1. Introduction

The presence of surface active agents (surfactants) can significantly alter the surface properties of a liquid and give rise to interesting phenomena, such as tip streaming from a highly deformed liquid droplet submerged in a shear or extensional flow (Eggers Reference Eggers1997; Anna Reference Anna2016; Montanero & Gañán-Calvo Reference Montanero and Gañán-Calvo2020) and flower-like patterning of an evaporating liquid droplet spreading on a liquid substrate (Wodlei et al. Reference Wodlei, Sebilleau, Magnaudet and Pimienta2018). In a variety of applications including atomization, ink-jet printing, spinning, coating, emulsification, enhanced oil recovery, microfluidics, food industry and drug delivery, the addition of surfactant molecules can help to control actively and easily the motion, spread, transport, formation, deformation and breakup of films, jets, threads, drops, bubbles, colloids or biological molecules. Surfactants have been one of the most attractive and most studied factors in those liquid–air surface and liquid–liquid interfacial problems in the last three decades (Eggers & Villermaux Reference Eggers and Villermaux2008; Vlahovska Reference Vlahovska2019; Montanero & Gañán-Calvo Reference Montanero and Gañán-Calvo2020). Nevertheless, the underlying mechanisms have not yet been fully understood.

An insoluble surfactant monolayer at a liquid surface may affect the dynamics of the liquid in three ways (Kamat et al. Reference Kamat, Wagoner, Thete and Basaran2018; Montanero & Gañán-Calvo Reference Montanero and Gañán-Calvo2020; Wee, Wagoner & Basaran Reference Wee, Wagoner and Basaran2022): it lowers the average capillary force by reducing the surface tension coefficient, i.e. the so-called soluto-capillarity effect; the non-uniform distribution of surfactant molecules at the surface causes a non-zero surface tension gradient and thereby the Marangoni stress that tends to eliminate the non-uniformity; it induces the surface rheological effects characterized by the surface shear and dilatational viscosities, and with shear and dilatational deformations of the surface, it yields the viscous stresses that participate in the force balance at the surface. The reduction in the surface tension, the surface tension gradient and the resulting Marangoni stress and the surface viscous stresses are all associated with the distribution of surfactant at the surface. The distribution of insoluble surfactant is basically determined by two mechanisms: surface convection and surface diffusion. The former gives rise to inhomogeneity and thereby surface tension gradients, whereas the latter tends to restore homogeneity (Hameed et al. Reference Hameed, Siegal, Young, Li, Booty and Papageorgiou2008; Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2018; Montanero & Gañán-Calvo Reference Montanero and Gañán-Calvo2020). The relative importance of surface convection and surface diffusion, represented by the surface Péclet number, may substantially influence the dynamics of a fluid system. In general, the multiple effects of a surfactant monolayer together with their complex mathematical descriptions make the related theoretical, numerical and experimental investigations challenging.

The situation can be more intricate when the surfactant is soluble. In such a case, surfactant molecules exist not only at the surface but also in the bulk. The solubility cannot be neglected when the adsorption/desorption characteristic time of the surfactant is comparable to or smaller than the other characteristic times of the system (e.g. the capillary time for a Newtonian jet or both the capillary time and the extensional relaxation time for a viscoelastic jet). If the bulk concentration of the surfactant is below the critical micellar concentration (CMC), it is presented as monomers in the bulk; if the bulk concentration is above the CMC, surfactant molecules partially aggregate into micelles spontaneously (Craster, Matar & Papageorgiou Reference Craster, Matar and Papageorgiou2009; Montanero & Gañán-Calvo Reference Montanero and Gañán-Calvo2020). The concentrations of monomers and micelles are governed by their respective conservation equations. There is a term describing the breakup or formation of micelles in each equation. Moreover, there is a term denoting the flux of surfactant from the bulk to the surface due to the adsorption/desorption process in the conservation equation at the surface. Surfactant solubility seems to affect fluid dynamics in an indirect way.

Studying how capillarity, bulk viscosity, inertia, Marangoni stress, surface viscosity and other possible factors compete with or cooperate with each other in a fluid system has both scientific and practical relevance. There have been many reports in the literature devoted to understanding the effects of insoluble or soluble surfactants on the linear and nonlinear dynamics of films, drops, bubbles, jets, threads and other similar configurations, e.g. Liao, Franses & Basaran (Reference Liao, Franses and Basaran2006), Hameed et al. (Reference Hameed, Siegal, Young, Li, Booty and Papageorgiou2008), Craster et al. (Reference Craster, Matar and Papageorgiou2009), Young et al. (Reference Young, Booty, Siegel and Li2009), Ponce-Torres et al. (Reference Ponce-Torres, Herrada, Montanero and Vega2016), Martínez-Calvo & Sevilla (Reference Martínez-Calvo and Sevilla2018), Hu, Fu & Yang (Reference Hu, Fu and Yang2020), He & Wylie (Reference He and Wylie2021) and Wee et al. (Reference Wee, Wagoner, Garg, Kamat and Basaran2021). The mechanism in one geometric configuration may be extrapolated to another. It is also possible that different mechanisms play a major role in different configurations. In the following, we introduce the studies of cylindrical liquid jets and threads.

Linear theory has confirmed that the presence of surfactants has a stabilizing effect on the Rayleigh–Plateau instability of Newtonian viscous liquid jets (Craster, Matar & Papageorgiou Reference Craster, Matar and Papageorgiou2002; Timmermans & Lister Reference Timmermans and Lister2002; Ponce-Torres et al. Reference Ponce-Torres, Herrada, Montanero and Vega2016; Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2018). That is, surfactants reduce the growth rates of small disturbances. This effect is unsurprising, since the average capillary force is lowered and the Marangoni and surface viscous stresses are created in the presence of surfactants. Similarly, increasing surfactant activity or surface viscosity stabilizes liquid jets. Another finding is that the linear analysis based on the long wave approximation cannot accurately predict some instability features (such as the cutoff wavenumber) of surfactant-laden liquid jets and threads without the inclusion of the necessary high-order terms (Hansen, Peters & Meijer Reference Hansen, Peters and Meijer1999; Timmermans & Lister Reference Timmermans and Lister2002; Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2018).

The nonlinear effects come into play, as disturbances grow with time. Linear theory fails to predict the late stages of jet or thread instability. The nonlinear dynamics of Newtonian jets and threads in the presence of surfactants has been studied via the asymptotic methods and numerical simulations, e.g. Anshus (Reference Anshus1973), Craster et al. (Reference Craster, Matar and Papageorgiou2002), Timmermans & Lister (Reference Timmermans and Lister2002), Dravid et al. (Reference Dravid, Songsermpong, Xue, Corvalan and Sojka2006), McGough & Basaran (Reference McGough and Basaran2006), Craster et al. (Reference Craster, Matar and Papageorgiou2009), Hameed & Maldarelli (Reference Hameed and Maldarelli2016), Martínez-Calvo et al. (Reference Martínez-Calvo, Rivero-Rodríguez, Scheid and Sevilla2020) and Wee et al. (Reference Wee, Wagoner, Garg, Kamat and Basaran2021). It was found that the pinch-off of Newtonian liquid threads can be delayed by surfactants (Anshus Reference Anshus1973; Craster et al. Reference Craster, Matar and Papageorgiou2002). The addition of surfactants to Newtonian viscous threads favours the formation of secondary droplets between primary droplets. The size of secondary droplets is increased or decreased by surfactants, depending on their strength and diffusivity (Dravid et al. Reference Dravid, Songsermpong, Xue, Corvalan and Sojka2006). Surface viscosities were found to be responsible for the accumulation of surfactant molecules in secondary droplets (Ponce-Torres et al. Reference Ponce-Torres, Herrada, Montanero and Vega2016, Reference Ponce-Torres, Montanero, Herrada, Vega and Vega2017). The detachment of primary droplets will never take place and the formation of secondary droplets will be impeded, as long as the Marangoni stress is sufficiently large (Hameed et al. Reference Hameed, Siegal, Young, Li, Booty and Papageorgiou2008). The experimental and numerical studies of McGough & Basaran (Reference McGough and Basaran2006) and Kamat et al. (Reference Kamat, Wagoner, Thete and Basaran2018) showed that the Marangoni stress near the pinching point of a thread induces the formation of microthread cascades. When the transport of an insoluble surfactant is dominated by surface convection (the surface Péclet number is large), surfactant molecules are swept away from the pinching point (Newtonian liquid threads pinch off at the neck where the primary droplet joins the ligament). As a result, surfactant-laden jets behave in a similar way to surfactant-free jets prior to pinch-off and exhibit the same similarity (Eggers Reference Eggers1993; Craster et al. Reference Craster, Matar and Papageorgiou2002; Timmermans & Lister Reference Timmermans and Lister2002; Liao et al. Reference Liao, Franses and Basaran2006; McGough & Basaran Reference McGough and Basaran2006; Eggers & Villermaux Reference Eggers and Villermaux2008). Remarkably, the surface viscous stresses can still play a role when most of surfactant molecules are swept away from the pinching point, because the surface-to-volume ratio at the pinching point becomes extremely large as the minimum radius of the jet tends to zero (Montanero & Gañán-Calvo Reference Montanero and Gañán-Calvo2020; Wee et al. Reference Wee, Wagoner, Kamat and Basaran2020, Reference Wee, Wagoner, Garg, Kamat and Basaran2021). However, surfactant molecules are not always evacuated from the pinching region, even for large surface Péclet numbers of the order of ![]() $10^5$, as detected by Ponce-Torres et al. (Reference Ponce-Torres, Rubio, Herrada, Eggers and Montanero2020). The one-dimensional (1-D) nonlinear analysis of surfactant-laden viscous threads in the Stokes limit showed that there exists a critical value of the surface Péclet number. Below this critical value, surface diffusion is dominant and the thread thins exponentially in time; above it, surface convection is dominant and the thinning of the thread exhibits a power-law dependence on time until pinch-off (Wee et al. Reference Wee, Wagoner and Basaran2022). In the Stokes limit, the surface viscous stresses enter the dominant force balance and tend to slow down the thinning of Newtonian threads (Ozan & Jakobsen Reference Ozan and Jakobsen2019; Wee et al. Reference Wee, Wagoner, Kamat and Basaran2020). The balance between the capillary force and the surface viscous stresses is established at sufficiently high surfactant surface concentrations, resulting in an asymptotic regime in which the filament thins exponentially in time at a rate only depending on the surface tension and the surface viscosities (Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2020). When the inertia is taken into account, the inertial, capillary, bulk viscous and surface viscous forces establish the dominant force balance as the jet nears pinch-off, whereas the Marangoni stress plays a secondary role (Wee et al. Reference Wee, Wagoner, Garg, Kamat and Basaran2021). For viscous threads laden with soluble surfactants at concentrations above the CMC, larger secondary droplets are formed due to the Marangoni stress (Craster et al. Reference Craster, Matar and Papageorgiou2009). The study of the surfactant effects has been extended to compound liquid jets (Craster, Matar & Papageorgiou Reference Craster, Matar and Papageorgiou2003; Yao, Yang & Fu Reference Yao, Yang and Fu2021).

