1. Introduction

Evaporating droplets frequently occur in nature and applications, be it a rain droplet evaporating on a leaf, a droplet on a hot surface in spray cooling, a droplet of insecticides sprayed on a leaf or an inkjet-printed ink droplet on paper. Many of such droplets are multicomponent, i.e. consisting of a mixture of liquids. From the physical point of view, an evaporating multicomponent droplet in a host gas is paradigmatic for combined multi-phase and multi-component flow including a phase transition. Scientifically, this process encompasses the various fields of fluid mechanics, thermodynamics and also aspects from the field of chemistry. The evaporation dynamics is also relevant for the deposit left behind the evaporation of a particle-laden droplet. Here, pioneering work was done by Deegan et al. (Reference Deegan, Bakajin, Dupont, Huber, Nagel and Witten1997) around 20 years ago, when they identified the coffee-stain effect – i.e. the phenomenon of finding a typical ring structure of deposited particles after the evaporation of a coffee droplet – and successfully explained it by the combination of a non-uniform evaporation rate along the droplet interface and a pinned contact line. In applications, one usually wants to prevent such coffee-stain effect, e.g. for obtaining a homogeneous deposition pattern in inkjet printing (Park & Moon Reference Park and Moon2006; Kuang, Wang & Song Reference Kuang, Wang and Song2014; Sefiane Reference Sefiane2014; Hoath Reference Hoath2016). For reviews on evaporating pure droplets we refer to Cazabat & Guéna (Reference Cazabat and Guéna2010) and Erbil (Reference Erbil2012).

Preventing the coffee-stain effect can be achieved by altering the flow inside the droplet during the drying process by inducing gradients in the acting forces. Focussing on the interfacial forces first, a tangential gradient of the surface tension along the liquid–gas interface leads to the well-known Marangoni effect, i.e. a tangential traction that drives the liquid towards positions of higher surface tension (Pearson Reference Pearson1958; Scriven & Sternling Reference Scriven and Sternling1960). By that, the entire flow in the droplet can be altered from the typical outwards flow towards the contact line to a recirculating flow driven by a persistent Marangoni effect (Hu & Larson Reference Hu and Larson2006). For the case of a pure droplet, the necessary gradient in surface tension can be generated by thermal effects, e.g. either self-induced by latent heat of evaporation or externally imposed by heating or cooling the substrate (Girard et al. Reference Girard, Antoni, Faure and Steinchen2006; Sodtke, Ajaev & Stephan Reference Sodtke, Ajaev and Stephan2008; Dunn et al. Reference Dunn, Wilson, Duffy, David and Sefiane2009; Tam et al. Reference Tam, von Arnim, McKinley and Hosoi2009).

The other mechanism to induce Marangoni flow is known as the solutal Marangoni effect, which is usually much stronger. For solutal Marangoni flow, the droplet must consist of more than one component, e.g. a solvent and one or more surfactants (Still, Yunker & Yodh Reference Still, Yunker and Yodh2012; Marin et al. Reference Marin, Liepelt, Rossi and Kähler2016; Kwieciński et al. Reference Kwieciński, Segers, Van Der Werf, Van Houselt, Lohse, Zandvliet and Kooij2019) or a solvent and possibly multiple co-solvents (Sefiane, Tadrist & Douglas Reference Sefiane, Tadrist and Douglas2003; Christy, Hamamoto & Sefiane Reference Christy, Hamamoto and Sefiane2011; Tan et al. Reference Tan, Diddens, Lv, Kuerten, Zhang and Lohse2016; Li et al. Reference Li, Lv, Diddens, Tan, Wijshoff, Versluis and Lohse2018) or dissolved salts (Soulié et al. Reference Soulié, Karpitschka, Lequien, Prené, Zemb, Moehwald and Riegler2015; Marin et al. Reference Marin, Karpitschka, Noguera-Marín, Cabrerizo-Vílchez, Rossi, Kähler and Rodríguez Valverde2019). For a recent perspective review on droplets consisting of more than one component, we refer to Lohse & Zhang (Reference Lohse and Zhang2020). The difference in the volatilities of the individual constituents leads to preferential evaporation of one or the other component and thereby compositional gradients are induced. Since the surface tension is a function of the composition and due to the non-uniform evaporation profile, a surface tension gradient along the liquid–gas interface can build up and result in a similar Marangoni circulation as in the thermally driven case. The nature of the resulting flow can be quite different, mostly depending on whether the evaporation process leads to an overall decreasing or increasing surface tension, i.e. whether the more volatile component has a higher or lower surface tension than the less volatile component.

In a binary droplet consisting e.g. of water and glycerol, with water being more volatile and having the higher surface tension, the overall surface tension decreases during the preferential evaporation of water and the resulting Marangoni flow is usually regular, axisymmetric and directed towards the position of the lowest evaporation rate of water, i.e. towards the contact line for contact angles above ![]() ${90}^{\circ }$ and towards the apex for contact angles below

${90}^{\circ }$ and towards the apex for contact angles below ![]() ${90}^{\circ }$ (Diddens Reference Diddens2017; Diddens et al. Reference Diddens, Kuerten, van der Geld and Wijshoff2017a).

${90}^{\circ }$ (Diddens Reference Diddens2017; Diddens et al. Reference Diddens, Kuerten, van der Geld and Wijshoff2017a).

On the contrary, e.g. in the case of a binary droplet consisting of water and ethanol, where the overall surface tension increases due to the predominant evaporation of ethanol, the typical Marangoni effect is way more violent and chaotic (Christy et al. Reference Christy, Hamamoto and Sefiane2011; Bennacer & Sefiane Reference Bennacer and Sefiane2014). Here, in particular, the axial symmetry of the droplet is usually broken, leading to a complicated scenario of initially chaotic flow driven by the solutal Marangoni effect and followed by either thermal Marangoni flow or the typical coffee-stain flow, when the droplet consists almost only of water at the end of the drying time (Diddens et al. Reference Diddens, Tan, Lv, Versluis, Kuerten, Zhang and Lohse2017b). Remarkably, the presence of a strong Marangoni effect can also have a significant influence on the shape and wetting behaviour of droplets (Tsoumpas et al. Reference Tsoumpas, Dehaeck, Rednikov and Colinet2015; Karpitschka, Liebig & Riegler Reference Karpitschka, Liebig and Riegler2017). Finally, the evaporation of mixture droplets can show a variety of additional intriguing phenomena, e.g. multiple phase changes and microdroplet nucleation in ternary droplets like ouzo (Tan et al. Reference Tan, Diddens, Lv, Kuerten, Zhang and Lohse2016, Reference Tan, Diddens, Versluis, Butt, Lohse and Zhang2017), and phase segregation in binary droplets (Li et al. Reference Li, Lv, Diddens, Tan, Wijshoff, Versluis and Lohse2018) or rather homogeneous deposition patterns by an interplay of Marangoni flow, surfactants and polymers (Kim et al. Reference Kim, Boulogne, Um, Jacobi, Button and Stone2016).

As highlighted above, besides the gradient in the surface tension, i.e. in the interfacial forces, also gradients in the mass density, i.e. in the bulk force due to gravity, can influence the flow by natural convection. Similar to the surface tension, the mass density is a function of the temperature and, in the case of mixtures, of the composition, so that thermally and solutally driven natural convection can be realized in evaporating droplets. Flow driven by natural convection is one of the most important fields of fluid mechanics, as e.g. in Rayleigh–Bénard systems; however, these are usually investigated at large spatial dimensions.

For small droplets, on the other hand, it is frequently argued in the literature that the presence of a small Bond number suggests that surface tension effects would dominate over gravity. As a consequence, these studies on droplet evaporation focus on the Marangoni effect, but disregard the presence of natural convection by this argument (e.g. Kim et al. Reference Kim, Boulogne, Um, Jacobi, Button and Stone2016; Diddens et al. Reference Diddens, Kuerten, van der Geld and Wijshoff2017a,b). However, the Bond number does not consider local variations of the surface tension and the mass density. Therefore, the Bond number may not be used as an indicator of whether natural convection can be disregarded or not. This has been also shown in recent studies by Edwards et al. (Reference Edwards, Atkinson, Cheung, Liang, Fairhurst and Ouali2018) and Li et al. (Reference Li, Diddens, Lv, Wijshoff, Versluis and Lohse2019a), where it has been proven that, even in small droplets with small Bond numbers, the internal flow can be decisively determined by natural convection and not by Marangoni flow.

Obviously, these findings give rise to the following question: How does the resulting flow type in an evaporating binary droplet depend on the parameters, i.e. when is the flow dominated by the Marangoni effect and when by natural convection?

In this manuscript, we answer this question by carefully investigating both kinds of driving force and their mutual interaction. The corresponding effects can be quantified by non-dimensional numbers, namely the Marangoni number for flow due to surface tension gradients and the Rayleigh (or Archimedes/Grashof) number for the natural convection. By considering quasi-stationary instants during the drying process, these numbers successfully allow us to predict the flow inside the droplets on the basis of phase diagrams in the ![]() $Ra$-

$Ra$-![]() $Ma$ parameter space. We also validated these phase diagrams with full simulations and corresponding experiments.

$Ma$ parameter space. We also validated these phase diagrams with full simulations and corresponding experiments.

