1. Introduction

Vortex-induced vibration (VIV) is a significant phenomenon affecting many engineering structures in fluid flow. These structures can be, for example, offshore risers used in petroleum extraction, heat exchanger tubes in nuclear plants, aircraft control surfaces in aeronautical applications and civil engineering structures such as bridges, towers and industrial chimneys, to name a few. The cause of VIV is the periodic vortex shedding from an elastic or elastically mounted rigid bluff structure. Periodically shed vortices impose alternating pressure forces on the surface of the structure, and these forces can lead to large-amplitude structural vibrations if the vortex shedding frequency is close to the natural frequency of the structure. The present knowledge base researchers have developed on the VIV of cylinders over the years is discussed in detail in the reviews of Sarpkaya (Reference Sarpkaya2004), Williamson & Govardhan (Reference Williamson and Govardhan2004, Reference Williamson and Govardhan2008), Gabbai & Benaroya (Reference Gabbai and Benaroya2005), Nakamura & Kaneko (Reference Nakamura and Kaneko2008) and Naudascher & Rockwell (Reference Naudascher and Rockwell2012).

The VIV of an elastically mounted rigid cylinder in the transverse direction mainly depends on the mass ratio ![]() $({m^\ast } = {m_t}/{m_d})$, damping ratio

$({m^\ast } = {m_t}/{m_d})$, damping ratio ![]() $(\zeta = {c_{sys}}/{c_{crit}})$ and reduced velocity

$(\zeta = {c_{sys}}/{c_{crit}})$ and reduced velocity ![]() $({U^\ast } = U/{f_n}D)$, where

$({U^\ast } = U/{f_n}D)$, where ![]() ${m_t}$ is the total mass of the oscillating system,

${m_t}$ is the total mass of the oscillating system, ![]() ${m_d}$ is the mass of the displaced fluid,

${m_d}$ is the mass of the displaced fluid, ![]() ${c_{sys}}$ is the damping of the system,

${c_{sys}}$ is the damping of the system, ![]() ${c_{crit}}$ is the critical damping, U is the free-stream velocity,

${c_{crit}}$ is the critical damping, U is the free-stream velocity, ![]() ${f_n}$ is the natural frequency of the system and D is the cylinder diameter. The dependency of the transverse VIV response on these parameters has been experimentally investigated by many studies, such as Khalak & Williamson (Reference Khalak and Williamson1997a). For an elastically mounted cylinder with a high mass-damping parameter,

${f_n}$ is the natural frequency of the system and D is the cylinder diameter. The dependency of the transverse VIV response on these parameters has been experimentally investigated by many studies, such as Khalak & Williamson (Reference Khalak and Williamson1997a). For an elastically mounted cylinder with a high mass-damping parameter, ![]() ${m^\ast }\zeta $, the work of Feng (Reference Feng1968) showed that the amplitude of transverse-direction VIVs in the synchronization range follows two response branches as the reduced velocity is varied: commonly named as the initial branch and the lower branch. On the other hand, for a system with a low mass-damping parameter, Khalak & Williamson (Reference Khalak and Williamson1997b) showed that three response branches exist: namely, initial, upper and lower branches. It should be noted that some studies, such as Sarpkaya (Reference Sarpkaya2004), consider the added mass coefficient

${m^\ast }\zeta $, the work of Feng (Reference Feng1968) showed that the amplitude of transverse-direction VIVs in the synchronization range follows two response branches as the reduced velocity is varied: commonly named as the initial branch and the lower branch. On the other hand, for a system with a low mass-damping parameter, Khalak & Williamson (Reference Khalak and Williamson1997b) showed that three response branches exist: namely, initial, upper and lower branches. It should be noted that some studies, such as Sarpkaya (Reference Sarpkaya2004), consider the added mass coefficient ![]() ${C_a}$ in the calculation of the mass-damping parameter, which then takes the form of

${C_a}$ in the calculation of the mass-damping parameter, which then takes the form of ![]() $({m^\ast } + {C_a})\zeta $ rather than

$({m^\ast } + {C_a})\zeta $ rather than ![]() ${m^\ast }\zeta $. The added mass is related to the coupling of the cylinder motion to the surrounding fluid and is equal to the mass of fluid displaced by the volume of the immersed structure multiplied by an added mass coefficient

${m^\ast }\zeta $. The added mass is related to the coupling of the cylinder motion to the surrounding fluid and is equal to the mass of fluid displaced by the volume of the immersed structure multiplied by an added mass coefficient ![]() ${C_a}$. For a circular cylinder in unconfined flow, the added mass coefficient takes the value of

${C_a}$. For a circular cylinder in unconfined flow, the added mass coefficient takes the value of ![]() ${C_a} = 1$.

${C_a} = 1$.

A further parameter that affects the free vibration response of a cylinder in the transverse direction is identified to be its spanwise end condition by Morse, Govardhan & Williamson (Reference Morse, Govardhan and Williamson2008). They conducted their tests in a water tunnel under low mass-damping conditions. The top end of their submerged cylinder was bounded by the free surface of the water, while for the bottom end, the following three end conditions were tested: a plate unattached from the cylinder, a plate attached to the cylinder and a free end with no endplate. They saw that the free vibration response, with its well-documented initial, upper and lower branches, is virtually the same for the attached and unattached plate cases, provided that the unattached plate is sufficiently close to the cylinder's end. On the other hand, without an endplate, they found that the vibration amplitudes in the lower branch increase significantly, and the transitional jump between the upper and lower branches disappears. Also, although the maximum amplitude in the upper branch remains unchanged for the no endplate case compared with the case with an endplate, the time traces of the cylinder displacement with no endplate differ from their characteristic patterns found under the effect of an endplate for both the upper and lower branches. Perhaps the most remarkable finding of their study is that the vibration response of a cylinder with an unattached endplate becomes equivalent to having no plate at all when the unattached plate is placed at a sufficient distance away from the cylinder. This distance was argued to be around 15 % of the cylinder diameter and higher, which for a 50.8 mm cylinder corresponds to a distance of nearly 7 mm and above.

Brika & Laneville (1993) were the first to show a correspondence between the vortex shedding patterns and the response branches in the synchronization regime. In their wind tunnel tests of a high mass-damping flexible cable that is allowed to undergo transversal free vibrations, they found that the initial and lower response branches, which are the only two response branches encountered in a system with a high mass-damping parameter, are associated with the vortex shedding patterns, denoted as 2S and 2P modes, respectively. The naming of these modes follows the terminology used by Williamson & Roshko (Reference Williamson and Roshko1988) for the vortex patterns of forced oscillating cylinders. In the 2S mode, two single vortices are shed per cycle, and vortices travel downstream along the centreline of the oscillating cylinder. In the 2P mode, two vortex pairs are shed per cycle, and they travel laterally outward from the wake centreline while convecting downstream. Govardhan & Williamson (Reference Govardhan and Williamson2000) showed for the first time that the 2P mode of vortex formation also exists in the upper branch, which is the additional high-amplitude response branch encountered in systems with low mass-damping. Subsequently, Morse & Williamson (Reference Morse and Williamson2009) discovered, in their study, a new vortex mode for the upper branch and called it the 2Po mode. In the 2Po mode, two vortex pairs are formed in each cycle, similar to the 2P mode, but the second vortex in each pair is much weaker than the first vortex. Furthermore, they demonstrated that the 2S, 2P and 2Po modes result in positive excitation from vortex-induced forces, which is a necessary condition for free structural vibrations to occur, and among these modes, the 2Po mode yields the peak resonant amplitude within the synchronization region.

While analysing the vibration response and the associated vortex modes, as discussed by Konstantinidis (Reference Konstantinidis2014), the condition of lock-in (also known as synchronization) is important. In general, the lock-in condition is defined as the situation when the ratio of two frequencies is constant while some input parameter is varied. In the case of the freely oscillating cylinder, there are three characteristic frequencies: the natural frequency of the system ![]() $({f_n})$ determined by its mechanical properties, the frequency of the structural oscillation motion

$({f_n})$ determined by its mechanical properties, the frequency of the structural oscillation motion ![]() $({f_d})$ and the frequency of vortex shedding, which is equivalent to the frequency of streamwise and transverse flow velocity fluctuations in the wake (

$({f_d})$ and the frequency of vortex shedding, which is equivalent to the frequency of streamwise and transverse flow velocity fluctuations in the wake (![]() ${f_u}$ and

${f_u}$ and ![]() ${f_v}$). Traditionally, the lock-in or synchronization during free vibrations was considered to happen when the frequency of structural oscillation, as well as the vortex shedding frequency, matches the natural frequency of the structure so that

${f_v}$). Traditionally, the lock-in or synchronization during free vibrations was considered to happen when the frequency of structural oscillation, as well as the vortex shedding frequency, matches the natural frequency of the structure so that ![]() $f_d^\ast = {f_d}/{f_n} \approx 1$. This is indeed found to be true for systems with high mass ratios (Govardhan & Williamson Reference Govardhan and Williamson2000). However, for low mass ratios, a structure can oscillate at frequencies higher than its natural frequency during lock-in (for example,

$f_d^\ast = {f_d}/{f_n} \approx 1$. This is indeed found to be true for systems with high mass ratios (Govardhan & Williamson Reference Govardhan and Williamson2000). However, for low mass ratios, a structure can oscillate at frequencies higher than its natural frequency during lock-in (for example, ![]() $f_d^\ast \approx 1.4$ was reported in Khalak & Williamson Reference Khalak and Williamson1997b). Thereby, lock-in can be defined better as the matching between the frequency of vortex shedding in the wake and the frequency of structural oscillations (Williamson & Govardhan Reference Williamson and Govardhan2004).

