1 Introduction

Skin friction drag reduction (DR) in turbulent flow is a topic of research that is relevant for many industrial applications. In particular, the maritime industry may benefit from this, since reducing fuel consumption by only a few per cent will lead to significant cost savings and reduction of pollutant emission (van den Berg et al. Reference van den Berg, van Gils, Lathrop and Lohse2007; Ceccio Reference Ceccio2010; Murai Reference Murai2014; Park, Sun & Kim Reference Park, Sun and Kim2014; Gose et al. Reference Gose, Golovin, Boban, Mabry, Tuteja, Perlin and Ceccio2018).

In this work, we combine hydrophobic surfaces with two-phase flow to study drag reduction, a combination that, to our best knowledge, has not often been studied before, especially not at the high Reynolds numbers ![]() $Re$ of up to

$Re$ of up to ![]() $1.8\times 10^{6}$ that we reach. The physics behind this combination is interesting, since both hydrophobic surfaces and (air) bubble injection have shown individually to decrease the skin friction drag. At the same time, by increasing the amount of gas in the liquid, the effectivity and life span of a drag reducing superhydrophobic surface can be increased (Lv et al. Reference Lv, Xue, Shi, Lin and Duan2014; Xiang et al. Reference Xiang, Huang, Lv, Xue, Su and Duan2017). Compared to a hydrophilic surface, gas bubbles that impact a hydrophobic surface are more likely to attach to the surface and form a lubricating layer (Kim & Lee Reference Kim and Lee2017). Although the wall shear stress in our set-up is much larger than what the bubbles in the work of Kim & Lee (Reference Kim and Lee2017) are exposed to, a possible result is that the number of bubbles close to the wall increases, which is beneficial for bubbly DR. A set of experiments of two-phase flow over a hydrophobic plate up to

$1.8\times 10^{6}$ that we reach. The physics behind this combination is interesting, since both hydrophobic surfaces and (air) bubble injection have shown individually to decrease the skin friction drag. At the same time, by increasing the amount of gas in the liquid, the effectivity and life span of a drag reducing superhydrophobic surface can be increased (Lv et al. Reference Lv, Xue, Shi, Lin and Duan2014; Xiang et al. Reference Xiang, Huang, Lv, Xue, Su and Duan2017). Compared to a hydrophilic surface, gas bubbles that impact a hydrophobic surface are more likely to attach to the surface and form a lubricating layer (Kim & Lee Reference Kim and Lee2017). Although the wall shear stress in our set-up is much larger than what the bubbles in the work of Kim & Lee (Reference Kim and Lee2017) are exposed to, a possible result is that the number of bubbles close to the wall increases, which is beneficial for bubbly DR. A set of experiments of two-phase flow over a hydrophobic plate up to ![]() $Re=5000$ by Kitagawa, Denissenko & Murai (Reference Kitagawa, Denissenko and Murai2019) showed two groups of bubbles. One group of medium-sized free bubbles, and a group of small wall-adhered bubbles, that coalesce into large bubbles. Since the bubbles that stick to the plate change the flow close to the plate, they suggest that the hydrophobic plate is likely to experience more friction drag. Based on this reasoning, they suggest that these results should be carefully considered, when air bubble behaviour is controlled using functionalized (hydrophobic) surfaces in bubbly DR applications (Kitagawa et al. Reference Kitagawa, Denissenko and Murai2019). Hence, the two methods of drag reduction (bubbly and with hydrophobic surfaces) will influence one another. However, it is yet unknown whether this is positive or negative for the total combined drag reduction and we want to find this out in this paper.

$Re=5000$ by Kitagawa, Denissenko & Murai (Reference Kitagawa, Denissenko and Murai2019) showed two groups of bubbles. One group of medium-sized free bubbles, and a group of small wall-adhered bubbles, that coalesce into large bubbles. Since the bubbles that stick to the plate change the flow close to the plate, they suggest that the hydrophobic plate is likely to experience more friction drag. Based on this reasoning, they suggest that these results should be carefully considered, when air bubble behaviour is controlled using functionalized (hydrophobic) surfaces in bubbly DR applications (Kitagawa et al. Reference Kitagawa, Denissenko and Murai2019). Hence, the two methods of drag reduction (bubbly and with hydrophobic surfaces) will influence one another. However, it is yet unknown whether this is positive or negative for the total combined drag reduction and we want to find this out in this paper.

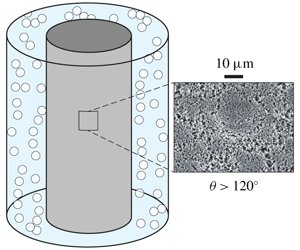

We explore the difference in skin friction coefficient between two types of surfaces: a very smooth hydrophilic surface and a more rough hydrophobic surface. The hydrophobic surface is a sheet of porous polypropylene material, commercially available in large quantities. Representative to more practical applications, it has a sponge-like isotropic geometry of distributed (roughness) length scales formed by the porous structure. To study the fully developed turbulence typical for maritime applications, it is desirable to experimentally achieve high Reynolds numbers, and have both the bulk flow and boundary layer in a state of turbulence. To this end, we use the Twente Turbulent Taylor–Couette facility (![]() $\text{T}^{3}\text{C}$) described in van Gils et al. (Reference van Gils, Bruggert, Lathrop, Sun and Lohse2011), of which the inner cylinder is made hydrophobic using the porous polypropylene material. This closed system, with an exact energy balance between input (driving of the flow) and output (viscous energy dissipation), allows for accurate measurement of global drag. Due to its excellent optical accessibility, this can be combined with local flow measurements, for instance using particle image velocimetry (PIV), as well as visualizations of the flow structure and the hydrophobic surface using (high-speed) imaging techniques. Air bubbles are introduced to the working liquid to demonstrate the drag reducing effect of the hydrophobic inner cylinder. This combination of the

$\text{T}^{3}\text{C}$) described in van Gils et al. (Reference van Gils, Bruggert, Lathrop, Sun and Lohse2011), of which the inner cylinder is made hydrophobic using the porous polypropylene material. This closed system, with an exact energy balance between input (driving of the flow) and output (viscous energy dissipation), allows for accurate measurement of global drag. Due to its excellent optical accessibility, this can be combined with local flow measurements, for instance using particle image velocimetry (PIV), as well as visualizations of the flow structure and the hydrophobic surface using (high-speed) imaging techniques. Air bubbles are introduced to the working liquid to demonstrate the drag reducing effect of the hydrophobic inner cylinder. This combination of the ![]() $\text{T}^{3}\text{C}$ with a superhydrophobic (SH) inner cylinder and air bubbles in the working fluid, enables us to study hydrophobic bubbly drag reduction at industrially relevant high Reynolds numbers in a well controlled condition, giving a better understanding of the mechanisms involved.

$\text{T}^{3}\text{C}$ with a superhydrophobic (SH) inner cylinder and air bubbles in the working fluid, enables us to study hydrophobic bubbly drag reduction at industrially relevant high Reynolds numbers in a well controlled condition, giving a better understanding of the mechanisms involved.

The paper is organized as follows: in § 2 we give an extensive overview of prior work on bubbly drag reduction, drag on hydrophobic surfaces and drag enhancement of rough walls, as all these effects are crucial to understanding the competing effects explored in this paper. In § 3 the experimental methods are described. Section 4 presents the results and discusses them. The paper ends with conclusions.

2 Overview of prior work on bubbly drag reduction and (super)hydrophobic surfaces

2.1 Drag reduction with hydrophobic surfaces

Superhydrophobic surfaces are typically created by combining a hydrophobic chemistry (resulting in low surface energy) with micro or nanoscale asperities on the surface (Li, Reinhoudt & Crego-Calama Reference Li, Reinhoudt and Crego-Calama2007). The top of these asperities are in contact with the liquid, while air is captured between the asperities. This effectively reduces the solid–liquid contact area, partially replacing it with a gas–liquid interface, that locally changes the no-slip boundary condition to a shear-free boundary condition. The gas–liquid interface is supported by the capillary forces, which in general are larger for hydrophobic materials compared to hydrophilic materials of equal geometry. Dependent on chemistry and geometry, a gas–liquid interface can collapse under the influence of a pressure or shear force, and transition into a thermodynamically favoured wetting state. Various types of asperities exist, ranging from structures such as pillars and ridges to pyramids and mushroom-like shapes (Peters et al. Reference Peters, Pirat, Sbragaglia, Borkent, Wessling, Lohse and Lammertink2009; Qi et al. Reference Qi, Lu, Xu, Yang, Huang, Xu, Gao, Wang and Chi2009; Park et al. Reference Park, Sun and Kim2014; Domingues, Arunachalam & Mishra Reference Domingues, Arunachalam and Mishra2017). However, such well-defined shapes are expensive and time consuming to produce. Therefore, larger areas of SH surfaces (![]() ${>}100~\text{cm}^{2}$) usually have a random roughness structure (Hokmabad & Ghaemi Reference Hokmabad and Ghaemi2016). We refer the reader to the review article by Li et al. (Reference Li, Reinhoudt and Crego-Calama2007) for a broader introduction to SH surfaces.

${>}100~\text{cm}^{2}$) usually have a random roughness structure (Hokmabad & Ghaemi Reference Hokmabad and Ghaemi2016). We refer the reader to the review article by Li et al. (Reference Li, Reinhoudt and Crego-Calama2007) for a broader introduction to SH surfaces.

