, though, of course, the former is effective over a larger area than the latter (i.e. over

$J$ from a non-annular droplet is smaller than that from an annular droplet with the same outer radius, though, of course, the former is effective over a larger area than the latter (i.e. over ![]() $0 \le r \le 1$ rather than

$0 \le r \le 1$ rather than ![]() $R \le r \le 1$), and so leads to a larger value of the total flux

$R \le r \le 1$), and so leads to a larger value of the total flux ![]() $F$. Figure 6 also shows that

$F$. Figure 6 also shows that ![]() $J \to \infty$ as

$J \to \infty$ as ![]() $r \to R^{+}$ and

$r \to R^{+}$ and ![]() $r \to 1^{-}$, and a local analysis shows that

$r \to 1^{-}$, and a local analysis shows that ![]() $J$ has square-root singularities at both contact lines (i.e. the same singularity as a non-annular droplet). This is true even in the limit

$J$ has square-root singularities at both contact lines (i.e. the same singularity as a non-annular droplet). This is true even in the limit ![]() $R \to 0^{+}$, showing that the local flux

$R \to 0^{+}$, showing that the local flux ![]() $J$ due to an annular droplet with a vanishingly small hole at its centre is different from that due to a non-annular droplet (for which

$J$ due to an annular droplet with a vanishingly small hole at its centre is different from that due to a non-annular droplet (for which ![]() $J$ is well behaved at

$J$ is well behaved at ![]() $r = 0$); the difference is, however, confined to a small region near to

$r = 0$); the difference is, however, confined to a small region near to ![]() $r = R \to 0^{+}$ whose contribution to the total flux

$r = R \to 0^{+}$ whose contribution to the total flux ![]() $F$ is small, leading to

$F$ is small, leading to ![]() $F \to 4^{-}$ as

$F \to 4^{-}$ as ![]() $R \to 0^{+}$, in agreement with the value

$R \to 0^{+}$, in agreement with the value ![]() $F = 4$ in the case of a non-annular droplet which appears in (3.20). Note that, as figure 6 shows,

$F = 4$ in the case of a non-annular droplet which appears in (3.20). Note that, as figure 6 shows, ![]() $J$ is asymmetric about the midpoint

$J$ is asymmetric about the midpoint ![]() $(R + 1)/2$ between the contact lines, and, as figure 7 shows,

$(R + 1)/2$ between the contact lines, and, as figure 7 shows, ![]() $F \to 0^{+}$ as

$F \to 0^{+}$ as ![]() $R \to 1^{-}$, i.e. as the width of the annulus approaches zero.

$R \to 1^{-}$, i.e. as the width of the annulus approaches zero.

Figure 5. Plot of contours of the concentration ![]() $c$ in the

$c$ in the ![]() $r$–

$r$–![]() $z$ plane for an annular droplet in the case

$z$ plane for an annular droplet in the case ![]() $R = 1/2$. The contours are drawn at intervals of

$R = 1/2$. The contours are drawn at intervals of ![]() $0.04$.

$0.04$.

Figure 6. Plot of the local flux ![]() $J$ from an annular droplet as a function of

$J$ from an annular droplet as a function of ![]() $r$ (

$r$ (![]() $R \le r \le 1$) in the cases

$R \le r \le 1$) in the cases ![]() $R = 0.2$,

$R = 0.2$, ![]() $0.4$,

$0.4$, ![]() $0.6$ and

$0.6$ and ![]() $0.8$, as well as that from a non-annular droplet given by (3.19).

$0.8$, as well as that from a non-annular droplet given by (3.19).

Figure 7. Plot of the total flux ![]() $F$ from an annular droplet as a function of

$F$ from an annular droplet as a function of ![]() $R$ (

$R$ (![]() $0 \le R \le 1$).

$0 \le R \le 1$).

As figure 7 shows, the total flux ![]() $F$ is nearly independent of

$F$ is nearly independent of ![]() $R$ until

$R$ until ![]() $R$ gets close to 1, showing that the increase of the perimeter

$R$ gets close to 1, showing that the increase of the perimeter ![]() $2{\rm \pi} R$ of the receding inner contact line (where

$2{\rm \pi} R$ of the receding inner contact line (where ![]() $J$ is singular), which tends to increase the total flux, almost compensates for the decrease of the surface area

$J$ is singular), which tends to increase the total flux, almost compensates for the decrease of the surface area ![]() ${\rm \pi} (1 - R^{2})$ of the annular droplet, which tends to decrease the total flux, for most of the lifetime of the droplet. It is only near to the complete evaporation of the droplet, i.e. when

${\rm \pi} (1 - R^{2})$ of the annular droplet, which tends to decrease the total flux, for most of the lifetime of the droplet. It is only near to the complete evaporation of the droplet, i.e. when ![]() $R$ gets close to 1, that

$R$ gets close to 1, that ![]() $F$ rapidly decreases to zero.

$F$ rapidly decreases to zero.

With the total flux ![]() $F$ now known, (4.18) and (4.23) give

$F$ now known, (4.18) and (4.23) give

where again a dash denotes differentiation with respect to argument, leading to an implicit solution for ![]() $R$ after touchdown, namely

$R$ after touchdown, namely

\begin{equation} t = t_{touchdown} - {\rm \pi}H_0\int_0^{R} \frac{f'(\hat{R})}{F(\hat{R})} \, \textrm{d} \hat{R}, \end{equation}

\begin{equation} t = t_{touchdown} - {\rm \pi}H_0\int_0^{R} \frac{f'(\hat{R})}{F(\hat{R})} \, \textrm{d} \hat{R}, \end{equation}

with ![]() $h$ given by (4.17) and

$h$ given by (4.17) and ![]() $V$ given by (4.18).

$V$ given by (4.18).