$f_d^\ast \approx 1.4$ was reported in Khalak & Williamson Reference Khalak and Williamson1997b). Thereby, lock-in can be defined better as the matching between the frequency of vortex shedding in the wake and the frequency of structural oscillations (Williamson & Govardhan Reference Williamson and Govardhan2004).

Several methods have been proposed and investigated so far for controlling the oscillation of structures undergoing VIV. The VIV in civil engineering structures can be avoided by altering the structures’ stiffness or using vibration dampers; however, these methods are expensive and sometimes impractical compared with fluid mechanics methods that mainly modify the flow around the structure. Fluid mechanics methods of VIV control are based on energizing the boundary layer or altering the vortex shedding process. These methods include using roughness elements (Chang, Ajith Kumar & Bernitsas Reference Chang, Ajith Kumar and Bernitsas2011), surface bumps (Owen, Bearman & Szewczyk Reference Owen, Bearman and Szewczyk2001), splitter plates (Assi, Bearman & Kitney Reference Assi, Bearman and Kitney2009), vortex generators (Ünal & Atlar Reference Ünal and Atlar2010), helical strakes (Zhou et al. Reference Zhou2011), cactus inspired spines (Levy & Liu Reference Levy and Liu2013), fins (Khashehchi et al. Reference Khashehchi2014), dimples (Zhou et al. Reference Zhou2015), rectangular grooves (Canpolat & Sahin Reference Canpolat and Sahin2017), strips (Vinod, Auvil & Banerjee Reference Vinod, Auvil and Banerjee2018), plasma actuators (Castro Hebrero et al. Reference Castro Hebrero2020) and surface wires (Hover, Tvedt & Triantafyllou Reference Hover, Tvedt and Triantafyllou2001). The fluid mechanics methods can be employed to intensify VIV as well as to suppress it. For instance, Chang et al. (Reference Chang, Ajith Kumar and Bernitsas2011) utilized surface roughness strips to enhance VIV with the purpose of harnessing electricity from the hydrokinetic energy of ocean/river currents. By appropriately selecting the placement angle, coverage area and height of the roughness strips, they could amplify the oscillation amplitude by 1.7 times that of the clean cylinder. In contrast, Owen et al. (Reference Owen, Bearman and Szewczyk2001) used an arrangement of surface bumps to lessen VIV by suppressing vortex shedding. In their results, regular vortex shedding could not be detected for a stationary cylinder with surface bumps; however, when the same cylinder was flexibly mounted, the transverse oscillation was detectable at low values of the mass-damping parameter ![]() ${m^\ast }\zeta $ with a maximum amplitude 25 % lower than that of the clean cylinder.

${m^\ast }\zeta $ with a maximum amplitude 25 % lower than that of the clean cylinder.

The simplest fluid mechanics control devices that can be applied on the surface of a cylindrical body are spanwise wires. Their effects on the flow and loading characteristics have been widely investigated in the literature for fixed cylinders in the subcritical flow regime. In particular, the work of Nebres & Batill (Reference Nebres and Batill1993) has laid the groundwork for research in this area. For a stationary cylinder fitted with a single spanwise surface wire, they discussed the variation of the non-dimensionalized vortex shedding frequency with the wire diameter ![]() $(d)$-to-cylinder diameter (D) ratio, wire angular position

$(d)$-to-cylinder diameter (D) ratio, wire angular position ![]() $\theta $ and Reynolds number. They showed that the dimensionless form of the vortex shedding frequency (Strouhal number,

$\theta $ and Reynolds number. They showed that the dimensionless form of the vortex shedding frequency (Strouhal number, ![]() $St$) undergoes fundamental changes at multiple wire locations for a given wire diameter-to-cylinder diameter

$St$) undergoes fundamental changes at multiple wire locations for a given wire diameter-to-cylinder diameter ![]() $(d/D)$ ratio and Reynolds number. Based on these changes, they defined several fundamental angles for a single-wire application on the cylinder surface. By carrying out particle image velocimetry (PIV) measurements, Ekmekci (Reference Ekmekci2006) and Ekmekci & Rockwell (Reference Ekmekci and Rockwell2010) examined the near-wake and shear-layer flow patterns of a stationary cylinder tripped with a single spanwise wire for various wire positions. Their results, collected at the subcritical Reynolds number of

$(d/D)$ ratio and Reynolds number. Based on these changes, they defined several fundamental angles for a single-wire application on the cylinder surface. By carrying out particle image velocimetry (PIV) measurements, Ekmekci (Reference Ekmekci2006) and Ekmekci & Rockwell (Reference Ekmekci and Rockwell2010) examined the near-wake and shear-layer flow patterns of a stationary cylinder tripped with a single spanwise wire for various wire positions. Their results, collected at the subcritical Reynolds number of ![]() $Re = {10^4}$, demonstrated that a single spanwise surface wire can significantly attenuate the Kármán vortex shedding from a fixed cylinder when it is placed at a specific small range of angular positions on the cylinder surface, which they called the first critical wire locations

$Re = {10^4}$, demonstrated that a single spanwise surface wire can significantly attenuate the Kármán vortex shedding from a fixed cylinder when it is placed at a specific small range of angular positions on the cylinder surface, which they called the first critical wire locations ![]() ${\theta _{c1}}$. Furthermore, they showed that the same wire can be used to intensify the Kármán vortex shedding when placed at another range of critical locations, named the second critical locations

${\theta _{c1}}$. Furthermore, they showed that the same wire can be used to intensify the Kármán vortex shedding when placed at another range of critical locations, named the second critical locations ![]() ${\theta _{c2}}$. Other than the attenuation and enhancement of the Kármán instability, they associated these two critical wire locations,

${\theta _{c2}}$. Other than the attenuation and enhancement of the Kármán instability, they associated these two critical wire locations, ![]() ${\theta _{c1}}$ and

${\theta _{c1}}$ and ![]() ${\theta _{c2}}$, with further distinctive characteristics. Namely, a spanwise surface wire at the first critical angle

${\theta _{c2}}$, with further distinctive characteristics. Namely, a spanwise surface wire at the first critical angle ![]() ${\theta _{c1}}$ also led to a bistable flow regime, early onset of shear-layer instability in the shear layer separating from the wire side of the cylinder and significant extension in the streamwise length of the time-averaged recirculation bubble in the near wake. The same surface wire, when placed at the second critical angle

${\theta _{c1}}$ also led to a bistable flow regime, early onset of shear-layer instability in the shear layer separating from the wire side of the cylinder and significant extension in the streamwise length of the time-averaged recirculation bubble in the near wake. The same surface wire, when placed at the second critical angle ![]() ${\theta _{c2}}$, depicted increased amplitudes of shear-layer flapping, early onset of shear-layer instability and the utmost level of near-wake contraction. The subsequent work conducted by Ekmekci & Rockwell (Reference Ekmekci and Rockwell2011) proved that only a spanwise surface wire that is larger than the boundary layer thickness can attenuate or intensify the Kármán instability at the critical locations, while a surface wire that is smaller than the boundary layer thickness was found to have no detectable impact on the strength and coherence of the Kármán vortex shedding. Soon after, Aydin, Joshi & Ekmekci (Reference Aydin, Joshi and Ekmekci2014) confirmed that a single spanwise surface wire stops the regular formation of Kármán vortices over long periods of time when placed at a first critical wire location