An overview of various experimental and numerical studies in the laminar and low Reynolds number (![]() $Re$) turbulent regime is given in the review article by Rothstein (Reference Rothstein2010). Under laminar flow conditions, the behaviour of SH surfaces is typically studied in microchannels. Drag reduction is then quantified by defining a slip length, a slip velocity or by a decrease in pressure drop over the channel (Tsai et al. Reference Tsai, Peters, Pirat, Wessling, Lammertink and Lohse2009; Haase et al. Reference Haase, Karatay, Tsai and Lammertink2013; Park et al. Reference Park, Lee, Moreira, Bandaru, Han and Yun2015). As many industrial flows are highly turbulent, it is crucial to study the behaviour of such surfaces in the high Reynolds number flow regime. For marine vessels for example, Reynolds numbers are of the order of

$Re$) turbulent regime is given in the review article by Rothstein (Reference Rothstein2010). Under laminar flow conditions, the behaviour of SH surfaces is typically studied in microchannels. Drag reduction is then quantified by defining a slip length, a slip velocity or by a decrease in pressure drop over the channel (Tsai et al. Reference Tsai, Peters, Pirat, Wessling, Lammertink and Lohse2009; Haase et al. Reference Haase, Karatay, Tsai and Lammertink2013; Park et al. Reference Park, Lee, Moreira, Bandaru, Han and Yun2015). As many industrial flows are highly turbulent, it is crucial to study the behaviour of such surfaces in the high Reynolds number flow regime. For marine vessels for example, Reynolds numbers are of the order of ![]() $Re=O(10^{9})$.

$Re=O(10^{9})$.

Superhydrophobic DR in laminar flow only depends on the geometry of the asperities on the surface that set the slip length and determine the slip velocity. For turbulent flows, SH drag reduction also depends on the Reynolds number (Park, Park & Kim Reference Park, Park and Kim2013). With increasing ![]() $Re$, the thickness of the viscous sublayer decreases, which is the most relevant length scale when comparing the geometric features of the superhydrophobic surface (Daniello, Waterhouse & Rothstein Reference Daniello, Waterhouse and Rothstein2009). In the near-wall region inside the boundary layer of a turbulent flow, the momentum transfer is dominated by molecular interactions, whereas the role of turbulent momentum transfer is negligible. In other words, viscous stress dominates over Reynolds stress. Altering this region affects the entire boundary layer and hence the drag. The outer edge of the viscous sublayer is typically given by a distance

$Re$, the thickness of the viscous sublayer decreases, which is the most relevant length scale when comparing the geometric features of the superhydrophobic surface (Daniello, Waterhouse & Rothstein Reference Daniello, Waterhouse and Rothstein2009). In the near-wall region inside the boundary layer of a turbulent flow, the momentum transfer is dominated by molecular interactions, whereas the role of turbulent momentum transfer is negligible. In other words, viscous stress dominates over Reynolds stress. Altering this region affects the entire boundary layer and hence the drag. The outer edge of the viscous sublayer is typically given by a distance ![]() $y_{vsl}=5\unicode[STIX]{x1D708}/u_{\unicode[STIX]{x1D70F}}=5\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D708}}$ from the wall, where

$y_{vsl}=5\unicode[STIX]{x1D708}/u_{\unicode[STIX]{x1D70F}}=5\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D708}}$ from the wall, where ![]() $\unicode[STIX]{x1D708}$ is the kinematic viscosity, and

$\unicode[STIX]{x1D708}$ is the kinematic viscosity, and ![]() $u_{\unicode[STIX]{x1D70F}}=\sqrt{\unicode[STIX]{x1D70F}_{w}/\unicode[STIX]{x1D70C}}$ the friction velocity for wall shear stress

$u_{\unicode[STIX]{x1D70F}}=\sqrt{\unicode[STIX]{x1D70F}_{w}/\unicode[STIX]{x1D70C}}$ the friction velocity for wall shear stress ![]() $\unicode[STIX]{x1D70F}_{w}$ and density

$\unicode[STIX]{x1D70F}_{w}$ and density ![]() $\unicode[STIX]{x1D70C}$. The viscous length scale

$\unicode[STIX]{x1D70C}$. The viscous length scale ![]() $\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D708}}=\unicode[STIX]{x1D708}/u_{\unicode[STIX]{x1D70F}}$ is the usual scaling parameter for non-dimensionalization to viscous wall units, indicated by a superscript ‘

$\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D708}}=\unicode[STIX]{x1D708}/u_{\unicode[STIX]{x1D70F}}$ is the usual scaling parameter for non-dimensionalization to viscous wall units, indicated by a superscript ‘![]() $+$’, e.g.

$+$’, e.g. ![]() $y^{+}=y/\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D708}}$.

$y^{+}=y/\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D708}}$.

In laminar flow, DR is a direct result of the shear-free (slip) boundary condition. An additional effect matters in turbulence, where near-wall turbulent structures are suppressed due to the slip boundary condition, resulting in additional DR (Park et al. Reference Park, Park and Kim2013). The numerical work of Park et al. (Reference Park, Park and Kim2013) showed that DR increases with the slip length ![]() $b^{+}$, defined as the length below the surface where the extrapolated velocity profile reaches zero. When

$b^{+}$, defined as the length below the surface where the extrapolated velocity profile reaches zero. When ![]() $b^{+}\gtrapprox 30{-}40$, the drag is not further affected by an increase of

$b^{+}\gtrapprox 30{-}40$, the drag is not further affected by an increase of ![]() $b^{+}$. This length scale corresponds to the outer edge of the buffer layer

$b^{+}$. This length scale corresponds to the outer edge of the buffer layer ![]() $5<y^{+}<30$ (Pope Reference Pope2000), where streamwise near-wall vortical structures primarily reside (Park et al. Reference Park, Park and Kim2013). Both observations point in the direction that these near-wall structures are very important for the larger DR that is found for turbulent flows over SH surfaces compared to laminar flow over SH surfaces (Park et al. Reference Park, Park and Kim2013). In the work of Rastegari & Akhavan (Reference Rastegari and Akhavan2018) similar conclusions were drawn. A balance was found between the drag-reducing mechanisms of superhydrophobic microgrooves and riblets in the form of a slip velocity together with weakened Reynolds shear stress and near-wall vortical structures on the one hand, and a drag increase from the interactions between the microtextures and the flow on the other hand. Results from experiments by Daniello et al. (Reference Daniello, Waterhouse and Rothstein2009) suggest a critical Reynolds number that prompts the onset of DR, which corresponds to the transition to turbulent flow. For their system of streamwise-aligned SH ridges in channel flow, they find no DR in the laminar regime, whereas after the flow has transitioned to turbulent flow, significant drag reduction was found. Hence, the physics behind the onset of DR must be related to the structure of the wall-bounded turbulent flow (Daniello et al. Reference Daniello, Waterhouse and Rothstein2009).

$5<y^{+}<30$ (Pope Reference Pope2000), where streamwise near-wall vortical structures primarily reside (Park et al. Reference Park, Park and Kim2013). Both observations point in the direction that these near-wall structures are very important for the larger DR that is found for turbulent flows over SH surfaces compared to laminar flow over SH surfaces (Park et al. Reference Park, Park and Kim2013). In the work of Rastegari & Akhavan (Reference Rastegari and Akhavan2018) similar conclusions were drawn. A balance was found between the drag-reducing mechanisms of superhydrophobic microgrooves and riblets in the form of a slip velocity together with weakened Reynolds shear stress and near-wall vortical structures on the one hand, and a drag increase from the interactions between the microtextures and the flow on the other hand. Results from experiments by Daniello et al. (Reference Daniello, Waterhouse and Rothstein2009) suggest a critical Reynolds number that prompts the onset of DR, which corresponds to the transition to turbulent flow. For their system of streamwise-aligned SH ridges in channel flow, they find no DR in the laminar regime, whereas after the flow has transitioned to turbulent flow, significant drag reduction was found. Hence, the physics behind the onset of DR must be related to the structure of the wall-bounded turbulent flow (Daniello et al. Reference Daniello, Waterhouse and Rothstein2009).

We divide the literature on turbulent flow over hydrophobic surfaces into two regimes: low (but still turbulent) ![]() $Re$ turbulence (

$Re$ turbulence (![]() $Re<10^{5}$) and high

$Re<10^{5}$) and high ![]() $Re$ turbulence (

$Re$ turbulence (![]() $Re>10^{5}$). In these regimes, a difference between single-phase and two-phase flow can be made, although most of the research so far has focussed on single-phase flow. Note that in single-phase flow, i.e. when no air is actively added to the working liquid, air might be trapped by the SH surface when the surface is submerged in the working liquid. In two-phase flow, gas is actively dispersed by (for instance air) bubble injection into the working liquid.

$Re>10^{5}$). In these regimes, a difference between single-phase and two-phase flow can be made, although most of the research so far has focussed on single-phase flow. Note that in single-phase flow, i.e. when no air is actively added to the working liquid, air might be trapped by the SH surface when the surface is submerged in the working liquid. In two-phase flow, gas is actively dispersed by (for instance air) bubble injection into the working liquid.