The paper is organized as follows: we will first present the complete set of dynamical equations describing the evaporation of a binary mixture droplet. In § 3, these equations are solved to discuss an illustrative example case. We will then introduce the quasi-stationary approximation in § 4 and discuss the phase diagrams obtained by this model in § 5. The paper ends with a conclusion and a comparison with experimental data and a linearized investigation in appendix A and appendix B, respectively.

2. Governing equations

The evaporation of a mixture droplet is a multi-phase and free interface problem with multi-component dynamics in both the liquid and gas phase. For a binary droplet, the liquid is constituted by two components, ![]() $\alpha ={A},{B}$, whereas the gas phase is in general a ternary gas mixture of the ambient medium, e.g. air, and the vapours of the components

$\alpha ={A},{B}$, whereas the gas phase is in general a ternary gas mixture of the ambient medium, e.g. air, and the vapours of the components ![]() ${A}$ and

${A}$ and ![]() ${B}$. When the droplet evaporates at a temperature

${B}$. When the droplet evaporates at a temperature ![]() $T$ far below the boiling point and in the absence of forced or strong natural convection, the Péclet number in the gas phase is sufficiently small to consider only diffusive vapour transport, which can be treated as quasi-stationary since the diffusive time scale is several orders of magnitude smaller than the droplet drying time (Deegan et al. Reference Deegan, Bakajin, Dupont, Huber, Nagel and Witten2000; Hu & Larson Reference Hu and Larson2002; Popov Reference Popov2005; Diddens et al. Reference Diddens, Kuerten, van der Geld and Wijshoff2017a). This leads to the Laplace equation

$T$ far below the boiling point and in the absence of forced or strong natural convection, the Péclet number in the gas phase is sufficiently small to consider only diffusive vapour transport, which can be treated as quasi-stationary since the diffusive time scale is several orders of magnitude smaller than the droplet drying time (Deegan et al. Reference Deegan, Bakajin, Dupont, Huber, Nagel and Witten2000; Hu & Larson Reference Hu and Larson2002; Popov Reference Popov2005; Diddens et al. Reference Diddens, Kuerten, van der Geld and Wijshoff2017a). This leads to the Laplace equation

for the vapour concentrations ![]() $c_{\alpha }$, i.e. the partial mass densities. The corresponding boundary conditions are given by the vapour–liquid equilibrium according to Raoult's law at the liquid–gas interface and the ambient vapour concentration at infinity, i.e.

$c_{\alpha }$, i.e. the partial mass densities. The corresponding boundary conditions are given by the vapour–liquid equilibrium according to Raoult's law at the liquid–gas interface and the ambient vapour concentration at infinity, i.e.

where ![]() $c^{pure}_\alpha$ is the saturation vapour concentration in case of the pure liquid

$c^{pure}_\alpha$ is the saturation vapour concentration in case of the pure liquid ![]() $\alpha$ and

$\alpha$ and ![]() $x_\alpha$ is the liquid mole fraction, which can be calculated from the liquid mass fraction

$x_\alpha$ is the liquid mole fraction, which can be calculated from the liquid mass fraction ![]() $y_\alpha$. The value of

$y_\alpha$. The value of ![]() $c^{pure}_\alpha$ can be calculated from the saturation pressure

$c^{pure}_\alpha$ can be calculated from the saturation pressure ![]() $p_{sat,\alpha }$ and molar mass

$p_{sat,\alpha }$ and molar mass ![]() $M_\alpha$ via

$M_\alpha$ via ![]() $c^{pure}_\alpha =p_{sat,\alpha }M_\alpha /(RT)$, with R being the universal gas constant. The activity coefficients

$c^{pure}_\alpha =p_{sat,\alpha }M_\alpha /(RT)$, with R being the universal gas constant. The activity coefficients ![]() $\gamma _{\alpha }$ account for thermodynamic non-idealities and are functions of the composition, i.e. of

$\gamma _{\alpha }$ account for thermodynamic non-idealities and are functions of the composition, i.e. of ![]() $x_{\alpha }$. Neglecting the small contribution of the Stefan flow, i.e. the convective transport of vapour governed by the sudden decrease of the mass density when molecules are entering the gas phase (Carle et al. Reference Carle, Semenov, Medale and Brutin2016), which is a minor effect at temperatures sufficiently below the boiling point, the evaporation rates

$x_{\alpha }$. Neglecting the small contribution of the Stefan flow, i.e. the convective transport of vapour governed by the sudden decrease of the mass density when molecules are entering the gas phase (Carle et al. Reference Carle, Semenov, Medale and Brutin2016), which is a minor effect at temperatures sufficiently below the boiling point, the evaporation rates ![]() $j_{\alpha }$ are given by the diffusive fluxes at the liquid–gas interface, i.e.

$j_{\alpha }$ are given by the diffusive fluxes at the liquid–gas interface, i.e.

While the dynamics in the gas phase can be considered in the diffusive and quasi-stationary limit, convection can be dominant in the liquid phase, which can be attributed to the typical diffusion coefficients, namely ![]() $D_{\alpha }^{{vap}}\sim 10^{-5}\ \textrm {m}^{2}\ \textrm {s}^{-1}$ in the gas phase and

$D_{\alpha }^{{vap}}\sim 10^{-5}\ \textrm {m}^{2}\ \textrm {s}^{-1}$ in the gas phase and ![]() $D\sim 10^{-9}\ \textrm {m}^{2}\ \textrm {s}^{-1}$ in the liquid phase, leading to Péclet numbers between approximately

$D\sim 10^{-9}\ \textrm {m}^{2}\ \textrm {s}^{-1}$ in the liquid phase, leading to Péclet numbers between approximately ![]() $10$ and

$10$ and ![]() $100$ in the liquid phase and

$100$ in the liquid phase and ![]() $0.001$ and

$0.001$ and ![]() $0.01$ in the gas phase of the example case presented later in figure 2. Therefore, the liquid phase has to be described by the full convection–diffusion equation for the liquid mass fraction

$0.01$ in the gas phase of the example case presented later in figure 2. Therefore, the liquid phase has to be described by the full convection–diffusion equation for the liquid mass fraction ![]() $y_{\alpha }$, which is expressed for the component

$y_{\alpha }$, which is expressed for the component ![]() $A$ only due to the identity

$A$ only due to the identity ![]() $y_{{A}}+y_{{B}}=1$, i.e.

$y_{{A}}+y_{{B}}=1$, i.e.

The liquid density ![]() $\rho$ and the mutual diffusivity

$\rho$ and the mutual diffusivity ![]() $D$ are in general functions of the composition, i.e. of

$D$ are in general functions of the composition, i.e. of ![]() $y_{{A}}$. The mass transfer rates

$y_{{A}}$. The mass transfer rates ![]() $j_{\alpha }$ due to evaporation induce a change in composition at the liquid–gas interface. The mass transfer rate

$j_{\alpha }$ due to evaporation induce a change in composition at the liquid–gas interface. The mass transfer rate ![]() $j_\alpha$ of component

$j_\alpha$ of component ![]() $\alpha$ is given by the mass of particles crossing the interface per area and time, which can be expressed by

$\alpha$ is given by the mass of particles crossing the interface per area and time, which can be expressed by ![]() $j_\alpha =\rho y_\alpha (\boldsymbol {u}_\alpha - \boldsymbol {u}_{I})\boldsymbol {\cdot }\boldsymbol {n}$. Here,

$j_\alpha =\rho y_\alpha (\boldsymbol {u}_\alpha - \boldsymbol {u}_{I})\boldsymbol {\cdot }\boldsymbol {n}$. Here, ![]() $\boldsymbol {u}_\alpha$ is the species velocity, i.e. the locally averaged velocity of molecules of component

$\boldsymbol {u}_\alpha$ is the species velocity, i.e. the locally averaged velocity of molecules of component ![]() $\alpha$,

$\alpha$, ![]() $\boldsymbol {u}_{I}$ is the movement of the interface and

$\boldsymbol {u}_{I}$ is the movement of the interface and ![]() $\boldsymbol {n}$ is the interface normal. Using the relation between species velocity and the mass-averaged velocity

$\boldsymbol {n}$ is the interface normal. Using the relation between species velocity and the mass-averaged velocity ![]() $\boldsymbol {u}$, one can write

$\boldsymbol {u}$, one can write ![]() $j_\alpha =\rho y_\alpha (\boldsymbol {u} - \boldsymbol {u}_{I})\boldsymbol {\cdot }\boldsymbol {n}+\boldsymbol {J}_\alpha \boldsymbol {\cdot } \boldsymbol {n}$, where

$j_\alpha =\rho y_\alpha (\boldsymbol {u} - \boldsymbol {u}_{I})\boldsymbol {\cdot }\boldsymbol {n}+\boldsymbol {J}_\alpha \boldsymbol {\cdot } \boldsymbol {n}$, where ![]() $\boldsymbol {J}_\alpha =-\rho D \boldsymbol {\nabla } y_\alpha$ is the diffusive flux in the liquid. By taking the sum, one obtains the kinematic boundary condition

$\boldsymbol {J}_\alpha =-\rho D \boldsymbol {\nabla } y_\alpha$ is the diffusive flux in the liquid. By taking the sum, one obtains the kinematic boundary condition

which finally allows us to express the compositional change due to preferential evaporation by a Robin boundary condition for (2.5) in the frame co-moving with the interface, namely

Finally, the flow in the droplet is given by the Navier–Stokes equations and the continuity equation

Here, we have chosen the ![]() $z$-axis to point towards the apex of the droplet, i.e. a sessile droplet and a pendant droplet can be realized by negative and positive values for

$z$-axis to point towards the apex of the droplet, i.e. a sessile droplet and a pendant droplet can be realized by negative and positive values for ![]() $g$, respectively. Note that the viscosity

$g$, respectively. Note that the viscosity ![]() $\mu$ and the mass density

$\mu$ and the mass density ![]() $\rho$ are in general functions of the composition

$\rho$ are in general functions of the composition ![]() $y_{{A}}$. A dependence on the temperature is disregarded in the following due to the fact that thermal effects at lower temperatures are usually considerably inferior to the impact of solutal gradients.

