Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Zykov, Aleksandr

Vavilov, Vladimir

and

Kuimova, Marina

2021.

Photothermocapillary Method for the Nondestructive Testing of Solid Materials and Thin Coatings.

Sensors,

Vol. 21,

Issue. 19,

p.

6671.

Varas, R.

Salgado Sánchez, P.

Porter, J.

Ezquerro, J.M.

and

Lapuerta, V.

2021.

Thermocapillary effects during the melting in microgravity of phase change materials with a liquid bridge geometry.

International Journal of Heat and Mass Transfer,

Vol. 178,

Issue. ,

p.

121586.

Porter, J.

Salgado Sánchez, P.

Shevtsova, V.

Yasnou, V.

Samoilova, Anna

and

Nepomnyashchy, Alexander

2021.

A review of fluid instabilities and control strategies with applications in microgravity.

Mathematical Modelling of Natural Phenomena,

Vol. 16,

Issue. ,

p.

24.

Gaponenko, Y.

Yasnou, V.

Mialdun, A.

Nepomnyashchy, A.

and

Shevtsova, V.

2021.

Effect of the supporting disks shape on nonlinear flow dynamics in a liquid bridge.

Physics of Fluids,

Vol. 33,

Issue. 4,

Borshchak Kachalov, A.

Salgado Sánchez, P.

Porter, J.

and

Ezquerro, J.M.

2021.

The combined effect of natural and thermocapillary convection on the melting of phase change materials in rectangular containers.

International Journal of Heat and Mass Transfer,

Vol. 168,

Issue. ,

p.

120864.

Martínez, N.

Salgado Sánchez, P.

Porter, J.

and

Ezquerro, J. M.

2021.

Effect of surface heat exchange on phase change materials melting with thermocapillary flow in microgravity.

Physics of Fluids,

Vol. 33,

Issue. 8,

Chen, Enhui

and

Xu, Feng

2021.

Transient Marangoni convection induced by an isothermal sidewall of a rectangular liquid pool.

Journal of Fluid Mechanics,

Vol. 928,

Issue. ,

Zhou, Xiaoming

Duan, Wenhao

Chi, Faxuan

and

Jiang, Yanni

2022.

Numerical Investigation of nano-PCM Melting Enhanced by Thermocapillary Convection under Microgravity Condition.

Microgravity Science and Technology,

Vol. 34,

Issue. 3,

Gligor, D.

Salgado Sánchez, P.

Porter, J.

and

Tinao, I.

2022.

Thermocapillary-driven dynamics of a free surface in microgravity: Response to steady and oscillatory thermal excitation.

Physics of Fluids,

Vol. 34,

Issue. 4,

Mahmud, Hasibuzzaman

and

Ahmed, Dewan Hasan

2022.

Numerical Investigations on Melting of Phase Change Material (PCM) with Different Arrangements of Heat Source-sink Pairs Under Microgravity.

Microgravity Science and Technology,

Vol. 34,

Issue. 2,

Salgado Sánchez, P.

Porter, J.

Ezquerro, J. M.

Tinao, I.

and

Laverón-Simavilla, A.

2022.

Pattern selection for thermocapillary flow in rectangular containers in microgravity.

Physical Review Fluids,

Vol. 7,

Issue. 5,

Waris, Wasim

and

Lappa, Marcello

2022.

Patterning Behavior of Hybrid Buoyancy-Marangoni Convection in Inclined Layers Heated from Below.

Fluids,

Vol. 8,

Issue. 1,

p.

12.

Borshchak Kachalov, A.

Salgado Sánchez, P.

Martínez, U.

Fernández, J.

and

Ezquerro, J.M.

2022.

Optimization of thermocapillary-driven melting in trapezoidal and triangular geometry in microgravity.

International Journal of Heat and Mass Transfer,

Vol. 185,

Issue. ,

p.

122427.

García-Acosta, Nathaly

Salgado Sánchez, Pablo

Jiménez, Jaime

Martínez, Úrsula

and

Ezquerro, Jose Miguel

2022.

Thermocapillary-enhanced Melting of Different Phase-change Materials in Microgravity.

Microgravity Science and Technology,

Vol. 34,

Issue. 5,

Saha, Sandip K.

2022.