Different design rules are suggested in the literature for optimal size and spacing of the geometrical features forming the SH surface. In the low ![]() $Re$ turbulence regime, authors mainly seem to use, or suggest the use of, surfaces with pillar/ridge spacing

$Re$ turbulence regime, authors mainly seem to use, or suggest the use of, surfaces with pillar/ridge spacing ![]() $w^{+}>1$, or with a roughness parameter

$w^{+}>1$, or with a roughness parameter ![]() $k^{+}>1$. For the high

$k^{+}>1$. For the high ![]() $Re$ turbulence regime, however, the opposite is the case:

$Re$ turbulence regime, however, the opposite is the case: ![]() $w^{+}<1$, or

$w^{+}<1$, or ![]() $k^{+}<1$ is suggested. The study by Gose et al. (Reference Gose, Golovin, Boban, Mabry, Tuteja, Perlin and Ceccio2018) suggests not only the use of the normalized roughness

$k^{+}<1$ is suggested. The study by Gose et al. (Reference Gose, Golovin, Boban, Mabry, Tuteja, Perlin and Ceccio2018) suggests not only the use of the normalized roughness ![]() $k^{+}$ to predict the drag-reducing properties of a superhydrophobic surface, but also inclusion of the contact angle hysteresis measured at a pressure higher than atmospheric pressure. This is done to simulate the large pressure fluctuations and high shear rates generated by high Reynolds number flows (Gose et al. Reference Gose, Golovin, Boban, Mabry, Tuteja, Perlin and Ceccio2018). The roughness of the superhydrophobic surfaces they studied varied between

$k^{+}$ to predict the drag-reducing properties of a superhydrophobic surface, but also inclusion of the contact angle hysteresis measured at a pressure higher than atmospheric pressure. This is done to simulate the large pressure fluctuations and high shear rates generated by high Reynolds number flows (Gose et al. Reference Gose, Golovin, Boban, Mabry, Tuteja, Perlin and Ceccio2018). The roughness of the superhydrophobic surfaces they studied varied between ![]() $k^{+}=0.2$ and

$k^{+}=0.2$ and ![]() $k^{+}=4.5$, with corresponding drag reduction changing from

$k^{+}=4.5$, with corresponding drag reduction changing from ![]() $-90\,\%$ to 90 %. Specifically, around

$-90\,\%$ to 90 %. Specifically, around ![]() $\text{DR}=0\,\%$, the trend of increasing DR with decreasing

$\text{DR}=0\,\%$, the trend of increasing DR with decreasing ![]() $k^{+}$ is absent, showing drag reduction for one surface with

$k^{+}$ is absent, showing drag reduction for one surface with ![]() $k^{+}=1$ and an increase of drag for another surface with

$k^{+}=1$ and an increase of drag for another surface with ![]() $k^{+}<1$. When

$k^{+}<1$. When ![]() $k^{+}$ was scaled with the roughness parameter and the wetted area fraction, or the high-pressure contact angle hysteresis (370 Pa for a 250 nanolitre droplet), the DR data collapsed to a single curve (Gose et al. Reference Gose, Golovin, Boban, Mabry, Tuteja, Perlin and Ceccio2018).

$k^{+}$ was scaled with the roughness parameter and the wetted area fraction, or the high-pressure contact angle hysteresis (370 Pa for a 250 nanolitre droplet), the DR data collapsed to a single curve (Gose et al. Reference Gose, Golovin, Boban, Mabry, Tuteja, Perlin and Ceccio2018).

An overview of the different surface parameters found in the literature focussing on DR with SH surfaces is shown in table 1.

Table 1. Overview of the literature on drag reduction of turbulent flows over superhydrophobic surfaces, illustrating different surface design parameters ![]() $k^{+}$ and

$k^{+}$ and ![]() $w^{+}$ corresponding to the largest drag reduction found by different authors. The horizontal line separates the low

$w^{+}$ corresponding to the largest drag reduction found by different authors. The horizontal line separates the low ![]() $Re$ turbulence from the high

$Re$ turbulence from the high ![]() $Re$ turbulence as introduced in § 2.

$Re$ turbulence as introduced in § 2.

a Derived from data in paper.

b Normalized with value for no-slip surface.

c Optimal value obtained from parameter sweep.

d Additional surface characterization.

e Decreasing with ![]() $Re$.

$Re$.

f No DR for ![]() $Re_{L}>10^{6}$.

$Re_{L}>10^{6}$.

2.1.1 Low  $Re$ turbulence

$Re$ turbulence

Using channel flow, Daniello et al. (Reference Daniello, Waterhouse and Rothstein2009) studied a variety of SH surfaces consisting of streamwise-aligned ridges, with varying ridge spacing ![]() $w^{+}=1{-}4$. Over the whole range of

$w^{+}=1{-}4$. Over the whole range of ![]() $3\times 10^{3}\leqslant Re\leqslant 6\times 10^{3}$, a DR of 50 % was found (Daniello et al. Reference Daniello, Waterhouse and Rothstein2009). The dependence of DR on surface feature size has also been studied using direct numerical simulations (DNS) by Martell et al. (Reference Martell, Perot and Rothstein2009), finding good agreement to the work of Daniello et al. (Reference Daniello, Waterhouse and Rothstein2009). More recent DNS of streamwise SH ridges in channel flow by Park et al. (Reference Park, Park and Kim2013), showed a maximum DR when the ridge spacing was similar to the spacing between near-wall turbulent structures

$3\times 10^{3}\leqslant Re\leqslant 6\times 10^{3}$, a DR of 50 % was found (Daniello et al. Reference Daniello, Waterhouse and Rothstein2009). The dependence of DR on surface feature size has also been studied using direct numerical simulations (DNS) by Martell et al. (Reference Martell, Perot and Rothstein2009), finding good agreement to the work of Daniello et al. (Reference Daniello, Waterhouse and Rothstein2009). More recent DNS of streamwise SH ridges in channel flow by Park et al. (Reference Park, Park and Kim2013), showed a maximum DR when the ridge spacing was similar to the spacing between near-wall turbulent structures ![]() $w^{+}=100$. The work of Park et al. (Reference Park, Park and Kim2013) was able to isolate the effect of the SH surface, since it was modelled as a flat surface with an alternating no-slip and no-shear boundary condition. Effects of roughness on the flow that would play a role in experiments, either from a non-flat gas–liquid interface or from surface features that protrude through the viscous sublayer, could therefore be ruled out.

$w^{+}=100$. The work of Park et al. (Reference Park, Park and Kim2013) was able to isolate the effect of the SH surface, since it was modelled as a flat surface with an alternating no-slip and no-shear boundary condition. Effects of roughness on the flow that would play a role in experiments, either from a non-flat gas–liquid interface or from surface features that protrude through the viscous sublayer, could therefore be ruled out.

Rather than a surface of well-defined feature size and geometry, a porous surface of random roughness structure was used by Srinivasan et al. (Reference Srinivasan, Chhatre, Mabry, Cohen and McKinley2011). The inner cylinder of their Taylor–Couette was was made superhydrophobic by spray coating a mixture of PMMA fibres and low surface energy fluorodecyl POSS molecules. Nonetheless, the resulting surface roughness parameters are similar to that of Daniello et al. (Reference Daniello, Waterhouse and Rothstein2009). From the work of Srinivasan et al. (Reference Srinivasan, Kleingartner, Gilbert, Cohen, Milne and McKinley2015) we calculate the average roughness height at the maximum ![]() $Re=8\times 10^{4}$ to be approximately

$Re=8\times 10^{4}$ to be approximately ![]() $k^{+}=1.5$ and the mean roughness spacing

$k^{+}=1.5$ and the mean roughness spacing ![]() $w^{+}=2.5$. The maximum

$w^{+}=2.5$. The maximum ![]() $Re$ also resulted in the largest DR of 22 %. Another study in Taylor–Couette, of similar

$Re$ also resulted in the largest DR of 22 %. Another study in Taylor–Couette, of similar ![]() $Re$, but with much larger surface roughness parameters of

$Re$, but with much larger surface roughness parameters of ![]() $k^{+}=27$ and

$k^{+}=27$ and ![]() $w^{+}=14$ formed by a SH pillar structure, found only 3 % DR (Panchanathan et al. Reference Panchanathan, Rajappan, Varanasi and McKinley2018). When instead of large SH pillars, large streamwise-aligned SH ridges were used in Taylor–Couette flow, an optimal groove spacing of

$w^{+}=14$ formed by a SH pillar structure, found only 3 % DR (Panchanathan et al. Reference Panchanathan, Rajappan, Varanasi and McKinley2018). When instead of large SH pillars, large streamwise-aligned SH ridges were used in Taylor–Couette flow, an optimal groove spacing of ![]() $w^{+}=35$ was found to achieve a maximum DR of 35 % (Van Buren & Smits Reference Van Buren and Smits2017). For the smallest groove spacing tested,

$w^{+}=35$ was found to achieve a maximum DR of 35 % (Van Buren & Smits Reference Van Buren and Smits2017). For the smallest groove spacing tested, ![]() $w^{+}=2$, no DR was found. The baseline drag used in the definition of the drag reduction is very important. Where Van Buren & Smits (Reference Van Buren and Smits2017) used their wetted surface as the baseline, a smooth surface was used for the baseline drag by Panchanathan et al. (Reference Panchanathan, Rajappan, Varanasi and McKinley2018). When the baselines are defined equally, the difference in DR found between the studies is much smaller.

$w^{+}=2$, no DR was found. The baseline drag used in the definition of the drag reduction is very important. Where Van Buren & Smits (Reference Van Buren and Smits2017) used their wetted surface as the baseline, a smooth surface was used for the baseline drag by Panchanathan et al. (Reference Panchanathan, Rajappan, Varanasi and McKinley2018). When the baselines are defined equally, the difference in DR found between the studies is much smaller.