$10^5$, as detected by Ponce-Torres et al. (Reference Ponce-Torres, Rubio, Herrada, Eggers and Montanero2020). The one-dimensional (1-D) nonlinear analysis of surfactant-laden viscous threads in the Stokes limit showed that there exists a critical value of the surface Péclet number. Below this critical value, surface diffusion is dominant and the thread thins exponentially in time; above it, surface convection is dominant and the thinning of the thread exhibits a power-law dependence on time until pinch-off (Wee et al. Reference Wee, Wagoner and Basaran2022). In the Stokes limit, the surface viscous stresses enter the dominant force balance and tend to slow down the thinning of Newtonian threads (Ozan & Jakobsen Reference Ozan and Jakobsen2019; Wee et al. Reference Wee, Wagoner, Kamat and Basaran2020). The balance between the capillary force and the surface viscous stresses is established at sufficiently high surfactant surface concentrations, resulting in an asymptotic regime in which the filament thins exponentially in time at a rate only depending on the surface tension and the surface viscosities (Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2020). When the inertia is taken into account, the inertial, capillary, bulk viscous and surface viscous forces establish the dominant force balance as the jet nears pinch-off, whereas the Marangoni stress plays a secondary role (Wee et al. Reference Wee, Wagoner, Garg, Kamat and Basaran2021). For viscous threads laden with soluble surfactants at concentrations above the CMC, larger secondary droplets are formed due to the Marangoni stress (Craster et al. Reference Craster, Matar and Papageorgiou2009). The study of the surfactant effects has been extended to compound liquid jets (Craster, Matar & Papageorgiou Reference Craster, Matar and Papageorgiou2003; Yao, Yang & Fu Reference Yao, Yang and Fu2021).

Polymer solutions are frequently encountered in applications. They belong to the family of non-Newtonian fluids, possessing rheological properties such as shear thinning and viscoelasticity. A dilute polymer solution can be approximately regarded as a viscoelastic liquid of constant viscosity (Tirtaatmadja, McKinley & Cooper-White Reference Tirtaatmadja, McKinley and Cooper-White2006; James Reference James2009). Thus the elastic effects are separated from the viscous effects, greatly facilitating the study of the viscoelastic liquid dynamics. The linear and nonlinear behaviour of viscoelastic liquid jets and threads has been studied analytically and numerically with the aid of simple viscoelastic models such as Oldroyd-B, Giesekus and finitely extensible nonlinear elastic (Goldin et al. Reference Goldin, Yerushalmi, Pfeffer and Shinnar1969; Goren & Gottlieb Reference Goren and Gottlieb1982; Entov & Hinch Reference Entov and Hinch1997; Chang, Demekhin & Kalaidin Reference Chang, Demekhin and Kalaidin1999; Brenn, Liu & Durst Reference Brenn, Liu and Durst2000; Fontelos & Li Reference Fontelos and Li2004; Clasen et al. Reference Clasen, Eggers, Fontelos, Li and McKinley2006a; Liu & Liu Reference Liu and Liu2006; Eggers & Villermaux Reference Eggers and Villermaux2008; Ardekani, Sharma & Mckinley Reference Ardekani, Sharma and Mckinley2010; Bhat et al. Reference Bhat, Appathurai, Harris, Pasquali, Mckinley and Basaran2010; Ye, Yang & Fu Reference Ye, Yang and Fu2016; Turkoz et al. Reference Turkoz, Lopez-Herrera, Eggers, Arnold and Deike2018; Alsharif Reference Alsharif2019). In the linear regime, viscoelastic jets were found to be more unstable than their Newtonian counterparts when the axial viscoelastic stress in the base flow is relaxed sufficiently far away from the nozzle. In the nonlinear regime, phenomenally different from Newtonian jets, viscoelastic jets evolve into a quasistatic topological structure, i.e. the beads-on-a-string structure, which is characterized by primary droplets connected by a thin filament of almost uniform thickness (sometimes secondary droplets exist in the filament). The pinch-off of viscoelastic liquid threads, if it occurs in finite time, can be greatly delayed by viscoelasticity. Note that the aforementioned viscoelastic models possess a constant viscosity and a single relaxation time and cannot account for the concentration dependence or the conformation dependence of the viscosity or the relaxation time (Beck & Shaqfeh Reference Beck and Shaqfeh2006; Clasen et al. Reference Clasen, Plog, Kulicke, Macosko, Scriven, Verani and Mckinley2006b; Prabhakar, Prakash & Sridhar Reference Prabhakar, Prakash and Sridhar2006; Tirtaatmadja et al. Reference Tirtaatmadja, McKinley and Cooper-White2006; Dinic & Sharma Reference Dinic and Sharma2020; Kumar, Richter & Schroeder Reference Kumar, Richter and Schroeder2020). As a consequence, they may fail to capture accurately the capillary thinning or pinching dynamics of viscoelastic threads observed in experiments. Future theoretical and numerical studies are expected to consider more realistic models.

The addition of soluble surfactants to polymer solutions may introduce additional complexity and difficulty in mathematical formulation and experimental measurement (Martínez Narváez, Mazur & Sharma Reference Martínez Narváez, Mazur and Sharma2021). On the one hand, surfactants may influence the rheological properties of polymer solutions to a certain extent, for example, increasing bulk viscosity and lowering the critical shear rate for the onset of shear thinning.On the other hand, the interaction between polymer molecules and surfactant molecules may lead to the self-aggregation of the latter above the critical aggregation concentration when the bulk concentration of surfactant is sufficiently high. To date, the dynamics of polymer–surfactant association complexes has been rarely reported. An experimental investigation was executed by Dechelette et al. (Reference Dechelette, Campanella, Corvalan and Sojka2011) to examine the combined effect of polymer and soluble surfactant on the jet breakup and secondary droplet formation. It was found that the Marangoni stress may lead to an increase in secondary droplet size at sufficiently high surfactant concentrations.

If the surfactant has a negligible solubility or is insoluble, the interaction between polymer and surfactant molecules can be appropriately neglected. Even for this much simpler case, few studies can be found in the literature addressing the dynamics of surfactant-laden viscoelastic liquid jets or threads. An asymptotic approach based on the slenderness of the jet was used by Alhushaybari & Uddin (Reference Alhushaybari and Uddin2020) to study the absolute and convective instability of a viscoelastic liquid jet falling under the gravity in the presence of insoluble surfactants. They identified the convective/absolute instability boundaries for various parameter regimes. He & Wylie (Reference He and Wylie2021) studied the temporal linear instability of a viscoelastic thread surrounded by another immiscible viscoelastic fluid in the presence of insoluble surfactants. They carried out a detailed parametric study and concluded that the surfactant decreases the growth rates and increases the most unstable wavenumber corresponding to the maximum growth rate.

At the nonlinear stages, viscoelastic liquid jets and threads behave differently from Newtonian ones, particularly the delay of pinch-off and the formation of the beads-on-a-string structure. To our knowledge, the effect of surfactants on the nonlinear characteristics of viscoelastic liquid jets and threads has not yet been reported. In the present work, we build a 1-D model to describe the nonlinear dynamic behaviour of viscoelastic threads in the presence of insoluble surfactants, taking into account the surface rheological effects. A number of 1-D models based on the slender body theory have been developed for clean Newtonian viscous threads, surfactant-laden Newtonian viscous threads or clean viscoelastic threads (Eggers & Villermaux Reference Eggers and Villermaux2008; Montanero & Gañán-Calvo Reference Montanero and Gañán-Calvo2020). It has been shown that these simplified 1-D models provide reasonable results at a much lower computational cost than the two-dimensional (2-D) and three-dimensional (3-D) numerical simulations.

The paper is organized as follows: in § 2, the theoretical model is described; in § 3, the 1-D equations are derived; in § 4, the dispersion relation for the 1-D linear analysis is derived and a parametric study is performed to examine the effects of the surfactant on the linear and nonlinear behaviour of the viscoelastic thread; finally, in § 5, the main conclusion is drawn.

2. Theoretical description

Consider an infinitely long cylindrical liquid thread of radius ![]() $R$ surrounded by atmospheric air, as sketched in figure 1. The liquid, which is a polymer solution, is incompressible and viscoelastic. Before being perturbed, the thread is quiescent with no base flow, and moreover, the thread surface is covered uniformly with a monolayer of bulk-insoluble surfactant molecules of concentration

$R$ surrounded by atmospheric air, as sketched in figure 1. The liquid, which is a polymer solution, is incompressible and viscoelastic. Before being perturbed, the thread is quiescent with no base flow, and moreover, the thread surface is covered uniformly with a monolayer of bulk-insoluble surfactant molecules of concentration ![]() $\varGamma _0$. The rheological properties of the surfactant, characterized by the surface shear and dilatational viscosities, are taken into account. The hydrodynamic effect of the ambient air is neglected. The effect of the gravitational force, temperature and mass transfer is neglected as well. The cylindrical coordinate system

$\varGamma _0$. The rheological properties of the surfactant, characterized by the surface shear and dilatational viscosities, are taken into account. The hydrodynamic effect of the ambient air is neglected. The effect of the gravitational force, temperature and mass transfer is neglected as well. The cylindrical coordinate system ![]() $(z, r, \theta )$ with

$(z, r, \theta )$ with ![]() $z, r, \theta$ the axial, radial and azimuthal coordinates, respectively, is used to describe the problem. Upon a small-amplitude axisymmetric harmonic disturbance being imposed, the thread begins to deform, whose shape is denoted by

$z, r, \theta$ the axial, radial and azimuthal coordinates, respectively, is used to describe the problem. Upon a small-amplitude axisymmetric harmonic disturbance being imposed, the thread begins to deform, whose shape is denoted by ![]() $r=S(z,t)$. Simultaneously, the surfactant is redistributed along the thread surface, whose concentration is denoted by

$r=S(z,t)$. Simultaneously, the surfactant is redistributed along the thread surface, whose concentration is denoted by ![]() $\varGamma =\varGamma (z,t)$.

$\varGamma =\varGamma (z,t)$.

Figure 1. Schematic of a viscoelastic liquid thread covered with an insoluble surfactant.