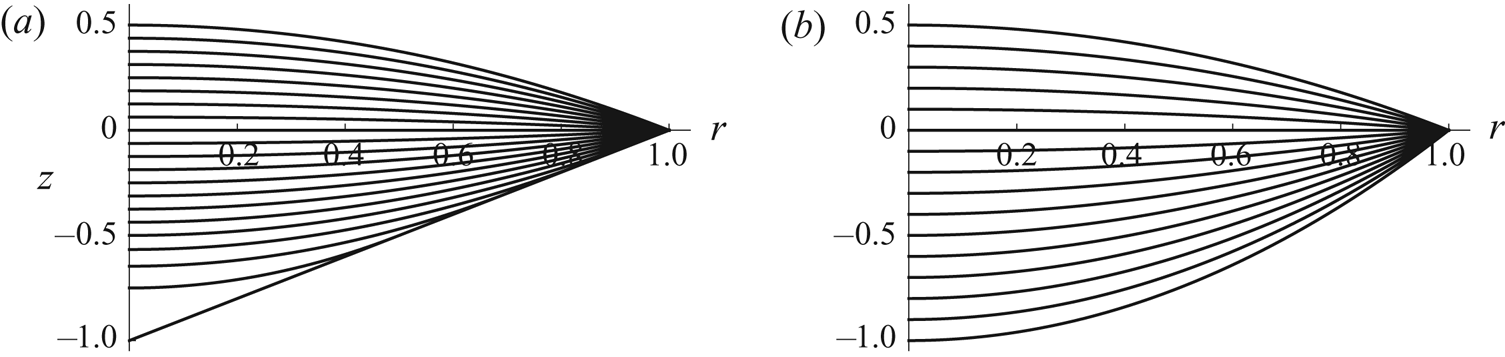

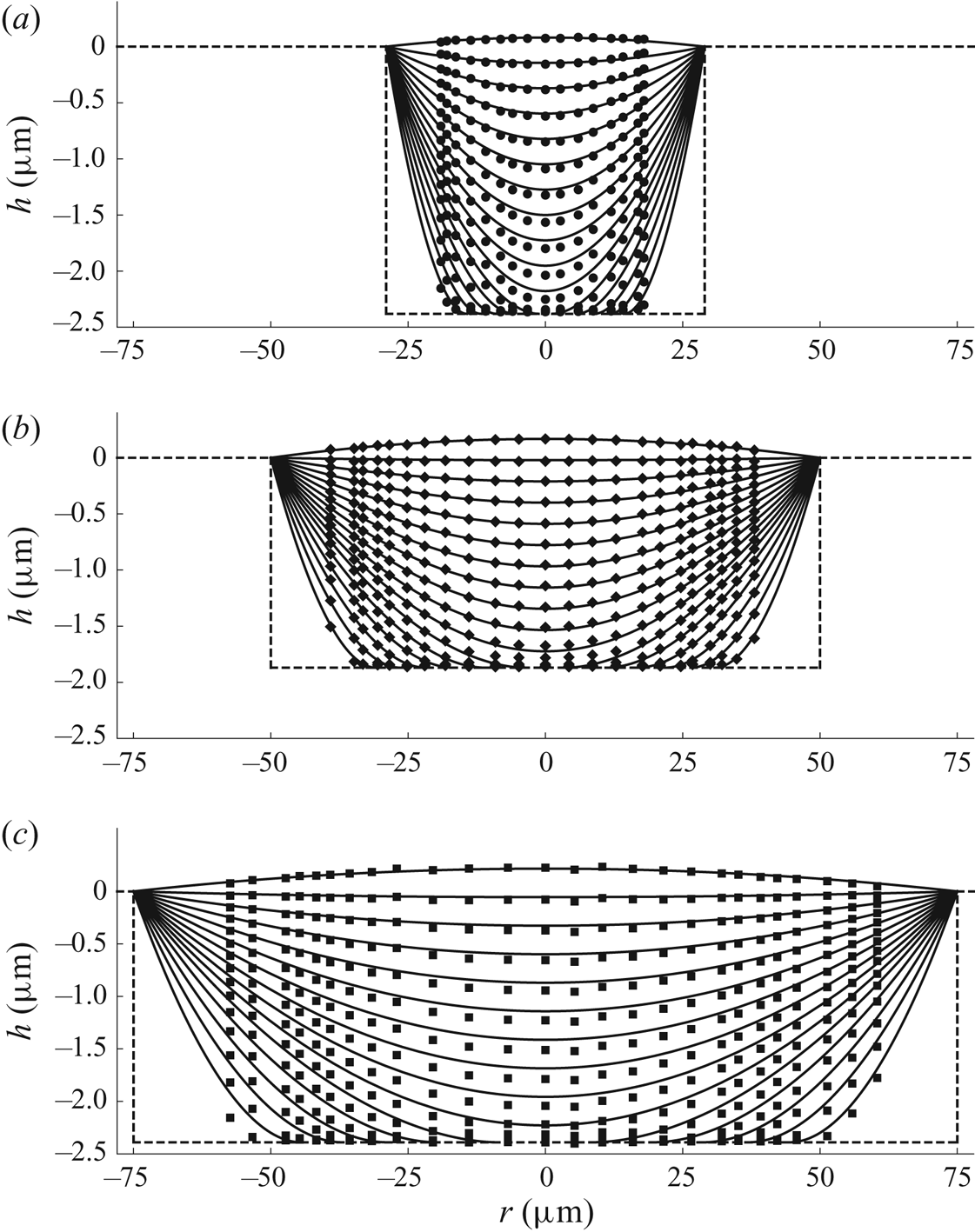

Figure 8(a) shows the evolution of the free-surface profile ![]() $h$ for

$h$ for ![]() $n=9$ with

$n=9$ with ![]() $H_0=1$. Figure 9 shows plots of

$H_0=1$. Figure 9 shows plots of ![]() $R$ and

$R$ and ![]() $V$ as functions of

$V$ as functions of ![]() $t$ for a range of values of

$t$ for a range of values of ![]() $n$, again with

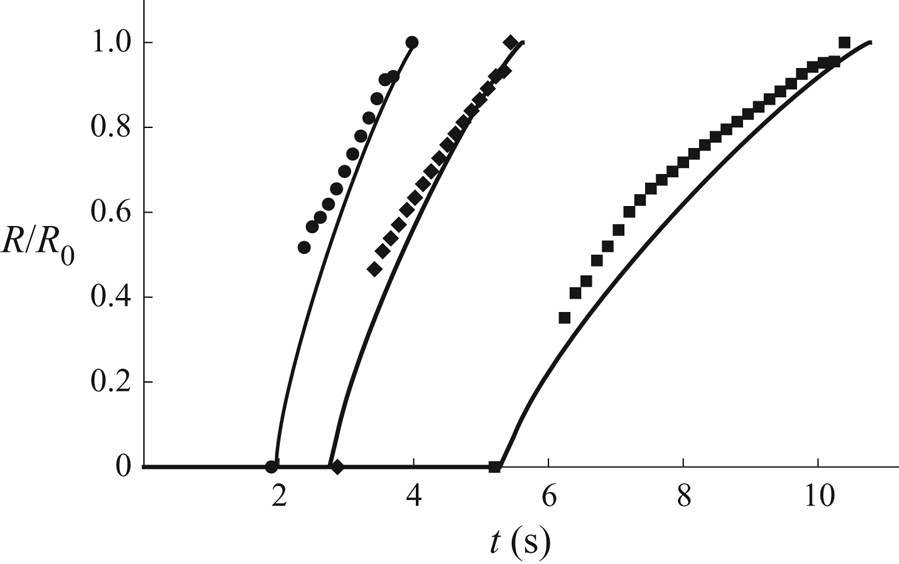

$n$, again with ![]() $H_0 = 1$. The nearly linear dependence of

$H_0 = 1$. The nearly linear dependence of ![]() $V$ on

$V$ on ![]() $t$ for

$t$ for ![]() $t_{touchdown} < t \le t_{lifetime}$ evident in figure 9(b) is a consequence of the fact that the total flux

$t_{touchdown} < t \le t_{lifetime}$ evident in figure 9(b) is a consequence of the fact that the total flux ![]() $F$ is nearly independent of

$F$ is nearly independent of ![]() $R$ until

$R$ until ![]() $R$ gets close to 1 discussed above. Note that

$R$ gets close to 1 discussed above. Note that ![]() $\textrm {d} R/\textrm {d} t \to \infty$ and (although impossible to see in figure 9b)

$\textrm {d} R/\textrm {d} t \to \infty$ and (although impossible to see in figure 9b) ![]() $\textrm {d} V/\textrm {d} t \to 0^{+}$ in the limit

$\textrm {d} V/\textrm {d} t \to 0^{+}$ in the limit ![]() $t \to t_{lifetime}^{-}$ (i.e. the same behaviour as when

$t \to t_{lifetime}^{-}$ (i.e. the same behaviour as when ![]() $0 < n < 2$).

$0 < n < 2$).