Dynamics of phase change of gallium under magnetic field and thermocapillary effects under variable gravity conditions.

Thermal Science and Engineering Progress,

Vol. 29,

Issue. ,

p.

101234.

Varas, Roberto

Martínez, Úrsula

Olfe, Karl

Salgado Sánchez, Pablo

Porter, Jeff

and

Ezquerro, José Miguel

2023.

Effects of Thermocapillary and Natural Convection During the Melting of PCMs with a Liquid Bridge Geometry.

Microgravity Science and Technology,

Vol. 35,

Issue. 2,

Borshchak Kachalov, A.

Salgado Sánchez, P.

Martínez, U.

and

Ezquerro, J. M.

2023.

Preliminary Design of a Space Habitat Thermally Controlled Using Phase Change Materials.

Thermo,

Vol. 3,

Issue. 2,

p.

232.

Peromingo, C.

Salgado Sánchez, P.

Gligor, D.

Bello, A.

and

Rodríguez, J.

2023.

Sloshing reduction in microgravity with passive baffles: Design, performance, and supplemental thermocapillary control.

Physics of Fluids,

Vol. 35,

Issue. 11,

Porter, J.

Laverón-Simavilla, A.

Bou-Ali, M.M.

Ruiz, X.

Gavalda, F.

Ezquerro, J.M.

Salgado Sánchez, P.

Martínez, U.

Gligor, D.

Tinao, I.

Gómez, J.

Fernández, J.

Rodríguez, J.

Borshchak Kachalov, A.

Lapuerta, V.

Seta, B.

Massons, J.

Dubert, D.

Sanjuan, A.

Shevtsova, V.

and

García-Fernández, L.

2023.

The “Effect of Marangoni Convection on Heat Transfer in Phase Change Materials” experiment.

Acta Astronautica,

Vol. 210,

Issue. ,

p.

212.

Peromingo, C.

Gligor, D.

Salgado Sánchez, P.

Bello, A.

and

Olfe, K.

2023.

Sloshing reduction in microgravity: Thermocapillary-based control and passive baffles.

Physics of Fluids,

Vol. 35,

Issue. 10,

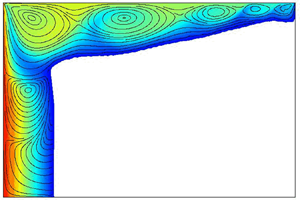

$\varGamma$, and on the Marangoni number,

$\varGamma$, and on the Marangoni number,  $Ma$. For large

$Ma$. For large  $\varGamma$, this flow initially adopts a steady return flow structure characterised by a single large vortex, which splits into a series of smaller vortices to create a steady multicellular structure (SMC) with increasing

$\varGamma$, this flow initially adopts a steady return flow structure characterised by a single large vortex, which splits into a series of smaller vortices to create a steady multicellular structure (SMC) with increasing  $Ma$. At larger values of

$Ma$. At larger values of  $Ma$, this SMC undergoes a transition to oscillatory flow through the appearance of a hydrothermal travelling wave (HTW), characterised by the creation of travelling vortices near the cold boundary. For small

$Ma$, this SMC undergoes a transition to oscillatory flow through the appearance of a hydrothermal travelling wave (HTW), characterised by the creation of travelling vortices near the cold boundary. For small  $\varGamma$, the thermocapillary flow at small to moderate

$\varGamma$, the thermocapillary flow at small to moderate  $Ma$ is characterised by an SMC that develops initially within a thin layer near the free surface. At larger times, the SMC evolves into a large-scale steady vortical structure. With increasing applied

$Ma$ is characterised by an SMC that develops initially within a thin layer near the free surface. At larger times, the SMC evolves into a large-scale steady vortical structure. With increasing applied  $Ma$, a complex oscillatory mode is observed. This state, referred to as an oscillatory standing wave (OSW), is characterised by the pulsation of the vortical structure. Finally, for an intermediate

$Ma$, a complex oscillatory mode is observed. This state, referred to as an oscillatory standing wave (OSW), is characterised by the pulsation of the vortical structure. Finally, for an intermediate  $\varGamma$ both HTW and OSW modes can be found depending on

$\varGamma$ both HTW and OSW modes can be found depending on  $Ma$.

$Ma$.