The continuity and momentum equations governing the flow field are

$$\begin{gather}\rho\left(\frac{\partial

v}{\partial t}+v\frac{\partial v}{\partial

r}+u\frac{\partial v}{\partial z}\right)={-}\frac{\partial

p}{\partial r}+\eta_s\left(\frac{\partial^2 v}{\partial

r^2}+\frac{1}{r}\frac{\partial v}{\partial

r}-\frac{v}{r^2}+\frac{\partial^2 v}{\partial

z^2}\right)\nonumber\\

\qquad \qquad \qquad\qquad +\frac{\partial \tau_{rr}}{\partial

r}+\frac{\partial \tau_{rz}}{\partial

z}+\frac{\tau_{rr}-\tau_{\theta\theta}}{r},

\end{gather}$$

$$\begin{gather}\rho\left(\frac{\partial

v}{\partial t}+v\frac{\partial v}{\partial

r}+u\frac{\partial v}{\partial z}\right)={-}\frac{\partial

p}{\partial r}+\eta_s\left(\frac{\partial^2 v}{\partial

r^2}+\frac{1}{r}\frac{\partial v}{\partial

r}-\frac{v}{r^2}+\frac{\partial^2 v}{\partial

z^2}\right)\nonumber\\

\qquad \qquad \qquad\qquad +\frac{\partial \tau_{rr}}{\partial

r}+\frac{\partial \tau_{rz}}{\partial

z}+\frac{\tau_{rr}-\tau_{\theta\theta}}{r},

\end{gather}$$

where ![]() $u$ and

$u$ and ![]() $v$ are the axial and radial components of the velocity vector

$v$ are the axial and radial components of the velocity vector ![]() $\boldsymbol {u}$, respectively,

$\boldsymbol {u}$, respectively, ![]() $\rho$ is the density of the polymer solution,

$\rho$ is the density of the polymer solution, ![]() $p$ is the pressure,

$p$ is the pressure, ![]() $\eta _s$ is the contribution of the solvent to the viscosity and

$\eta _s$ is the contribution of the solvent to the viscosity and ![]() $\tau _{zz}, \tau _{rr}, \tau _{rz}$ and

$\tau _{zz}, \tau _{rr}, \tau _{rz}$ and ![]() $\tau _{\theta \theta }$ are the components of the polymer stress tensor

$\tau _{\theta \theta }$ are the components of the polymer stress tensor ![]() $\boldsymbol {\tau }_p$ which, in the form of a matrix, is

$\boldsymbol {\tau }_p$ which, in the form of a matrix, is

\begin{equation} \boldsymbol{\tau}_p=\left( \begin{array}{@{}ccc@{}} \tau_{zz} & \tau_{rz} & 0 \\ \tau_{rz} & \tau_{rr} & 0 \\ 0 & 0 & \tau_{\theta\theta} \\ \end{array} \right). \end{equation}

\begin{equation} \boldsymbol{\tau}_p=\left( \begin{array}{@{}ccc@{}} \tau_{zz} & \tau_{rz} & 0 \\ \tau_{rz} & \tau_{rr} & 0 \\ 0 & 0 & \tau_{\theta\theta} \\ \end{array} \right). \end{equation}The viscoelasticity of the liquid is assumed to be described by the FENE-P (finitely extensible nonlinear elastic-Peterlin approximation) constitutive equation (Fontelos & Li Reference Fontelos and Li2004)

\begin{equation} \boldsymbol{\tau}_p=\frac{\eta_p}{\lambda_c}\left( \frac{{{\boldsymbol{\mathsf{A}}}}}{1-\dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}- {{\boldsymbol{\mathsf{I}}}}\right),\end{equation}

\begin{equation} \boldsymbol{\tau}_p=\frac{\eta_p}{\lambda_c}\left( \frac{{{\boldsymbol{\mathsf{A}}}}}{1-\dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}- {{\boldsymbol{\mathsf{I}}}}\right),\end{equation}

where ![]() $\eta _p$ is the contribution of the polymer to the viscosity,

$\eta _p$ is the contribution of the polymer to the viscosity, ![]() $\lambda _c$ is the stress relaxation time,

$\lambda _c$ is the stress relaxation time, ![]() $L$ is the finite extensibility parameter,

$L$ is the finite extensibility parameter, ![]() ${{\boldsymbol{\mathsf{I}}}}$ is the identity tensor,

${{\boldsymbol{\mathsf{I}}}}$ is the identity tensor, ![]() ${{\boldsymbol{\mathsf{A}}}}$ is the conformation tensor whose components are

${{\boldsymbol{\mathsf{A}}}}$ is the conformation tensor whose components are

\begin{equation} {{\boldsymbol{\mathsf{A}}}}=\left( \begin{array}{@{}ccc@{}} A_{zz} & A_{rz} & 0 \\ A_{rz} & A_{rr} & 0 \\ 0 & 0 & A_{\theta\theta} \\ \end{array} \right), \end{equation}

\begin{equation} {{\boldsymbol{\mathsf{A}}}}=\left( \begin{array}{@{}ccc@{}} A_{zz} & A_{rz} & 0 \\ A_{rz} & A_{rr} & 0 \\ 0 & 0 & A_{\theta\theta} \\ \end{array} \right), \end{equation}

and ![]() $tr({{\boldsymbol{\mathsf{A}}}})$ is the trace of

$tr({{\boldsymbol{\mathsf{A}}}})$ is the trace of ![]() ${{\boldsymbol{\mathsf{A}}}}$. The four non-zero components of

${{\boldsymbol{\mathsf{A}}}}$. The four non-zero components of ![]() ${{\boldsymbol{\mathsf{A}}}}$ are governed by

${{\boldsymbol{\mathsf{A}}}}$ are governed by

$$\begin{gather} \frac{\partial A_{zz}}{\partial t} +v\frac{\partial A_{zz}}{\partial r}+u\frac{\partial A_{zz}}{\partial z}=2\frac{\partial u}{\partial z} A_{zz}+2\frac{\partial u}{\partial r}A_{rz}+\frac{1}{\lambda_c}\left(1-\frac{A_{zz}}{1- \dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}\right), \end{gather}$$

$$\begin{gather} \frac{\partial A_{zz}}{\partial t} +v\frac{\partial A_{zz}}{\partial r}+u\frac{\partial A_{zz}}{\partial z}=2\frac{\partial u}{\partial z} A_{zz}+2\frac{\partial u}{\partial r}A_{rz}+\frac{1}{\lambda_c}\left(1-\frac{A_{zz}}{1- \dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}\right), \end{gather}$$ $$\begin{gather}\frac{\partial A_{rr}}{\partial t} +v\frac{\partial A_{rr}}{\partial r}+u\frac{\partial A_{rr}}{\partial z}=2\frac{\partial v}{\partial r} A_{rr}+2\frac{\partial v}{\partial z}A_{rz}+\frac{1}{\lambda_c}\left(1-\frac{A_{rr}}{1- \dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}\right), \end{gather}$$

$$\begin{gather}\frac{\partial A_{rr}}{\partial t} +v\frac{\partial A_{rr}}{\partial r}+u\frac{\partial A_{rr}}{\partial z}=2\frac{\partial v}{\partial r} A_{rr}+2\frac{\partial v}{\partial z}A_{rz}+\frac{1}{\lambda_c}\left(1-\frac{A_{rr}}{1- \dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}\right), \end{gather}$$ $$\begin{gather}\frac{\partial A_{\theta\theta}}{\partial t} +v\frac{\partial A_{\theta\theta}}{\partial r}+u\frac{\partial A_{\theta\theta}}{\partial z}=2\frac{v}{r} A_{\theta\theta}+\frac{1}{\lambda_c}\left(1- \dfrac{A_{\theta\theta}}{1-\dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}\right), \end{gather}$$

$$\begin{gather}\frac{\partial A_{\theta\theta}}{\partial t} +v\frac{\partial A_{\theta\theta}}{\partial r}+u\frac{\partial A_{\theta\theta}}{\partial z}=2\frac{v}{r} A_{\theta\theta}+\frac{1}{\lambda_c}\left(1- \dfrac{A_{\theta\theta}}{1-\dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}\right), \end{gather}$$ $$\begin{gather}\frac{\partial A_{rz}}{\partial t} +v\frac{\partial A_{rz}}{\partial r}+u\frac{\partial A_{rz}}{\partial z}=\frac{\partial v}{\partial z} A_{zz}+\frac{\partial u}{\partial r}-\frac{v}{r}A_{rz}+\frac{1}{\lambda_c}\left(-\frac{A_{rz}}{1- \dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}\right). \end{gather}$$

$$\begin{gather}\frac{\partial A_{rz}}{\partial t} +v\frac{\partial A_{rz}}{\partial r}+u\frac{\partial A_{rz}}{\partial z}=\frac{\partial v}{\partial z} A_{zz}+\frac{\partial u}{\partial r}-\frac{v}{r}A_{rz}+\frac{1}{\lambda_c}\left(-\frac{A_{rz}}{1- \dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}\right). \end{gather}$$ The surfactant concentration ![]() $\varGamma$ is governed by the time-dependent advection–diffusion equation (Hameed et al. Reference Hameed, Siegal, Young, Li, Booty and Papageorgiou2008; Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2018)

$\varGamma$ is governed by the time-dependent advection–diffusion equation (Hameed et al. Reference Hameed, Siegal, Young, Li, Booty and Papageorgiou2008; Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2018)

\begin{equation} \frac{\partial \varGamma}{\partial t}+u\frac{\partial \varGamma}{\partial z}+\frac{\varGamma}{S\sqrt{1+S'^2}}\frac{\partial(Su_t)}{\partial z}+\mathcal{C} \varGamma u_n=\frac{D_s}{S\sqrt{1+S'^2}}\frac{\partial \left(\dfrac{S\varGamma'}{\sqrt{1+S'^2}}\right) }{\partial z}, \end{equation}

\begin{equation} \frac{\partial \varGamma}{\partial t}+u\frac{\partial \varGamma}{\partial z}+\frac{\varGamma}{S\sqrt{1+S'^2}}\frac{\partial(Su_t)}{\partial z}+\mathcal{C} \varGamma u_n=\frac{D_s}{S\sqrt{1+S'^2}}\frac{\partial \left(\dfrac{S\varGamma'}{\sqrt{1+S'^2}}\right) }{\partial z}, \end{equation}

where the prime ![]() $'$ denotes the partial derivative with respect to

$'$ denotes the partial derivative with respect to ![]() $z, D_s$ is the surface diffusion coefficient of the surfactant,

$z, D_s$ is the surface diffusion coefficient of the surfactant, ![]() $u_n$ and

$u_n$ and ![]() $u_t$ are the normal and tangential components of the velocity at the surface, i.e.

$u_t$ are the normal and tangential components of the velocity at the surface, i.e.

and ![]() $\mathcal {C}$ is the mean curvature given by

$\mathcal {C}$ is the mean curvature given by

with ![]() $''$ denoting the second-order derivative with respective to

$''$ denoting the second-order derivative with respective to ![]() $z$.

$z$.

At the thread surface ![]() $r=S(z,t)$, the kinematic condition must be satisfied, i.e.