Figure 8. Evolution of the free-surface profile ![]() $h$ given by (3.21a) for

$h$ given by (3.21a) for ![]() $0 \le t \le t_{touchdown}$ and by (4.17) for

$0 \le t \le t_{touchdown}$ and by (4.17) for ![]() $t_{touchdown} < t \le t_{lifetime}$ for (a) a well with

$t_{touchdown} < t \le t_{lifetime}$ for (a) a well with ![]() $n = 9$ and

$n = 9$ and ![]() $H_0 = 1$, and (b) a cylindrical well (i.e. in the limit

$H_0 = 1$, and (b) a cylindrical well (i.e. in the limit ![]() $n \to \infty$) with

$n \to \infty$) with ![]() $H_0 = 1$. In (a) the curves are drawn at intervals of

$H_0 = 1$. In (a) the curves are drawn at intervals of ![]() $t_{touchdown}/10 \simeq 0.0589$, and the lifetime is

$t_{touchdown}/10 \simeq 0.0589$, and the lifetime is ![]() $t_{lifetime} \simeq 0.8454$, while in (b) the curves are drawn at intervals of

$t_{lifetime} \simeq 0.8454$, while in (b) the curves are drawn at intervals of ![]() $t_{touchdown}/10 \simeq 0.0589$, and the lifetime is

$t_{touchdown}/10 \simeq 0.0589$, and the lifetime is ![]() $t_{lifetime} \simeq 1.0193$.

$t_{lifetime} \simeq 1.0193$.

Figure 9. Plots of (a) the radius ![]() $R$ of the receding inner contact line given by (4.27), and (b) the volume

$R$ of the receding inner contact line given by (4.27), and (b) the volume ![]() $V$ of the droplet given by (3.21d) for

$V$ of the droplet given by (3.21d) for ![]() $0 \le t \le t_{touchdown}$ and by (4.18) for

$0 \le t \le t_{touchdown}$ and by (4.18) for ![]() $t_{touchdown} < t \le t_{lifetime}$ as functions of

$t_{touchdown} < t \le t_{lifetime}$ as functions of ![]() $t$ for

$t$ for ![]() $n = 2$,

$n = 2$, ![]() $3$,

$3$, ![]() $4$, …,

$4$, …, ![]() $10$,

$10$, ![]() $20$,

$20$, ![]() $40$,

$40$, ![]() $60$,

$60$, ![]() $80$ and

$80$ and ![]() $100$, and in the limit

$100$, and in the limit ![]() $n \to \infty$, in the case

$n \to \infty$, in the case ![]() $H_0 = 1$. The vertical dashed line in (a) corresponds to the limit

$H_0 = 1$. The vertical dashed line in (a) corresponds to the limit ![]() $n \to 2^{+}$, and the dots in (b) correspond to touchdown (at the centre of the well) at

$n \to 2^{+}$, and the dots in (b) correspond to touchdown (at the centre of the well) at ![]() $t = t_{touchdown} = {\rm \pi}(1 + 2H_0)/16 \simeq 0.5890$.

$t = t_{touchdown} = {\rm \pi}(1 + 2H_0)/16 \simeq 0.5890$.

The lifetime of the droplet, which corresponds to ![]() $R = 1$ and

$R = 1$ and ![]() $V=0$, is given by

$V=0$, is given by

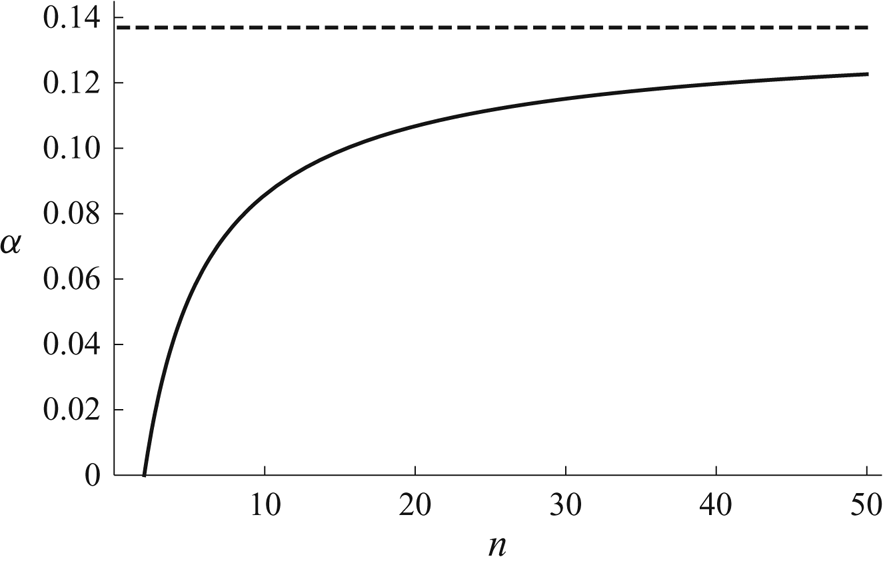

where the function ![]() $\alpha = \alpha (n) \, (\ge 0)$ is given by

$\alpha = \alpha (n) \, (\ge 0)$ is given by

which varies monotonically from ![]() $\alpha = 0$ when

$\alpha = 0$ when ![]() $n = 2$ to

$n = 2$ to ![]() $\alpha = \alpha _{\infty } \simeq 0.1369$ in the limit

$\alpha = \alpha _{\infty } \simeq 0.1369$ in the limit ![]() $n \to \infty$. Note that, like the corresponding expression for

$n \to \infty$. Note that, like the corresponding expression for ![]() $0 < n < 2$ given by (4.16),

$0 < n < 2$ given by (4.16), ![]() $t_{lifetime}$ given by (4.28) is linear in

$t_{lifetime}$ given by (4.28) is linear in ![]() $H_0$. Figure 10 shows a plot of

$H_0$. Figure 10 shows a plot of ![]() $\alpha$ as a function of

$\alpha$ as a function of ![]() $n$ for

$n$ for ![]() $n \ge 2$, and figure 4 includes a plot of

$n \ge 2$, and figure 4 includes a plot of ![]() $t_{lifetime}$ given by (4.28) as a function of

$t_{lifetime}$ given by (4.28) as a function of ![]() $n$ for

$n$ for ![]() $n > 2$ (i.e. to the right of the dots) for a range of values of

$n > 2$ (i.e. to the right of the dots) for a range of values of ![]() $H_0$.

$H_0$.

Figure 10. Plot of ![]() $\alpha$ given by (4.29) as a function of

$\alpha$ given by (4.29) as a function of ![]() $n$ for

$n$ for ![]() $n \ge 2$. The dashed line shows the asymptotic value

$n \ge 2$. The dashed line shows the asymptotic value ![]() $\alpha = \alpha _{\infty } \simeq 0.1369$ in the limit

$\alpha = \alpha _{\infty } \simeq 0.1369$ in the limit ![]() $n \to \infty$.

$n \to \infty$.

4.3. The limit  $n \to \infty$

$n \to \infty$

In the limit ![]() $n \to \infty$, corresponding to a cylindrical well with vertical side

$n \to \infty$, corresponding to a cylindrical well with vertical side ![]() $r=1$ and flat bottom

$r=1$ and flat bottom ![]() $z=-H_0$, after touchdown the annular droplet again has a pinned circular outer contact line

$z=-H_0$, after touchdown the annular droplet again has a pinned circular outer contact line ![]() $r=1$ and a receding circular inner contact line

$r=1$ and a receding circular inner contact line ![]() $r=R$. The solution for

$r=R$. The solution for ![]() $h$ given by (4.17) reduces to

$h$ given by (4.17) reduces to

for ![]() $R \le r \le 1$, and

$R \le r \le 1$, and ![]() $V$ is again given by (4.18), where the function

$V$ is again given by (4.18), where the function ![]() $f$ reduces to

$f$ reduces to

The evolution of the droplet in this limit is as described in § 4.2, with, in particular, the lifetime of the droplet given by (4.28) with ![]() $\alpha = \alpha _{\infty }$, namely

$\alpha = \alpha _{\infty }$, namely

Figure 8(b) shows the evolution of the free-surface profile ![]() $h$ in the limit

$h$ in the limit ![]() $n \to \infty$ with

$n \to \infty$ with ![]() $H_0=1$.