$y_{{A}}$. A dependence on the temperature is disregarded in the following due to the fact that thermal effects at lower temperatures are usually considerably inferior to the impact of solutal gradients.

The free liquid–gas interface is subject to the kinematic boundary condition considering the mass transfer, i.e. (2.6), and furthermore to the Laplace pressure in the normal direction

where the traction in the gas phase has been neglected due to the viscosity ratio. Here, ![]() $\sigma$ is the local surface tension,

$\sigma$ is the local surface tension, ![]() $\kappa$ the curvature of the interface and

$\kappa$ the curvature of the interface and ![]() $p$ denotes the pressure difference with respect to the ambient gas pressure. Finally, also the Marangoni shear stress in tangential direction has to be considered

$p$ denotes the pressure difference with respect to the ambient gas pressure. Finally, also the Marangoni shear stress in tangential direction has to be considered

Here, ![]() $\boldsymbol {\nabla }_{t}=(\boldsymbol {1}-\boldsymbol {n}\boldsymbol {n})\boldsymbol {\cdot }\boldsymbol {\nabla }$ is the surface gradient operator.

$\boldsymbol {\nabla }_{t}=(\boldsymbol {1}-\boldsymbol {n}\boldsymbol {n})\boldsymbol {\cdot }\boldsymbol {\nabla }$ is the surface gradient operator.

For the contact line dynamics, we are focussing here on a pinned contact line, i.e. evaporation in the constant radius mode (CR-mode, Picknett & Bexon Reference Picknett and Bexon1977; Stauber et al. Reference Stauber, Wilson, Duffy and Sefiane2014). Directly at the contact line, (2.6) is incompatible with a no-slip boundary condition at the substrate, since the latter would enforce the left-hand side of (2.6) to be zero, whereas the right-hand side is usually non-zero for droplets with contact angles below ![]() ${90}^{\circ }$. To resolve this incompatibility of a no-slip boundary condition at the substrate and the evaporative mass loss at the contact line, a Navier-slip boundary condition with a small slip length in the nanometre scale is imposed instead. This effectively resembles a no-slip boundary condition in the main part of the droplet–substrate interface, but still allows for a consistent mass transfer directly at the contact line. According to our simulations, the exact value of the slip length does not influence the dynamics, as long as the slip length is several orders of magnitude smaller than the droplet size. The contact line position is kept fixed, whereas the contact angle

${90}^{\circ }$. To resolve this incompatibility of a no-slip boundary condition at the substrate and the evaporative mass loss at the contact line, a Navier-slip boundary condition with a small slip length in the nanometre scale is imposed instead. This effectively resembles a no-slip boundary condition in the main part of the droplet–substrate interface, but still allows for a consistent mass transfer directly at the contact line. According to our simulations, the exact value of the slip length does not influence the dynamics, as long as the slip length is several orders of magnitude smaller than the droplet size. The contact line position is kept fixed, whereas the contact angle ![]() $\theta$ emerges due to effects of capillarity and gravity.

$\theta$ emerges due to effects of capillarity and gravity.

A sketch of the model is depicted in figure 1.

Figure 1. Schematic of the model. The problem is considered to be axisymmetric and isothermal. The flow and the advection–diffusion equation for the composition in the droplet are solved with consideration of gravity and the composition dependence of the liquid mass density, dynamic viscosity and diffusivity. The transport in the gas phase is assumed to be diffusion limited. At the interface, Raoult's law is used to enforce the vapour–liquid equilibrium, mass transfer due to evaporation is considered and the Marangoni shear stress due to a composition-dependent surface tension is taken into account.

3. Numerical solution of the dynamical equations as an instructive example

In order to solve the given set of equations numerically, we have generalized the sharp-interface arbitrary Lagrangian–Eulerian finite element method described in Diddens (Reference Diddens2017) by considering the gravitational force, and also validated it by a more general reimplementation of the same model with the finite element package oomph-lib (oomph-lib.maths.man.ac.uk) (Heil & Hazel Reference Heil and Hazel2006), which allows for interface deformations and considers the general continuity equation (2.9). The latter method has been successfully validated against various experiments (Li et al. Reference Li, Lv, Diddens, Tan, Wijshoff, Versluis and Lohse2018, Reference Li, Diddens, Lv, Wijshoff, Versluis and Lohse2019a; Gauthier et al. Reference Gauthier, Diddens, Proville, Lohse and van der Meer2019; Li et al. Reference Li, Diddens, Prosperetti, Chong, Zhang and Lohse2019b).

In figure 2, a simulation of a sessile glycerol–water droplet (initially 5 wt.% glycerol) with an initial volume of ![]() ${1}\ {\mathrm {\mu }}\textrm {l}$ and an initial contact angle of

${1}\ {\mathrm {\mu }}\textrm {l}$ and an initial contact angle of ![]() ${120}^{\circ }$ evaporating at a constant temperature of

${120}^{\circ }$ evaporating at a constant temperature of ![]() ${22}\,^{\circ }\textrm {C}$ and a relative humidity of

${22}\,^{\circ }\textrm {C}$ and a relative humidity of ![]() ${20}\,\%$ (entering the model in the parameter

${20}\,\%$ (entering the model in the parameter ![]() $c_\alpha ^{\infty }$) is shown. The contact line remains pinned during drying and glycerol (liquid

$c_\alpha ^{\infty }$) is shown. The contact line remains pinned during drying and glycerol (liquid ![]() $B$) is assumed to be non-volatile due to its low volatility compared to water (liquid

$B$) is assumed to be non-volatile due to its low volatility compared to water (liquid ![]() $A$), i.e.

$A$), i.e. ![]() $c_{{B}}=c_{{B}}^{\infty }=0$ and

$c_{{B}}=c_{{B}}^{\infty }=0$ and ![]() $j_{{B}}=0$. The simulation considers the variations of all physical properties with the composition. To that end, experimental data of glycerol–water mixtures were fitted and imposed as locally varying mass density, surface tension, diffusivity, dynamic viscosity and thermodynamic activity. For plots of these relations and more details about these kinds of simulations we refer to Diddens et al. (Reference Diddens, Tan, Lv, Versluis, Kuerten, Zhang and Lohse2017b) and Diddens (Reference Diddens2017), where, however, we did not consider of the influence of gravity.

$j_{{B}}=0$. The simulation considers the variations of all physical properties with the composition. To that end, experimental data of glycerol–water mixtures were fitted and imposed as locally varying mass density, surface tension, diffusivity, dynamic viscosity and thermodynamic activity. For plots of these relations and more details about these kinds of simulations we refer to Diddens et al. (Reference Diddens, Tan, Lv, Versluis, Kuerten, Zhang and Lohse2017b) and Diddens (Reference Diddens2017), where, however, we did not consider of the influence of gravity.

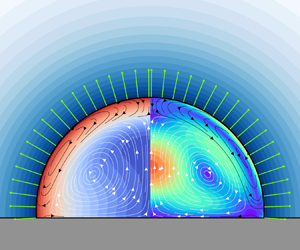

Figure 2. Simulation of a ![]() ${1}\ {\mathrm {\mu }}\textrm {l}$ glycerol–water droplet revealing rich flow patterns during the evaporation process. The water vapour mass fraction is shown in the gas phase, whereas the glycerol mass fraction (left) and the velocity magnitude (right) are shown inside the droplet. (a) Initially, both Rayleigh and Marangoni convection support the flow from the apex to the contact line. (b) Although the contact angle is still above

${1}\ {\mathrm {\mu }}\textrm {l}$ glycerol–water droplet revealing rich flow patterns during the evaporation process. The water vapour mass fraction is shown in the gas phase, whereas the glycerol mass fraction (left) and the velocity magnitude (right) are shown inside the droplet. (a) Initially, both Rayleigh and Marangoni convection support the flow from the apex to the contact line. (b) Although the contact angle is still above ![]() $\theta >{90}^{\circ }$, a Marangoni-induced counter-rotating vortex (black) emerges close to the interface, whereas the bulk flow is driven by natural convection (white). (c) Due to the increased evaporation rate at the contact line for

$\theta >{90}^{\circ }$, a Marangoni-induced counter-rotating vortex (black) emerges close to the interface, whereas the bulk flow is driven by natural convection (white). (c) Due to the increased evaporation rate at the contact line for ![]() $\theta <{90}^{\circ }$, the Marangoni-driven vortex grows in size until (d) the vortex driven by natural convection disappears. See supplementary movie 1 available at https://doi.org/10.1017/jfm.2020.734 for the entire simulation.

$\theta <{90}^{\circ }$, the Marangoni-driven vortex grows in size until (d) the vortex driven by natural convection disappears. See supplementary movie 1 available at https://doi.org/10.1017/jfm.2020.734 for the entire simulation.