$r=S(z,t)$, the kinematic condition must be satisfied, i.e.

and the force balance requires

where ![]() ${{\boldsymbol{\mathsf{T}}}}=-p{{\boldsymbol{\mathsf{I}}}}+\eta _s[\boldsymbol {\nabla }\boldsymbol {u} +(\boldsymbol {\nabla }\boldsymbol {u})^T]+\boldsymbol \tau _p$ is the stress tensor from the liquid phase but evaluated at the thread surface (the superscript

${{\boldsymbol{\mathsf{T}}}}=-p{{\boldsymbol{\mathsf{I}}}}+\eta _s[\boldsymbol {\nabla }\boldsymbol {u} +(\boldsymbol {\nabla }\boldsymbol {u})^T]+\boldsymbol \tau _p$ is the stress tensor from the liquid phase but evaluated at the thread surface (the superscript ![]() $T$ indicates the transpose),

$T$ indicates the transpose), ![]() $\boldsymbol n$ is the unit outward vector normal to the surface,

$\boldsymbol n$ is the unit outward vector normal to the surface, ![]() $\nabla _s$ is the surface gradient operator defined as

$\nabla _s$ is the surface gradient operator defined as ![]() $\nabla _s={{\boldsymbol{\mathsf{I}}}}_s\boldsymbol {\cdot }\boldsymbol {\nabla }=({{\boldsymbol{\mathsf{I}}}}-\boldsymbol n \boldsymbol n)\boldsymbol {\cdot }\boldsymbol {\nabla }$ and

$\nabla _s={{\boldsymbol{\mathsf{I}}}}_s\boldsymbol {\cdot }\boldsymbol {\nabla }=({{\boldsymbol{\mathsf{I}}}}-\boldsymbol n \boldsymbol n)\boldsymbol {\cdot }\boldsymbol {\nabla }$ and ![]() ${{\boldsymbol{\mathsf{T}}}}_s$ is the surface stress tensor modelled by the Boussinesq–Scriven approximation (Boussinesq Reference Boussinesq1913; Scriven Reference Scriven1960; Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2018)

${{\boldsymbol{\mathsf{T}}}}_s$ is the surface stress tensor modelled by the Boussinesq–Scriven approximation (Boussinesq Reference Boussinesq1913; Scriven Reference Scriven1960; Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2018)

where ![]() $\kappa _s$ and

$\kappa _s$ and ![]() $\mu _s$ are the surface dilatational and shear viscosities, respectively,

$\mu _s$ are the surface dilatational and shear viscosities, respectively, ![]() $\boldsymbol {u}_s$ is the velocity of the polymer solution at the surface and

$\boldsymbol {u}_s$ is the velocity of the polymer solution at the surface and ![]() $\sigma$ is the surface tension coefficient (hereafter, it is called the surface tension for short). Note that

$\sigma$ is the surface tension coefficient (hereafter, it is called the surface tension for short). Note that ![]() $\kappa _s, \mu _s$ and

$\kappa _s, \mu _s$ and ![]() $\sigma$ are all functions of the local surfactant concentration

$\sigma$ are all functions of the local surfactant concentration ![]() $\varGamma$. We simply assume that

$\varGamma$. We simply assume that ![]() $\kappa _s$ and

$\kappa _s$ and ![]() $\mu _s$ are linearly dependent on

$\mu _s$ are linearly dependent on ![]() $\varGamma$ (Ponce-Torres et al. Reference Ponce-Torres, Montanero, Herrada, Vega and Vega2017; Wee et al. Reference Wee, Wagoner, Garg, Kamat and Basaran2021), i.e.

$\varGamma$ (Ponce-Torres et al. Reference Ponce-Torres, Montanero, Herrada, Vega and Vega2017; Wee et al. Reference Wee, Wagoner, Garg, Kamat and Basaran2021), i.e.

where the subscript ![]() $r$ denotes the reference values. The dependence of the surface tension

$r$ denotes the reference values. The dependence of the surface tension ![]() $\sigma$ on the surfactant surface concentration

$\sigma$ on the surfactant surface concentration ![]() $\varGamma$ is assumed to be described by the Langmuir equation of state (Liao et al. Reference Liao, Franses and Basaran2006; Hameed et al. Reference Hameed, Siegal, Young, Li, Booty and Papageorgiou2008; Wee et al. Reference Wee, Wagoner, Garg, Kamat and Basaran2021)

$\varGamma$ is assumed to be described by the Langmuir equation of state (Liao et al. Reference Liao, Franses and Basaran2006; Hameed et al. Reference Hameed, Siegal, Young, Li, Booty and Papageorgiou2008; Wee et al. Reference Wee, Wagoner, Garg, Kamat and Basaran2021)

where ![]() $\sigma _0$ is the surface tension of the clean surface,

$\sigma _0$ is the surface tension of the clean surface, ![]() $R_g$ is the universal gas constant,

$R_g$ is the universal gas constant, ![]() $T$ is the absolute temperature and

$T$ is the absolute temperature and ![]() $\varGamma _{\infty }$ is the maximum packing concentration of the surfactant. Introducing the surface pressure

$\varGamma _{\infty }$ is the maximum packing concentration of the surfactant. Introducing the surface pressure ![]() $\varPi (\varGamma )=\sigma _0-\sigma (\varGamma )$, the combination of (2.17a,b) and (2.18) gives the following dependence

$\varPi (\varGamma )=\sigma _0-\sigma (\varGamma )$, the combination of (2.17a,b) and (2.18) gives the following dependence

As a matter of fact, the dependence of the surface viscosities on the surface pressure diverges. For instance, it was found in the experiments that the surface shear viscosity ![]() $\mu _s$ often increases exponentially with the surface pressure

$\mu _s$ often increases exponentially with the surface pressure ![]() $\varPi$ (Fuller & Vermant Reference Fuller and Vermant2012; Manikantan & Squires Reference Manikantan and Squires2020). The

$\varPi$ (Fuller & Vermant Reference Fuller and Vermant2012; Manikantan & Squires Reference Manikantan and Squires2020). The ![]() $\varPi$-dependent surface viscosities have been shown to lead to surprising consequences in lubrication flows and affect significantly the deformation and breakup of droplets (Manikantan & Squires Reference Manikantan and Squires2017; Singh & Narsimhan Reference Singh and Narsimhan2021, Reference Singh and Narsimhan2022; Herrada et al. Reference Herrada, Ponce-Torres, Rubio, Eggers and Montanero2022). They may also affect the dynamics of liquid jets and threads, which remains an open problem to be explored.

$\varPi$-dependent surface viscosities have been shown to lead to surprising consequences in lubrication flows and affect significantly the deformation and breakup of droplets (Manikantan & Squires Reference Manikantan and Squires2017; Singh & Narsimhan Reference Singh and Narsimhan2021, Reference Singh and Narsimhan2022; Herrada et al. Reference Herrada, Ponce-Torres, Rubio, Eggers and Montanero2022). They may also affect the dynamics of liquid jets and threads, which remains an open problem to be explored.

The substitution of (2.16) into (2.15) yields

\begin{align} &-{{\boldsymbol{\mathsf{T}}}}\boldsymbol{\cdot}{\boldsymbol n}+\nabla_s \sigma-{\boldsymbol n}(\nabla_s \boldsymbol{\cdot} {\boldsymbol n}) \sigma+\nabla_s \left[(\kappa_s-\mu_s)(\nabla_s\boldsymbol{\cdot} {\boldsymbol u}_s)\right]\nonumber\\ &\quad -{\boldsymbol n}(\nabla_s \boldsymbol{\cdot} {\boldsymbol n})(\kappa_s-\mu_s)(\nabla_s\boldsymbol{\cdot}{\boldsymbol u}_s)+\nabla_s\boldsymbol{\cdot}\left\{\mu_s\left[(\nabla_s{\boldsymbol u}_s)\boldsymbol{\cdot} {\boldsymbol I}_s+ {\boldsymbol I}_s\boldsymbol{\cdot} (\nabla_s {\boldsymbol u}_s)^T\right]\right\}=0. \end{align}

\begin{align} &-{{\boldsymbol{\mathsf{T}}}}\boldsymbol{\cdot}{\boldsymbol n}+\nabla_s \sigma-{\boldsymbol n}(\nabla_s \boldsymbol{\cdot} {\boldsymbol n}) \sigma+\nabla_s \left[(\kappa_s-\mu_s)(\nabla_s\boldsymbol{\cdot} {\boldsymbol u}_s)\right]\nonumber\\ &\quad -{\boldsymbol n}(\nabla_s \boldsymbol{\cdot} {\boldsymbol n})(\kappa_s-\mu_s)(\nabla_s\boldsymbol{\cdot}{\boldsymbol u}_s)+\nabla_s\boldsymbol{\cdot}\left\{\mu_s\left[(\nabla_s{\boldsymbol u}_s)\boldsymbol{\cdot} {\boldsymbol I}_s+ {\boldsymbol I}_s\boldsymbol{\cdot} (\nabla_s {\boldsymbol u}_s)^T\right]\right\}=0. \end{align}After some algebraic operations, the force balance in the normal direction is written as

\begin{align} &p-\frac{1}{1+S'^2}\left[2\eta_s\frac{\partial v}{\partial r}-2\eta_s\left(\frac{\partial v}{\partial z}+\frac{\partial u}{\partial r}\right)+2\eta_s S'^2\frac{\partial u}{\partial z}+S'^2\tau_{zz}-2S'\tau_{rz}+\tau_{rr}\right]\nonumber\\ &\quad=\mathcal{C}\left[\sigma+(\kappa_s-\mu_s) \left(\frac{(Su_t)'}{S\sqrt{1+S'^2}}+\mathcal{C} u_n\right)\right]\nonumber\\ &\qquad+\frac{2\mu_s}{1+S'^2}\left[\frac{S'u_t+u_n}{S^2}- \frac{S''}{1+S'^2}\left(\frac{\partial (u_t)}{\partial z}-\frac{S''u_n}{1+S'^2}\right)\right], \end{align}

\begin{align} &p-\frac{1}{1+S'^2}\left[2\eta_s\frac{\partial v}{\partial r}-2\eta_s\left(\frac{\partial v}{\partial z}+\frac{\partial u}{\partial r}\right)+2\eta_s S'^2\frac{\partial u}{\partial z}+S'^2\tau_{zz}-2S'\tau_{rz}+\tau_{rr}\right]\nonumber\\ &\quad=\mathcal{C}\left[\sigma+(\kappa_s-\mu_s) \left(\frac{(Su_t)'}{S\sqrt{1+S'^2}}+\mathcal{C} u_n\right)\right]\nonumber\\ &\qquad+\frac{2\mu_s}{1+S'^2}\left[\frac{S'u_t+u_n}{S^2}- \frac{S''}{1+S'^2}\left(\frac{\partial (u_t)}{\partial z}-\frac{S''u_n}{1+S'^2}\right)\right], \end{align}and in the tangential direction as

\begin{align}

&\frac{1}{\sqrt{1+S'^2}}\left[2\eta_sS'\left(\frac{\partial

v}{\partial r}-\frac{\partial u}{\partial

z}\right)+\eta_s\left(1-S'^2\right)\left(\frac{\partial

v}{\partial z}+\frac{\partial u}{\partial

r}\right)\right.\nonumber\\

&\quad +\left.S'\left(\tau_{rr}-\tau_{zz}\right)

+(1-S'^2)\tau_{rz}\right]\nonumber\\

&\quad =\frac{\partial \sigma}{\partial z}+\frac{\partial }{\partial

z}\left[(\kappa_s-\mu_s)\left(\frac{(Su_t)'}{S\sqrt{1+S'^2}}+\mathcal{C}

u_n\right)\right]\nonumber\\

&\qquad +\frac{\sqrt{1+S'^2}}{S}\frac{\partial }{\partial

z}\left[\frac{2\mu_sS}{1+S'^2}\left(\frac{\partial

u_t}{\partial z}-\frac{u_nS''}{1+S'^2}\right)\right]\nonumber\\

&\qquad-\frac{2\mu_sS'}{\sqrt{1+S'^2}}\left[\frac{S'u_t+u_n}{S^2}-

\frac{S''}{1+S'^2}\left(\frac{\partial u_t}{\partial

z}-\frac{S'' u_n}{1+S'^2}\right)\right].

