Article contents

Curved detonation and its reflections

Published online by Cambridge University Press: 01 April 2024

Abstract

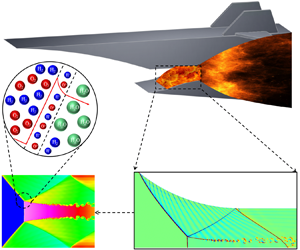

This paper investigates the effect of curvature on curved detonation and its reflections. Specifically, the study focuses on two aspects: the effect of curvature on the postwave parameters and their gradients, and the stabilization of Mach reflection. Relationships are established between the curvature and the gradients of the postwave parameters, thus providing a basis for examining detonation reflections and obtaining a comprehensive understanding of curved detonation. In particular, these relationships offer a valuable analytical tool to predict the postwave gradients, as well as providing a fresh perspective to understand the transformation from Mach reflection to regular reflection in curved detonation. The validity of these relationships is confirmed by comparison with simulation results. Two mechanisms by which curvature influences the stationarity of Mach reflection are identified. An increase in wave angle and interference between wave systems leading to the generation and integration of subsonic zones are the reasons for the non-stationarity of the Mach reflection in curved detonation. Besides, the effect mechanisms of choked flow which is considered to be the root cause are analysed in detail. On the basis of a theoretical model, the development of a quantitative criterion for the stability of detonation reflection is proposed, and its validity is confirmed by simulations. This criterion is used in a comprehensive investigation of the primary factors affecting the stability of detonation wave reflections, providing insights that will be of great value for the further development of detonation engines.

JFM classification

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2024. Published by Cambridge University Press

References

- 5

- Cited by