Initially, in figure 2(a), one can see a single vortex in the entire droplet, directed from the apex towards the contact line. This vortex is generated for two reasons, namely Marangoni convection and natural convection (Rayleigh convection). Due to the enhanced evaporation rate of water at the apex at the high contact angle, the water content is predominantly reduced at the top of the droplet, resulting in a lower surface tension compared to the region near the contact line. This drives a Marangoni flow towards the contact line. Since glycerol is more dense than water, the glycerol-rich outer shell of the droplet also sinks down due to natural convection, which also results in a flow from the apex to the contact line due to the spherical geometry. Hence, both mechanisms support recirculating flow in the same direction.

Remarkably, in figure 2(b), the situation changes. The contact angle is still above ![]() ${90}^{\circ }$, i.e. the highest water evaporation rate is still at the top of the droplet. According to the aforementioned discussion, one would still naively expect the same kind of single-vortex flow. However, the simulation clearly shows two vortices, one in the bulk driven by natural convection (white) and another one close to the interface, which is driven by Marangoni flow in the opposite direction (black). The reason why the Marangoni flow is reversed, i.e. why there is more water at the top of the droplet although the evaporation rate of water is still dominant at the apex, is the fact that there is enhanced water replenishment by diffusion at the apex, which compensates for the rather small difference in the evaporation rates at the top and near the contact line. This can be seen by the rather steep concentration gradient in the normal direction at the apex compared to the region near the contact line. The reason for the steep concentration gradient in the normal direction close to the apex is the upward directed convective water replenishment from the bulk, which is governed by the internal vortex driven by natural convection. This means that sufficiently strong natural convection in the bulk can reverse the Marangoni flow at the interface, although one would not anticipate this by just considering the profile of the evaporation rate at this contact angle.

${90}^{\circ }$, i.e. the highest water evaporation rate is still at the top of the droplet. According to the aforementioned discussion, one would still naively expect the same kind of single-vortex flow. However, the simulation clearly shows two vortices, one in the bulk driven by natural convection (white) and another one close to the interface, which is driven by Marangoni flow in the opposite direction (black). The reason why the Marangoni flow is reversed, i.e. why there is more water at the top of the droplet although the evaporation rate of water is still dominant at the apex, is the fact that there is enhanced water replenishment by diffusion at the apex, which compensates for the rather small difference in the evaporation rates at the top and near the contact line. This can be seen by the rather steep concentration gradient in the normal direction at the apex compared to the region near the contact line. The reason for the steep concentration gradient in the normal direction close to the apex is the upward directed convective water replenishment from the bulk, which is governed by the internal vortex driven by natural convection. This means that sufficiently strong natural convection in the bulk can reverse the Marangoni flow at the interface, although one would not anticipate this by just considering the profile of the evaporation rate at this contact angle.

Upon further evaporation, in figure 2(c), the contact angle falls below ![]() ${90}^{\circ }$, resulting in a higher water evaporation rate near the contact line. Hence, less water is present at the contact line as compared to the apex due two facts, namely, the effect of preferential evaporation at the contact line and the lower replenishing diffusive flux of water from the bulk at the contact line. Thereby, the Marangoni flow gets enhanced compared to the situation in figure 2(b) and the relative size of the Marangoni-induced vortex at the interface grows at the expense of the counter-rotating bulk vortex by natural convection.

${90}^{\circ }$, resulting in a higher water evaporation rate near the contact line. Hence, less water is present at the contact line as compared to the apex due two facts, namely, the effect of preferential evaporation at the contact line and the lower replenishing diffusive flux of water from the bulk at the contact line. Thereby, the Marangoni flow gets enhanced compared to the situation in figure 2(b) and the relative size of the Marangoni-induced vortex at the interface grows at the expense of the counter-rotating bulk vortex by natural convection.

Finally, in figure 2(d), the contact angle becomes rather small so that the Marangoni flow at the interface is even stronger due to the enhanced non-uniformity of the evaporation rate. Furthermore, the influence of natural convection also diminishes rather quickly, i.e. with cubic power in terms of the length scale according to the Rayleigh number (see later for its definition), due to the reduced volume of the droplet. This results in the depicted situation, i.e. that the flow direction within the entire droplet is completely determined by the Marangoni effect.

In a nutshell, one can infer from the direct numerical simulation results in figure 2 that there can be multiple flow scenarios during the drying of a single binary droplet, driven by an interplay of natural (i.e. Rayleigh) convection and Marangoni convection. One also clearly sees that, for a particle laden droplet, the coffee-stain effect would not occur as there is no noticeable flow towards the contact line (which for pure evaporating droplets transports the suspended particles to the rim of the pinned droplet) as compared to the strongly recirculating flow due to Marangoni flow and gravity.

4. Quasi-stationary approximation of the dynamical equations

After discussing some possible flow scenarios by considering a representative numerical example in the previous section, we will now focus on a simplification of the full model described in § 2. We generalize again from the particular case of a water–glycerol droplet to the general case of a binary droplet, where both liquids ![]() ${A}$ and

${A}$ and ![]() ${B}$ are allowed to evaporate. The goal is to find the simplest model possible that allows one to predict the expected flow scenario in the droplet by a minimum number of non-dimensional quantities.

${B}$ are allowed to evaporate. The goal is to find the simplest model possible that allows one to predict the expected flow scenario in the droplet by a minimum number of non-dimensional quantities.

4.1. Evaporation numbers

As shown in the example simulation, the liquid recirculates multiple times during the evaporation process due to the fast flow in the droplet. Hence, the typical liquid velocity ![]() $\boldsymbol {u}$ is much larger than the normal interface movement velocity

$\boldsymbol {u}$ is much larger than the normal interface movement velocity ![]() $\boldsymbol {u}_{{I}}$. Moreover, this leads to a rather well-mixed droplet, i.e. with typical compositional deviations of approximately a few per cent in terms of mass fractions, which can be attributed to the considerable Péclet number inside the droplet. These observations allow for several simplifications of the model. First of all, the liquid composition is expanded into two terms, i.e.

$\boldsymbol {u}_{{I}}$. Moreover, this leads to a rather well-mixed droplet, i.e. with typical compositional deviations of approximately a few per cent in terms of mass fractions, which can be attributed to the considerable Péclet number inside the droplet. These observations allow for several simplifications of the model. First of all, the liquid composition is expanded into two terms, i.e. ![]() $y_{{A}}(\boldsymbol {x},t)=y_{{A},0}+y$, namely the spatially averaged composition

$y_{{A}}(\boldsymbol {x},t)=y_{{A},0}+y$, namely the spatially averaged composition ![]() $y_{{A},0}$, which slowly evolves over the entire drying time, and the small local composition deviations

$y_{{A},0}$, which slowly evolves over the entire drying time, and the small local composition deviations ![]() $y(\boldsymbol {x},t)$. Since the composition-dependent liquid properties are usually rather smooth functions of the composition, this separation can be transferred to a first-order Taylor expansion of the liquid properties, i.e.

$y(\boldsymbol {x},t)$. Since the composition-dependent liquid properties are usually rather smooth functions of the composition, this separation can be transferred to a first-order Taylor expansion of the liquid properties, i.e.

\begin{equation} \left.\begin{gathered} \rho=\rho_0+y\partial_{y_{A}}\rho, \quad \sigma=\sigma_0+y\partial_{y_{A}}\sigma,\\ \mu=\mu_0+y\partial_{y_{A}}\mu,\quad D=D_{0}+y\partial_{y_{A}}D, \\ c_{{A}}^{{eq}}=c_{{A},0}^{{eq}}+y\partial_{y_{A}}c_{{A}}^{{eq}} , \quad c_{{B}}^{{eq}}=c_{{B},0}^{{eq}}+y\partial_{y_{A}}c_{{B}}^{{eq}} . \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \rho=\rho_0+y\partial_{y_{A}}\rho, \quad \sigma=\sigma_0+y\partial_{y_{A}}\sigma,\\ \mu=\mu_0+y\partial_{y_{A}}\mu,\quad D=D_{0}+y\partial_{y_{A}}D, \\ c_{{A}}^{{eq}}=c_{{A},0}^{{eq}}+y\partial_{y_{A}}c_{{A}}^{{eq}} , \quad c_{{B}}^{{eq}}=c_{{B},0}^{{eq}}+y\partial_{y_{A}}c_{{B}}^{{eq}} . \end{gathered}\right\} \end{equation}

Since the averaged composition ![]() $y_{\text {A},0}$ evolves slowly, this expansion can be done at any specific time of interest during the evaporation process. In particular, this means that the coefficients of the Taylor expansions (4.1) can be treated as constants during some time close to the considered instant. This allows us to introduce the following non-dimensionalized scales

$y_{\text {A},0}$ evolves slowly, this expansion can be done at any specific time of interest during the evaporation process. In particular, this means that the coefficients of the Taylor expansions (4.1) can be treated as constants during some time close to the considered instant. This allows us to introduce the following non-dimensionalized scales

where the spatial scale is chosen in that way such that the non-dimensionalized droplet volume ![]() $\tilde {V}$ becomes unity.

$\tilde {V}$ becomes unity.

Of course, the introduced scales are only constant for a short instant in time, since the droplet volume ![]() $V$ will decrease over time and the averaged mass fraction

$V$ will decrease over time and the averaged mass fraction ![]() $y_{{A,0}}$ will change, resulting in varying Taylor expansions of the liquid properties. However, later in § 4.4, it is argued that the process can be considered to be quasi-stationary at each instant of the drying time. Thereby, the following non-dimensionalization and characteristic numbers are only valid for a specific considered instant of the drying time.