\end{align}

\begin{align}

&\frac{1}{\sqrt{1+S'^2}}\left[2\eta_sS'\left(\frac{\partial

v}{\partial r}-\frac{\partial u}{\partial

z}\right)+\eta_s\left(1-S'^2\right)\left(\frac{\partial

v}{\partial z}+\frac{\partial u}{\partial

r}\right)\right.\nonumber\\

&\quad +\left.S'\left(\tau_{rr}-\tau_{zz}\right)

+(1-S'^2)\tau_{rz}\right]\nonumber\\

&\quad =\frac{\partial \sigma}{\partial z}+\frac{\partial }{\partial

z}\left[(\kappa_s-\mu_s)\left(\frac{(Su_t)'}{S\sqrt{1+S'^2}}+\mathcal{C}

u_n\right)\right]\nonumber\\

&\qquad +\frac{\sqrt{1+S'^2}}{S}\frac{\partial }{\partial

z}\left[\frac{2\mu_sS}{1+S'^2}\left(\frac{\partial

u_t}{\partial z}-\frac{u_nS''}{1+S'^2}\right)\right]\nonumber\\

&\qquad-\frac{2\mu_sS'}{\sqrt{1+S'^2}}\left[\frac{S'u_t+u_n}{S^2}-

\frac{S''}{1+S'^2}\left(\frac{\partial u_t}{\partial

z}-\frac{S'' u_n}{1+S'^2}\right)\right].

\end{align}3. One-dimensional model

If the radius of the perturbed thread varies gradually along the axial direction, the thread can be considered as a slender body and a 1-D analysis can be applied (Clasen et al. Reference Clasen, Eggers, Fontelos, Li and McKinley2006a; Eggers & Villermaux Reference Eggers and Villermaux2008). The equations for the 1-D model are derived in Appendix A. Taking the thread radius ![]() $R$, the capillary time

$R$, the capillary time ![]() $t_c=\sqrt {\rho R^3/\sigma _0}$, the zero-shear viscosity

$t_c=\sqrt {\rho R^3/\sigma _0}$, the zero-shear viscosity ![]() $\eta _0=\eta _s+\eta _p$, the surface tension of the clear surface

$\eta _0=\eta _s+\eta _p$, the surface tension of the clear surface ![]() $\sigma _0$, the capillary force

$\sigma _0$, the capillary force ![]() $\sigma _0/R$ and the maximum packing concentration of the surfactant

$\sigma _0/R$ and the maximum packing concentration of the surfactant ![]() $\varGamma _\infty$ as the scales of length, time, viscosity, surface tension, pressure and surfactant concentration, respectively, the 1-D equations are non-dimensionalized as

$\varGamma _\infty$ as the scales of length, time, viscosity, surface tension, pressure and surfactant concentration, respectively, the 1-D equations are non-dimensionalized as

\begin{gather}

\frac{\partial u}{\partial t}+u\frac{\partial u}{\partial

z}= \frac{3\beta

Oh}{S^2}\frac{\partial\left(S^2\dfrac{\partial u}{\partial

z}\right)}{\partial z}+\frac{1}{S^2}

\frac{\partial\left[S^2\left(\tau_{zz}-\tau_{rr}

\right)\right]}{\partial z}\nonumber\\

-\frac{\partial}{\partial

z}\left\{\mathcal{C}\left[\sigma+\frac{Oh\left(\kappa_s-\mu_s\right)}{S}\left(\frac{\partial(uS)}{\partial

z}-\frac{\mathcal{C}}{2}\frac{\partial(uS^2)}{\partial

z}\right)\right]\right\}\nonumber\\

{\bigcirc{\kern-6pt 1}} \qquad \ \qquad \qquad {\bigcirc{\kern-6pt 2}} \nonumber\\

+\frac{2}{S}\left\{\frac{\partial \sigma}{\partial z}+\frac{\partial}{\partial

z}\left[\frac{Oh(\kappa_s-\mu_s)}{S}\left(\frac{\partial(uS)}{\partial

z}-\frac{\mathcal{C}}{2}\frac{\partial(uS^2)}{\partial z}\right)\right]\right\}\nonumber\\

\qquad {\bigcirc{\kern-6pt 3}} \qquad \ \ \qquad \qquad \qquad {\bigcirc{\kern-6pt 4}} \nonumber\\

+\frac{5Oh}{S^2}\frac{\partial }{\partial

z}\left(\mu_sS\frac{\partial u}{\partial z}\right), \nonumber\\

\qquad \quad \ {\bigcirc{\kern-6pt 5}}

\end{gather}

\begin{gather}

\frac{\partial u}{\partial t}+u\frac{\partial u}{\partial

z}= \frac{3\beta

Oh}{S^2}\frac{\partial\left(S^2\dfrac{\partial u}{\partial

z}\right)}{\partial z}+\frac{1}{S^2}

\frac{\partial\left[S^2\left(\tau_{zz}-\tau_{rr}

\right)\right]}{\partial z}\nonumber\\

-\frac{\partial}{\partial

z}\left\{\mathcal{C}\left[\sigma+\frac{Oh\left(\kappa_s-\mu_s\right)}{S}\left(\frac{\partial(uS)}{\partial

z}-\frac{\mathcal{C}}{2}\frac{\partial(uS^2)}{\partial

z}\right)\right]\right\}\nonumber\\

{\bigcirc{\kern-6pt 1}} \qquad \ \qquad \qquad {\bigcirc{\kern-6pt 2}} \nonumber\\

+\frac{2}{S}\left\{\frac{\partial \sigma}{\partial z}+\frac{\partial}{\partial

z}\left[\frac{Oh(\kappa_s-\mu_s)}{S}\left(\frac{\partial(uS)}{\partial

z}-\frac{\mathcal{C}}{2}\frac{\partial(uS^2)}{\partial z}\right)\right]\right\}\nonumber\\

\qquad {\bigcirc{\kern-6pt 3}} \qquad \ \ \qquad \qquad \qquad {\bigcirc{\kern-6pt 4}} \nonumber\\

+\frac{5Oh}{S^2}\frac{\partial }{\partial

z}\left(\mu_sS\frac{\partial u}{\partial z}\right), \nonumber\\

\qquad \quad \ {\bigcirc{\kern-6pt 5}}

\end{gather} $$\begin{gather} \tau_{zz}=\frac{(1-\beta)Oh}{De}\left(\frac{A_{zz}}{1- \dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}-1\right), \end{gather}$$

$$\begin{gather} \tau_{zz}=\frac{(1-\beta)Oh}{De}\left(\frac{A_{zz}}{1- \dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}-1\right), \end{gather}$$ $$\begin{gather}\tau_{rr}=\frac{(1-\beta)Oh}{De}\left(\frac{A_{rr}}{1- \dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}-1\right), \end{gather}$$

$$\begin{gather}\tau_{rr}=\frac{(1-\beta)Oh}{De}\left(\frac{A_{rr}}{1- \dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}-1\right), \end{gather}$$ $$\begin{gather}De\left(\frac{\partial A_{zz}}{\partial t}+u\frac{\partial A_{zz}}{\partial z}-2 A_{zz}\frac{\partial u}{\partial z}\right) =1-\frac{A_{zz}}{1-\dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}, \end{gather}$$

$$\begin{gather}De\left(\frac{\partial A_{zz}}{\partial t}+u\frac{\partial A_{zz}}{\partial z}-2 A_{zz}\frac{\partial u}{\partial z}\right) =1-\frac{A_{zz}}{1-\dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}, \end{gather}$$ $$\begin{gather}De\left(\frac{\partial A_{rr}}{\partial t}+u\frac{\partial A_{rr}}{\partial z}+ A_{rr}\frac{\partial u}{\partial z}\right)=1-\frac{A_{rr}}{1-\dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}, \end{gather}$$

$$\begin{gather}De\left(\frac{\partial A_{rr}}{\partial t}+u\frac{\partial A_{rr}}{\partial z}+ A_{rr}\frac{\partial u}{\partial z}\right)=1-\frac{A_{rr}}{1-\dfrac{tr({{\boldsymbol{\mathsf{A}}}})}{L^2}}, \end{gather}$$ $$\begin{gather}\frac{\partial \varGamma}{\partial t}+\frac{1}{S}\frac{\partial (Su\varGamma)}{\partial z}-\frac{\mathcal{C} \varGamma}{2S}\frac{\partial (S^2u)}{\partial z}=\frac{1}{Pe}\frac{1}{S}\frac{\partial \left(S\dfrac{\partial \varGamma}{\partial z}\right)}{\partial z}, \end{gather}$$

$$\begin{gather}\frac{\partial \varGamma}{\partial t}+\frac{1}{S}\frac{\partial (Su\varGamma)}{\partial z}-\frac{\mathcal{C} \varGamma}{2S}\frac{\partial (S^2u)}{\partial z}=\frac{1}{Pe}\frac{1}{S}\frac{\partial \left(S\dfrac{\partial \varGamma}{\partial z}\right)}{\partial z}, \end{gather}$$where

$$\begin{gather}\mathcal{C}=\frac{1}{S\sqrt{1+\left(\dfrac{\partial S}{\partial z}\right)^2}}-\frac{\dfrac{\partial^2S}{\partial z^2}}{\left[1+\left(\dfrac{\partial S}{\partial z}\right)^2\right]^{3/2}}, \end{gather}$$

$$\begin{gather}\mathcal{C}=\frac{1}{S\sqrt{1+\left(\dfrac{\partial S}{\partial z}\right)^2}}-\frac{\dfrac{\partial^2S}{\partial z^2}}{\left[1+\left(\dfrac{\partial S}{\partial z}\right)^2\right]^{3/2}}, \end{gather}$$

Note that the same symbols are used to denote both the dimensional and the dimensionless quantities for brevity. The dimensionless numbers appearing in the above 1-D equations are the Ohnesorge number ![]() $Oh={\eta _0}/{\sqrt {\rho \sigma _0R}}$ representing the relative importance of bulk viscosity and capillarity, the solvent to solution viscosity ratio

$Oh={\eta _0}/{\sqrt {\rho \sigma _0R}}$ representing the relative importance of bulk viscosity and capillarity, the solvent to solution viscosity ratio ![]() $\beta ={\eta _s}/{\eta _0}$, the Deborah number

$\beta ={\eta _s}/{\eta _0}$, the Deborah number ![]() $De={\lambda _c}/{t_c}$ measuring the relative importance of elasticity and capillarity, the surface Péclet number

$De={\lambda _c}/{t_c}$ measuring the relative importance of elasticity and capillarity, the surface Péclet number ![]() $Pe={R^2}/{t_c D_s}$ measuring the relative importance of surface convection and surface diffusion in surfactant transport, the elasticity number