2.1.2 High  $Re$ turbulence

$Re$ turbulence

Ling et al. (Reference Ling, Srinivasan, Golovin, Mckinley, Tuteja and Katz2016) measured the velocity in the inner part of the turbulent boundary layers over SH surfaces subjected to single-phase flow. Surfaces were made SH by means of spray coating, resulting in a randomly oriented roughness, and by etching and coating, giving both ridges and randomly oriented roughness. Measurements were done in a water tunnel, operated at ![]() $1\times 10^{5}\leqslant Re\leqslant 3\times 10^{5}$. Their results revealed a delicate balance between the contribution of viscous stresses and Reynolds stresses to the wall shear stress. This balance determines whether DR is found (viscosity dominates), or the surface roughness increases the drag (turbulence dominates). It was found that, when the roughness

$1\times 10^{5}\leqslant Re\leqslant 3\times 10^{5}$. Their results revealed a delicate balance between the contribution of viscous stresses and Reynolds stresses to the wall shear stress. This balance determines whether DR is found (viscosity dominates), or the surface roughness increases the drag (turbulence dominates). It was found that, when the roughness ![]() $k^{+}\gtrapprox 1$, the Reynolds stresses become the main contributor to the wall shear stress, and less DR was found (Ling et al. Reference Ling, Srinivasan, Golovin, Mckinley, Tuteja and Katz2016).

$k^{+}\gtrapprox 1$, the Reynolds stresses become the main contributor to the wall shear stress, and less DR was found (Ling et al. Reference Ling, Srinivasan, Golovin, Mckinley, Tuteja and Katz2016).

The number of studies we found that combine a SH surface and air injection (two-phase flow) is limited. Du et al. (Reference Du, Wen, Zhang, Song, Ouahsine and Hu2017) only found DR when air was being injected through their SH surface. The DR was the result of weakened near-wall vortices, pushed away from the SH surface, and smaller shear rates on top of the SH surface (Du et al. Reference Du, Wen, Zhang, Song, Ouahsine and Hu2017). A variety of flow geometries were studied by Fukuda et al. (Reference Fukuda, Tokunaga, Nobunaga, Nakatani, Iwasaki and Kunitake2000): rectangular pipe flow (![]() $5\times 10^{4}\leqslant Re\leqslant 4\times 10^{5}$), flat plate (

$5\times 10^{4}\leqslant Re\leqslant 4\times 10^{5}$), flat plate (![]() $3\times 10^{5}\leqslant Re_{L}\leqslant 1.7\times 10^{7}$) and ship models in a towing tank (

$3\times 10^{5}\leqslant Re_{L}\leqslant 1.7\times 10^{7}$) and ship models in a towing tank (![]() $9\times 10^{5}\leqslant Re_{L}\leqslant 8\times 10^{8}$). For the pipe flow and flat plate experiments, the maximum DR of 50 % was found to decrease with

$9\times 10^{5}\leqslant Re_{L}\leqslant 8\times 10^{8}$). For the pipe flow and flat plate experiments, the maximum DR of 50 % was found to decrease with ![]() $Re$ to

$Re$ to ![]() ${\sim}0\,\%$. Negligible influence of an increased air injection rate on DR was observed for all flow geometries (Fukuda et al. Reference Fukuda, Tokunaga, Nobunaga, Nakatani, Iwasaki and Kunitake2000).

${\sim}0\,\%$. Negligible influence of an increased air injection rate on DR was observed for all flow geometries (Fukuda et al. Reference Fukuda, Tokunaga, Nobunaga, Nakatani, Iwasaki and Kunitake2000).

One of the few experiments in the high ![]() $Re$ turbulence regime that uses a surface with a geometrically well-defined pattern is done by Park et al. (Reference Park, Sun and Kim2014) (

$Re$ turbulence regime that uses a surface with a geometrically well-defined pattern is done by Park et al. (Reference Park, Sun and Kim2014) (![]() $1\times 10^{5}\leqslant Re\leqslant 1\times 10^{6}$), allowing for a direct comparison to the work of Daniello et al. (Reference Daniello, Waterhouse and Rothstein2009) (

$1\times 10^{5}\leqslant Re\leqslant 1\times 10^{6}$), allowing for a direct comparison to the work of Daniello et al. (Reference Daniello, Waterhouse and Rothstein2009) (![]() $3\times 10^{3}\leqslant Re\leqslant 6\times 10^{3}$) in the low

$3\times 10^{3}\leqslant Re\leqslant 6\times 10^{3}$) in the low ![]() $Re$ turbulence. Both studies made use of a fully turbulent, single-phase channel flow over a surface of streamwise SH ridges. Daniello et al. (Reference Daniello, Waterhouse and Rothstein2009) suggested an optimum ridge spacing of

$Re$ turbulence. Both studies made use of a fully turbulent, single-phase channel flow over a surface of streamwise SH ridges. Daniello et al. (Reference Daniello, Waterhouse and Rothstein2009) suggested an optimum ridge spacing of ![]() $w^{+}=5$, which is equal to the size of the viscous sublayer. Park et al. (Reference Park, Sun and Kim2014) however, found their maximum DR for

$w^{+}=5$, which is equal to the size of the viscous sublayer. Park et al. (Reference Park, Sun and Kim2014) however, found their maximum DR for ![]() $w^{+}<1$. This is a difference typically found between studies in the low and the high

$w^{+}<1$. This is a difference typically found between studies in the low and the high ![]() $Re$ turbulence regimes, as can also be seen in table 1.

$Re$ turbulence regimes, as can also be seen in table 1.

2.2 The air plastron

The air layer captured between the SH surface and the water is commonly referred to as the air plastron. When the SH surface transits from a non-wetted Cassie–Baxter state to a wetted Wenzel state, the plastron and the DR are lost. Since the Wenzel state is typically the thermodynamically more favoured state, it is therefore crucial to prevent or delay this transition. This can, for instance, be achieved by reducing the size (diameter or ![]() $w^{+}$) of the asperities in which the gas is trapped to increase the Laplace pressure, or by increasing the hydrophobicity of the surface. The diffusion of gas from the plastron into the liquid is another factor to minimize in order to sustain DR, which can for instance be achieved by increasing the amount of saturated gas in the liquid (Lv et al. Reference Lv, Xue, Shi, Lin and Duan2014; Xiang et al. Reference Xiang, Huang, Lv, Xue, Su and Duan2017).

$w^{+}$) of the asperities in which the gas is trapped to increase the Laplace pressure, or by increasing the hydrophobicity of the surface. The diffusion of gas from the plastron into the liquid is another factor to minimize in order to sustain DR, which can for instance be achieved by increasing the amount of saturated gas in the liquid (Lv et al. Reference Lv, Xue, Shi, Lin and Duan2014; Xiang et al. Reference Xiang, Huang, Lv, Xue, Su and Duan2017).

In the experiments by Srinivasan et al. (Reference Srinivasan, Kleingartner, Gilbert, Cohen, Milne and McKinley2015), the SH surface was not fully submerged, resulting in a connection between the plastron and the air present in the room. More DR (22 %) was found compared to the case where the air layer is isolated (![]() $\text{DR}=15\,\%$) for the same

$\text{DR}=15\,\%$) for the same ![]() $Re$ (Srinivasan et al. Reference Srinivasan, Kleingartner, Gilbert, Cohen, Milne and McKinley2015). When the surface is exposed to flow, the loss of plastron volume can be described by a convection–diffusion mechanism. Larger flow velocities give shorter effective diffusion lengths, resulting in an accelerated transport of gas from the plastron into the liquid (Xiang et al. Reference Xiang, Xue, Lv, Li and Duan2016). Video recordings of the plastron exposed to turbulent flow (

$Re$ (Srinivasan et al. Reference Srinivasan, Kleingartner, Gilbert, Cohen, Milne and McKinley2015). When the surface is exposed to flow, the loss of plastron volume can be described by a convection–diffusion mechanism. Larger flow velocities give shorter effective diffusion lengths, resulting in an accelerated transport of gas from the plastron into the liquid (Xiang et al. Reference Xiang, Xue, Lv, Li and Duan2016). Video recordings of the plastron exposed to turbulent flow (![]() $5.0\times 10^{5}\leqslant Re_{L}\leqslant 1.5\times 10^{6}$) showed constant movement and variations in the thickness of the plastron, caused by pressure fluctuations in the turbulent boundary layer (Reholon & Ghaemi Reference Reholon and Ghaemi2018). Du et al. (Reference Du, Wen, Zhang, Song, Ouahsine and Hu2017) found DR when injecting air through a pinhole in their SH surface. The amount of injected air was not enough to form an air bubbly flow, but was enough to maintain a plastron that was thick enough to prevent the surface roughness features from contacting the liquid. When the air injection was stopped, the air plastron became thinner, and roughness effects started to play a role (Du et al. Reference Du, Wen, Zhang, Song, Ouahsine and Hu2017). When the roughness elements are exposed to the flow, the Reynolds stresses become the main contributor to the wall shear stress, resulting in less DR (Ling et al. Reference Ling, Srinivasan, Golovin, Mckinley, Tuteja and Katz2016).

$5.0\times 10^{5}\leqslant Re_{L}\leqslant 1.5\times 10^{6}$) showed constant movement and variations in the thickness of the plastron, caused by pressure fluctuations in the turbulent boundary layer (Reholon & Ghaemi Reference Reholon and Ghaemi2018). Du et al. (Reference Du, Wen, Zhang, Song, Ouahsine and Hu2017) found DR when injecting air through a pinhole in their SH surface. The amount of injected air was not enough to form an air bubbly flow, but was enough to maintain a plastron that was thick enough to prevent the surface roughness features from contacting the liquid. When the air injection was stopped, the air plastron became thinner, and roughness effects started to play a role (Du et al. Reference Du, Wen, Zhang, Song, Ouahsine and Hu2017). When the roughness elements are exposed to the flow, the Reynolds stresses become the main contributor to the wall shear stress, resulting in less DR (Ling et al. Reference Ling, Srinivasan, Golovin, Mckinley, Tuteja and Katz2016).