${\theta _{c2}}$, depicted increased amplitudes of shear-layer flapping, early onset of shear-layer instability and the utmost level of near-wake contraction. The subsequent work conducted by Ekmekci & Rockwell (Reference Ekmekci and Rockwell2011) proved that only a spanwise surface wire that is larger than the boundary layer thickness can attenuate or intensify the Kármán instability at the critical locations, while a surface wire that is smaller than the boundary layer thickness was found to have no detectable impact on the strength and coherence of the Kármán vortex shedding. Soon after, Aydin, Joshi & Ekmekci (Reference Aydin, Joshi and Ekmekci2014) confirmed that a single spanwise surface wire stops the regular formation of Kármán vortices over long periods of time when placed at a first critical wire location ![]() ${\theta _{c1}}$, but the regular shedding still resumes intermittently for short times. As a result, in the time-averaged sense, a drastic attenuation is observed in the autospectral density of velocity fluctuations at the frequency of Kármán vortex shedding. Also, Aydin et al. (Reference Aydin, Joshi and Ekmekci2014) investigated the dependence of the critical wire locations on the wire size and Reynolds number (within the subcritical Reynolds number range of

${\theta _{c1}}$, but the regular shedding still resumes intermittently for short times. As a result, in the time-averaged sense, a drastic attenuation is observed in the autospectral density of velocity fluctuations at the frequency of Kármán vortex shedding. Also, Aydin et al. (Reference Aydin, Joshi and Ekmekci2014) investigated the dependence of the critical wire locations on the wire size and Reynolds number (within the subcritical Reynolds number range of ![]() $Re = 5 \times {10^3}$ to

$Re = 5 \times {10^3}$ to ![]() $3 \times {10^4}$). Their results indicated that the range of

$3 \times {10^4}$). Their results indicated that the range of ![]() ${\theta _{c2}}$ is generally independent of both the Reynolds number and wire size, while the range of

${\theta _{c2}}$ is generally independent of both the Reynolds number and wire size, while the range of ![]() ${\theta _{c1}}$ depends on the wire size, and for a given wire size,

${\theta _{c1}}$ depends on the wire size, and for a given wire size, ![]() ${\theta _{c1}}$ increases with increasing Reynolds number until the Reynolds number of

${\theta _{c1}}$ increases with increasing Reynolds number until the Reynolds number of ![]() $Re = {10^4}$ is reached, beyond which

$Re = {10^4}$ is reached, beyond which ![]() ${\theta _{c1}}$ becomes independent of the Reynolds number within the

${\theta _{c1}}$ becomes independent of the Reynolds number within the ![]() $Re$ range that they studied. Ekmekci (Reference Ekmekci2006) and Ekmekci & Rockwell (Reference Ekmekci and Rockwell2010) showed that the bistable phenomenon, observed when the spanwise wire is at the

$Re$ range that they studied. Ekmekci (Reference Ekmekci2006) and Ekmekci & Rockwell (Reference Ekmekci and Rockwell2010) showed that the bistable phenomenon, observed when the spanwise wire is at the ![]() ${\theta _{c1}}$ location, involves intermittent switching of the shear layer between the states of reattachment and no reattachment after separation from the wire. This switch in separation mode occurred at a broad, low-frequency band that is one order of magnitude smaller than the nominal Kármán vortex shedding frequency. A further independent study conducted by Alam et al. (Reference Alam, Zhou, Zhao, Flamand and Boujard2010) observed this bistable phenomenon for the case of a fixed cylinder involving two spanwise wires that are symmetrically placed with respect to the approach flow, and Joshi & Ekmekci (Reference Joshi and Ekmekci2019) also detected the bistable state for asymmetrically arranged spanwise surface wires when one of the wires passes from the critical location on the cylinder surface.

${\theta _{c1}}$ location, involves intermittent switching of the shear layer between the states of reattachment and no reattachment after separation from the wire. This switch in separation mode occurred at a broad, low-frequency band that is one order of magnitude smaller than the nominal Kármán vortex shedding frequency. A further independent study conducted by Alam et al. (Reference Alam, Zhou, Zhao, Flamand and Boujard2010) observed this bistable phenomenon for the case of a fixed cylinder involving two spanwise wires that are symmetrically placed with respect to the approach flow, and Joshi & Ekmekci (Reference Joshi and Ekmekci2019) also detected the bistable state for asymmetrically arranged spanwise surface wires when one of the wires passes from the critical location on the cylinder surface.

Spanwise surface wires can be used as a method to modify the VIV of cylinders, but few studies have been conducted on this topic. One of the earliest studies on the use of spanwise surface wires on cylinders undergoing VIV is the work of Price (Reference Price1956), which involved water channel tests at a Reynolds number of ![]() $Re = 4.64 \times {10^3}$ for a cylinder fitted with three straight wires placed at the specific angles

$Re = 4.64 \times {10^3}$ for a cylinder fitted with three straight wires placed at the specific angles ![]() $0^\circ $,

$0^\circ $, ![]() $+ 60^\circ $ and

$+ 60^\circ $ and ![]() $- 60^\circ $ from the forward stagnation point of the cylinder. For this tripped cylinder arrangement, Price (Reference Price1956) detected the same amplitude of vibration found for the clean cylinder and presumed that the spanwise surface wires are ineffective in suppressing large-scale VIV. However, the observed results were due to the wire size. The wires they used were smaller than the boundary layer thickness, and as a result, they did not influence the flow field appreciably in that work. Hover et al. (Reference Hover, Tvedt and Triantafyllou2001) studied the vortex-induced load and vibration characteristics at

$- 60^\circ $ from the forward stagnation point of the cylinder. For this tripped cylinder arrangement, Price (Reference Price1956) detected the same amplitude of vibration found for the clean cylinder and presumed that the spanwise surface wires are ineffective in suppressing large-scale VIV. However, the observed results were due to the wire size. The wires they used were smaller than the boundary layer thickness, and as a result, they did not influence the flow field appreciably in that work. Hover et al. (Reference Hover, Tvedt and Triantafyllou2001) studied the vortex-induced load and vibration characteristics at ![]() $Re = 3.0 \times {10^4}$ for a cylinder fitted with two spanwise wires (having a wire-to-cylinder diameter ratio of

$Re = 3.0 \times {10^4}$ for a cylinder fitted with two spanwise wires (having a wire-to-cylinder diameter ratio of ![]() $d/D = 0.3\%$) at the angular positions of

$d/D = 0.3\%$) at the angular positions of ![]() $+ 70^\circ $ and

$+ 70^\circ $ and ![]() $- 70^\circ $. These surface wires decreased the peak oscillation amplitude moderately in the reduced velocity range of

$- 70^\circ $. These surface wires decreased the peak oscillation amplitude moderately in the reduced velocity range of ![]() ${U^\ast } = 5.1\unicode{x2013}6$; while above

${U^\ast } = 5.1\unicode{x2013}6$; while above ![]() ${U^\ast } = 6$, the decrease in vibrations was quite substantial. In particular, at higher reduced velocities, near

${U^\ast } = 6$, the decrease in vibrations was quite substantial. In particular, at higher reduced velocities, near ![]() ${U^\ast } = 8$ and above, their results suggest total disruption of synchronization with the addition of the wires at the particular wire position that they tested for the cylinder, which would otherwise undergo VIV in the lower synchronization branch. At such high reduced frequencies, the wires induced very-high-frequency and uncorrelated fluctuating lift and drag forces on the cylinder. More recently, the fluid forces and vibration response of an elastically mounted cylinder with two symmetrically positioned spanwise wires

${U^\ast } = 8$ and above, their results suggest total disruption of synchronization with the addition of the wires at the particular wire position that they tested for the cylinder, which would otherwise undergo VIV in the lower synchronization branch. At such high reduced frequencies, the wires induced very-high-frequency and uncorrelated fluctuating lift and drag forces on the cylinder. More recently, the fluid forces and vibration response of an elastically mounted cylinder with two symmetrically positioned spanwise wires ![]() $(d/D = 12\,\%)$ were investigated by Quadrante & Nishi (Reference Quadrante and Nishi2014) for a range of Reynolds numbers from

$(d/D = 12\,\%)$ were investigated by Quadrante & Nishi (Reference Quadrante and Nishi2014) for a range of Reynolds numbers from ![]() $3.45 \times {10^3}$ to

$3.45 \times {10^3}$ to ![]() $2.04 \times {10^4}$. They considered four angular positions for the application of the wires, and reported that the cylinder vibration is intensified when the wires are at

$2.04 \times {10^4}$. They considered four angular positions for the application of the wires, and reported that the cylinder vibration is intensified when the wires are at ![]() ${\mp} 60^\circ $ and

${\mp} 60^\circ $ and ![]() ${\mp} 75^\circ $ and considerably suppressed for wires at

${\mp} 75^\circ $ and considerably suppressed for wires at ![]() ${\mp} 105^\circ $ and

${\mp} 105^\circ $ and ![]() ${\mp} 120^\circ $. It should be noted that, in their set-up, the cylinder and the spanwise wires had a gap, which was 10 % of the cylinder diameter, and their mass ratio was quite high

${\mp} 120^\circ $. It should be noted that, in their set-up, the cylinder and the spanwise wires had a gap, which was 10 % of the cylinder diameter, and their mass ratio was quite high ![]() $({m^\ast } = 6.13)$.