$y_{{A,0}}$ will change, resulting in varying Taylor expansions of the liquid properties. However, later in § 4.4, it is argued that the process can be considered to be quasi-stationary at each instant of the drying time. Thereby, the following non-dimensionalization and characteristic numbers are only valid for a specific considered instant of the drying time.

In a next step, the vapour fields are decomposed in a similar manner as (4.1), namely into a normalized contribution ![]() $\tilde {c}_0$ which is one at the interface and zero at infinity and a contribution

$\tilde {c}_0$ which is one at the interface and zero at infinity and a contribution ![]() $\tilde {c}_\varDelta$ accounting for the effect of local composition variations on the vapour concentration via Raoult's law to the first order, i.e.

$\tilde {c}_\varDelta$ accounting for the effect of local composition variations on the vapour concentration via Raoult's law to the first order, i.e.

The Laplace equation (2.1) splits into two Laplace equations, i.e. ![]() $\tilde {\nabla }^{2} \tilde {c}_0=0$ and

$\tilde {\nabla }^{2} \tilde {c}_0=0$ and ![]() $\tilde {\nabla }^{2} \tilde {c}_\varDelta =0$ and the boundary conditions (2.3) are transformed to

$\tilde {\nabla }^{2} \tilde {c}_\varDelta =0$ and the boundary conditions (2.3) are transformed to

Thereby, the evaporation rates (2.4) separate in the same way, i.e.

where ![]() $\tilde {j}_0=-\tilde \partial _n\tilde {c}_0$ only depends on the shape of the droplet, i.e. resembles the normalized evaporation profile of a homogeneous droplet, and

$\tilde {j}_0=-\tilde \partial _n\tilde {c}_0$ only depends on the shape of the droplet, i.e. resembles the normalized evaporation profile of a homogeneous droplet, and ![]() $\tilde {j}_y=-\tilde {\partial }_n\tilde {c}_\varDelta$ is a nonlocal linear operator applied on

$\tilde {j}_y=-\tilde {\partial }_n\tilde {c}_\varDelta$ is a nonlocal linear operator applied on ![]() $y$, i.e. the Dirichlet-to-Neumann map, accounting for deviations in the evaporation rate due to a varying interfacial composition via the composition-dependent vapour–liquid equilibrium, i.e. Raoult's law.

$y$, i.e. the Dirichlet-to-Neumann map, accounting for deviations in the evaporation rate due to a varying interfacial composition via the composition-dependent vapour–liquid equilibrium, i.e. Raoult's law.

When dropping terms of quadratic order in ![]() $y$, the convection–diffusion equation (2.5) within the droplet becomes

$y$, the convection–diffusion equation (2.5) within the droplet becomes

and the corresponding interface boundary condition (2.7) reads

with the non-dimensional evaporation numbers

The number ![]() ${Ev}_y$ quantifies the intensity of the concentration gradient induced in the liquid by preferential evaporation of one of the components, i.e. it compares the differences of the two diffusive vapour transports in the gas phase with the mutual diffusion in the binary liquid. Since the resulting composition gradient along the interface and in the bulk is the driving mechanism for Marangoni flow and natural convection, this number will become important to quantify these processes later on. Note that dependence on the volatilities of the components and their mass fractions in the liquid,

${Ev}_y$ quantifies the intensity of the concentration gradient induced in the liquid by preferential evaporation of one of the components, i.e. it compares the differences of the two diffusive vapour transports in the gas phase with the mutual diffusion in the binary liquid. Since the resulting composition gradient along the interface and in the bulk is the driving mechanism for Marangoni flow and natural convection, this number will become important to quantify these processes later on. Note that dependence on the volatilities of the components and their mass fractions in the liquid, ![]() ${Ev}_y$ may be positive or negative.

${Ev}_y$ may be positive or negative.

The parameter ![]() ${Ev}_{{vap}}$ is an estimate for the influence of local variations in the liquid concentration on the preferential evaporation, i.e. the linear feedback due to the quasi-stationary diffusion in the gas phase. If the composition is rather uniform in the droplet, which is usually by fast recirculating convection, the term

${Ev}_{{vap}}$ is an estimate for the influence of local variations in the liquid concentration on the preferential evaporation, i.e. the linear feedback due to the quasi-stationary diffusion in the gas phase. If the composition is rather uniform in the droplet, which is usually by fast recirculating convection, the term ![]() ${Ev}_{{vap}}\tilde {j}_y$ provides only a minor contribution in (4.8), meaning that the profile of the evaporation rates is similar to the one of a pure droplet. Since

${Ev}_{{vap}}\tilde {j}_y$ provides only a minor contribution in (4.8), meaning that the profile of the evaporation rates is similar to the one of a pure droplet. Since ![]() $\partial _{y_{A}}c_{{A}}^{{eq}}>0$ and

$\partial _{y_{A}}c_{{A}}^{{eq}}>0$ and ![]() $\partial _{y_{A}}c_{{B}}^{{eq}}<0$, i.e. the vapour concentration of

$\partial _{y_{A}}c_{{B}}^{{eq}}<0$, i.e. the vapour concentration of ![]() $A$ increases and

$A$ increases and ![]() $B$ decreases for an increasing fraction of

$B$ decreases for an increasing fraction of ![]() $A$ in the liquid,

$A$ in the liquid, ![]() ${Ev}_{{vap}}$ is always positive. Large values of

${Ev}_{{vap}}$ is always positive. Large values of ![]() ${Ev}_{{vap}}$ can actually arise towards the end of the drying of a glycerol–water droplet, as discussed later in § 6.

${Ev}_{{vap}}$ can actually arise towards the end of the drying of a glycerol–water droplet, as discussed later in § 6.

Finally, ![]() ${Ev}_{{tot}}$ is a measure for the total evaporation speed, i.e. for the typical interface speed

${Ev}_{{tot}}$ is a measure for the total evaporation speed, i.e. for the typical interface speed ![]() $\tilde {\boldsymbol {u}}_{{I}}$ and the volume evolution. Note that the total evaporation speed and volume evolution are measures of the flow towards a pinned contact line, i.e. the flow leading to the coffee-stain effect. If none of the components condenses, i.e. both either evaporate or are non-volatile, the modulus of

$\tilde {\boldsymbol {u}}_{{I}}$ and the volume evolution. Note that the total evaporation speed and volume evolution are measures of the flow towards a pinned contact line, i.e. the flow leading to the coffee-stain effect. If none of the components condenses, i.e. both either evaporate or are non-volatile, the modulus of ![]() ${Ev}_y$ is smaller than

${Ev}_y$ is smaller than ![]() ${Ev}_{{tot}}$. Nevertheless, since the deviation from the average composition is small, i.e.

${Ev}_{{tot}}$. Nevertheless, since the deviation from the average composition is small, i.e. ![]() $y\ll 1$, and the Marangoni convection and/or natural convection are sufficiently large, the contribution of the latter to the flow can still be dominant compared to

$y\ll 1$, and the Marangoni convection and/or natural convection are sufficiently large, the contribution of the latter to the flow can still be dominant compared to ![]() ${Ev}_{{tot}} y \tilde {j}_0$ in (4.8).

${Ev}_{{tot}} y \tilde {j}_0$ in (4.8).

The evaporation numbers can be considered as Péclet numbers, e.g. the number ![]() ${Ev}_{{tot}}$ actually compares the velocity of the interface motion due to evaporation to the liquid diffusion.

${Ev}_{{tot}}$ actually compares the velocity of the interface motion due to evaporation to the liquid diffusion.

4.2. Non-dimensionalized flow

For the Navier–Stokes equations, we employ the established Boussinesq approximation, which is valid as long as ![]() $y\partial _{y_{A}}\rho$ is small compared to

$y\partial _{y_{A}}\rho$ is small compared to ![]() $\rho _0$ (Gray & Giorgini Reference Gray and Giorgini1976). Due to the usually small composition gradients, this assumption is valid here. Therefore, except for the bulk force term

$\rho _0$ (Gray & Giorgini Reference Gray and Giorgini1976). Due to the usually small composition gradients, this assumption is valid here. Therefore, except for the bulk force term ![]() $\rho g \boldsymbol {e}_z$, only the zeroth-order terms proportional to

$\rho g \boldsymbol {e}_z$, only the zeroth-order terms proportional to ![]() $\rho _0$ are kept, whereas

$\rho _0$ are kept, whereas ![]() $y\partial _{y_{A}}\rho$-terms are disregarded. With the same argument, terms proportional to

$y\partial _{y_{A}}\rho$-terms are disregarded. With the same argument, terms proportional to ![]() $y\partial _{y_{A}}\mu$ and

$y\partial _{y_{A}}\mu$ and ![]() $y\partial _{y_{A}}\sigma$ can be disregarded whenever there is a dominant term proportional to

$y\partial _{y_{A}}\sigma$ can be disregarded whenever there is a dominant term proportional to ![]() $\mu _0$ or

$\mu _0$ or ![]() $\sigma _0$, respectively. Following this argument, the Navier–Stokes equations can be written as

$\sigma _0$, respectively. Following this argument, the Navier–Stokes equations can be written as

Here, the shifted non-dimensionalized pressure, the Schmidt number and the starred Rayleigh number read

The Schmidt number for liquids is usually ![]() ${Sc}>10^{3}$ which suggests that the left-hand side of (4.12) can be disregarded. However, since the chosen velocity and time scale in (4.2a–c) do not necessarily coincide with the actual present scales, this argument is only valid for small Reynolds numbers. In small droplets with rather low volatilities and regular Marangoni flow, however, this assumption is surely met, e.g.