For this particular reason, Gose et al. (Reference Gose, Golovin, Boban, Mabry, Tuteja, Perlin and Ceccio2018) suggested measuring the surface characteristic contact angle hysteresis under higher than ambient pressures. Also, mechanical interactions between the plastron and solid pollutants in the liquid phase can decrease the plastron stability. Collisions between particles added to the flow and the plastron were shown to shorten its lifetime by approximately 50 % (Hokmabad & Ghaemi Reference Hokmabad and Ghaemi2017). Once the air plastron is destroyed and the surface has transited to the wetted state, energy is required to reverse the surface to the un-wetted state. Different studies explored, for instance, film boiling, water splitting by electrolysis and the injection of air bubbles into the boundary layer (two-phase flow) to achieve this (Saranadhi et al. Reference Saranadhi, Chen, Kleingartner, Srinivasan, Cohen and McKinley2016; Panchanathan et al. Reference Panchanathan, Rajappan, Varanasi and McKinley2018).

2.3 Bubbly drag reduction

The introduction of air bubbles to a flow can also result in reduced skin friction drag. A typical approach is to inject air bubbles close to (or in) the boundary layer. We refer to the review articles by Ceccio (Reference Ceccio2010) and Murai (Reference Murai2014) for an overview of various studies on bubbly DR. Early air-lubrication DR experiments, in which gas microbubbles were injected (or created) in the (turbulent) boundary layer, showed an increase in DR with increasing air injection rate, and a decrease in DR with increasing Reynolds number (McCormick & Bhattacharyya Reference McCormick and Bhattacharyya1973; Madavan, Deutsch & Merkle Reference Madavan, Deutsch and Merkle1985; Watanabe, Masuko & Yasushi Reference Watanabe, Masuko and Yasushi1998). Up to 80 % reduction of skin friction drag using microbubble injection was reported (Madavan, Deutsch & Merkle Reference Madavan, Deutsch and Merkle1984). This DR was attributed to a thickening of the viscous sublayer (so a smaller gradient in the velocity profile near the wall) caused by the microbubbles that were present in the near-wall buffer layer (Ceccio Reference Ceccio2010).

For Taylor–Couette flow, for low ![]() $Re$ and microbubble injection, the drag reduction was shown to be due to the weakening or even destruction of the Taylor vortices, due to the rising microbubbles. This gravity effect (controlled by the Froude number) indeed decreases with increasing Reynolds numbers (Sugiyama, Calzavarini & Lohse Reference Sugiyama, Calzavarini and Lohse2008; Lohse Reference Lohse2018). More recent research showed the influence of the bubble size on DR, concluding that the existence of large, deformable bubbles, i.e. those that have a large Weber number, is crucial for drag reduction in high

$Re$ and microbubble injection, the drag reduction was shown to be due to the weakening or even destruction of the Taylor vortices, due to the rising microbubbles. This gravity effect (controlled by the Froude number) indeed decreases with increasing Reynolds numbers (Sugiyama, Calzavarini & Lohse Reference Sugiyama, Calzavarini and Lohse2008; Lohse Reference Lohse2018). More recent research showed the influence of the bubble size on DR, concluding that the existence of large, deformable bubbles, i.e. those that have a large Weber number, is crucial for drag reduction in high ![]() $Re$ turbulent flows (van den Berg et al. Reference van den Berg, Luther, Lathrop and Lohse2005; Lu, Fernández & Tryggvason Reference Lu, Fernández and Tryggvason2005; van Gils et al. Reference van Gils, Narezo Guzman, Sun and Lohse2013; Verschoof et al. Reference Verschoof, van der Veen, Sun and Lohse2016; Spandan, Verzicco & Lohse Reference Spandan, Verzicco and Lohse2018). In these papers, the increase of the Weber number with increasing

$Re$ turbulent flows (van den Berg et al. Reference van den Berg, Luther, Lathrop and Lohse2005; Lu, Fernández & Tryggvason Reference Lu, Fernández and Tryggvason2005; van Gils et al. Reference van Gils, Narezo Guzman, Sun and Lohse2013; Verschoof et al. Reference Verschoof, van der Veen, Sun and Lohse2016; Spandan, Verzicco & Lohse Reference Spandan, Verzicco and Lohse2018). In these papers, the increase of the Weber number with increasing ![]() $Re$ is used to explain the enhanced bubbly DR that is typically found for larger

$Re$ is used to explain the enhanced bubbly DR that is typically found for larger ![]() $Re$ (van den Berg et al. Reference van den Berg, Luther, Lathrop and Lohse2005).

$Re$ (van den Berg et al. Reference van den Berg, Luther, Lathrop and Lohse2005).

Although the principle of air bubbly DR is not yet fully understood, it is clear that the effect is largest when the bubbles are close to, or in, the boundary layer. For flat plate experiments, the skin friction bubbly drag reduction is commonly limited to the first few metres downstream of the air injector (Watanabe et al. Reference Watanabe, Masuko and Yasushi1998; Sanders et al. Reference Sanders, Winkel, Dowling, Perlin and Ceccio2006). Further downstream, turbulent diffusion causes bubbles to move away from the wall (Murai Reference Murai2014). A similar mechanism was observed in Taylor–Couette flow, where strong secondary flows transport bubbles away from the inner cylinder, resulting in a decrease of DR (van den Berg et al. Reference van den Berg, van Gils, Lathrop and Lohse2007; Fokoua et al. Reference Fokoua, Gabillet, Aubert and Colin2015; Verschoof et al. Reference Verschoof, Bakhuis, Bullee, Huisman, Sun and Lohse2018a).

2.4 Roughness

To create a SH surface, some form of roughness has to be introduced to the surface, to facilitate an asperity where air can be trapped. Since any form of surface roughness increases the drag on a wall-bound flow, we therefore deal with opposing effects in drag reduction using SH surfaces: drag reduction due to air (plastron) lubrication and drag increase from the added roughness. We refer to the reviews of Jiménez (Reference Jiménez2004) and Flack & Schultz (Reference Flack and Schultz2010) for a comprehensive overview of studies towards the influence of roughness on turbulent flows.

Three different roughness regimes are distinguished. In the hydrodynamically smooth regime, where the equivalent sand roughness is less than the thickness of the viscous sublayer (![]() $k^{+}<5$), the surface can be regarded as smooth (Schlichting & Gersten Reference Schlichting and Gersten2000). The perturbations in the flow that are generated by the roughness features of the surface are completely damped out by the viscosity (Flack & Schultz Reference Flack and Schultz2014). When the roughness

$k^{+}<5$), the surface can be regarded as smooth (Schlichting & Gersten Reference Schlichting and Gersten2000). The perturbations in the flow that are generated by the roughness features of the surface are completely damped out by the viscosity (Flack & Schultz Reference Flack and Schultz2014). When the roughness ![]() $k^{+}$ increases, parts of it will extend through the viscous sublayer, corresponding to the transitionally rough regime (

$k^{+}$ increases, parts of it will extend through the viscous sublayer, corresponding to the transitionally rough regime (![]() $5\leqslant k^{+}<70$). The log law that describes the velocity profile close to the wall shifts inwards, maintaining its shape, but reduced in magnitude. The mean velocity profile in the bulk of the flow however remains unaffected by the roughness (Flack & Schultz Reference Flack and Schultz2014). Hence, universality is only seen for the larger length scales of the flows (Pope Reference Pope2000).

$5\leqslant k^{+}<70$). The log law that describes the velocity profile close to the wall shifts inwards, maintaining its shape, but reduced in magnitude. The mean velocity profile in the bulk of the flow however remains unaffected by the roughness (Flack & Schultz Reference Flack and Schultz2014). Hence, universality is only seen for the larger length scales of the flows (Pope Reference Pope2000).

The wall shear stress in the transitionally rough regime is composed of a combination of viscosity and pressure drag on the roughness elements. With increasing roughness height, the contribution of pressure drag increases (Verschoof et al. Reference Verschoof, Zhu, Bakhuis, Huisman, Verzicco, Sun and Lohse2018b). In the fully rough regime (![]() $k^{+}\geqslant 70$), the pressure drag heavily dominates over viscosity. As a result, the shift in the log law (the roughness function

$k^{+}\geqslant 70$), the pressure drag heavily dominates over viscosity. As a result, the shift in the log law (the roughness function ![]() $\unicode[STIX]{x0394}U^{+}$), scales linearly with

$\unicode[STIX]{x0394}U^{+}$), scales linearly with ![]() $k^{+}$, and the skin friction coefficient becomes independent of

$k^{+}$, and the skin friction coefficient becomes independent of ![]() $Re$ (Flack & Schultz Reference Flack and Schultz2014).

$Re$ (Flack & Schultz Reference Flack and Schultz2014).

The size of the roughness ![]() $k^{+}$ gives a good indication of the state of the roughness: hydrodynamically smooth, transitionally rough or fully rough, which also depends on the geometry of the roughness. For instance, a stepwise geometry that consists of steep slopes will transition to the fully rough regime at smaller

$k^{+}$ gives a good indication of the state of the roughness: hydrodynamically smooth, transitionally rough or fully rough, which also depends on the geometry of the roughness. For instance, a stepwise geometry that consists of steep slopes will transition to the fully rough regime at smaller ![]() $k^{+}$ than a roughness of more gentle slope (Busse, Thakkar & Sandham Reference Busse, Thakkar and Sandham2017). Similarly, a surface of very closely packed roughness elements (high solidity), or a surface where the roughness elements are sparse (high porosity) will behave more like a surface of smaller

$k^{+}$ than a roughness of more gentle slope (Busse, Thakkar & Sandham Reference Busse, Thakkar and Sandham2017). Similarly, a surface of very closely packed roughness elements (high solidity), or a surface where the roughness elements are sparse (high porosity) will behave more like a surface of smaller ![]() $k^{+}$ (MacDonald et al. Reference MacDonald, Chan, Chung, Hutchins and Ooi2016). In the context of Taylor–Couette turbulence, roughness effects were analysed by Zhu et al. (Reference Zhu, Verschoof, Bakhuis, Huisman, Verzicco, Sun and Lohse2018) and Berghout et al. (Reference Berghout, Zhu, Chung, Verzicco, Stevens and Lohse2019), who found the same universal

$k^{+}$ (MacDonald et al. Reference MacDonald, Chan, Chung, Hutchins and Ooi2016). In the context of Taylor–Couette turbulence, roughness effects were analysed by Zhu et al. (Reference Zhu, Verschoof, Bakhuis, Huisman, Verzicco, Sun and Lohse2018) and Berghout et al. (Reference Berghout, Zhu, Chung, Verzicco, Stevens and Lohse2019), who found the same universal ![]() $\unicode[STIX]{x0394}U^{+}(k^{+})$ for the velocity reduction as was found by Nikuradse (Reference Nikuradse1933) for pipe flow.