$({m^\ast } = 6.13)$.

As seen from the review of the previous studies above, while the effects of spanwise wires have been well documented for fixed cylinders, such efforts have remained very limited for cylinders undergoing VIV. As reviewed above, only a few studies have investigated the VIV of cylinders tripped by spanwise wires, where the efforts have remained limited to having two to four wires at less than a handful of wire placement angles (at the most) on the cylinder surface, and these studies have lacked an understanding of the wire-induced changes in the flow patterns. Thus, there is an apparent lack of knowledge regarding the wire-induced flow structure and vibration response of flexibly mounted cylinders, where a wide range of wire locations needs to be systematically assessed. Furthermore, as the plurality of wires may complicate the development of a thorough understanding in the early stages, rather than starting with exploring the effects of two or more wires, as has been done in the previous VIV investigations that involved tripped cylinders, keeping the arrangement deliberately simple in the first steps by considering a single-wire application on the cylinder surface may provide guidance and explanation in deciphering the effects of more complex surface modifications. Previously, Joshi & Ekmekci (Reference Joshi and Ekmekci2019) used such an approach for stationary cylinders and successfully explained the origins of more complex effects of multi-wire spanwise tripping based on the understandings of single-wire tripping.

A further relevant point that has been totally overlooked by previous researchers is the effects of tripping when the cylinder undergoing VIV is free ended. All previous experiments in the literature concerning the VIV of a tripped cylinder utilized endplates that are either attached to the spanwise end of the cylinder or unattached with a very small gap from the cylinder, whereby VIV of surface-wire-fitted cylinders with a free-end condition remained unexplored. For example, Quadrante & Nishi (Reference Quadrante and Nishi2014) had attached endplates at the spanwise ends of the tripped cylinder, and the endplates used in Hover et al. (Reference Hover, Tvedt and Triantafyllou2001) had a small gap (2.6 % of the cylinder diameter), producing a VIV response as if the endplates were attached to the cylinder in accord with Morse et al. (Reference Morse, Govardhan and Williamson2008). As mentioned above, it is known for a plain cylinder undergoing VIV that the presence of a free spanwise end significantly changes the character of the vibration response (Morse et al. Reference Morse, Govardhan and Williamson2008). Understanding the effects of spanwise wires for such free-ended cylinders can find uses, for example, in energy harvesting applications. Although large-amplitude VIV in engineering structures is usually unwanted and should be avoided or mitigated to prevent structural damages, with recent advances in piezoelectric technology, VIV-based energy harvesting has started to gain attention (Erturk & Inman Reference Erturk and Inman2011). A recent example of such a study is the work of Azadeh-Ranjbar, Elvin & Andreopoulos (Reference Azadeh-ranjbar, Elvin and Andreopoulos2018), where the focus was on harvesting energy from the VIV of a plain, finite-length cylinder with spanwise free ends in a wind tunnel, where the cylinder was elastically mounted on a cantilever beam equipped with a piezoelectric patch. A simple possible arrangement for a VIV-based energy harvester extracting hydrokinetic energy from ocean or river flows may involve a flexibly mounted cylinder submerged in water with its top end piercing the free surface of the water while its bottom end is essentially free. Evaluating surface wire-induced effects on the VIV response of such a system is part of the stimulus of the present paper. Enhancing the amplitude of the structural oscillations by the effect of a wire could directly maximize the harvested energy.

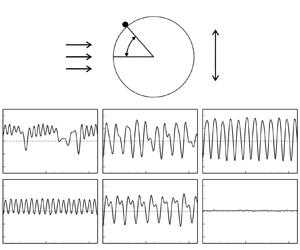

Taking the unresolved issues mentioned above into consideration, the current experimental research focuses on the effects of a single spanwise surface wire on the oscillation response and flow structure of a low mass-damping rigid circular cylinder undergoing VIV in the transverse direction. This elastically mounted cylinder was immersed in a free-surface water channel, leaving a free end at the bottom while its top end pierced the free surface of the water channel. To ensure that the system responds as if its bottom end is free, a sufficient gap was left between the bottom end of the cylinder and an unattached plate in accordance with Morse et al. (Reference Morse, Govardhan and Williamson2008). The focus of this study was on the lower synchronization branch because it is known from Morse et al. (Reference Morse, Govardhan and Williamson2008) for a plain cylinder undergoing VIV that the free spanwise end condition affects the lower synchronization branch the most, yielding vibration amplitudes much higher than the amplitudes that would be achieved if it were to end with an endplate. To address the shortcomings of the previous studies in this area, numerous wire positions are considered over the full range of angular positions on the cylinder surface from ![]() $\theta = 0^\circ $ to

$\theta = 0^\circ $ to ![]() $180^\circ $ (with respect to the most upstream point of the cylinder), while keeping the characteristics of the oscillation system (such as mass and damping) and the incoming flow properties constant. The oscillation motion and near-wake velocity fields are measured simultaneously to reveal the interplay between the vortex formation and the VIV response of the structure under the surface wire influence. The amplitude, frequency and time traces of structural oscillations are identified along with the associated vortex shedding modes for the entire range of wire locations. These results led to the first-time identification of several VIV response categories depending on the wire location. As an important outcome of this work, the spanwise wire at specific positions is shown to be effective in suppressing or amplifying the VIV of the cylinder in question. In comparison with the oscillation amplitude of the clean cylinder under identical conditions, up to 98 % amplitude reduction and 102 % amplitude increase in cylinder oscillations are shown to be possible in this study through the use of the single spanwise surface wire.

$180^\circ $ (with respect to the most upstream point of the cylinder), while keeping the characteristics of the oscillation system (such as mass and damping) and the incoming flow properties constant. The oscillation motion and near-wake velocity fields are measured simultaneously to reveal the interplay between the vortex formation and the VIV response of the structure under the surface wire influence. The amplitude, frequency and time traces of structural oscillations are identified along with the associated vortex shedding modes for the entire range of wire locations. These results led to the first-time identification of several VIV response categories depending on the wire location. As an important outcome of this work, the spanwise wire at specific positions is shown to be effective in suppressing or amplifying the VIV of the cylinder in question. In comparison with the oscillation amplitude of the clean cylinder under identical conditions, up to 98 % amplitude reduction and 102 % amplitude increase in cylinder oscillations are shown to be possible in this study through the use of the single spanwise surface wire.

2. Experimental set-up

Experiments were conducted in a recirculating water tunnel at the University of Toronto Institute for Aerospace Studies. The main test section of this tunnel is 5000 mm long and has a width of 610 mm and a height of 685 mm. The free-stream turbulence intensity is less than 0.5 % and the flow uniformity is better than 0.3 % within the test section. The test section walls are made out of Plexiglas material to allow visual access to the flow. The current study required the test model, which was mounted to a mechanism above the tunnel, to go through VIV. The top tunnel wall was removed to permit those oscillations, yielding an end condition where the cylinder pierced the water surface.