$Pe={R^2}/{t_c D_s}$ measuring the relative importance of surface convection and surface diffusion in surfactant transport, the elasticity number ![]() $E={R_gT\varGamma _{\infty }}/{\sigma _0}$ measuring the activity of the surfactant or the sensitivity of the surface tension to changes in the surfactant concentration (in order to distinguish from the elasticity of the viscoelastic liquid, hereafter it is called the Marangoni number, as referred to in Ponce-Torres et al. Reference Ponce-Torres, Herrada, Montanero and Vega2016; Martínez-Calvo et al. Reference Martínez-Calvo, Rivero-Rodríguez, Scheid and Sevilla2020; Herrada et al. Reference Herrada, Ponce-Torres, Rubio, Eggers and Montanero2022) and the dilatational Boussinesq number

$E={R_gT\varGamma _{\infty }}/{\sigma _0}$ measuring the activity of the surfactant or the sensitivity of the surface tension to changes in the surfactant concentration (in order to distinguish from the elasticity of the viscoelastic liquid, hereafter it is called the Marangoni number, as referred to in Ponce-Torres et al. Reference Ponce-Torres, Herrada, Montanero and Vega2016; Martínez-Calvo et al. Reference Martínez-Calvo, Rivero-Rodríguez, Scheid and Sevilla2020; Herrada et al. Reference Herrada, Ponce-Torres, Rubio, Eggers and Montanero2022) and the dilatational Boussinesq number ![]() $B_{\kappa \infty }={\kappa _s(\varGamma =\varGamma _\infty )}/{\eta _0 R}=({\kappa _{sr}}/{\eta _0 R})({\varGamma _\infty }/{\varGamma _r})$ and the shear Boussinesq number

$B_{\kappa \infty }={\kappa _s(\varGamma =\varGamma _\infty )}/{\eta _0 R}=({\kappa _{sr}}/{\eta _0 R})({\varGamma _\infty }/{\varGamma _r})$ and the shear Boussinesq number ![]() $B_{\mu \infty }={\mu _s(\varGamma =\varGamma _\infty )}/{\eta _0 R}=({\mu _{sr}}/{\eta _0 R})({\varGamma _\infty }/{\varGamma _r})$ measuring the relative importance of surface and bulk viscosities.

$B_{\mu \infty }={\mu _s(\varGamma =\varGamma _\infty )}/{\eta _0 R}=({\mu _{sr}}/{\eta _0 R})({\varGamma _\infty }/{\varGamma _r})$ measuring the relative importance of surface and bulk viscosities.

Equation (3.1) expresses the volume conservation, (3.2) is the 1-D momentum equation, (3.3)–(3.6) are the constitutive equations for the FENE-P viscoelastic model and (3.7) expresses the surfactant mass conservation. On the right-hand side of (3.2), the first term is the viscous force from the solvent, the second term is the viscoelastic force from the polymer and the rest of the terms, numbered ![]() ${\bigcirc{\kern-6pt 1}}$–

${\bigcirc{\kern-6pt 1}}$–![]() ${\bigcirc{\kern-6pt 5}}$, are all related to the surfactant, indicating that the surfactant influences the nonlinear dynamics of the viscoelastic thread in a complicated way. Specifically, term

${\bigcirc{\kern-6pt 5}}$, are all related to the surfactant, indicating that the surfactant influences the nonlinear dynamics of the viscoelastic thread in a complicated way. Specifically, term ![]() ${\bigcirc{\kern-6pt 1}}$ is the capillary force, term

${\bigcirc{\kern-6pt 1}}$ is the capillary force, term ![]() ${\bigcirc{\kern-6pt 3}}$ is the Marangoni stress resulting from the spatial non-uniformity of the surface tension and terms

${\bigcirc{\kern-6pt 3}}$ is the Marangoni stress resulting from the spatial non-uniformity of the surface tension and terms ![]() ${\bigcirc{\kern-6pt 2}}$,

${\bigcirc{\kern-6pt 2}}$, ![]() ${\bigcirc{\kern-6pt 4}}$ and

${\bigcirc{\kern-6pt 4}}$ and ![]() ${\bigcirc{\kern-6pt 5}}$ are the surface viscous stresses associated with surface dilatational and shear deformations. If the surface dilatational viscosity

${\bigcirc{\kern-6pt 5}}$ are the surface viscous stresses associated with surface dilatational and shear deformations. If the surface dilatational viscosity ![]() $\kappa _s$ is equal to the surface shear viscosity

$\kappa _s$ is equal to the surface shear viscosity ![]() $\mu _s$, both term

$\mu _s$, both term ![]() ${\bigcirc{\kern-6pt 2}}$ and term

${\bigcirc{\kern-6pt 2}}$ and term ![]() ${\bigcirc{\kern-6pt 4}}$ vanish and the momentum equation (3.2) is, fortunately, reduced. On the left-hand side of (3.7), the full curvature is preserved. If the slender body approximation is considered, (3.7) is simplified as

${\bigcirc{\kern-6pt 4}}$ vanish and the momentum equation (3.2) is, fortunately, reduced. On the left-hand side of (3.7), the full curvature is preserved. If the slender body approximation is considered, (3.7) is simplified as

\begin{equation} \frac{\partial(\varGamma^2)}{\partial t}+\frac{\partial(\varGamma^2u)}{\partial z}=\frac{2}{Pe}\frac{\varGamma}{S}\frac{\partial \left(S\dfrac{\partial \varGamma}{\partial z}\right)}{\partial z}. \end{equation}

\begin{equation} \frac{\partial(\varGamma^2)}{\partial t}+\frac{\partial(\varGamma^2u)}{\partial z}=\frac{2}{Pe}\frac{\varGamma}{S}\frac{\partial \left(S\dfrac{\partial \varGamma}{\partial z}\right)}{\partial z}. \end{equation} When the finite extensibility ![]() $L$ approaches infinity (polymer chains are infinitely extensible), the Oldroyd-B viscoelastic model is recovered, for which (3.1) and (3.2) and (3.7) remain unchanged, but the constitutive equations (3.3)–(3.6) reduce to

$L$ approaches infinity (polymer chains are infinitely extensible), the Oldroyd-B viscoelastic model is recovered, for which (3.1) and (3.2) and (3.7) remain unchanged, but the constitutive equations (3.3)–(3.6) reduce to

If the Deborah number is set to be zero, the 1-D model reduces to that for Newtonian viscous liquid threads covered with insoluble surfactants, as proposed by Martínez-Calvo & Sevilla (Reference Martínez-Calvo and Sevilla2018) and Wee et al. (Reference Wee, Wagoner, Garg, Kamat and Basaran2021). In addition, if the surfactant concentration ![]() $\varGamma$ is set to zero, the 1-D model reduces to that for surfactant-free viscoelastic threads of FENE-P type as built in Fontelos & Li (Reference Fontelos and Li2004).

$\varGamma$ is set to zero, the 1-D model reduces to that for surfactant-free viscoelastic threads of FENE-P type as built in Fontelos & Li (Reference Fontelos and Li2004).

4. Numerical results

The 1-D equations (3.1)–(3.7) are solved by using an implicit finite difference scheme with adaptive mesh refinement (Li & He Reference Li and He2021). Considering both accuracy and efficiency, the number of spatial discrete points is ![]() $1000$–

$1000$–![]() $1600$, and the time step varies between

$1600$, and the time step varies between ![]() $10^{-6}$ and

$10^{-6}$ and ![]() $0.005$. The convergence condition at each time step is that the maximum relative error is below

$0.005$. The convergence condition at each time step is that the maximum relative error is below ![]() $0.001$. The calculation stops when the dimensionless minimum radius of the thread is less than 0.001. The validity of the code is checked by comparing with the results in Fontelos & Li (Reference Fontelos and Li2004), Li & He (Reference Li and He2021) and Wee et al. (Reference Wee, Wagoner, Garg, Kamat and Basaran2021).

$0.001$. The calculation stops when the dimensionless minimum radius of the thread is less than 0.001. The validity of the code is checked by comparing with the results in Fontelos & Li (Reference Fontelos and Li2004), Li & He (Reference Li and He2021) and Wee et al. (Reference Wee, Wagoner, Garg, Kamat and Basaran2021).

At the initial time ![]() $t=0$, the thread is perturbed by a small cosinusoidal harmonic disturbance, i.e.

$t=0$, the thread is perturbed by a small cosinusoidal harmonic disturbance, i.e.

where ![]() $k$ is the dimensionless axial wavenumber and

$k$ is the dimensionless axial wavenumber and ![]() $\epsilon _0$ is the initial amplitude of the disturbance whose value is fixed to 0.01.

$\epsilon _0$ is the initial amplitude of the disturbance whose value is fixed to 0.01.

Due to spatial periodicity and symmetry, only a half-wavelength long segment of the thread needs to be calculated. Therefore, in the calculation, the domain is limited to ![]() $z\in [0,\ \lambda /2]$, where

$z\in [0,\ \lambda /2]$, where ![]() $\lambda =2{\rm \pi} /k$ is the dimensionless wavelength of the disturbance.The periodic boundary conditions are imposed at

$\lambda =2{\rm \pi} /k$ is the dimensionless wavelength of the disturbance.The periodic boundary conditions are imposed at ![]() $z=0$ and

$z=0$ and ![]() $z=\lambda /2$, i.e.

$z=\lambda /2$, i.e.

\begin{align}

\left.\begin{array}{@{}c@{}} \displaystyle \dfrac{\partial

S}{\partial z}(z=0,t)=\dfrac{\partial S}{\partial

z}\left(z=\dfrac{\lambda}{2},t\right)=0,\quad

u(z=0,t)=u\left(z=\dfrac{\lambda}{2},t\right)=0,\\

\displaystyle \dfrac{\partial \tau_{zz}}{\partial

z}(z=0,t)=\dfrac{\partial \tau_{zz}}{\partial

z}\left(z=\dfrac{\lambda}{2},t\right)=0,\quad

\dfrac{\partial \tau_{rr}}{\partial

z}(z=0,t)=\dfrac{\partial \tau_{rr}}{\partial

z}\left(z=\dfrac{\lambda}{2},t\right)=0,\\

\displaystyle \dfrac{\partial A_{zz}}{\partial z}(z=0,t)=\dfrac{\partial

A_{zz}}{\partial

z}\left(z=\dfrac{\lambda}{2},t\right)=0,\quad

\dfrac{\partial A_{rr}}{\partial z}(z=0,t)=\dfrac{\partial

A_{rr}}{\partial z}\left(z=\dfrac{\lambda}{2},t\right)=0,\\

\displaystyle \dfrac{\partial \varGamma}{\partial

z}(z=0,t)=\dfrac{\partial \varGamma}{\partial

z}\left(z=\dfrac{\lambda}{2},t\right)=0.