$\unicode[STIX]{x0394}U^{+}(k^{+})$ for the velocity reduction as was found by Nikuradse (Reference Nikuradse1933) for pipe flow.

3 Experimental method

3.1 Experimental set-up

All experiments were performed in the Twente Turbulent Taylor–Couette (![]() $\text{T}^{3}\text{C}$) facility described in van Gils et al. (Reference van Gils, Bruggert, Lathrop, Sun and Lohse2011) and shown in figure 1. It consists of two independently rotating concentric cylinders of length

$\text{T}^{3}\text{C}$) facility described in van Gils et al. (Reference van Gils, Bruggert, Lathrop, Sun and Lohse2011) and shown in figure 1. It consists of two independently rotating concentric cylinders of length ![]() $L=0.927~\text{m}$. The inner cylinder is fabricated from grade 316 hydrophilic stainless steel. The outer cylinder is cast from clear acrylic, which allows for full optical access to the flow between the cylinders. The inner radius of the outer cylinder is

$L=0.927~\text{m}$. The inner cylinder is fabricated from grade 316 hydrophilic stainless steel. The outer cylinder is cast from clear acrylic, which allows for full optical access to the flow between the cylinders. The inner radius of the outer cylinder is ![]() $r_{o}=0.279~\text{m}$ and the outer radius of the inner cylinder equals

$r_{o}=0.279~\text{m}$ and the outer radius of the inner cylinder equals ![]() $r_{i}=0.200~\text{m}$, thus the radius ratio is

$r_{i}=0.200~\text{m}$, thus the radius ratio is ![]() $\unicode[STIX]{x1D702}=r_{i}/r_{o}=0.716$. The resulting gap has a width

$\unicode[STIX]{x1D702}=r_{i}/r_{o}=0.716$. The resulting gap has a width ![]() $d=r_{o}-r_{i}=0.079~\text{m}$ and was filled with fully air saturated deionized water. For inner cylinder rotation, the Reynolds defined, based on the gap width and velocity of the inner cylinder is

$d=r_{o}-r_{i}=0.079~\text{m}$ and was filled with fully air saturated deionized water. For inner cylinder rotation, the Reynolds defined, based on the gap width and velocity of the inner cylinder is

where ![]() $\unicode[STIX]{x1D714}_{i}$ is the angular velocity of the inner cylinder and

$\unicode[STIX]{x1D714}_{i}$ is the angular velocity of the inner cylinder and ![]() $\unicode[STIX]{x1D708}$ is the kinematic viscosity of the working fluid. The inner cylinder rotates at frequencies in the range

$\unicode[STIX]{x1D708}$ is the kinematic viscosity of the working fluid. The inner cylinder rotates at frequencies in the range ![]() $\unicode[STIX]{x1D714}_{i}=5{-}18~\text{Hz}$, while the outer cylinder is kept stationary. Typical values used in this research range from

$\unicode[STIX]{x1D714}_{i}=5{-}18~\text{Hz}$, while the outer cylinder is kept stationary. Typical values used in this research range from ![]() $Re=5\times 10^{5}$ to

$Re=5\times 10^{5}$ to ![]() $Re=1.8\times 10^{6}$. The system is actively cooled to keep the temperature of the working fluid at

$Re=1.8\times 10^{6}$. The system is actively cooled to keep the temperature of the working fluid at ![]() $21\,^{\circ }\text{C}\pm 0.5\,^{\circ }\text{C}$.

$21\,^{\circ }\text{C}\pm 0.5\,^{\circ }\text{C}$.

Figure 1. Schematic overview of the measurement set-up. Shown are the outer and inner cylinders, of which the latter consists of three sections. The middle section is connected to the driving shaft by means of a torque sensor, which is also shown in the figure. The gap between the two cylinders ![]() $r_{o}-r_{i}$ is filled with water and air, of which the quantity of the air is expressed by means of a void fraction

$r_{o}-r_{i}$ is filled with water and air, of which the quantity of the air is expressed by means of a void fraction ![]() $\unicode[STIX]{x1D6FC}$, ranging between 0 % and 6 %. When the inner cylinder is rotating (

$\unicode[STIX]{x1D6FC}$, ranging between 0 % and 6 %. When the inner cylinder is rotating (![]() $\unicode[STIX]{x1D714}_{i}>0~\text{Hz}$), bubbles are formed and distributed in the radial and axial directions over the gap due to turbulent mixing. PIV measurements can be done only when there are no bubbles present in the working liquid (

$\unicode[STIX]{x1D714}_{i}>0~\text{Hz}$), bubbles are formed and distributed in the radial and axial directions over the gap due to turbulent mixing. PIV measurements can be done only when there are no bubbles present in the working liquid (![]() $\unicode[STIX]{x1D6FC}=0\,\%$). The PIV laser sheet is placed at cylinder mid-height and the flow is observed through a window in the bottom plate using a mirror and a camera.

$\unicode[STIX]{x1D6FC}=0\,\%$). The PIV laser sheet is placed at cylinder mid-height and the flow is observed through a window in the bottom plate using a mirror and a camera.

By partly filling the apparatus, as in figure 1, we vary the volume fraction of air ![]() $\unicode[STIX]{x1D6FC}$ in the working fluid from 0 % to 6 %. The turbulence mixes the air and water, generating bubbles that are distributed over the height and over the gap between the cylinders (van Gils et al. Reference van Gils, Narezo Guzman, Sun and Lohse2013).

$\unicode[STIX]{x1D6FC}$ in the working fluid from 0 % to 6 %. The turbulence mixes the air and water, generating bubbles that are distributed over the height and over the gap between the cylinders (van Gils et al. Reference van Gils, Narezo Guzman, Sun and Lohse2013).

3.2 Torque measurements

The inner cylinder is composed of three sections. The torque exerted by the fluid on the inner cylinder is measured using a Honeywell 2404-1K hollow reaction torque sensor that is placed inside the middle section of the inner cylinder, as indicated in figure 1. Only the torque on the middle section of length ![]() $L_{mid}=0.536$ m is taken into account to reduce end-plate effects between the rotating lid of the inner cylinder and the stationary lid of the outer cylinder. We express the torque in non-dimensional form using the skin friction coefficient

$L_{mid}=0.536$ m is taken into account to reduce end-plate effects between the rotating lid of the inner cylinder and the stationary lid of the outer cylinder. We express the torque in non-dimensional form using the skin friction coefficient

where ![]() ${\mathcal{T}}$ denotes the torque,

${\mathcal{T}}$ denotes the torque, ![]() $\unicode[STIX]{x1D70C}$ and

$\unicode[STIX]{x1D70C}$ and ![]() $\unicode[STIX]{x1D708}$ are the density and kinematic viscosity, respectively, of the working fluid.

$\unicode[STIX]{x1D708}$ are the density and kinematic viscosity, respectively, of the working fluid.

The drag reduction for the hydrophobic coating and the hydrophilic reference is determined using (3.3).

This shows the influence of adding bubbles to the flow on the drag. The difference in drag reduction ![]() $\unicode[STIX]{x0394}\text{DR}$ between a hydrophobic inner cylinder (IC) and a hydrophilic IC is defined as

$\unicode[STIX]{x0394}\text{DR}$ between a hydrophobic inner cylinder (IC) and a hydrophilic IC is defined as

In order to provide insight into the influence of the hydrophobic IC on the flow, we define a net drag reduction as

Here, ![]() $C_{f,hydrophobic}(\unicode[STIX]{x1D6FC})$ is the skin friction coefficient for the hydrophobic IC and different values of

$C_{f,hydrophobic}(\unicode[STIX]{x1D6FC})$ is the skin friction coefficient for the hydrophobic IC and different values of ![]() $\unicode[STIX]{x1D6FC}$, and

$\unicode[STIX]{x1D6FC}$, and ![]() $C_{f,hydrophilic}(\unicode[STIX]{x1D6FC}=0)$ is the skin friction coefficient for the smooth hydrophillic inner cylinder, without air bubbles present in the flow (

$C_{f,hydrophilic}(\unicode[STIX]{x1D6FC}=0)$ is the skin friction coefficient for the smooth hydrophillic inner cylinder, without air bubbles present in the flow (![]() $\unicode[STIX]{x1D6FC}=0$). In (3.3) the focus is only on the influence of bubbles on the drag, with either a hydrophobic or a hydrophilic IC, whereas (3.5) show the influence of both drag reducing measures: bubbles and a hydrophobic coating.

$\unicode[STIX]{x1D6FC}=0$). In (3.3) the focus is only on the influence of bubbles on the drag, with either a hydrophobic or a hydrophilic IC, whereas (3.5) show the influence of both drag reducing measures: bubbles and a hydrophobic coating.