$H_0=1$.

4.4. The critical times  $t_{flat}$,

$t_{flat}$,  $t_{touchdown}$ and

$t_{touchdown}$ and  $t_{lifetime}$

$t_{lifetime}$

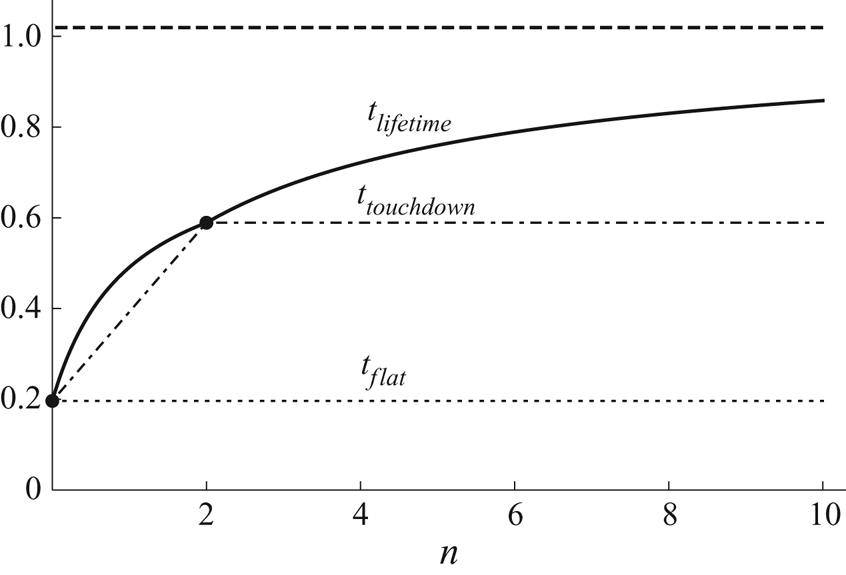

Figure 11 shows a plot of the critical times ![]() $t_{flat}$, given by (3.22),

$t_{flat}$, given by (3.22), ![]() $t_{touchdown}$, given by (3.23a) and (3.24a), and

$t_{touchdown}$, given by (3.23a) and (3.24a), and ![]() $t_{lifetime}$, given by (4.16) and (4.28), as functions of

$t_{lifetime}$, given by (4.16) and (4.28), as functions of ![]() $n$ in the case

$n$ in the case ![]() $H_0 = 1$. In particular, figure 11 illustrates that

$H_0 = 1$. In particular, figure 11 illustrates that ![]() $t_{flat}$ is independent of

$t_{flat}$ is independent of ![]() $n$,

$n$, ![]() $t_{touchdown}$ increases linearly with

$t_{touchdown}$ increases linearly with ![]() $n$ for

$n$ for ![]() $0 \le n \le 2$ but is independent of

$0 \le n \le 2$ but is independent of ![]() $n$ for

$n$ for ![]() $n > 2$,

$n > 2$, ![]() $t_{lifetime}$ increases nonlinearly with

$t_{lifetime}$ increases nonlinearly with ![]() $n$,

$n$, ![]() $t_{lifetime} = t_{touchdown} = t_{flat} = {\rm \pi}/16$ when

$t_{lifetime} = t_{touchdown} = t_{flat} = {\rm \pi}/16$ when ![]() $n=0$,

$n=0$, ![]() $t_{lifetime} = t_{touchdown} = {\rm \pi}(1 + 2 H_0)/16$ when

$t_{lifetime} = t_{touchdown} = {\rm \pi}(1 + 2 H_0)/16$ when ![]() $n=2$, and

$n=2$, and ![]() $t_{lifetime} \to {\rm \pi}[1 + 2(1 + 8\alpha _{\infty })H_0]/16$ in the limit

$t_{lifetime} \to {\rm \pi}[1 + 2(1 + 8\alpha _{\infty })H_0]/16$ in the limit ![]() $n \to \infty$.

$n \to \infty$.

Figure 11. Plot of the critical times ![]() $t_{flat}$, given by (3.22) (dotted line),

$t_{flat}$, given by (3.22) (dotted line), ![]() $t_{touchdown}$, given by (3.23a) for

$t_{touchdown}$, given by (3.23a) for ![]() $0 \le n \le 2$ and by (3.24a) for

$0 \le n \le 2$ and by (3.24a) for ![]() $n > 2$ (dash-dotted line), and

$n > 2$ (dash-dotted line), and ![]() $t_{lifetime}$, given by (4.16) for

$t_{lifetime}$, given by (4.16) for ![]() $0 \le n \le 2$ and by (4.28) for

$0 \le n \le 2$ and by (4.28) for ![]() $n > 2$ (solid line), as functions of

$n > 2$ (solid line), as functions of ![]() $n$ in the case

$n$ in the case ![]() $H_0 = 1$. The dashed line shows the asymptotic value

$H_0 = 1$. The dashed line shows the asymptotic value ![]() $t_{lifetime} = {\rm \pi}[1 + 2(1 + 8\alpha _{\infty })H_0]/16 \simeq 1.0191$ in the limit

$t_{lifetime} = {\rm \pi}[1 + 2(1 + 8\alpha _{\infty })H_0]/16 \simeq 1.0191$ in the limit ![]() $n \to \infty$.

$n \to \infty$.