\end{array}\right\}

\end{align}

\begin{align}

\left.\begin{array}{@{}c@{}} \displaystyle \dfrac{\partial

S}{\partial z}(z=0,t)=\dfrac{\partial S}{\partial

z}\left(z=\dfrac{\lambda}{2},t\right)=0,\quad

u(z=0,t)=u\left(z=\dfrac{\lambda}{2},t\right)=0,\\

\displaystyle \dfrac{\partial \tau_{zz}}{\partial

z}(z=0,t)=\dfrac{\partial \tau_{zz}}{\partial

z}\left(z=\dfrac{\lambda}{2},t\right)=0,\quad

\dfrac{\partial \tau_{rr}}{\partial

z}(z=0,t)=\dfrac{\partial \tau_{rr}}{\partial

z}\left(z=\dfrac{\lambda}{2},t\right)=0,\\

\displaystyle \dfrac{\partial A_{zz}}{\partial z}(z=0,t)=\dfrac{\partial

A_{zz}}{\partial

z}\left(z=\dfrac{\lambda}{2},t\right)=0,\quad

\dfrac{\partial A_{rr}}{\partial z}(z=0,t)=\dfrac{\partial

A_{rr}}{\partial z}\left(z=\dfrac{\lambda}{2},t\right)=0,\\

\displaystyle \dfrac{\partial \varGamma}{\partial

z}(z=0,t)=\dfrac{\partial \varGamma}{\partial

z}\left(z=\dfrac{\lambda}{2},t\right)=0.

\end{array}\right\}

\end{align} There are in total ten dimensionless parameters involved in this problem: ![]() $Oh, \beta, De, L, Pe, E, B_{\kappa \infty }, B_{\mu \infty }, \varGamma _0$ and

$Oh, \beta, De, L, Pe, E, B_{\kappa \infty }, B_{\mu \infty }, \varGamma _0$ and ![]() $k$. The physical properties of surfactant-laden or viscoelastic fluids as well as the values of the dimensionless numbers considered in the literature are collected in table 1. As one can see, the properties span a wide range. We would like to consider a viscoelastic thread of moderate viscosity and moderate elasticity. Suppose the density

$k$. The physical properties of surfactant-laden or viscoelastic fluids as well as the values of the dimensionless numbers considered in the literature are collected in table 1. As one can see, the properties span a wide range. We would like to consider a viscoelastic thread of moderate viscosity and moderate elasticity. Suppose the density ![]() $\rho$ is

$\rho$ is ![]() $1000\ \textrm {kg\ m}^{-3}$, the zero-shear viscosity

$1000\ \textrm {kg\ m}^{-3}$, the zero-shear viscosity ![]() $\eta _0$ is

$\eta _0$ is ![]() $0.1\ \textrm {Pa s}$, the stress relaxation time

$0.1\ \textrm {Pa s}$, the stress relaxation time ![]() $\lambda _c$ is

$\lambda _c$ is ![]() $0.5\ \textrm {ms}$, the surface tension

$0.5\ \textrm {ms}$, the surface tension ![]() $\sigma _0$ is

$\sigma _0$ is ![]() $0.05\ \textrm {N\ m}^{-1}$ and the radius of the unperturbed thread

$0.05\ \textrm {N\ m}^{-1}$ and the radius of the unperturbed thread ![]() $R$ is

$R$ is ![]() $100\ \mathrm {\mu }\textrm {m}$. Then, the Ohnesorge number

$100\ \mathrm {\mu }\textrm {m}$. Then, the Ohnesorge number ![]() $Oh$ has a value of

$Oh$ has a value of ![]() $1.4$ and the Deborah number

$1.4$ and the Deborah number ![]() $De$ has a value of

$De$ has a value of ![]() $3.5$. The values of

$3.5$. The values of ![]() $Oh$ and

$Oh$ and ![]() $De$ are kept unchanged, since we focus on the effects of the surfactant on the dynamic behaviour of the viscoelastic thread. Without loss of generality, the solvent to solution viscosity ratio

$De$ are kept unchanged, since we focus on the effects of the surfactant on the dynamic behaviour of the viscoelastic thread. Without loss of generality, the solvent to solution viscosity ratio ![]() $\beta$ is fixed to 0.5 and the finite extensibility parameter

$\beta$ is fixed to 0.5 and the finite extensibility parameter ![]() $L$ takes a value of 5 for the FENE-P model. The surfactant surface diffusivity

$L$ takes a value of 5 for the FENE-P model. The surfactant surface diffusivity ![]() $D_s$ is about

$D_s$ is about ![]() $10^{-10}$–

$10^{-10}$–![]() $10^{-9}\ \textrm {m}^2\ \textrm{s}^{-1}$ (Timmermans & Lister Reference Timmermans and Lister2002; Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2018). The surface Péclet number

$10^{-9}\ \textrm {m}^2\ \textrm{s}^{-1}$ (Timmermans & Lister Reference Timmermans and Lister2002; Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2018). The surface Péclet number ![]() $Pe$ is of the order of magnitude of

$Pe$ is of the order of magnitude of ![]() $10^3$ to

$10^3$ to ![]() $10^6$, suggesting that surface convection is dominant in surfactant transport. In many studies, surface diffusion was reasonably neglected, i.e. the surface Péclet number was taken to be infinity (Timmermans & Lister Reference Timmermans and Lister2002; Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2018; Alhushaybari & Uddin Reference Alhushaybari and Uddin2020; Martínez-Calvo et al. Reference Martínez-Calvo, Rivero-Rodríguez, Scheid and Sevilla2020; Wee et al. Reference Wee, Wagoner, Garg, Kamat and Basaran2021). In addition to a case of large surface Péclet number (

$10^6$, suggesting that surface convection is dominant in surfactant transport. In many studies, surface diffusion was reasonably neglected, i.e. the surface Péclet number was taken to be infinity (Timmermans & Lister Reference Timmermans and Lister2002; Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2018; Alhushaybari & Uddin Reference Alhushaybari and Uddin2020; Martínez-Calvo et al. Reference Martínez-Calvo, Rivero-Rodríguez, Scheid and Sevilla2020; Wee et al. Reference Wee, Wagoner, Garg, Kamat and Basaran2021). In addition to a case of large surface Péclet number (![]() $Pe=10^5$), we will examine a case of moderate surface Péclet number (

$Pe=10^5$), we will examine a case of moderate surface Péclet number (![]() $Pe=1$), in which surface convection and surface diffusion are of equal importance. In small-scale applications such as microemulsions and nanoemulsions, the surface Péclet number can be order one (

$Pe=1$), in which surface convection and surface diffusion are of equal importance. In small-scale applications such as microemulsions and nanoemulsions, the surface Péclet number can be order one (![]() $O(1)$). We intend to discuss the effect of surfactant diffusivity on the nonlinear evolution of a viscoelastic thread via the moderate

$O(1)$). We intend to discuss the effect of surfactant diffusivity on the nonlinear evolution of a viscoelastic thread via the moderate ![]() $Pe$ case. The initial surfactant concentration

$Pe$ case. The initial surfactant concentration ![]() $\varGamma _0$ varies between 0 and 0.5. The range of the Marangoni number

$\varGamma _0$ varies between 0 and 0.5. The range of the Marangoni number ![]() $E$ is from 0 to 0.6. The surface shear and dilatational viscosities are

$E$ is from 0 to 0.6. The surface shear and dilatational viscosities are ![]() $10^{-5}$–

$10^{-5}$–![]() $10^{-4}\ \textrm {Pa\ s m}$ (Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2018) or much lower (

$10^{-4}\ \textrm {Pa\ s m}$ (Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2018) or much lower (![]() $\sim 10^{-8} \textrm {Pa\ s\ m}$) (Zell et al. Reference Zell, Nowbahar, Mansard, Leal, Deshmukh, Mecca, Tucker and Squires2014; Ponce-Torres et al. Reference Ponce-Torres, Rubio, Herrada, Eggers and Montanero2020). The Boussinesq numbers

$\sim 10^{-8} \textrm {Pa\ s\ m}$) (Zell et al. Reference Zell, Nowbahar, Mansard, Leal, Deshmukh, Mecca, Tucker and Squires2014; Ponce-Torres et al. Reference Ponce-Torres, Rubio, Herrada, Eggers and Montanero2020). The Boussinesq numbers ![]() $B_{\kappa \infty }$ and

$B_{\kappa \infty }$ and ![]() $B_{\mu \infty }$ range widely from 0 to

$B_{\mu \infty }$ range widely from 0 to ![]() $O(10^3)$. The larger the Boussinesq numbers, the more important the surface viscous stresses. We consider a relatively conservative range of

$O(10^3)$. The larger the Boussinesq numbers, the more important the surface viscous stresses. We consider a relatively conservative range of ![]() $B_{\kappa \infty }$ and

$B_{\kappa \infty }$ and ![]() $B_{\mu \infty }$ from 0 to 100. Moreover, we assume that

$B_{\mu \infty }$ from 0 to 100. Moreover, we assume that ![]() $B_{\kappa \infty }$ is equal to

$B_{\kappa \infty }$ is equal to ![]() $B_{\mu \infty }$. The measurement of surface shear and dilatational viscosities is an experimental challenge. Some experiments showed that the surface dilatational viscosity can be orders of magnitude larger than the surface shear viscosity and can be augmented by adsorption if the surfactant is soluble (Lucassen & van den Tempel Reference Lucassen and van den Tempel1972; Alvarez et al. Reference Alvarez, Anna, Saigal, Tilton and Walker2012; Singh & Narsimhan Reference Singh and Narsimhan2021, Reference Singh and Narsimhan2022; Herrada et al. Reference Herrada, Ponce-Torres, Rubio, Eggers and Montanero2022). The range of the axial wavenumber

$B_{\mu \infty }$. The measurement of surface shear and dilatational viscosities is an experimental challenge. Some experiments showed that the surface dilatational viscosity can be orders of magnitude larger than the surface shear viscosity and can be augmented by adsorption if the surfactant is soluble (Lucassen & van den Tempel Reference Lucassen and van den Tempel1972; Alvarez et al. Reference Alvarez, Anna, Saigal, Tilton and Walker2012; Singh & Narsimhan Reference Singh and Narsimhan2021, Reference Singh and Narsimhan2022; Herrada et al. Reference Herrada, Ponce-Torres, Rubio, Eggers and Montanero2022). The range of the axial wavenumber ![]() $k$ is from 0.3 to 0.9. All the values of the dimensionless numbers considered in the simulation are summarized in table 2. Finally, to facilitate simulation and analysis, a reference state is selected, in which

$k$ is from 0.3 to 0.9. All the values of the dimensionless numbers considered in the simulation are summarized in table 2. Finally, to facilitate simulation and analysis, a reference state is selected, in which ![]() $Oh=1.4, \beta =0.5, De=3.5, \varGamma _0=0.3, E=0.4, Pe=10^5, B_{\kappa \infty }=B_{\mu \infty }=0$ and

$Oh=1.4, \beta =0.5, De=3.5, \varGamma _0=0.3, E=0.4, Pe=10^5, B_{\kappa \infty }=B_{\mu \infty }=0$ and ![]() $L=5$ (FENE-P) or

$L=5$ (FENE-P) or ![]() $\infty$ (Oldroyd-B). The dimensionless numbers are fixed to the reference state unless specified otherwise.

$\infty$ (Oldroyd-B). The dimensionless numbers are fixed to the reference state unless specified otherwise.

Table 1. The physical properties of surfactant-laden fluids and viscoelastic fluids and the values of the dimensional numbers in the literature. The superscripts 0 and c denote the Boussinesq numbers at ![]() $\varGamma _0$ and the CMC, respectively.

$\varGamma _0$ and the CMC, respectively.

Table 2. The values of the dimensionless numbers considered in the simulation.