3.3 Hydrophobic coating

In the hydrophobic case, the IC of the ![]() $\text{T}^{3}\text{C}$ is fully coated with a 3M Membrana Accurel® PP 2E HF flat sheet membrane. This porous hydrophobic polypropylene material is commercially available in the large quantities that are needed to cover the complete IC. This coating is supplied on rolls that have a width of approximately 27 cm. It is attached to the inner cylinder using double-sided adhesive tape. From visual inspection it is estimated that 99 % of the IC is covered by the coating, see figure 4.

$\text{T}^{3}\text{C}$ is fully coated with a 3M Membrana Accurel® PP 2E HF flat sheet membrane. This porous hydrophobic polypropylene material is commercially available in the large quantities that are needed to cover the complete IC. This coating is supplied on rolls that have a width of approximately 27 cm. It is attached to the inner cylinder using double-sided adhesive tape. From visual inspection it is estimated that 99 % of the IC is covered by the coating, see figure 4.

We used a Dataphysics OCA 15EC device to measure the contact angle hysteresis for both the hydrophobic coating and the reference case, which is the hydrophilic, uncoated steel IC. The hydrophobic coating has advancing and receding water contact angles of ![]() $152^{\circ }\pm 2^{\circ }$ and

$152^{\circ }\pm 2^{\circ }$ and ![]() $120^{\circ }\pm 5^{\circ }$, respectively. For the hydrophilic IC, an advancing contact angle of

$120^{\circ }\pm 5^{\circ }$, respectively. For the hydrophilic IC, an advancing contact angle of ![]() $93^{\circ }\pm 2^{\circ }$ was found. The receding contact angle is set at

$93^{\circ }\pm 2^{\circ }$ was found. The receding contact angle is set at ![]() $10^{\circ }$, which is the lowest angle the set-up could measure.

$10^{\circ }$, which is the lowest angle the set-up could measure.

3.4 Roughness

The machining process to fabricate the standard hydrophilic IC gives a surface roughness of ![]() $k_{ic}=1.6~\unicode[STIX]{x03BC}\text{m}$. The viscous length scale

$k_{ic}=1.6~\unicode[STIX]{x03BC}\text{m}$. The viscous length scale ![]() $\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D708}}$ is derived from the measured torque data, as discussed in Huisman et al. (Reference Huisman, Scharnowski, Cierpka, Kähler, Lohse and Sun2013). For the maximum Reynolds number

$\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D708}}$ is derived from the measured torque data, as discussed in Huisman et al. (Reference Huisman, Scharnowski, Cierpka, Kähler, Lohse and Sun2013). For the maximum Reynolds number ![]() $Re_{max}=1.8\times 10^{6}$ used in this research, the viscous length scale reaches its lowest value of

$Re_{max}=1.8\times 10^{6}$ used in this research, the viscous length scale reaches its lowest value of ![]() $\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D708}}=1.9~\unicode[STIX]{x03BC}\text{m}$. The resulting roughness in wall units

$\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D708}}=1.9~\unicode[STIX]{x03BC}\text{m}$. The resulting roughness in wall units ![]() $k_{ic}^{+}\approx 0.8$. Therefore, the uncoated hydrophilic IC can be assumed to be a hydrodynamically smooth surface.

$k_{ic}^{+}\approx 0.8$. Therefore, the uncoated hydrophilic IC can be assumed to be a hydrodynamically smooth surface.

Figure 2. SEM photos of the side of the coating that is exposed to the flow. (a) Focuses on a region composed of smaller pores. (b) Shows a region with larger pores.

The average roughness of the coating is analysed from its pore size using 24 different scanning electron microscope (SEM) images, made using three different magnifications, as shown in figure 2. The coating consists of an isotropic sponge-like structure, meaning that the cross-section looks similar to the top and bottom surfaces. Therefore we use SEM images of the top surface to evaluate the size and roughness of the pores. The SEM images show a distribution of pore sizes, in the range of ![]() $1{-}10~\unicode[STIX]{x03BC}\text{m}$. The pores that correspond to the smaller length scale are found in regions separated by pores of the larger length scale. The size distribution is quantified with the image processing program ImageJ, using edge detection of the thresholded image (Analyse Particles tool). Eight different images of the smallest magnification were used for this. The images were pre-processed by subtracting a sliding background and by applying a local mean threshold algorithm. Erosion and dilation were used to remove small scale noise. It is difficult to define the error for the pore size distribution, since it is difficult to evaluate the edge of a pore from the perspective of the flow. For instance, in figure 2, when inspecting the large pores at highest magnification, we see thin thread-like fibres that span across a pore. Whereas in the image analysis this might be detected as an edge, the flow might experience this differently. However, from the SEM images and the pore size distribution it is clear that multiple roughness length scales are present on the surface of the coating. Hence, dependent on

$1{-}10~\unicode[STIX]{x03BC}\text{m}$. The pores that correspond to the smaller length scale are found in regions separated by pores of the larger length scale. The size distribution is quantified with the image processing program ImageJ, using edge detection of the thresholded image (Analyse Particles tool). Eight different images of the smallest magnification were used for this. The images were pre-processed by subtracting a sliding background and by applying a local mean threshold algorithm. Erosion and dilation were used to remove small scale noise. It is difficult to define the error for the pore size distribution, since it is difficult to evaluate the edge of a pore from the perspective of the flow. For instance, in figure 2, when inspecting the large pores at highest magnification, we see thin thread-like fibres that span across a pore. Whereas in the image analysis this might be detected as an edge, the flow might experience this differently. However, from the SEM images and the pore size distribution it is clear that multiple roughness length scales are present on the surface of the coating. Hence, dependent on ![]() $Re$, a larger or smaller fraction of the surface plays a role in influencing the flow. The resulting distribution of binned pore sizes is shown in figure 3. The combined area of all pores with diameter

$Re$, a larger or smaller fraction of the surface plays a role in influencing the flow. The resulting distribution of binned pore sizes is shown in figure 3. The combined area of all pores with diameter ![]() $D_{p}$ over the total area, the fraction

$D_{p}$ over the total area, the fraction ![]() $A/A_{0}$, is plotted versus

$A/A_{0}$, is plotted versus ![]() $D_{p}$. A maximum is found at

$D_{p}$. A maximum is found at ![]() $D_{p}=2.5~\unicode[STIX]{x03BC}\text{m}$, although the larger length scales that are more relevant to the flow are also found.

$D_{p}=2.5~\unicode[STIX]{x03BC}\text{m}$, although the larger length scales that are more relevant to the flow are also found.

3.5 Experimental procedure

During a measurement period of one hour and a half, the IC was accelerated in steps from 5 to 18 Hz, corresponding to a range of ![]() $Re$ between

$Re$ between ![]() $5\times 10^{5}$ and

$5\times 10^{5}$ and ![]() $1.8\times 10^{6}$, while continuously measuring the torque exerted by the fluid on the inner cylinder. Every variation of a hydrophobic IC with

$1.8\times 10^{6}$, while continuously measuring the torque exerted by the fluid on the inner cylinder. Every variation of a hydrophobic IC with ![]() $\unicode[STIX]{x1D6FC}>0\,\%$ was measured four times. Between changing the volume per cent of air

$\unicode[STIX]{x1D6FC}>0\,\%$ was measured four times. Between changing the volume per cent of air ![]() $\unicode[STIX]{x1D6FC}$, the reference case of

$\unicode[STIX]{x1D6FC}$, the reference case of ![]() $\unicode[STIX]{x1D6FC}=0\,\%$ air is measured twice, to account for changes to the coating caused by the flow itself. An overview of the measurements is shown in order of execution in table 2.

$\unicode[STIX]{x1D6FC}=0\,\%$ air is measured twice, to account for changes to the coating caused by the flow itself. An overview of the measurements is shown in order of execution in table 2.

Figure 3. Pore size diameter ![]() $D_{p}$ (roughness) distribution of the coating as a fraction of the coverage

$D_{p}$ (roughness) distribution of the coating as a fraction of the coverage ![]() $A$ of the total area of the coating

$A$ of the total area of the coating ![]() $A_{0}$. A range of length scales are observed, corresponding to the different regions identified in figure 2. The equivalent circle diameter has been used as a measure of the size

$A_{0}$. A range of length scales are observed, corresponding to the different regions identified in figure 2. The equivalent circle diameter has been used as a measure of the size ![]() $D_{p}=2\sqrt{A_{p}/\unicode[STIX]{x03C0}}$.

$D_{p}=2\sqrt{A_{p}/\unicode[STIX]{x03C0}}$.

Table 2. Overview of the measurement parameter space, in order of execution. Between changing the volume percentage of air ![]() $\unicode[STIX]{x1D6FC}$, the reference case of

$\unicode[STIX]{x1D6FC}$, the reference case of ![]() $\unicode[STIX]{x1D6FC}=0\,\%$ air was measured twice, to account for changes to the coating caused by the flow itself. Deviations from the standard frequency range

$\unicode[STIX]{x1D6FC}=0\,\%$ air was measured twice, to account for changes to the coating caused by the flow itself. Deviations from the standard frequency range ![]() $\unicode[STIX]{x1D714}_{i}=5{-}18~\text{Hz}$ were the result of heavy vibrations in the system, forcing us to skip a certain frequency range.

$\unicode[STIX]{x1D714}_{i}=5{-}18~\text{Hz}$ were the result of heavy vibrations in the system, forcing us to skip a certain frequency range.