5. Experimental procedure

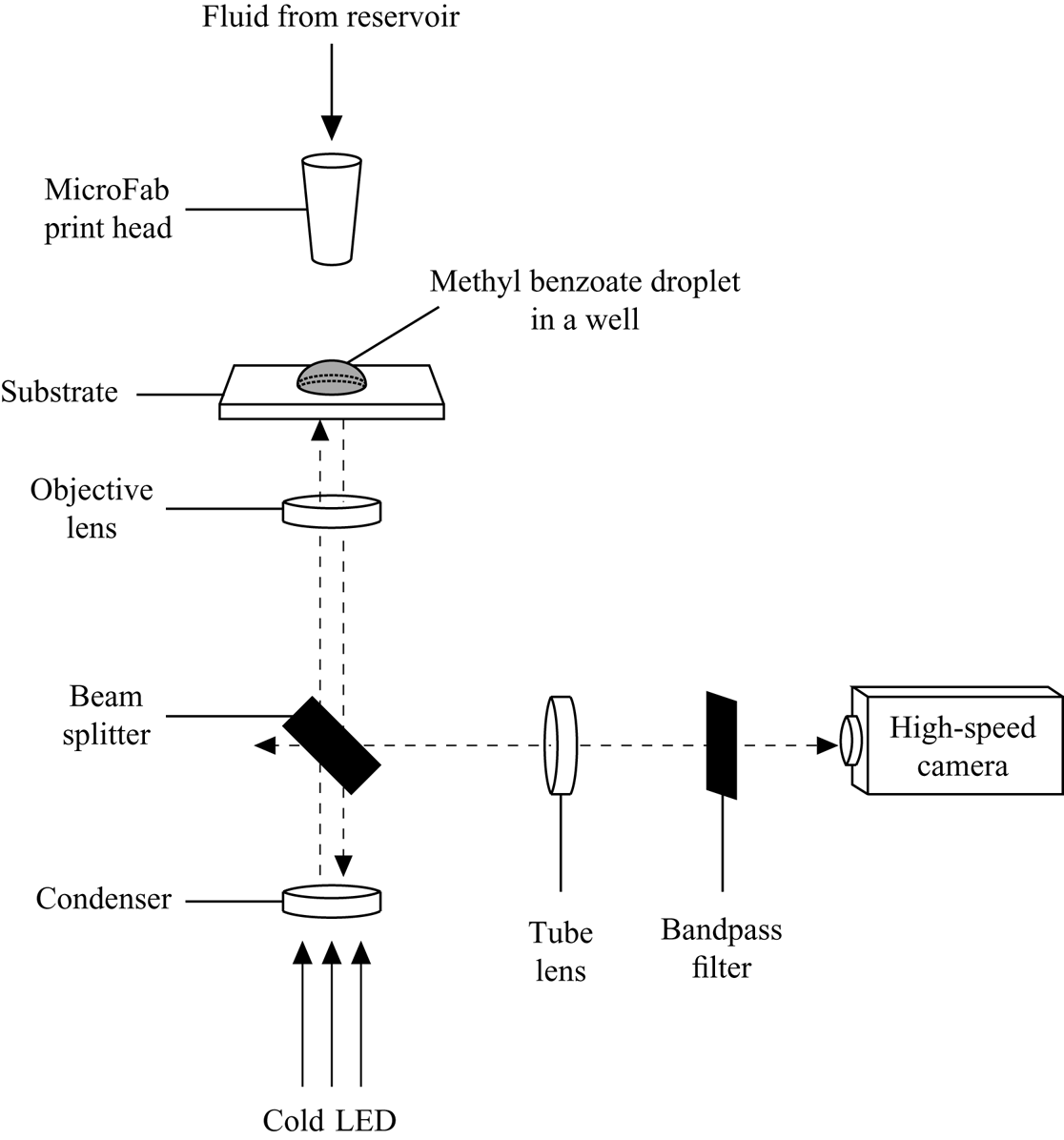

The experimental procedure employed involved depositing single droplets of the volatile solvent methyl benzoate into shallow axisymmetric cylindrical wells and observing their behaviour as they evaporated. Methyl benzoate is sufficiently volatile that the experiments could be conducted within a reasonable time frame, and its physical properties are consistent with the assumptions of the mathematical model. A schematic diagram of the experimental set-up used is shown in figure 12.

Figure 12. Schematic diagram of the experimental set-up used.

The experiments were carried out under ambient conditions with a relative humidity of methyl benzoate vapour of ![]() $RH = 0$ (and a relative humidity of water vapour of

$RH = 0$ (and a relative humidity of water vapour of ![]() $RH = 0.34 \pm 0.10$). The atmospheric pressure was uncontrolled and the ambient temperature was controlled only to within

$RH = 0.34 \pm 0.10$). The atmospheric pressure was uncontrolled and the ambient temperature was controlled only to within ![]() $1\,^{\circ }$C of

$1\,^{\circ }$C of ![]() $22\,^{\circ }$C. The temperature of the substrate was accurately maintained at

$22\,^{\circ }$C. The temperature of the substrate was accurately maintained at ![]() $22\,^{\circ }$C by means of a proportional-integral-derivative Peltier controller.

$22\,^{\circ }$C by means of a proportional-integral-derivative Peltier controller.

The experiments were performed using three shallow wells with radii ![]() $29$

$29$ ![]() $\mathrm {\mu }$m,

$\mathrm {\mu }$m, ![]() $50$

$50$ ![]() $\mathrm {\mu }$m and

$\mathrm {\mu }$m and ![]() $75$

$75$ ![]() $\mathrm {\mu }$m and depths

$\mathrm {\mu }$m and depths ![]() $2.38$

$2.38$ ![]() $\mathrm {\mu }$m,

$\mathrm {\mu }$m, ![]() $1.87$

$1.87$ ![]() $\mathrm {\mu }$m and

$\mathrm {\mu }$m and ![]() $2.39$

$2.39$ ![]() $\mathrm {\mu }$m, respectively. The wells were fabricated in spin-cast films of photo-resist deposited onto glass substrates coated with indium tin oxide (ITO). Further details of the fabrication of the wells are given in Appendix A. Because of the nature of the manufacturing process, the sides of the wells are not perfectly vertical, but, given their small aspect ratios, it is reasonable to regard the wells as being cylindrical for the purpose of comparison with the theoretical predictions of the mathematical model described in §§ 2–4.

$\mathrm {\mu }$m, respectively. The wells were fabricated in spin-cast films of photo-resist deposited onto glass substrates coated with indium tin oxide (ITO). Further details of the fabrication of the wells are given in Appendix A. Because of the nature of the manufacturing process, the sides of the wells are not perfectly vertical, but, given their small aspect ratios, it is reasonable to regard the wells as being cylindrical for the purpose of comparison with the theoretical predictions of the mathematical model described in §§ 2–4.

Picolitre droplets of methyl benzoate were ejected into the wells from a MicroFab print head (MJABP-01, Microfab Technologies Inc.) with a circular orifice of diameter ![]() $50$

$50$ ![]() $\mathrm {\mu }$m under a bipolar waveform generated by a MicroFab controller (JetDrive III CT-M3-02, Microfab Technologies Inc.). The droplet was illuminated from underneath by a cold LED at a wavelength of

$\mathrm {\mu }$m under a bipolar waveform generated by a MicroFab controller (JetDrive III CT-M3-02, Microfab Technologies Inc.). The droplet was illuminated from underneath by a cold LED at a wavelength of ![]() $470$ nm (M470L3, Thorlabs Inc.). The reflected light from the sample was collected by a

$470$ nm (M470L3, Thorlabs Inc.). The reflected light from the sample was collected by a ![]() $50\times$ objective lens (TU Plan ELWD, Nikon) with an image resolution of 0.4

$50\times$ objective lens (TU Plan ELWD, Nikon) with an image resolution of 0.4 ![]() $\mathrm {\mu }$m pixel

$\mathrm {\mu }$m pixel![]() $^{-1}$, and captured through a bandpass filter (bandwidth

$^{-1}$, and captured through a bandpass filter (bandwidth ![]() $10 \pm 2$ nm, Thorlabs Inc.) with a high-speed camera (FASTCAM SA4, Photron). The experiments were performed six times for each well to verify the reproducibility of the results.

$10 \pm 2$ nm, Thorlabs Inc.) with a high-speed camera (FASTCAM SA4, Photron). The experiments were performed six times for each well to verify the reproducibility of the results.