4.1. Linear instability analysis based on the 1-D model

In this subsection, a brief linear analysis is performed based on the present 1-D model. Following the normal mode method, the quantities are decomposed into a base and a perturbation part, i.e.

\begin{align} (S, u, \tau_{zz}, \tau_{rr}, A_{zz}, A_{rr}, \varGamma)&=\left(1, 0, 0, 0, \frac{L^2}{L^2+3},\frac{L^2}{L^2+3}, \varGamma_0\right)\nonumber\\ &\quad +(\hat{S}, \hat{u}, \hat{\tau}_{zz}, \hat{\tau}_{rr}, \hat{A}_{zz}, \hat{A}_{rr}, \hat{\varGamma})\exp(\alpha t+jkz)+{\rm c.c.}, \end{align}

\begin{align} (S, u, \tau_{zz}, \tau_{rr}, A_{zz}, A_{rr}, \varGamma)&=\left(1, 0, 0, 0, \frac{L^2}{L^2+3},\frac{L^2}{L^2+3}, \varGamma_0\right)\nonumber\\ &\quad +(\hat{S}, \hat{u}, \hat{\tau}_{zz}, \hat{\tau}_{rr}, \hat{A}_{zz}, \hat{A}_{rr}, \hat{\varGamma})\exp(\alpha t+jkz)+{\rm c.c.}, \end{align}

where the hat denotes the initial amplitudes of the perturbation parts, ![]() $\alpha$ is the complex frequency with the real part

$\alpha$ is the complex frequency with the real part ![]() $\alpha _r$ the temporal growth rate and the imaginary part

$\alpha _r$ the temporal growth rate and the imaginary part ![]() $\alpha _i$ the speed of wave propagation,

$\alpha _i$ the speed of wave propagation, ![]() $j$ is the imaginary unit and ‘c.c.’ denotes the complex conjugate.

$j$ is the imaginary unit and ‘c.c.’ denotes the complex conjugate.

Linearizing the 1-D equations (3.1)–(3.7) and then substituting the decomposition (4.3) into the linearized equations, we obtain a set of linear homogeneous algebraic equations for the unknowns ![]() $(\hat {S}, \hat {u}, \hat {\tau }_{zz}, \hat {\tau }_{rr}, \hat {A}_{zz}, \hat {A}_{rr}, \hat {\varGamma })$. The determinant of the coefficient matrix of the equations has to be zero to ensure the system has non-trivial solutions, which yields the following dispersion relation:

$(\hat {S}, \hat {u}, \hat {\tau }_{zz}, \hat {\tau }_{rr}, \hat {A}_{zz}, \hat {A}_{rr}, \hat {\varGamma })$. The determinant of the coefficient matrix of the equations has to be zero to ensure the system has non-trivial solutions, which yields the following dispersion relation:

\begin{align} \alpha+3\beta Ohk^2&={-}k^2(1-\beta)Oh\frac{L^2+3}{L^2} (\varXi_1-\varXi_2)-\frac{k^2E\varGamma_0}{2(1-\varGamma_0) \left(\alpha+\dfrac{k^2}{Pe}\right)}\nonumber\\ &\quad+\frac{\sigma_ik^2(1-k^2)}{2\alpha}-\frac{B_{\kappa\infty} +9B_{\mu\infty}}{2}\varGamma_0Ohk^2, \end{align}

\begin{align} \alpha+3\beta Ohk^2&={-}k^2(1-\beta)Oh\frac{L^2+3}{L^2} (\varXi_1-\varXi_2)-\frac{k^2E\varGamma_0}{2(1-\varGamma_0) \left(\alpha+\dfrac{k^2}{Pe}\right)}\nonumber\\ &\quad+\frac{\sigma_ik^2(1-k^2)}{2\alpha}-\frac{B_{\kappa\infty} +9B_{\mu\infty}}{2}\varGamma_0Ohk^2, \end{align}where

$$\begin{gather} \varXi_1=\dfrac{\left| \begin{array}{cc} \dfrac{2L^2}{L^2+3} & \dfrac{2(L^2+3)}{L^4} \\ -\dfrac{L^2}{L^2+3} & De \alpha +\dfrac{L^2+3}{L^2}+\dfrac{2(L^2+3)}{L^4} \\ \end{array} \right| }{\left| \begin{array}{cc} De \alpha +\dfrac{L^2+3}{L^2}+\dfrac{L^2+3}{L^4} & \dfrac{2(L^2+3)}{L^4} \\ \dfrac{L^2+3}{L^4} & De \alpha +\dfrac{L^2+3}{L^2}+\dfrac{2(L^2+3)}{L^4} \end{array} \right|}, \end{gather}$$

$$\begin{gather} \varXi_1=\dfrac{\left| \begin{array}{cc} \dfrac{2L^2}{L^2+3} & \dfrac{2(L^2+3)}{L^4} \\ -\dfrac{L^2}{L^2+3} & De \alpha +\dfrac{L^2+3}{L^2}+\dfrac{2(L^2+3)}{L^4} \\ \end{array} \right| }{\left| \begin{array}{cc} De \alpha +\dfrac{L^2+3}{L^2}+\dfrac{L^2+3}{L^4} & \dfrac{2(L^2+3)}{L^4} \\ \dfrac{L^2+3}{L^4} & De \alpha +\dfrac{L^2+3}{L^2}+\dfrac{2(L^2+3)}{L^4} \end{array} \right|}, \end{gather}$$ $$\begin{gather}\varXi_2=\dfrac{\left| \begin{array}{cc} De \alpha +\dfrac{L^2+3}{L^2}+\dfrac{L^2+3}{L^4} & \dfrac{2L^2}{L^2+3} \\ \dfrac{L^2+3}{L^4} & -\dfrac{L^2}{L^2+3} \\ \end{array} \right| }{\left| \begin{array}{cc} De \alpha +\dfrac{L^2+3}{L^2}+\dfrac{L^2+3}{L^4} & \dfrac{2(L^2+3)}{L^4} \\ \dfrac{L^2+3}{L^4} & De \alpha +\dfrac{L^2+3}{L^2}+\dfrac{2(L^2+3)}{L^4} \end{array} \right|}, \end{gather}$$

$$\begin{gather}\varXi_2=\dfrac{\left| \begin{array}{cc} De \alpha +\dfrac{L^2+3}{L^2}+\dfrac{L^2+3}{L^4} & \dfrac{2L^2}{L^2+3} \\ \dfrac{L^2+3}{L^4} & -\dfrac{L^2}{L^2+3} \\ \end{array} \right| }{\left| \begin{array}{cc} De \alpha +\dfrac{L^2+3}{L^2}+\dfrac{L^2+3}{L^4} & \dfrac{2(L^2+3)}{L^4} \\ \dfrac{L^2+3}{L^4} & De \alpha +\dfrac{L^2+3}{L^2}+\dfrac{2(L^2+3)}{L^4} \end{array} \right|}, \end{gather}$$

and ![]() $\sigma _i(=1+E\ln (1-\varGamma _0))$ is the initial surface tension corresponding to the initial surfactant concentration

$\sigma _i(=1+E\ln (1-\varGamma _0))$ is the initial surface tension corresponding to the initial surfactant concentration ![]() $\varGamma _0$. Note that the four terms on the right-hand side of (4.4) are related to the viscoelasticity of the polymer solution, the Marangoni stress, the surface tension and the surface shear and dilatational viscosities, respectively.

$\varGamma _0$. Note that the four terms on the right-hand side of (4.4) are related to the viscoelasticity of the polymer solution, the Marangoni stress, the surface tension and the surface shear and dilatational viscosities, respectively.

When the finite extensibility ![]() $L$ approaches infinity, the dispersion relation (4.4) reduces to that for the linear Jeffreys model and any nonlinear viscoelastic model (e.g. Oldroyd-B and FENE-P) that becomes the Jeffreys model after linearization, i.e.

$L$ approaches infinity, the dispersion relation (4.4) reduces to that for the linear Jeffreys model and any nonlinear viscoelastic model (e.g. Oldroyd-B and FENE-P) that becomes the Jeffreys model after linearization, i.e.

\begin{align} \alpha+3\beta Ohk^2&={-}\frac{3k^2(1-\beta)Oh}{1+De\alpha}- \frac{k^2E\varGamma_0}{2(1-\varGamma_0) \left(\alpha+\dfrac{k^2}{Pe}\right)}\nonumber\\ &\quad+\frac{\sigma_ik^2(1-k^2)}{2\alpha}- \frac{B_{\kappa\infty}+9B_{\mu\infty}}{2}\varGamma_0Ohk^2. \end{align}

\begin{align} \alpha+3\beta Ohk^2&={-}\frac{3k^2(1-\beta)Oh}{1+De\alpha}- \frac{k^2E\varGamma_0}{2(1-\varGamma_0) \left(\alpha+\dfrac{k^2}{Pe}\right)}\nonumber\\ &\quad+\frac{\sigma_ik^2(1-k^2)}{2\alpha}- \frac{B_{\kappa\infty}+9B_{\mu\infty}}{2}\varGamma_0Ohk^2. \end{align} When the Deborah number ![]() $De$ is equal to zero, (4.7) reduces to the dispersion relation determining the linear instability characteristics of surfactant-laden Newtonian viscous threads (Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2018), i.e.

$De$ is equal to zero, (4.7) reduces to the dispersion relation determining the linear instability characteristics of surfactant-laden Newtonian viscous threads (Martínez-Calvo & Sevilla Reference Martínez-Calvo and Sevilla2018), i.e.

\begin{equation} \alpha+3 Ohk^2={-}\frac{k^2E\varGamma_0}{2(1-\varGamma_0) \left(\alpha+\dfrac{k^2}{Pe}\right)}+\frac{\sigma_ik^2(1 -k^2)}{2\alpha}-\frac{B_{\kappa\infty}+9B_{\mu\infty}}{2}\varGamma_0Ohk^2. \end{equation}

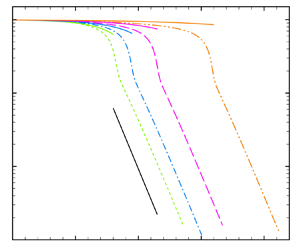

\begin{equation} \alpha+3 Ohk^2={-}\frac{k^2E\varGamma_0}{2(1-\varGamma_0) \left(\alpha+\dfrac{k^2}{Pe}\right)}+\frac{\sigma_ik^2(1 -k^2)}{2\alpha}-\frac{B_{\kappa\infty}+9B_{\mu\infty}}{2}\varGamma_0Ohk^2. \end{equation} The effect of the dimensionless numbers on the linear instability of the surfactant-covered viscoelastic thread is shown in figure 2. It can be seen that the temporal growth rate ![]() $\alpha _r$ decreases with the increase in the initial surfactant concentration

$\alpha _r$ decreases with the increase in the initial surfactant concentration ![]() $\varGamma _0$, the surface Péclet number

$\varGamma _0$, the surface Péclet number ![]() $Pe$, the Marangoni number

$Pe$, the Marangoni number ![]() $E$, the dilatational Boussinesq number

$E$, the dilatational Boussinesq number ![]() $B_{\kappa \infty }$ or the shear Boussinesq number