${Sc}>10^{3}$ which suggests that the left-hand side of (4.12) can be disregarded. However, since the chosen velocity and time scale in (4.2a–c) do not necessarily coincide with the actual present scales, this argument is only valid for small Reynolds numbers. In small droplets with rather low volatilities and regular Marangoni flow, however, this assumption is surely met, e.g. ![]() ${Re} < 0.05$ in the case of the simulation in figure 2. The starred Rayleigh number

${Re} < 0.05$ in the case of the simulation in figure 2. The starred Rayleigh number ![]() ${Ra}^{*}$ deviates from the conventional definition of the Rayleigh number just by the lack of an estimate for the composition difference, i.e. a term like

${Ra}^{*}$ deviates from the conventional definition of the Rayleigh number just by the lack of an estimate for the composition difference, i.e. a term like ![]() ${\rm \Delta} y_{}$. The dynamic boundary conditions at the interface, (2.10) and (2.11), read in the Boussinesq approximation

${\rm \Delta} y_{}$. The dynamic boundary conditions at the interface, (2.10) and (2.11), read in the Boussinesq approximation

Here, the non-dimensional number ![]() ${Ca}^{*}$, the Bond number and the starred Marangoni number read

${Ca}^{*}$, the Bond number and the starred Marangoni number read

Note that the definition of the starred capillary number ![]() ${Ca}^{*}$ does not coincide with the conventional definition of the capillary number, i.e. it does not consider the actually present typical velocity scale, i.e. the intensity of the capillary shape relaxations during evaporation cannot be inferred from

${Ca}^{*}$ does not coincide with the conventional definition of the capillary number, i.e. it does not consider the actually present typical velocity scale, i.e. the intensity of the capillary shape relaxations during evaporation cannot be inferred from ![]() ${Ca}^{*}$. However, both the real capillary number

${Ca}^{*}$. However, both the real capillary number ![]() ${Ca}=\mu _0U/\sigma _0$ and

${Ca}=\mu _0U/\sigma _0$ and ![]() ${Ca}^{*}$ are small in the systems considered here (

${Ca}^{*}$ are small in the systems considered here (![]() ${Ca}<1\times 10^{-6}$ and

${Ca}<1\times 10^{-6}$ and ![]() ${Ca}^{*}<1\times 10^{-7}$ in the simulation depicted in figure 2). Similar to

${Ca}^{*}<1\times 10^{-7}$ in the simulation depicted in figure 2). Similar to ![]() ${Ra}^{*}$, the starred Marangoni number

${Ra}^{*}$, the starred Marangoni number ![]() $\textit{Ma}^{*}$ lacks an estimate for the composition difference, i.e.

$\textit{Ma}^{*}$ lacks an estimate for the composition difference, i.e. ![]() ${\rm \Delta} y$, as compared to the conventional definition. Finally, the kinematic boundary condition (2.6) becomes

${\rm \Delta} y$, as compared to the conventional definition. Finally, the kinematic boundary condition (2.6) becomes

where

is the analogue of ![]() ${Ev}_{{vap}}$ for the total evaporation rate, i.e. the effect of a change in the saturation pressure due to a locally deviating composition on the total evaporation rate.

${Ev}_{{vap}}$ for the total evaporation rate, i.e. the effect of a change in the saturation pressure due to a locally deviating composition on the total evaporation rate.

4.3. Estimation of the outwards flow

Before focusing on natural convection and Marangoni flow in the droplet, it is beneficial to obtain an estimate for the velocity in the droplet in the absence of these mechanisms, i.e. ![]() ${Ma}^{*}={Ra}^{*}=0$. This case, exemplified e.g. by a pure isothermal droplet, combined with a pinned contact line represents the purely capillary-driven outward flow, which causes the coffee-stain effect.

${Ma}^{*}={Ra}^{*}=0$. This case, exemplified e.g. by a pure isothermal droplet, combined with a pinned contact line represents the purely capillary-driven outward flow, which causes the coffee-stain effect.

For small droplets, the capillary number ![]() ${Ca}$ is small, so that the surface tension forces according to (4.15) lead to an intense relaxing traction whenever the droplet deviates from the equilibrium shape. Since the Bond number

${Ca}$ is small, so that the surface tension forces according to (4.15) lead to an intense relaxing traction whenever the droplet deviates from the equilibrium shape. Since the Bond number ![]() ${Bo}$ is small also for small droplets, the hydrostatic term in (4.15) can be neglected, leading to a spherical cap with a homogeneous curvature

${Bo}$ is small also for small droplets, the hydrostatic term in (4.15) can be neglected, leading to a spherical cap with a homogeneous curvature ![]() $\tilde {\kappa }$ as the equilibrium shape. Hence, the shape evolution and thereby the interface velocity

$\tilde {\kappa }$ as the equilibrium shape. Hence, the shape evolution and thereby the interface velocity ![]() $\widetilde {\boldsymbol {u}_{{I}}}$ are solely given by the evaporation rate and the contact line kinetics, which is assumed to be pinned here. Since the term

$\widetilde {\boldsymbol {u}_{{I}}}$ are solely given by the evaporation rate and the contact line kinetics, which is assumed to be pinned here. Since the term ![]() ${Ev}_{{tot,vap}} \tilde {j}_y$ in (4.18) is proportional to

${Ev}_{{tot,vap}} \tilde {j}_y$ in (4.18) is proportional to ![]() $y$, it can be disregarded with respect to

$y$, it can be disregarded with respect to ![]() ${Ev}_{{tot}} \tilde {j}_0$ in accordance with the Boussinesq approximation. As a consequence, one ends up with a linear Stokes flow problem, where the entire bulk velocity is given by the instantaneous shape relaxation, which is proportional to the rate of evaporation, i.e. to

${Ev}_{{tot}} \tilde {j}_0$ in accordance with the Boussinesq approximation. As a consequence, one ends up with a linear Stokes flow problem, where the entire bulk velocity is given by the instantaneous shape relaxation, which is proportional to the rate of evaporation, i.e. to ![]() ${Ev}_{{tot}}$.

${Ev}_{{tot}}$.

By integrating the evaporation rate ![]() ${Ev}_{{tot}} \tilde {j}_0$ one obtains the volume loss and thereby one can reconstruct the normal velocity of the interface

${Ev}_{{tot}} \tilde {j}_0$ one obtains the volume loss and thereby one can reconstruct the normal velocity of the interface ![]() $\tilde {\boldsymbol {u}}_{{I}}\boldsymbol {\cdot }\boldsymbol {n}$. The flow in the bulk

$\tilde {\boldsymbol {u}}_{{I}}\boldsymbol {\cdot }\boldsymbol {n}$. The flow in the bulk ![]() $\tilde {\boldsymbol {u}}$ is subsequently given by solving the Stokes flow with the normal boundary condition

$\tilde {\boldsymbol {u}}$ is subsequently given by solving the Stokes flow with the normal boundary condition ![]() $\tilde {\boldsymbol {u}}\boldsymbol {\cdot }\boldsymbol {n}=\widetilde {\boldsymbol {u}_{{I}}} \boldsymbol {\cdot }\boldsymbol {n}+{Ev}_{{tot}}\tilde {j}_0$. In figure 3, representative solutions for the bulk flow

$\tilde {\boldsymbol {u}}\boldsymbol {\cdot }\boldsymbol {n}=\widetilde {\boldsymbol {u}_{{I}}} \boldsymbol {\cdot }\boldsymbol {n}+{Ev}_{{tot}}\tilde {j}_0$. In figure 3, representative solutions for the bulk flow ![]() $\tilde {\boldsymbol {u}}$ with unity evaporation number, i.e.

$\tilde {\boldsymbol {u}}$ with unity evaporation number, i.e. ![]() ${Ev}_{{tot}}=1$, are depicted. It is apparent that the typical bulk velocity is of the order of unity, i.e.

${Ev}_{{tot}}=1$, are depicted. It is apparent that the typical bulk velocity is of the order of unity, i.e. ![]() $\|\tilde {\boldsymbol {u}}\|\sim 1$. Since the flow is proportional to

$\|\tilde {\boldsymbol {u}}\|\sim 1$. Since the flow is proportional to ![]() ${Ev}_{{tot}}$, the typical velocity corresponding to an arbitrary evaporation number

${Ev}_{{tot}}$, the typical velocity corresponding to an arbitrary evaporation number ![]() ${Ev}_{{tot}}$ is hence

${Ev}_{{tot}}$ is hence ![]() $\|\tilde {\boldsymbol {u}}\|\sim {Ev}_{{tot}}$. This holds also for the typical interface movement, i.e.

$\|\tilde {\boldsymbol {u}}\|\sim {Ev}_{{tot}}$. This holds also for the typical interface movement, i.e. ![]() $\|\tilde {\boldsymbol {u}}_{{I}}\|\sim {Ev}_{{tot}}$.

$\|\tilde {\boldsymbol {u}}_{{I}}\|\sim {Ev}_{{tot}}$.