6. Experimental results

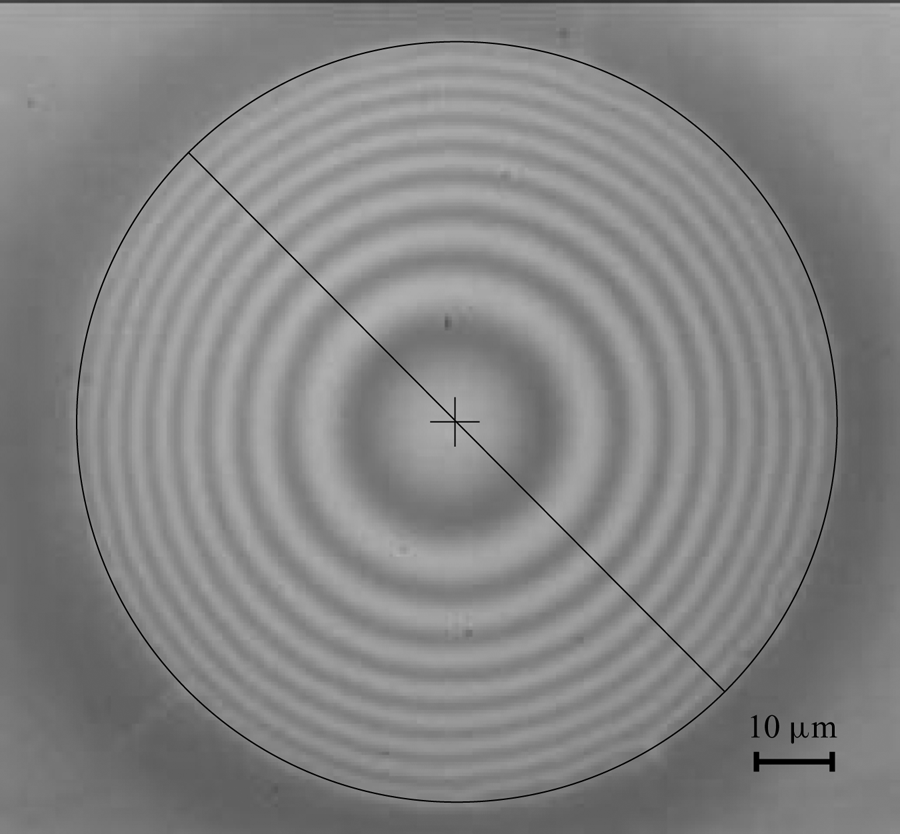

Thin-film interferometry was used to measure the evolution of the free surface of the droplet during its evaporation. Figure 13 shows a typical interferometric pattern observed during the present experiments. In particular, the high degree of axisymmetry shown in figure 13 was found in all of the experiments. Further details of the image-analysis procedure used are given in Appendix B. The initial time, ![]() $t=0$, was arbitrarily chosen to be a time at which well-resolved interference fringes were observed and the contact line of the droplet coincided with the lip of the well (taken to be at the boundary of the outermost bright fringe, as indicated by the circle in figure 13), i.e. no fluid overflow.

$t=0$, was arbitrarily chosen to be a time at which well-resolved interference fringes were observed and the contact line of the droplet coincided with the lip of the well (taken to be at the boundary of the outermost bright fringe, as indicated by the circle in figure 13), i.e. no fluid overflow.

Figure 13. A typical interferometric pattern observed during the present experiments. The circle indicates the lip of the well, the cross the centre of the well, and the line the cross-section along which the fringes are analysed.

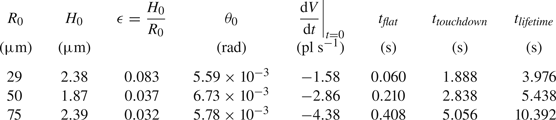

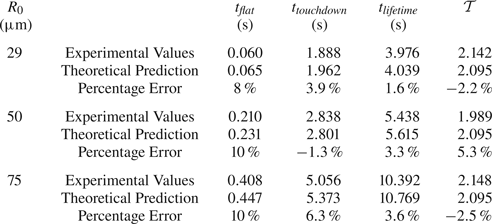

Table 1 shows experimental values of the radius ![]() $R_0$, the depth H 0 and the aspect ratio

$R_0$, the depth H 0 and the aspect ratio ![]() $\epsilon =H_0/R_0$ of the three wells investigated, together with values of the initial angle

$\epsilon =H_0/R_0$ of the three wells investigated, together with values of the initial angle ![]() $\theta _0$ and the initial evaporation rate

$\theta _0$ and the initial evaporation rate ![]() $\left .\textrm {d} V/\textrm {d} t\right \vert _{t=0}$, and the critical times

$\left .\textrm {d} V/\textrm {d} t\right \vert _{t=0}$, and the critical times ![]() $t_{flat}$,

$t_{flat}$, ![]() $t_{touchdown}$ and

$t_{touchdown}$ and ![]() $t_{lifetime}$, for a representative droplet in each well. Note that since the experimental values of the critical times depend on the arbitrarily chosen initial time,

$t_{lifetime}$, for a representative droplet in each well. Note that since the experimental values of the critical times depend on the arbitrarily chosen initial time, ![]() $t=0$, as well as on the values of the ambient temperature and the atmospheric pressure, we give representative (rather than average) results for each well. We will discuss a parameter-free quantity involving the relative values of the critical times in § 7.

$t=0$, as well as on the values of the ambient temperature and the atmospheric pressure, we give representative (rather than average) results for each well. We will discuss a parameter-free quantity involving the relative values of the critical times in § 7.

Table 1. Experimental values of the radius ![]() $R_0$, the depth

$R_0$, the depth ![]() $H_0$ and the aspect ratio

$H_0$ and the aspect ratio ![]() $\epsilon =H_0/R_0$ of the three wells investigated, together with values of the initial angle

$\epsilon =H_0/R_0$ of the three wells investigated, together with values of the initial angle ![]() $\theta _0$ and the initial evaporation rate

$\theta _0$ and the initial evaporation rate ![]() $\left .\textrm {d} V/\textrm {d} t\right \vert _{t=0}$, and the critical times

$\left .\textrm {d} V/\textrm {d} t\right \vert _{t=0}$, and the critical times ![]() $t_{flat}$,

$t_{flat}$, ![]() $t_{touchdown}$ and

$t_{touchdown}$ and ![]() $t_{lifetime}$, for a representative droplet in each well.

$t_{lifetime}$, for a representative droplet in each well.