The test model was a rigid polycarbonate circular cylinder with a diameter of ![]() $D = 50.8\;\textrm{mm}$ and a length of

$D = 50.8\;\textrm{mm}$ and a length of ![]() $L = 534\;\textrm{mm}$, giving a cylinder aspect ratio of

$L = 534\;\textrm{mm}$, giving a cylinder aspect ratio of ![]() $L/D = 10.5$. A transparent acrylic wire was tightly stretched and glued on the surface of this cylinder, parallel to its span. The diameter of this wire was

$L/D = 10.5$. A transparent acrylic wire was tightly stretched and glued on the surface of this cylinder, parallel to its span. The diameter of this wire was ![]() $d = 3.175\;\textrm{mm}$, which means the wire-to-cylinder diameter ratio was

$d = 3.175\;\textrm{mm}$, which means the wire-to-cylinder diameter ratio was ![]() $d/D = 0.0625$. All tests concerning the wire-fitted cylinder (both stationary and free oscillating) were carried out at a free-stream velocity of

$d/D = 0.0625$. All tests concerning the wire-fitted cylinder (both stationary and free oscillating) were carried out at a free-stream velocity of ![]() $U = 0.186\;\textrm{m}\;{\textrm{s}^{ - 1}}$, which corresponds to a cylinder-diameter-based Reynolds number of

$U = 0.186\;\textrm{m}\;{\textrm{s}^{ - 1}}$, which corresponds to a cylinder-diameter-based Reynolds number of ![]() $Re = 10\,000$. The surface wire used was larger than the boundary layer thickness forming around an equivalent plain circular cylinder at this Reynolds number. This inference is based on the boundary layer thickness data provided by Aydin et al. (Reference Aydin, Joshi and Ekmekci2014). For experiments where the VIV response branches of the plain cylinder (without a surface wire) were investigated by collecting the amplitude versus reduced velocity data, a free-stream velocity range of

$Re = 10\,000$. The surface wire used was larger than the boundary layer thickness forming around an equivalent plain circular cylinder at this Reynolds number. This inference is based on the boundary layer thickness data provided by Aydin et al. (Reference Aydin, Joshi and Ekmekci2014). For experiments where the VIV response branches of the plain cylinder (without a surface wire) were investigated by collecting the amplitude versus reduced velocity data, a free-stream velocity range of ![]() $U = 0.057\;\textrm{m}\;{\textrm{s}^{ - 1}}$ to

$U = 0.057\;\textrm{m}\;{\textrm{s}^{ - 1}}$ to ![]() $0.258\;\textrm{m}\;{\textrm{s}^{ - 1}}$ was used, corresponding to a Reynolds number range of

$0.258\;\textrm{m}\;{\textrm{s}^{ - 1}}$ was used, corresponding to a Reynolds number range of ![]() $Re = 3000$ to

$Re = 3000$ to ![]() $12\,500$. The angular position of the wire on the cylinder surface was changed by rotating the cylinder–wire arrangement around the longitudinal axis of the cylinder using a computer-controlled, high-precision step motor. The wire angular positions considered in the investigation ranged from

$12\,500$. The angular position of the wire on the cylinder surface was changed by rotating the cylinder–wire arrangement around the longitudinal axis of the cylinder using a computer-controlled, high-precision step motor. The wire angular positions considered in the investigation ranged from ![]() $\theta = 0^\circ $ to

$\theta = 0^\circ $ to ![]() $180^\circ $ (

$180^\circ $ (![]() $\theta \; = 0^\circ $ being the most upstream point of the cylinder). The angular increment of the wire position was

$\theta \; = 0^\circ $ being the most upstream point of the cylinder). The angular increment of the wire position was ![]() $0.2^\circ $,

$0.2^\circ $, ![]() $1^\circ $,

$1^\circ $, ![]() $2^\circ $ or

$2^\circ $ or ![]() $5^\circ $, depending on the angular resolution needed to detect the changes in the cylinder response and flow field. Whenever significant changes in cylinder response and/or flow field occurred with a change in wire location, a smaller angular increment was selected. The accuracy of the motorized angular positioning system was

$5^\circ $, depending on the angular resolution needed to detect the changes in the cylinder response and flow field. Whenever significant changes in cylinder response and/or flow field occurred with a change in wire location, a smaller angular increment was selected. The accuracy of the motorized angular positioning system was ![]() $0.067^\circ $; however, the reported angular positions of the wire on the cylinder surface had an uncertainty of

$0.067^\circ $; however, the reported angular positions of the wire on the cylinder surface had an uncertainty of ![]() ${\pm} 1.4^\circ $ due to the added uncertainty in defining the zero-reference angle (i.e. the most upstream point of the cylinder).

${\pm} 1.4^\circ $ due to the added uncertainty in defining the zero-reference angle (i.e. the most upstream point of the cylinder).

The entire length of the model was immersed vertically inside the water channel. Its top end was attached to a mechanism, as shown in figure 1, which permitted the model to vibrate in the cross-stream direction as a result of fluid forcing while preventing motion in the streamwise direction. For tests where the surface-wire-fitted cylinder was kept stationary (non-oscillating), this same mechanism was still utilized, but with the addition of a stopper that prevented structural vibrations. For the stationary cylinder experiments, the lower end of the cylinder was bounded by an endplate, with no gap left between the cylinder and the endplate. The endplate was made out of transparent Plexiglas material of ![]() $0.25D$ thickness. Its streamwise length was

$0.25D$ thickness. Its streamwise length was ![]() $7.5D$, and its width covered the entire width of the channel

$7.5D$, and its width covered the entire width of the channel ![]() $(12D)$. A

$(12D)$. A ![]() $23.6^\circ $ full-depth bevel was put on its upstream end, with the bevel facing the channel floor to minimize disturbances to the inflow. In accord with the recommendations of Stansby (Reference Stansby1974), Szepessy & Bearman (Reference Szepessy and Bearman1992) and Khoury (Reference Khoury2012), the cylinder axis was situated

$23.6^\circ $ full-depth bevel was put on its upstream end, with the bevel facing the channel floor to minimize disturbances to the inflow. In accord with the recommendations of Stansby (Reference Stansby1974), Szepessy & Bearman (Reference Szepessy and Bearman1992) and Khoury (Reference Khoury2012), the cylinder axis was situated ![]() $3D$ downstream of the leading edge of the endplate. This endplate design is consistent with those used in the previous literature for stationary cylinders (Ekmekci Reference Ekmekci2006; Ekmekci & Rockwell Reference Ekmekci and Rockwell2010; Aydin et al. Reference Aydin, Joshi and Ekmekci2014; Joshi & Ekmekci Reference Joshi and Ekmekci2019). For all experiments involving free oscillations of the cylinder, a gap equal to 13.8 % of the cylinder diameter (a gap spacing of 7 mm) was left between the bottom end of the cylinder and the endplate to induce conditions of a free-ended cylinder in accord with Morse et al. (Reference Morse, Govardhan and Williamson2008). In § 3.2, the VIV response of the plain cylinder with this end condition will be compared with the results from this reference to show that this gap left beneath the bottom end of the cylinder was sufficient to generate the response of a free-ended cylinder. The two-dimensionality of the flow field with this test set-up was assessed for the oscillating cylinder and proven to be sufficient in Vaziri (Reference Vaziri2021). The Froude number based on the cylinder length was

$3D$ downstream of the leading edge of the endplate. This endplate design is consistent with those used in the previous literature for stationary cylinders (Ekmekci Reference Ekmekci2006; Ekmekci & Rockwell Reference Ekmekci and Rockwell2010; Aydin et al. Reference Aydin, Joshi and Ekmekci2014; Joshi & Ekmekci Reference Joshi and Ekmekci2019). For all experiments involving free oscillations of the cylinder, a gap equal to 13.8 % of the cylinder diameter (a gap spacing of 7 mm) was left between the bottom end of the cylinder and the endplate to induce conditions of a free-ended cylinder in accord with Morse et al. (Reference Morse, Govardhan and Williamson2008). In § 3.2, the VIV response of the plain cylinder with this end condition will be compared with the results from this reference to show that this gap left beneath the bottom end of the cylinder was sufficient to generate the response of a free-ended cylinder. The two-dimensionality of the flow field with this test set-up was assessed for the oscillating cylinder and proven to be sufficient in Vaziri (Reference Vaziri2021). The Froude number based on the cylinder length was ![]() $F{r_L} = U/\sqrt {gL} = 0.08$, indicating a subcritical flow in the water channel. Also, the maximum elevation changes of the water around the cylinder were observed to be very small (close to the approximations provided by Hay Reference Hay1947 and Chaplin & Teigen Reference Chaplin and Teigen2003). Therefore, the effects associated with free-surface distortions on the response of the cylinder can be neglected in accord with Gonçlves et al. (Reference Gonçalves, Rosetti, Franzini, Meneghini and Fujarra2013). The channel blockage ratio for the experimental set-up was

$F{r_L} = U/\sqrt {gL} = 0.08$, indicating a subcritical flow in the water channel. Also, the maximum elevation changes of the water around the cylinder were observed to be very small (close to the approximations provided by Hay Reference Hay1947 and Chaplin & Teigen Reference Chaplin and Teigen2003). Therefore, the effects associated with free-surface distortions on the response of the cylinder can be neglected in accord with Gonçlves et al. (Reference Gonçalves, Rosetti, Franzini, Meneghini and Fujarra2013). The channel blockage ratio for the experimental set-up was ![]() $5.8\,\%$.

$5.8\,\%$.

Figure 1. Three-dimensional sketch of the experimental set-up.