Figure 3. Bulk flow for small capillary number ![]() ${Ca}$ and Bond number

${Ca}$ and Bond number ![]() ${Bo}$ in the absence of Marangoni flow and natural convection for a total evaporation number

${Bo}$ in the absence of Marangoni flow and natural convection for a total evaporation number ![]() ${Ev}_{{tot}}=1$ and contact angles of (a)

${Ev}_{{tot}}=1$ and contact angles of (a) ![]() $\theta ={60}^{\circ }$ and (b)

$\theta ={60}^{\circ }$ and (b) ![]() $\theta ={120}^{\circ }$. The evaporation rate

$\theta ={120}^{\circ }$. The evaporation rate ![]() ${Ev}_{{tot}}\tilde {j}_0$ causes a volume loss, which prescribes the normal interface movement

${Ev}_{{tot}}\tilde {j}_0$ causes a volume loss, which prescribes the normal interface movement ![]() $\tilde {\boldsymbol {u}}_{{I}}\boldsymbol {\cdot }\boldsymbol {n}$ (depicted on the left sides). The bulk flow (right sides) is governed by Stokes flow with the normal boundary condition

$\tilde {\boldsymbol {u}}_{{I}}\boldsymbol {\cdot }\boldsymbol {n}$ (depicted on the left sides). The bulk flow (right sides) is governed by Stokes flow with the normal boundary condition ![]() $\tilde {\boldsymbol {u}}\boldsymbol {\cdot }\boldsymbol {n}= \widetilde {\boldsymbol {u}_{{I}}}\boldsymbol {\cdot }\boldsymbol {n}+{Ev}_{{tot}}\tilde {j}_0$. Apparently, the typical purely capillary-driven velocity is of order

$\tilde {\boldsymbol {u}}\boldsymbol {\cdot }\boldsymbol {n}= \widetilde {\boldsymbol {u}_{{I}}}\boldsymbol {\cdot }\boldsymbol {n}+{Ev}_{{tot}}\tilde {j}_0$. Apparently, the typical purely capillary-driven velocity is of order ![]() ${Ev}_{{tot}}$.

${Ev}_{{tot}}$.

4.4. Quasi-stationary limit

Knowing that the capillary flow due to the volume loss is of the order of ![]() ${Ev}_{{tot}}$, we now focus on the contributions to the flow by Marangoni forces and natural convection. In a first step, one can consider the case where

${Ev}_{{tot}}$, we now focus on the contributions to the flow by Marangoni forces and natural convection. In a first step, one can consider the case where ![]() ${Ev}_{{tot}}=0$, i.e. no total mass transfer and hence a constant volume and shape of the droplet. This scenario can be realized by tuning the ambient humidities of

${Ev}_{{tot}}=0$, i.e. no total mass transfer and hence a constant volume and shape of the droplet. This scenario can be realized by tuning the ambient humidities of ![]() $A$ and

$A$ and ![]() $B$ so that the evaporative mass loss of component

$B$ so that the evaporative mass loss of component ![]() $A$ is balanced by the condensation of component

$A$ is balanced by the condensation of component ![]() $B$. In this case

$B$. In this case ![]() ${Ev}_{{tot}}=0$ and

${Ev}_{{tot}}=0$ and ![]() ${Ev}_y>0$ holds. Again, due to the small capillary number and the small Bond number, one can assume a spherical cap shape with volume

${Ev}_y>0$ holds. Again, due to the small capillary number and the small Bond number, one can assume a spherical cap shape with volume ![]() $\tilde {V}=1$ and contact angle

$\tilde {V}=1$ and contact angle ![]() $\theta$, which are both constant now. Furthermore, there is no interface movement,

$\theta$, which are both constant now. Furthermore, there is no interface movement, ![]() $\tilde {\boldsymbol {u}}_{{I}}\boldsymbol {\cdot }\boldsymbol {n}=0$, and no total mass transfer,

$\tilde {\boldsymbol {u}}_{{I}}\boldsymbol {\cdot }\boldsymbol {n}=0$, and no total mass transfer, ![]() $\tilde {\boldsymbol {u}}\boldsymbol {\cdot }\boldsymbol {n}=0$.

$\tilde {\boldsymbol {u}}\boldsymbol {\cdot }\boldsymbol {n}=0$.

By averaging (4.7) over the droplet volume ![]() $\tilde {V}=1$, defining the integrated evaporation rate

$\tilde {V}=1$, defining the integrated evaporation rate

and considering only the zeroth-order term in the boundary condition (4.8) in accordance with the Boussinesq approximation, one can separate the average composition ![]() $y_{{A},0}$ and the deviation

$y_{{A},0}$ and the deviation ![]() $y$ as follows:

$y$ as follows:

Here, the term ![]() ${Ev}_y \tilde {J}_0$ assures that

${Ev}_y \tilde {J}_0$ assures that ![]() $y_{{A},0}$ is indeed the average composition and that the average of

$y_{{A},0}$ is indeed the average composition and that the average of ![]() $y$ remains zero, i.e. the term compensates for the imposed composition gradient at the liquid–gas interface. As already stated in § 4.1, this splitting holds only for a limited time, since a variation in

$y$ remains zero, i.e. the term compensates for the imposed composition gradient at the liquid–gas interface. As already stated in § 4.1, this splitting holds only for a limited time, since a variation in ![]() $y_{{A},0}$ leads to a change in the liquid properties which were used for the non-dimensionalization. Usually, however, the coupled dynamics of flow

$y_{{A},0}$ leads to a change in the liquid properties which were used for the non-dimensionalization. Usually, however, the coupled dynamics of flow ![]() $\tilde {\boldsymbol {u}}$ and compositional differences

$\tilde {\boldsymbol {u}}$ and compositional differences ![]() $y$ due to Marangoni and natural convection is considerably faster than

$y$ due to Marangoni and natural convection is considerably faster than ![]() ${Ev}_y \tilde J_0$, This was already apparent from the simulations depicted in figure 2 and it will be validated later in § 6. Furthermore, this observation allows us to focus on stationary solutions. Finally, upon introducing

${Ev}_y \tilde J_0$, This was already apparent from the simulations depicted in figure 2 and it will be validated later in § 6. Furthermore, this observation allows us to focus on stationary solutions. Finally, upon introducing

one ends up at the following set of coupled equations:

subject to the following boundary conditions:

at the liquid–gas interface and

at the liquid–substrate interface. Note that the simplified kinematic boundary condition (4.28) is now compatible with the no-slip boundary condition (4.31) at the contact line, i.e. a slip length is not required. Since the mesh is static, the Laplace pressure (2.10) need not to be imposed. Equation (4.28) is enforced via a Lagrange multiplier field at the interface. Hence, any in- or outflow through the interface is prevented by adjusting the local normal traction accordingly.

Besides the contact angle ![]() $\theta$, only two parameters enter the system, namely the Marangoni number and the Rayleigh number, which read

$\theta$, only two parameters enter the system, namely the Marangoni number and the Rayleigh number, which read

Note that the characteristic numbers for both mechanisms are proportional to the induced composition gradient due to mass transfer, i.e. ![]() ${Ev}_y$. Of course, in particular the tangential gradient along the interface is also strongly dependent on the contact angle

${Ev}_y$. Of course, in particular the tangential gradient along the interface is also strongly dependent on the contact angle ![]() $\theta$, since this determines the profile of the evaporation rate

$\theta$, since this determines the profile of the evaporation rate ![]() $\tilde {j}_0$.

$\tilde {j}_0$.

These equations are not only valid for the specific assumed case of ![]() ${Ev}_{{tot}}=0$, but also when the combination of Marangoni and Rayleigh flow

${Ev}_{{tot}}=0$, but also when the combination of Marangoni and Rayleigh flow ![]() $\tilde {\boldsymbol {u}}$ predicted by this model is considerably faster than the capillary flow, i.e. a flow situation with outwards flow leading to the coffee-stain effect. According to the estimations in § 4.3, this is the case if

$\tilde {\boldsymbol {u}}$ predicted by this model is considerably faster than the capillary flow, i.e. a flow situation with outwards flow leading to the coffee-stain effect. According to the estimations in § 4.3, this is the case if ![]() $\tilde {\boldsymbol {u}}\gg {Ev}_{{tot}}$.

$\tilde {\boldsymbol {u}}\gg {Ev}_{{tot}}$.

5. Phase diagram for combined Marangoni and Rayleigh convection

5.1. Procedure

Unfortunately, the analytical treatment of the model equations (4.24)–(4.26) is hampered by the geometry, which demands rather complicated toroidal coordinates, and by the very strong nonlinear coupling of ![]() $\tilde {\boldsymbol {u}}$ and

$\tilde {\boldsymbol {u}}$ and ![]() $\xi$ due to the advection term. Therefore, we investigate the system by numerical means. Our analysis is limited to axisymmetric solutions and we only consider the case

$\xi$ due to the advection term. Therefore, we investigate the system by numerical means. Our analysis is limited to axisymmetric solutions and we only consider the case ![]() ${Ev}_{{vap}}=0$, i.e. neglecting the feedback of the altered gas composition due to the liquid–vapour equilibrium on the local evaporation rate. Finally, we will focus on the case

${Ev}_{{vap}}=0$, i.e. neglecting the feedback of the altered gas composition due to the liquid–vapour equilibrium on the local evaporation rate. Finally, we will focus on the case ![]() ${Ma} \geqslant 0$, for which evaporation leads to an overall reduction of the surface tension, as in the case of the water–glycerol depicted in figure 2. This results in a regular flow, i.e. no chaotic behaviour can be found, at least not for moderate flow conditions. In the case of negative Marangoni numbers, chaotic flow patterns cannot be excluded due to the Marangoni instability (Machrafi et al. Reference Machrafi, Rednikov, Colinet and Dauby2010; Christy et al. Reference Christy, Hamamoto and Sefiane2011; Bennacer & Sefiane Reference Bennacer and Sefiane2014). Of course, this spatio-temporal evolving type of flow cannot be captured within the assumption of a quasi-stationary process. One can, on the other hand, test the linear stability of the quasi-stationary solutions in the case of negative Marangoni numbers to find the transition to chaotic flow, but since also the axial symmetry is usually broken in the case of negative Marangoni numbers, one also would have to generalize the entire solution procedure from axisymmetric cylindrical coordinates to the full three-dimensional problem, as done by Diddens et al. (Reference Diddens, Tan, Lv, Versluis, Kuerten, Zhang and Lohse2017b). The transition into chaotic flow still remains to be investigated in detail, but the three-dimensional numerical results of Diddens et al. (Reference Diddens, Tan, Lv, Versluis, Kuerten, Zhang and Lohse2017b) indeed show that the route to chaos happens via a breaking of the axial symmetry, similarly to what is seen in the case of intense thermal Marangoni flow in a pure droplet (Sefiane et al. Reference Sefiane, Moffat, Matar and Craster2008).