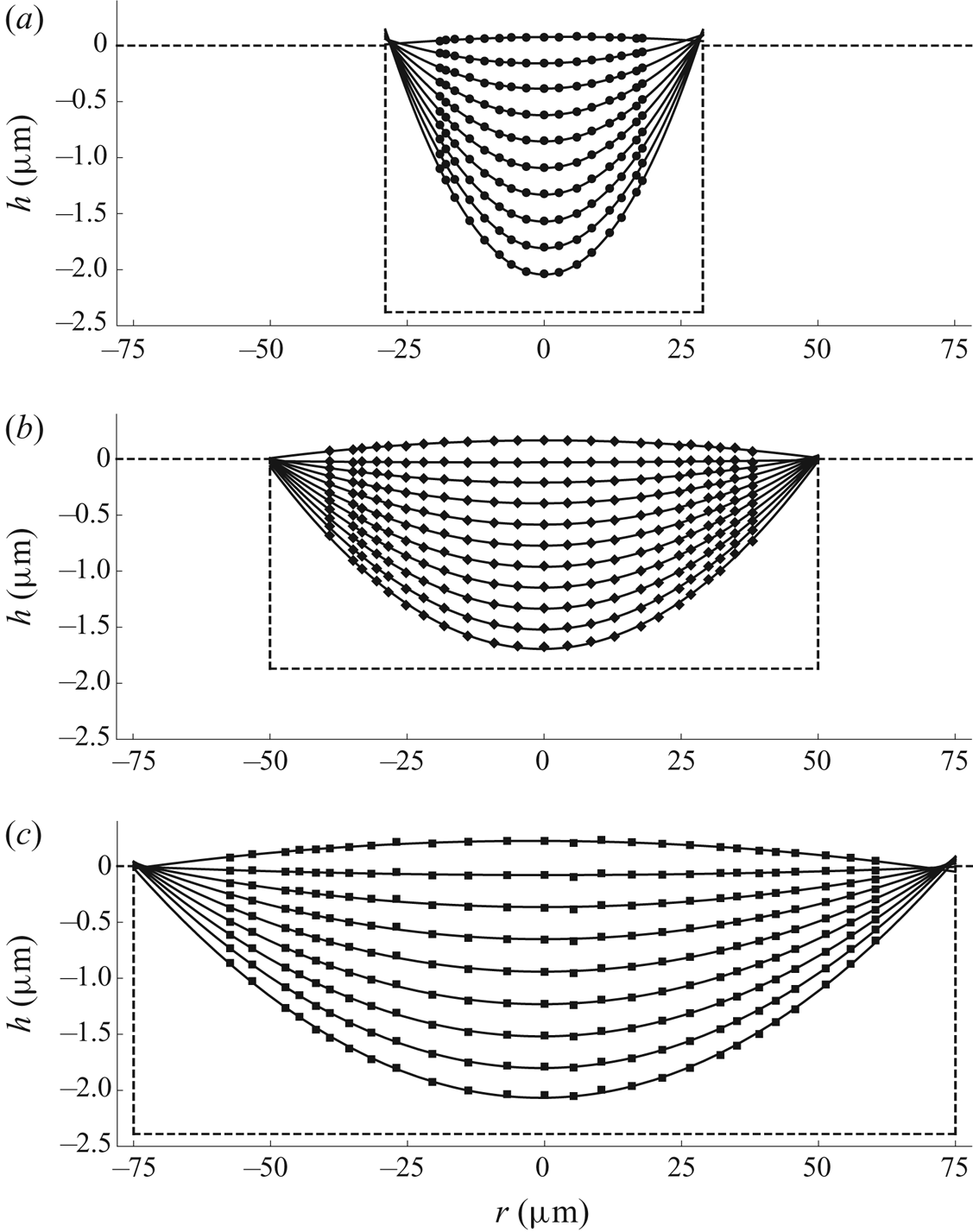

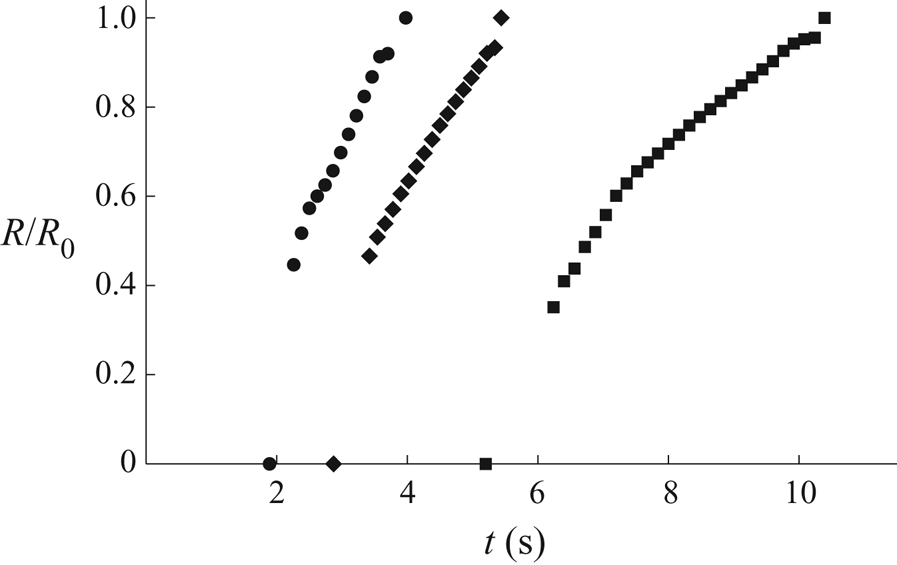

Figure 14 shows experimental results for the free-surface profile ![]() $h$ of a droplet before touchdown and paraboloidal fits to these values as functions of

$h$ of a droplet before touchdown and paraboloidal fits to these values as functions of ![]() $r$ for all three wells at equally spaced times. All of the paraboloidal fits intersect to within

$r$ for all three wells at equally spaced times. All of the paraboloidal fits intersect to within ![]() $\Delta r = \pm 1$

$\Delta r = \pm 1$ ![]() $\mathrm {\mu }$m and

$\mathrm {\mu }$m and ![]() $\Delta h = \pm 0.05$

$\Delta h = \pm 0.05$ ![]() $\mathrm {\mu }$m of each other, indicating that the contact line of the droplet remains pinned at the lip of the well before touchdown, and the position of the average intersection point was used to determine the radius

$\mathrm {\mu }$m of each other, indicating that the contact line of the droplet remains pinned at the lip of the well before touchdown, and the position of the average intersection point was used to determine the radius ![]() $R_0$ and the depth

$R_0$ and the depth ![]() $H_0$ of each well. The initial angle

$H_0$ of each well. The initial angle ![]() $\theta _0$ of the droplet was calculated from the average of the derivatives of the paraboloidal fit to the initial free-surface profile at the lip of the well.

$\theta _0$ of the droplet was calculated from the average of the derivatives of the paraboloidal fit to the initial free-surface profile at the lip of the well.

Figure 14. Experimental results for the free-surface profile ![]() $h$ of a droplet before touchdown (symbols) and paraboloidal fits to these values (solid black lines) as functions of

$h$ of a droplet before touchdown (symbols) and paraboloidal fits to these values (solid black lines) as functions of ![]() $r$ for wells of radius

$r$ for wells of radius ![]() $29$

$29$ ![]() $\mathrm {\mu }$m at times

$\mathrm {\mu }$m at times ![]() $t=0,0.18, \ldots , 1.62$ s,

$t=0,0.18, \ldots , 1.62$ s, ![]() $50$

$50$ ![]() $\mathrm {\mu }$m at times

$\mathrm {\mu }$m at times ![]() $t=0,0.26, \ldots , 2.34$ s and

$t=0,0.26, \ldots , 2.34$ s and ![]() $75$

$75$ ![]() $\mathrm {\mu }$m at times

$\mathrm {\mu }$m at times ![]() $t=0,0.56, \ldots , 4.48$ s. The experimental values are denoted by circles, diamonds and squares for the

$t=0,0.56, \ldots , 4.48$ s. The experimental values are denoted by circles, diamonds and squares for the ![]() $29$

$29$ ![]() $\mathrm {\mu }$m,

$\mathrm {\mu }$m, ![]() $50$

$50$ ![]() $\mathrm {\mu }$m and

$\mathrm {\mu }$m and ![]() $75$

$75$ ![]() $\mathrm {\mu }$m wells, respectively. The dashed lines correspond to the radius

$\mathrm {\mu }$m wells, respectively. The dashed lines correspond to the radius ![]() $R_0$, the depth

$R_0$, the depth ![]() $H_0$, and the position of the dry substrate for each well.

$H_0$, and the position of the dry substrate for each well.