To conduct free-oscillation experiments, a unique mechanism was designed with attention to minimizing the mass ratio ![]() ${m^\ast }$ and damping ratio

${m^\ast }$ and damping ratio ![]() $\zeta $ of the system. This mechanism was sitting atop the water channel, as seen in the sketch in figure 1. This mechanism consisted of a rotary step motor to which the cylinder was attached, a mounting square where the step motor and two supporting shafts were connected, two linear extension springs, two spring holders and four air bushings. The springs were placed between the mounting square and the spring holder on each side of the model. The use of air bushing technology in this set-up reduced the structural friction significantly while constraining the cylinder–wire model to move only in the transverse direction (perpendicular to the flow direction). The rotary step motor, mounting square and two supporting shafts were the components that moved with the cylinder while the spring holders and air bushings were fixed to the tunnel. During calibration of the mechanism in air, the response matched with the response of a damped harmonic oscillator with an average correlation coefficient of 0.953, signifying that the mechanism used behaves as a linear system. A detailed discussion of this mechanism and the determination of the damping ratio

$\zeta $ of the system. This mechanism was sitting atop the water channel, as seen in the sketch in figure 1. This mechanism consisted of a rotary step motor to which the cylinder was attached, a mounting square where the step motor and two supporting shafts were connected, two linear extension springs, two spring holders and four air bushings. The springs were placed between the mounting square and the spring holder on each side of the model. The use of air bushing technology in this set-up reduced the structural friction significantly while constraining the cylinder–wire model to move only in the transverse direction (perpendicular to the flow direction). The rotary step motor, mounting square and two supporting shafts were the components that moved with the cylinder while the spring holders and air bushings were fixed to the tunnel. During calibration of the mechanism in air, the response matched with the response of a damped harmonic oscillator with an average correlation coefficient of 0.953, signifying that the mechanism used behaves as a linear system. A detailed discussion of this mechanism and the determination of the damping ratio ![]() $\zeta $ and natural frequency

$\zeta $ and natural frequency ![]() ${f_n}$ of the system via a ‘pluck test’ can be found in Vaziri (Reference Vaziri2021). The free-oscillation system used in the present study, as a whole, had a mass ratio of

${f_n}$ of the system via a ‘pluck test’ can be found in Vaziri (Reference Vaziri2021). The free-oscillation system used in the present study, as a whole, had a mass ratio of ![]() ${m^\ast } = 2.581$, a damping ratio of

${m^\ast } = 2.581$, a damping ratio of ![]() $\zeta = 0.027$ and its natural frequency was

$\zeta = 0.027$ and its natural frequency was ![]() ${f_n} = 0.36\;\textrm{Hz}$.

${f_n} = 0.36\;\textrm{Hz}$.

A high-resolution laser distance sensor (Wenglor CP24MHT80) was mounted at a fixed position on top of the channel (see figure 1) to capture the instantaneous position of the cylinder with no contact. Its output voltage was sampled at a frequency of ![]() $1000\;\textrm{Hz}$. The uncertainty of the cylinder position, captured by this sensor, is

$1000\;\textrm{Hz}$. The uncertainty of the cylinder position, captured by this sensor, is ![]() $0.025D,$ and the uncertainty associated with the frequency of the acquired oscillation motion of the cylinder is

$0.025D,$ and the uncertainty associated with the frequency of the acquired oscillation motion of the cylinder is ![]() ${\pm} 0.005\;\textrm{Hz}$.

${\pm} 0.005\;\textrm{Hz}$.

The motion of the cylinder undergoing free vibrations can be highly irregular for some surface wire positions. As a result, the amplitude of oscillations cannot be simply defined as half of the difference between the maximum (peak) and minimum (valley) points in the displacement signal. To account for the variations in peaks and valleys, the present study reported the cylinder amplitude as half of the distance swept by the cylinder between the overall upper and lower limits of the oscillation motion. The overall upper limit was defined as the average value of peaks ![]() ${\bar{y}_p}$ plus the standard deviation of the peak values

${\bar{y}_p}$ plus the standard deviation of the peak values ![]() ${\sigma _p}$. Similarly, the overall lower limit was defined as the average value of valleys

${\sigma _p}$. Similarly, the overall lower limit was defined as the average value of valleys ![]() ${\bar{y}_v}$ minus the standard deviation of valley values

${\bar{y}_v}$ minus the standard deviation of valley values ![]() ${\sigma _v}$. To employ this method, a peak detection algorithm was applied to the time series of the displacement signal to determine the peaks

${\sigma _v}$. To employ this method, a peak detection algorithm was applied to the time series of the displacement signal to determine the peaks ![]() ${y_p}$ and valleys

${y_p}$ and valleys ![]() ${y_v}$. Then, the following expression was used to determine the oscillation amplitude normalized by the cylinder diameter:

${y_v}$. Then, the following expression was used to determine the oscillation amplitude normalized by the cylinder diameter:

High-image-density PIV was used to capture the velocity field information in the near wake. For this technique, the flow was seeded with neutrally buoyant hollow-glass particles, having a nominal mean diameter of 8 to 1 μm. Illumination of the flow field was achieved using a double-pulsed Nd:YAG laser system with a maximum energy output of 20 mJ pulse−1 at a wavelength of ![]() $532\;\textrm{nm}$. A series of cylindrical and spherical lenses converted the laser-beam output of this system to a laser sheet, which illuminated the planar flow region of interest. In all tests, a sequence of 1000 image pairs was recorded at a rate of 14.5 frame pairs per second via a PowerView Plus 2 MP CCD camera, which had an array size of

$532\;\textrm{nm}$. A series of cylindrical and spherical lenses converted the laser-beam output of this system to a laser sheet, which illuminated the planar flow region of interest. In all tests, a sequence of 1000 image pairs was recorded at a rate of 14.5 frame pairs per second via a PowerView Plus 2 MP CCD camera, which had an array size of ![]() $1600 \times 1200$ pixels. This sampling rate corresponded to approximately 69 s of sequential data acquisition. For tests involving cylinder vibrations, the PIV data acquisition was synchronized with the laser distance sensor data employing a LaserPulse Model 610035 synchronizer. As seen in figure 1, the laser sheet was aligned horizontally, and the CCD camera was placed vertically beneath the water channel. The acquired field of view during the free-oscillation tests covered

$1600 \times 1200$ pixels. This sampling rate corresponded to approximately 69 s of sequential data acquisition. For tests involving cylinder vibrations, the PIV data acquisition was synchronized with the laser distance sensor data employing a LaserPulse Model 610035 synchronizer. As seen in figure 1, the laser sheet was aligned horizontally, and the CCD camera was placed vertically beneath the water channel. The acquired field of view during the free-oscillation tests covered ![]() $2.1D$ in the streamwise direction starting from the cylinder's most downstream point and had a total length of

$2.1D$ in the streamwise direction starting from the cylinder's most downstream point and had a total length of ![]() $3.2D$ in the cross-stream direction. This field of view included the downstream regions of both shear layers separating from the oscillating cylinder. For the stationary cylinder, the field of visualization was

$3.2D$ in the cross-stream direction. This field of view included the downstream regions of both shear layers separating from the oscillating cylinder. For the stationary cylinder, the field of visualization was ![]() $3D \times 2.2D$, which also contained the two shear layers separating from the cylinder. During image processing, an interrogation window size of 32 × 32 was used with an overlap of 50 %, producing a total of 7227 velocity vectors

$3D \times 2.2D$, which also contained the two shear layers separating from the cylinder. During image processing, an interrogation window size of 32 × 32 was used with an overlap of 50 %, producing a total of 7227 velocity vectors ![]() $(99 \times 73)$ for both the free-oscillation and stationary cylinder tests. Based on the dimensions of the field of view, the velocity vector resolution for the PIV data was approximately

$(99 \times 73)$ for both the free-oscillation and stationary cylinder tests. Based on the dimensions of the field of view, the velocity vector resolution for the PIV data was approximately ![]() $0.0321D$ for the free-oscillation tests and

$0.0321D$ for the free-oscillation tests and ![]() $0.0297D$ for the stationary cylinder tests. The dominant frequency of the streamwise and transverse velocity components (

$0.0297D$ for the stationary cylinder tests. The dominant frequency of the streamwise and transverse velocity components (![]() ${f_u}$ and

${f_u}$ and ![]() ${f_v}$) over the global flow field was determined by applying fast Fourier transformation (FFT) to PIV snapshots. The selected size of the visualization field provided sufficient spatial resolution for both velocity vectors and the autospectral density amplitude of velocity fluctuations. The uncertainty associated with the frequency of velocity fluctuations obtained from the FFT of the PIV data was

${f_v}$) over the global flow field was determined by applying fast Fourier transformation (FFT) to PIV snapshots. The selected size of the visualization field provided sufficient spatial resolution for both velocity vectors and the autospectral density amplitude of velocity fluctuations. The uncertainty associated with the frequency of velocity fluctuations obtained from the FFT of the PIV data was ![]() ${\pm} 0.007\;\textrm{Hz}$.