${Ma} \geqslant 0$, for which evaporation leads to an overall reduction of the surface tension, as in the case of the water–glycerol depicted in figure 2. This results in a regular flow, i.e. no chaotic behaviour can be found, at least not for moderate flow conditions. In the case of negative Marangoni numbers, chaotic flow patterns cannot be excluded due to the Marangoni instability (Machrafi et al. Reference Machrafi, Rednikov, Colinet and Dauby2010; Christy et al. Reference Christy, Hamamoto and Sefiane2011; Bennacer & Sefiane Reference Bennacer and Sefiane2014). Of course, this spatio-temporal evolving type of flow cannot be captured within the assumption of a quasi-stationary process. One can, on the other hand, test the linear stability of the quasi-stationary solutions in the case of negative Marangoni numbers to find the transition to chaotic flow, but since also the axial symmetry is usually broken in the case of negative Marangoni numbers, one also would have to generalize the entire solution procedure from axisymmetric cylindrical coordinates to the full three-dimensional problem, as done by Diddens et al. (Reference Diddens, Tan, Lv, Versluis, Kuerten, Zhang and Lohse2017b). The transition into chaotic flow still remains to be investigated in detail, but the three-dimensional numerical results of Diddens et al. (Reference Diddens, Tan, Lv, Versluis, Kuerten, Zhang and Lohse2017b) indeed show that the route to chaos happens via a breaking of the axial symmetry, similarly to what is seen in the case of intense thermal Marangoni flow in a pure droplet (Sefiane et al. Reference Sefiane, Moffat, Matar and Craster2008).

In order to find solutions of the system, we employed a finite element method on an axisymmetric mesh with triangular elements. We used linear basis functions for ![]() $\xi$ and

$\xi$ and ![]() $\tilde {p}$ and quadratic basis functions for

$\tilde {p}$ and quadratic basis functions for ![]() $\tilde {\boldsymbol {u}}$, i.e. typical Taylor–Hood elements. The equations have been implemented in both FEniCS (https://fenicsproject.org/) (Logg et al. Reference Logg, Mardal and Wells2012) and oomph-lib for mutual validation. The condition of zero velocity in the normal direction, i.e. (4.28), has been implemented by Lagrange multipliers. For an enhanced stability in the Newton method during the solution process, it has been found beneficial to replace

$\tilde {\boldsymbol {u}}$, i.e. typical Taylor–Hood elements. The equations have been implemented in both FEniCS (https://fenicsproject.org/) (Logg et al. Reference Logg, Mardal and Wells2012) and oomph-lib for mutual validation. The condition of zero velocity in the normal direction, i.e. (4.28), has been implemented by Lagrange multipliers. For an enhanced stability in the Newton method during the solution process, it has been found beneficial to replace ![]() $\tilde {J}_0$ in (4.24) by a Lagrange multiplier which ensures that the average of

$\tilde {J}_0$ in (4.24) by a Lagrange multiplier which ensures that the average of ![]() $\xi$ is zero. This removes the null space with respect to a constant shift in

$\xi$ is zero. This removes the null space with respect to a constant shift in ![]() $\xi$ and a corresponding adjustment of the pressure

$\xi$ and a corresponding adjustment of the pressure ![]() $\tilde {p}$.

$\tilde {p}$.

Due to the nonlinear advection term, it is in general possible that multiple solutions exist for a given parameter combination ![]() $(\theta ,{Ma},{Ra})$. For the parameter ranges considered in the following, however, we are confident that we found the generic solutions due to the following strategy: for every considered contact angle

$(\theta ,{Ma},{Ra})$. For the parameter ranges considered in the following, however, we are confident that we found the generic solutions due to the following strategy: for every considered contact angle ![]() $\theta$, we performed adiabatic scans along

$\theta$, we performed adiabatic scans along ![]() ${Ra}$ in the increasing and decreasing directions for fixed

${Ra}$ in the increasing and decreasing directions for fixed ![]() ${Ma}$ and vice versa. During that, no hysteresis, i.e. bistable regions, have been found. Furthermore, by tracing these parameter paths with continuation, we have not detected any unstable branches. This has been furthermore validated by investigating the eigenvalues with a shift-inverted Arnoldi method (using Spectra https://spectralib.org). Finally, for each parameter combination, we performed temporal integrations of the unsteady model equations starting from a homogeneous state

${Ma}$ and vice versa. During that, no hysteresis, i.e. bistable regions, have been found. Furthermore, by tracing these parameter paths with continuation, we have not detected any unstable branches. This has been furthermore validated by investigating the eigenvalues with a shift-inverted Arnoldi method (using Spectra https://spectralib.org). Finally, for each parameter combination, we performed temporal integrations of the unsteady model equations starting from a homogeneous state ![]() $\xi =0$. Since these runs converged to the same solutions as obtained by the steady parameter scans, we are sure that all solutions discussed in the following are indeed generic and stable. Note, however, that this is in general not true outside the considered parameter ranges.

$\xi =0$. Since these runs converged to the same solutions as obtained by the steady parameter scans, we are sure that all solutions discussed in the following are indeed generic and stable. Note, however, that this is in general not true outside the considered parameter ranges.

5.2. Phase diagrams

The phase diagrams for small and large contact angles, i.e. for ![]() $\theta ={60}^{\circ }$ and

$\theta ={60}^{\circ }$ and ![]() $\theta ={120}^{\circ }$, are depicted in figures 4 and 5, respectively. Here we have assumed, as in the case of the glycerol–water droplet, that the blue liquid

$\theta ={120}^{\circ }$, are depicted in figures 4 and 5, respectively. Here we have assumed, as in the case of the glycerol–water droplet, that the blue liquid ![]() $A$ (e.g. water) is more volatile, less dense but associated with a higher surface tension than the red liquid

$A$ (e.g. water) is more volatile, less dense but associated with a higher surface tension than the red liquid ![]() $B$ (e.g. glycerol). This means by definition that

$B$ (e.g. glycerol). This means by definition that ![]() ${Ma}>0$ holds and that a sessile droplet is described by

${Ma}>0$ holds and that a sessile droplet is described by ![]() ${Ra}>0$ whereas a pendant droplet is given by

${Ra}>0$ whereas a pendant droplet is given by ![]() ${Ra}<0$. While in the diagrams (figures 4 and 5) a negative Rayleigh number is always indicated by a pendant droplet, it can also be realized by changing the sign of

${Ra}<0$. While in the diagrams (figures 4 and 5) a negative Rayleigh number is always indicated by a pendant droplet, it can also be realized by changing the sign of ![]() $\partial _y \rho$, i.e. by letting the red component be lighter than the blue component.

$\partial _y \rho$, i.e. by letting the red component be lighter than the blue component.

Figure 4. Qualitative flow types as functions of the Marangoni number ![]() ${Ma}$ and the Rayleigh number

${Ma}$ and the Rayleigh number ![]() ${Ra}$ for a small contact angle

${Ra}$ for a small contact angle ![]() $\theta =60^{\circ }$. For sessile droplets (

$\theta =60^{\circ }$. For sessile droplets (![]() ${Ra}>0$) with large Marangoni numbers and small Rayleigh numbers, Marangoni flow dominates in the droplet and results in a circulating flow from the contact line along the free interface towards the apex (Ma dominant, black streamlines). On the contrary, if

${Ra}>0$) with large Marangoni numbers and small Rayleigh numbers, Marangoni flow dominates in the droplet and results in a circulating flow from the contact line along the free interface towards the apex (Ma dominant, black streamlines). On the contrary, if ![]() ${Ma}$ is small and

${Ma}$ is small and ![]() ${Ra}$ is large, gravity-driven flow dominates with a flow direction from the apex along the free interface to the contact line (Ra dominant, white streamlines). While the other mechanism, i.e. natural convection in the regime Ma dominant and Marangoni flow in the regime Ra dominant, can still quantitatively influence the flow, only a single vortex can be found which is driven by the dominant mechanism. In between these regions, however, there is a regime where the bulk flow is driven by natural convection whereas the flow close to the interface is dominated by the Marangoni effect (Ma vs. Ra). Here, two counter-rotating vortices can be seen. For pendant droplets (