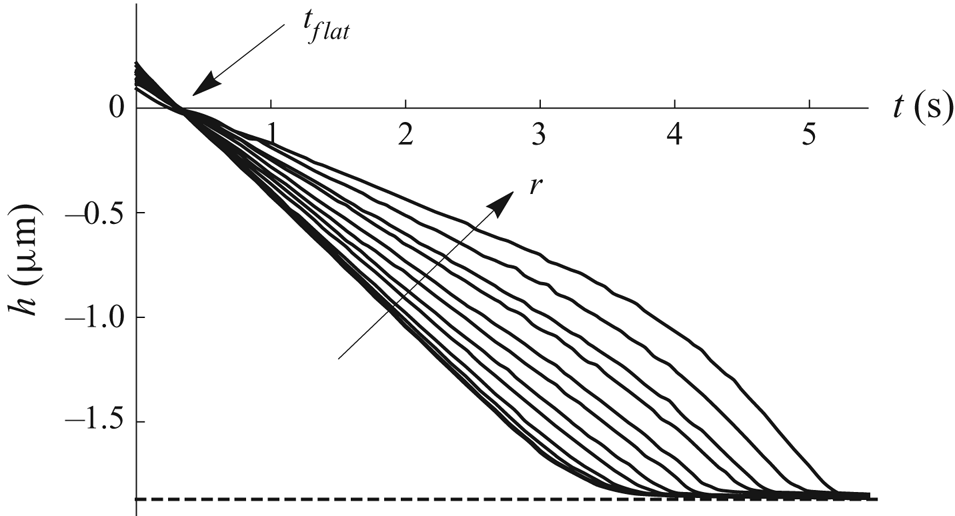

Figure 15 shows experimental results for the free-surface profile ![]() $h$ of a droplet as functions of

$h$ of a droplet as functions of ![]() $t$ for a range of values of

$t$ for a range of values of ![]() $r$ for the

$r$ for the ![]() $50$

$50$ ![]() $\mathrm {\mu }$m well. The time at which the free surface is instantaneously flat,

$\mathrm {\mu }$m well. The time at which the free surface is instantaneously flat, ![]() $t_{flat}$, was calculated from the average intersection point of the curves shown in figure 15. The uncertainty in the measurement of

$t_{flat}$, was calculated from the average intersection point of the curves shown in figure 15. The uncertainty in the measurement of ![]() $t_{flat}$ is

$t_{flat}$ is ![]() $\pm 0.006$ s.

$\pm 0.006$ s.

Figure 15. Experimental results for the free-surface profile ![]() $h$ of a droplet as functions of

$h$ of a droplet as functions of ![]() $t$ for

$t$ for ![]() $r=0$, 4.29, 8.57, 12.86, 17.68, 20.90, 26.79, 30.01, 32.15, 34.83 and 38.04 for the

$r=0$, 4.29, 8.57, 12.86, 17.68, 20.90, 26.79, 30.01, 32.15, 34.83 and 38.04 for the ![]() $50$

$50$ ![]() $\mathrm {\mu }$m well. The arrow indicates the direction of increasing

$\mathrm {\mu }$m well. The arrow indicates the direction of increasing ![]() $r$. The dashed line corresponds to the depth

$r$. The dashed line corresponds to the depth ![]() $H_0=1.87$

$H_0=1.87$ ![]() $\mathrm {\mu }$m of the well.

$\mathrm {\mu }$m of the well.

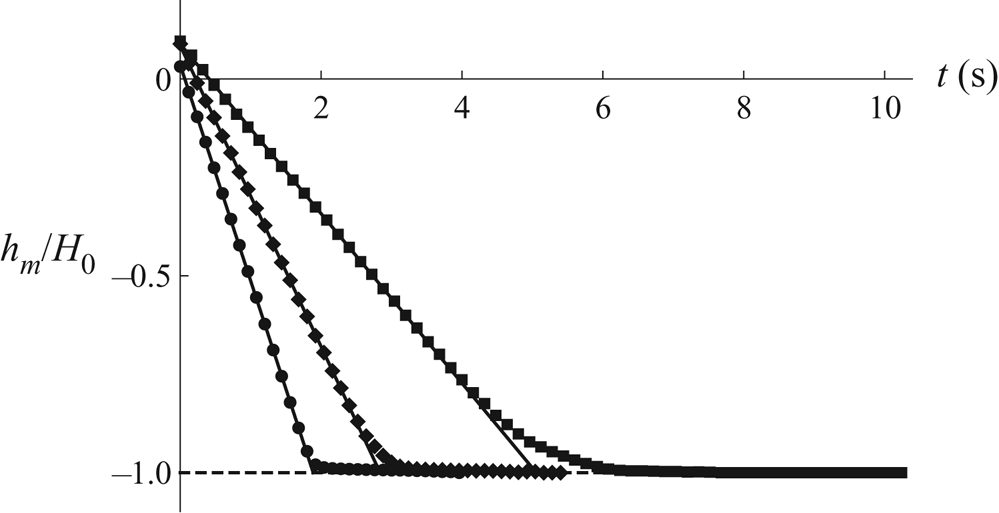

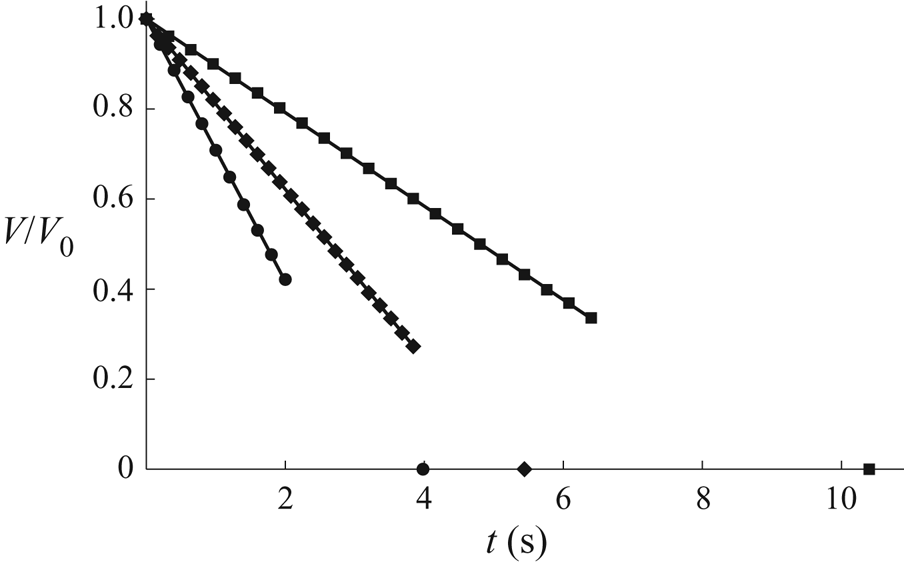

Figure 16 shows experimental results for the normalised height of the free surface at the centre of the well, ![]() $h_{m}/H_0$, and linear fits to these values as functions of

$h_{m}/H_0$, and linear fits to these values as functions of ![]() $t$ for all three wells. For each well, the time at which the free surface touches down at the centre of the well,

$t$ for all three wells. For each well, the time at which the free surface touches down at the centre of the well, ![]() $t_{touchdown}$, was calculated from the intersection point of the linear fit shown in figure 16 with the bottom of the well. However, note that whereas for the

$t_{touchdown}$, was calculated from the intersection point of the linear fit shown in figure 16 with the bottom of the well. However, note that whereas for the ![]() $29$

$29$ ![]() $\mathrm {\mu }$m well the behaviour of

$\mathrm {\mu }$m well the behaviour of ![]() $h_{m}$ is nearly linear until very close to touchdown, and hence the value of

$h_{m}$ is nearly linear until very close to touchdown, and hence the value of ![]() $t_{touchdown}$ calculated from the linear fit will be very close to the true value, for the

$t_{touchdown}$ calculated from the linear fit will be very close to the true value, for the ![]() $50$

$50$ ![]() $\mathrm {\mu }$m and

$\mathrm {\mu }$m and ![]() $75$

$75$ ![]() $\mathrm {\mu }$m wells the behaviour of