${\pm} 0.007\;\textrm{Hz}$.

3. Results

The focus of the present study is on developing an understanding of the structural oscillations and vortex shedding characteristics of a surface-wire-fitted, elastically mounted cylinder moving in the transverse direction with low mass-damping and one free end. The wire influence is assessed for having a single wire at different locations on the surface of the cylinder. First, before studying the impact of the wire on the elastically mounted cylinder that undergoes free transverse oscillations, the influence of the wire on the near-wake flow structure of the stationary cylinder for varying wire positions will be discussed in § 3.1 to form the baseline scenario. Then, in § 3.2, the oscillation response of the plain (untripped) cylinder as a function of reduced velocity for the end conditions and system parameters used in the VIV tests of this study will be characterized and compared with a similar previous investigation. Section 3.3 is where the results related to the wire-fitted cylinder undergoing free-oscillation motion will be presented. Therein, the § 3.3.1 will focus on the oscillation characteristics of the wire-fitted cylinder (again for various wire locations), while in § 3.3.2 the unsteady near-wake flow structure will be discussed for the same oscillating cylinder with the surface wire at different locations, and the vortex shedding frequency in comparison with the frequency of cylinder oscillations will be examined to explore the link between the structural oscillations and the flow field characteristics. Finally, in § 4, the conclusions will be outlined.

3.1. The surface-wire-fitted cylinder under stationary condition

For a stationary circular cylinder, it is known that several critical angular locations can be defined on its surface for the application of a large-scale wire. Most of these critical locations are related to distinct changes in the trend of the non-dimensional vortex shedding frequency (i.e. Strouhal number) with the change of the wire location, as shown by Nebres & Batill (Reference Nebres and Batill1993). Two specific critical angles are related to the attenuation and intensification of the Kármán instability. They can be distinguished as locations where the application of the wire significantly attenuates or intensifies the spectral amplitude of velocity fluctuations at the Kármán frequency, as addressed by Ekmekci (Reference Ekmekci2006), Ekmekci & Rockwell (Reference Ekmekci and Rockwell2010) and Aydin et al. (Reference Aydin, Joshi and Ekmekci2014). Critical locations generally depend on the wire diameter to cylinder diameter ratio ![]() $(d/D)$ and the Reynolds number (Nebres & Batill Reference Nebres and Batill1993; Aydin & Ekmekci Reference Aydin and Ekmekci2014). Among all the critical locations, those that are based on the spectral amplitude of velocity fluctuations associated with the Kármán instability are called the first and second critical locations

$(d/D)$ and the Reynolds number (Nebres & Batill Reference Nebres and Batill1993; Aydin & Ekmekci Reference Aydin and Ekmekci2014). Among all the critical locations, those that are based on the spectral amplitude of velocity fluctuations associated with the Kármán instability are called the first and second critical locations ![]() ${\theta _{c1}}$ and

${\theta _{c1}}$ and ![]() ${\theta _{c2}}$. A brief overview of these two critical angles and their essential features were discussed in the introduction section earlier.

${\theta _{c2}}$. A brief overview of these two critical angles and their essential features were discussed in the introduction section earlier.

For the ![]() $d/D$ ratio and Reynolds number used in the present study, the first critical angle

$d/D$ ratio and Reynolds number used in the present study, the first critical angle ![]() ${\theta _{c1}}$ ranged from

${\theta _{c1}}$ ranged from ![]() $41.2^\circ $ to

$41.2^\circ $ to ![]() $43^\circ $, and the second critical angle

$43^\circ $, and the second critical angle ![]() ${\theta _{c2}}$ ranged from

${\theta _{c2}}$ ranged from ![]() $50^\circ $ to

$50^\circ $ to ![]() $80^\circ $. These angular ranges are determined in the current study by evaluating the autospectra of the flow velocity taken from the PIV measurements in the near wake. It should be noted that the angular resolution of the test cases in these PIV experiments was refined to

$80^\circ $. These angular ranges are determined in the current study by evaluating the autospectra of the flow velocity taken from the PIV measurements in the near wake. It should be noted that the angular resolution of the test cases in these PIV experiments was refined to ![]() $0.2^\circ $ around these critical locations. The

$0.2^\circ $ around these critical locations. The ![]() ${\theta _{c1}}$ and

${\theta _{c1}}$ and ![]() ${\theta _{c2}}$ locations obtained in the present study show good correspondence with the values reported earlier by Joshi & Ekmekci (Reference Joshi and Ekmekci2019), where the range of

${\theta _{c2}}$ locations obtained in the present study show good correspondence with the values reported earlier by Joshi & Ekmekci (Reference Joshi and Ekmekci2019), where the range of ![]() ${\theta _{c1}}$ was reported as

${\theta _{c1}}$ was reported as ![]() $42^\circ $ to

$42^\circ $ to ![]() $44.5^\circ $, and the range of

$44.5^\circ $, and the range of ![]() ${\theta _{c2}}$ was

${\theta _{c2}}$ was ![]() $52^\circ $ to

$52^\circ $ to ![]() $80^\circ $ for the same

$80^\circ $ for the same ![]() $d/D$ ratio and Reynolds number. The slight discrepancy in the reported ranges of critical angles between the present study and Joshi and Ekmekci's study can be attributed to the error in defining the

$d/D$ ratio and Reynolds number. The slight discrepancy in the reported ranges of critical angles between the present study and Joshi and Ekmekci's study can be attributed to the error in defining the ![]() $\theta = 0^\circ $ wire location (

$\theta = 0^\circ $ wire location (![]() ${\pm} 1.4^\circ $ in the present study) and the arrangement of the experimental set-up (i.e. use of the open channel flow in the present study versus closed water tunnel in the Joshi and Ekmekci's work).

${\pm} 1.4^\circ $ in the present study) and the arrangement of the experimental set-up (i.e. use of the open channel flow in the present study versus closed water tunnel in the Joshi and Ekmekci's work).

The contour patterns in figure 2 illustrate the autospectral density of streamwise velocity fluctuations at the predominant Kármán frequency, ![]() ${S_u}(St)$, for the case where the wire is at the second critical position

${S_u}(St)$, for the case where the wire is at the second critical position ![]() ${\theta _{c2}} = 58.2^\circ $ and the case representing the non-tripped scenario

${\theta _{c2}} = 58.2^\circ $ and the case representing the non-tripped scenario ![]() $(\theta = 180^\circ )$. It is known from previous work on stationary cylinders that, being at the base region, a surface wire at

$(\theta = 180^\circ )$. It is known from previous work on stationary cylinders that, being at the base region, a surface wire at ![]() $\theta = 180^\circ $ shows no significant influence on the strength and coherence of the Kármán instability (Nebres & Batill Reference Nebres and Batill1993; Ekmekci & Rockwell Reference Ekmekci and Rockwell2010). Also, in this figure, the global contour patterns of autospectral density are shown for the first critical angle

$\theta = 180^\circ $ shows no significant influence on the strength and coherence of the Kármán instability (Nebres & Batill Reference Nebres and Batill1993; Ekmekci & Rockwell Reference Ekmekci and Rockwell2010). Also, in this figure, the global contour patterns of autospectral density are shown for the first critical angle ![]() ${\theta _{c1}} = 41.6^\circ $ at the frequency corresponding to the bistable flow separation, as identified by Ekmekci & Rockwell (Reference Ekmekci and Rockwell2010). To obtain these results, first, the autospectral density of the streamwise velocity fluctuations was determined at a total of 7227 locations over the global near-wake region from the PIV data. Then, the autospectral magnitude corresponding to the frequency in question was extracted from each spectrum and shown as a contour plot. The frequencies corresponding to the autospectral density contours in figure 2 are indicated in the insets in terms of Strouhal number

${\theta _{c1}} = 41.6^\circ $ at the frequency corresponding to the bistable flow separation, as identified by Ekmekci & Rockwell (Reference Ekmekci and Rockwell2010). To obtain these results, first, the autospectral density of the streamwise velocity fluctuations was determined at a total of 7227 locations over the global near-wake region from the PIV data. Then, the autospectral magnitude corresponding to the frequency in question was extracted from each spectrum and shown as a contour plot. The frequencies corresponding to the autospectral density contours in figure 2 are indicated in the insets in terms of Strouhal number ![]() $St$. It should be noted here that the value of the dominant

$St$. It should be noted here that the value of the dominant ![]() $St$ varies as a function of the wire application location