3.6 Flow visualization

A Nikon D800E camera was used to capture still images of the flow. This provides insight into the presence of an air plastron: air captured by the coating is visible in the form of a silvery reflection on the surface (Shirtcliffe et al. Reference Shirtcliffe, McHale, Newton, Perry and Pyatt2006; Daniello et al. Reference Daniello, Waterhouse and Rothstein2009; McHale et al. Reference McHale, Shirtcliffe, Evans and Newton2009; Poetes et al. Reference Poetes, Holtzmann, Franze and Steiner2010; McHale, Flynn & Newton Reference McHale, Flynn and Newton2011; Dong et al. Reference Dong, Cheng, Zhang, Wei and Shi2013; Park et al. Reference Park, Sun and Kim2014, Reference Park, Lee, Moreira, Bandaru, Han and Yun2015; Saranadhi et al. Reference Saranadhi, Chen, Kleingartner, Srinivasan, Cohen and McKinley2016). This can be seen in figure 4, where the highlighted area points out locations where the incident light is of the right angle to see the plastron. It was found that an air plastron was present during the measurements featuring a hydrophobic IC. To test the stability of the plastron and force the surface in a wetted state, the surface tension was lowered by adding TritonX surfactant whilst rotating the inner cylinder at ![]() $Re=1.0\times 10^{6}$ with single-phase flow conditions. From image analysis it was determined that after

$Re=1.0\times 10^{6}$ with single-phase flow conditions. From image analysis it was determined that after ![]() $1.5\times 10^{-4}~\text{mol}~\text{l}^{-1}$ TritonX was added, the silvery reflection completely disappeared. At this concentration of TritonX the surface tension is approximately

$1.5\times 10^{-4}~\text{mol}~\text{l}^{-1}$ TritonX was added, the silvery reflection completely disappeared. At this concentration of TritonX the surface tension is approximately ![]() $35~\text{mN}~\text{m}^{-1}$ (Göbel & Joppien Reference Göbel and Joppien1997). So both surface tension and Laplace pressure are approximately half the values as those for pure water.

$35~\text{mN}~\text{m}^{-1}$ (Göbel & Joppien Reference Göbel and Joppien1997). So both surface tension and Laplace pressure are approximately half the values as those for pure water.

Figure 4. Digitally enhanced photograph of the inner cylinder, covered with the hydrophobic coating and visible through the transparent outer cylinder. It is estimated that 99 % of the inner cylinder is covered by the hydrophobic coating. The silvery reflection, which is typically associated with the presence of an air plastron, is visible as a darker shaded region. This plastron can only be observed under certain angles of incident light. The curved surface of the inner cylinder explains why the plastron is only visible in a narrow vertical band.

3.6.1 Velocity profile measurements

Particle image velocimetry was used to obtain local flow field information. We measured the velocity field in the ![]() $(r,\unicode[STIX]{x1D703})$ plane;

$(r,\unicode[STIX]{x1D703})$ plane; ![]() $u_{\unicode[STIX]{x1D703}}=u_{\unicode[STIX]{x1D703}}(r,\unicode[STIX]{x1D703},t)$ and

$u_{\unicode[STIX]{x1D703}}=u_{\unicode[STIX]{x1D703}}(r,\unicode[STIX]{x1D703},t)$ and ![]() $u_{r}=u_{r}(r,\unicode[STIX]{x1D703},t)$. This can only be achieved for single-phase flow with

$u_{r}=u_{r}(r,\unicode[STIX]{x1D703},t)$. This can only be achieved for single-phase flow with ![]() $\unicode[STIX]{x1D6FC}=0$, since the air bubbles otherwise scatter the light significantly. The laser light sheet (Quantel Evergreen 145 laser, 532 nm) used to illuminate the seeding particles added to the flow (Dantec fluorescent polyamide, with a distribution of diameters

$\unicode[STIX]{x1D6FC}=0$, since the air bubbles otherwise scatter the light significantly. The laser light sheet (Quantel Evergreen 145 laser, 532 nm) used to illuminate the seeding particles added to the flow (Dantec fluorescent polyamide, with a distribution of diameters ![]() ${\leqslant}20~\unicode[STIX]{x03BC}\text{m}$) was placed at mid-height of the cylinder. Images were captured using a LaVision sCMOS (

${\leqslant}20~\unicode[STIX]{x03BC}\text{m}$) was placed at mid-height of the cylinder. Images were captured using a LaVision sCMOS (![]() $2560\times 2160$ pixel) camera through the window in the bottom plate of the set-up. Figure 1 gives a schematic overview of the measurement set-up. Average velocity fields were calculated from 1000 image pairs using LaVision DaVis software in a multi-pass method, starting at a window size of

$2560\times 2160$ pixel) camera through the window in the bottom plate of the set-up. Figure 1 gives a schematic overview of the measurement set-up. Average velocity fields were calculated from 1000 image pairs using LaVision DaVis software in a multi-pass method, starting at a window size of ![]() $64\times 64$ pixel decreasing to a final size of

$64\times 64$ pixel decreasing to a final size of ![]() $24\times 24$ pixel with 50 % overlap. A calibration is required to transform pixels to metres. To this end, image analysis is used to locate the edges of the inner and outer cylinders. Since the measured fields are in Cartesian coordinates, a coordinate transformation is necessary to obtain finally the radial and azimuthal velocities

$24\times 24$ pixel with 50 % overlap. A calibration is required to transform pixels to metres. To this end, image analysis is used to locate the edges of the inner and outer cylinders. Since the measured fields are in Cartesian coordinates, a coordinate transformation is necessary to obtain finally the radial and azimuthal velocities ![]() $u_{r}$ and

$u_{r}$ and ![]() $u_{\unicode[STIX]{x1D703}}$ in the cylindrical coordinate system.

$u_{\unicode[STIX]{x1D703}}$ in the cylindrical coordinate system.

4 Results and discussion

4.1 Torque measurements

First, the results of the torque measurements in single-phase flow are presented and discussed, where drag reduction is purely the result of a hydrophobic surface capturing an air plastron. Second, we show the results for two-phase flow, where air bubbles are added to the flow, that provide bubbly DR and might also add to the stability of the air plastron.

4.1.1 Single-phase flow

Figure 5. (a) Plot of the drag reduction as in (3.5) versus ![]() $Re$, with

$Re$, with ![]() $\unicode[STIX]{x1D6FC}=0$ for the hydrophobic inner cylinder. (b) Evolution of the thickness of the viscous sublayer (

$\unicode[STIX]{x1D6FC}=0$ for the hydrophobic inner cylinder. (b) Evolution of the thickness of the viscous sublayer (![]() $y^{+}=5$), the viscous length scale (

$y^{+}=5$), the viscous length scale (![]() $y^{+}=1$) and half the viscous length scale (

$y^{+}=1$) and half the viscous length scale (![]() $y^{+}=0.5$) with

$y^{+}=0.5$) with ![]() $Re$. The design parameters

$Re$. The design parameters ![]() $w^{+}<1$ and

$w^{+}<1$ and ![]() $k^{+}<0.5$ for the hydrophobic surface are suggested by Park et al. (Reference Park, Sun and Kim2014) and Bidkar et al. (Reference Bidkar, Leblanc, Kulkarni, Bahadur, Ceccio and Perlin2014) respectively to result in drag-reducing behaviour of the surface and are shown here as a reference for the reader. These values are derived from the torque measurements and give therefore an averaged, global value. From figure 6 we find that for our lowest

$k^{+}<0.5$ for the hydrophobic surface are suggested by Park et al. (Reference Park, Sun and Kim2014) and Bidkar et al. (Reference Bidkar, Leblanc, Kulkarni, Bahadur, Ceccio and Perlin2014) respectively to result in drag-reducing behaviour of the surface and are shown here as a reference for the reader. These values are derived from the torque measurements and give therefore an averaged, global value. From figure 6 we find that for our lowest ![]() $Re$ tested, the majority of the roughness length scales is below

$Re$ tested, the majority of the roughness length scales is below ![]() $k^{+}=1$ and part of it is below

$k^{+}=1$ and part of it is below ![]() $k^{+}=0.5$. The DR plot however shows a nearly constant increase of the drag by approximately 14 % over the whole range of

$k^{+}=0.5$. The DR plot however shows a nearly constant increase of the drag by approximately 14 % over the whole range of ![]() $Re$ measured.

$Re$ measured.

In the top of figure 5, the drag reduction, as defined in (3.5), is plotted versus ![]() $Re$, for the hydrophobic inner cylinder with

$Re$, for the hydrophobic inner cylinder with ![]() $\unicode[STIX]{x1D6FC}=0$. This shows an increase in the drag of approximately 14 % over the whole range of

$\unicode[STIX]{x1D6FC}=0$. This shows an increase in the drag of approximately 14 % over the whole range of ![]() $Re$ measured. The bottom figure shows the evolution of the thickness of the viscous sublayer (

$Re$ measured. The bottom figure shows the evolution of the thickness of the viscous sublayer (![]() $y^{+}=5$), the viscous length scale and the design parameter suggested by Park et al. (Reference Park, Sun and Kim2014) (

$y^{+}=5$), the viscous length scale and the design parameter suggested by Park et al. (Reference Park, Sun and Kim2014) (![]() $y^{+}=1$), and the design parameter suggested by Bidkar et al. (Reference Bidkar, Leblanc, Kulkarni, Bahadur, Ceccio and Perlin2014) (

$y^{+}=1$), and the design parameter suggested by Bidkar et al. (Reference Bidkar, Leblanc, Kulkarni, Bahadur, Ceccio and Perlin2014) (![]() $y^{+}=0.5$), with the Reynolds number. In figure 6 we show the roughness of the surface expressed in wall units for four different values of

$y^{+}=0.5$), with the Reynolds number. In figure 6 we show the roughness of the surface expressed in wall units for four different values of ![]() $Re$: the minimum, the maximum and two intermediate values, for which we use the same data as in figure 3. For the lowest