$St$ varies as a function of the wire application location ![]() $\theta $, as reported in previous investigations (Ekmekci & Rockwell Reference Ekmekci and Rockwell2010; Aydin et al. Reference Aydin, Joshi and Ekmekci2014). When the wire is applied at the first critical angle

$\theta $, as reported in previous investigations (Ekmekci & Rockwell Reference Ekmekci and Rockwell2010; Aydin et al. Reference Aydin, Joshi and Ekmekci2014). When the wire is applied at the first critical angle ![]() ${\theta _{c1}}$, figure 2 shows that the bistable separation of the shear layer induces moderate levels of low-frequency activity (at

${\theta _{c1}}$, figure 2 shows that the bistable separation of the shear layer induces moderate levels of low-frequency activity (at ![]() $St = 0.004$) in the upper shear layer separating from the wire side of the cylinder; however, a dominant frequency corresponding to the Kármán vortex shedding did not exist for this case in the entire near wake, implying an attenuation in the Kármán vortex shedding process. The wire at the second critical angle

$St = 0.004$) in the upper shear layer separating from the wire side of the cylinder; however, a dominant frequency corresponding to the Kármán vortex shedding did not exist for this case in the entire near wake, implying an attenuation in the Kármán vortex shedding process. The wire at the second critical angle ![]() ${\theta _{c2}}$ enhances the strength and coherence of the Kármán instability as apparent from the existence of high autospectral amplitudes in the near wake. These results are in total agreement with the results shown earlier for a wire-fitted stationary cylinder by Ekmekci & Rockwell (Reference Ekmekci and Rockwell2010).

${\theta _{c2}}$ enhances the strength and coherence of the Kármán instability as apparent from the existence of high autospectral amplitudes in the near wake. These results are in total agreement with the results shown earlier for a wire-fitted stationary cylinder by Ekmekci & Rockwell (Reference Ekmekci and Rockwell2010).

Figure 2. Contours of autospectral density of the streamwise velocity fluctuations at the specific Strouhal number value indicated in the inset for the stationary cylinder fitted with the surface wire at the first ![]() ${\theta _{c1}}$ and second

${\theta _{c1}}$ and second ![]() ${\theta _{c2}}$ critical angles, and at

${\theta _{c2}}$ critical angles, and at ![]() $\theta = 180^\circ \; $(representing the clean cylinder). Minimum and incremental values of the contours are

$\theta = 180^\circ \; $(representing the clean cylinder). Minimum and incremental values of the contours are ![]() ${[|{S_u}(St)|]_{min}} = 25\;\textrm{mm}\;{\textrm{s}^{ - 1}}$ and

${[|{S_u}(St)|]_{min}} = 25\;\textrm{mm}\;{\textrm{s}^{ - 1}}$ and ![]() $\Delta [|{S_u}(St)|] = 2.5\;\textrm{mm}\;{\textrm{s}^{ - 1}}$.

$\Delta [|{S_u}(St)|] = 2.5\;\textrm{mm}\;{\textrm{s}^{ - 1}}$.

From the global spectrum results discussed in this section, it is apparent that the surface wire used in this study affects the Kármán vortex shedding substantially for the stationary cylinder. Plausibly, it is not unreasonable to expect the spanwise wire to affect the oscillation response of a cylinder undergoing VIV significantly. For example, the observed time-averaged attenuation of the Kármán vortex shedding with the wire at ![]() ${\theta _{c1}}$ position for the stationary cylinder suggests that VIV may be suppressed when the wire is placed at this critical location. With similar reasoning, because of the observed enhancement in the coherence and strength of the Kármán vortex shedding with the placement of the wire at

${\theta _{c1}}$ position for the stationary cylinder suggests that VIV may be suppressed when the wire is placed at this critical location. With similar reasoning, because of the observed enhancement in the coherence and strength of the Kármán vortex shedding with the placement of the wire at ![]() ${\theta _{c2}}$ in the stationary cylinder case, the wire at the same critical location may be expected to aggravate the VIV response of an elastically mounted cylinder. However, as will be seen in § 3.3, the effects of the spanwise wire on the free-oscillation motion of the cylinder are not as expected at the critical angles of the stationary cylinder. Other critical locations will be identified where the placement of the wire substantially affects the characteristics of the cylinder oscillations and the flow field.

${\theta _{c2}}$ in the stationary cylinder case, the wire at the same critical location may be expected to aggravate the VIV response of an elastically mounted cylinder. However, as will be seen in § 3.3, the effects of the spanwise wire on the free-oscillation motion of the cylinder are not as expected at the critical angles of the stationary cylinder. Other critical locations will be identified where the placement of the wire substantially affects the characteristics of the cylinder oscillations and the flow field.

3.2. The VIV response of the plain cylinder

Figure 3 shows the variation of the vibration amplitude ![]() ${A^\ast }$ with reduced velocity

${A^\ast }$ with reduced velocity ![]() ${U^\ast }$ for the plain version of the cylinder used in this study (i.e. cylinder without a wire) as it undergoes VIV with the end conditions and system parameters used throughout this investigation compared with those obtained by Morse et al. (Reference Morse, Govardhan and Williamson2008). In the referenced work, the top end of their submerged plain cylinder was bounded by the free surface of the water channel as in the present study, while different end conditions were considered for the lower end. The response plots for two of these end conditions are included in figure 3. These are: the case with an unattached endplate, leaving a gap of 2 mm (which corresponds to a distance of 4 % of the cylinder diameter) at the bottom end of the cylinder, and the case with no endplate. They noticed that the free vibration response of the cylinder when the endplate is unattached with such a small gap is nearly equivalent to the response for having the plate attached to the cylinder, with the typical initial, upper and lower response branches (as seen in the response plot corresponding to the unattached plate case taken from Morse et al. Reference Morse, Govardhan and Williamson2008 in figure 3). However, with no endplate, the free-ended cylinder depicts remarkable distinctions in its response plot. While the peak amplitude in the upper branch stays almost unchanged, the vibration amplitude of the case with no endplate shows a gradual decrease from this peak as

${U^\ast }$ for the plain version of the cylinder used in this study (i.e. cylinder without a wire) as it undergoes VIV with the end conditions and system parameters used throughout this investigation compared with those obtained by Morse et al. (Reference Morse, Govardhan and Williamson2008). In the referenced work, the top end of their submerged plain cylinder was bounded by the free surface of the water channel as in the present study, while different end conditions were considered for the lower end. The response plots for two of these end conditions are included in figure 3. These are: the case with an unattached endplate, leaving a gap of 2 mm (which corresponds to a distance of 4 % of the cylinder diameter) at the bottom end of the cylinder, and the case with no endplate. They noticed that the free vibration response of the cylinder when the endplate is unattached with such a small gap is nearly equivalent to the response for having the plate attached to the cylinder, with the typical initial, upper and lower response branches (as seen in the response plot corresponding to the unattached plate case taken from Morse et al. Reference Morse, Govardhan and Williamson2008 in figure 3). However, with no endplate, the free-ended cylinder depicts remarkable distinctions in its response plot. While the peak amplitude in the upper branch stays almost unchanged, the vibration amplitude of the case with no endplate shows a gradual decrease from this peak as ![]() ${U^\ast }$ is increased, with this trend continuing in the lower branch. Also, no sign of a jump is distinguishable between the upper and lower branches for the no-endplate response. An important finding in their study is that the vibration response of the cylinder with the unattached endplate becomes equivalent to the response of the free-ended cylinder (with no endplate at all), provided that the unattached plate case has a large enough gap. This gap was estimated in their study to be around 15 % of the cylinder diameter, which means that for a 50.8 mm-diameter cylinder, the gap should be close to approximately 7.6 mm or above to produce the vibration response of a free-ended cylinder. In the present investigation, leaving a gap of 7 mm between the free end of the cylinder and the endplate yielded the response plot given in figure 3, which exhibits good correspondence with the no-endplate case of Morse et al. (Reference Morse, Govardhan and Williamson2008). It shows a gradual decrease from the peak amplitude in the upper branch until the end of the lower branch, with no distinct transitional jump between the two branches. Because the response data in the present study are from a system with slightly higher mass-damping than the no-endplate case of Morse et al. (Reference Morse, Govardhan and Williamson2008), the amplitudes in the upper branch are smaller in the present study compared with theirs. Also, having a smaller mass ratio compared with theirs results in the range of synchronization being wider in the present, in accord with Govardhan & Williamson (Reference Govardhan and Williamson2000). Consequently, a one-to-one comparison of the response plots between the present study and the no-endplate case of Morse et al. (Reference Morse, Govardhan and Williamson2008) shows that the 7 mm gap left between the lower end of the cylinder and the unattached endplate is sufficient to produce the response of a free-ended cylinder.