Published online by Cambridge University Press: 25 January 2022

We investigated the propagation of turbulent fronts in pipe flow at high Reynolds numbers by direct numerical simulation. We used a technique combining a moving frame of reference and an artificial damping to isolate the fronts in short periodic pipes, which enabled us to explore the bulk Reynolds number up to  $Re=10^5$ with affordable computation power. We measured the propagation speed of the downstream front and observed that a fit of

$Re=10^5$ with affordable computation power. We measured the propagation speed of the downstream front and observed that a fit of  $1.971-(Re/1925)^{-0.825}$ (in unit of bulk speed) captures this speed above

$1.971-(Re/1925)^{-0.825}$ (in unit of bulk speed) captures this speed above  $Re\simeq 5000$ very well. The speed increases monotonically as

$Re\simeq 5000$ very well. The speed increases monotonically as  $Re$ increases, in stark contrast to the decreasing trend above

$Re$ increases, in stark contrast to the decreasing trend above  $Re\simeq 10\,000$ reported by Wygnanski & Champagne (J. Fluid Mech., vol. 59, 1973, pp. 281–335). The speed of the upstream front overall agrees with the former studies and

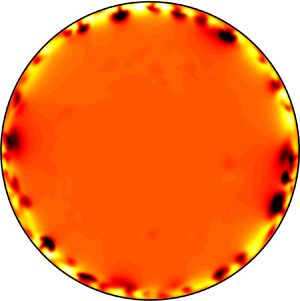

$Re\simeq 10\,000$ reported by Wygnanski & Champagne (J. Fluid Mech., vol. 59, 1973, pp. 281–335). The speed of the upstream front overall agrees with the former studies and  $0.024+(Re/1936)^{-0.528}$ fits our data well, and those from the literature. Based on our analysis of the front dynamics, we proposed that both front speeds would keep their respective monotonic trends as the Reynolds number increases further. We show that, at high Reynolds numbers, the local transition at the upstream front tip is via high-azimuthal-wavenumber structures in the high-shear region near the pipe wall, whereas at the downstream front tip is via low-azimuthal-wavenumber structures in the low-shear region near the pipe centre. This difference is possibly responsible for the asymmetric speed scalings between the upstream and downstream fronts.

$0.024+(Re/1936)^{-0.528}$ fits our data well, and those from the literature. Based on our analysis of the front dynamics, we proposed that both front speeds would keep their respective monotonic trends as the Reynolds number increases further. We show that, at high Reynolds numbers, the local transition at the upstream front tip is via high-azimuthal-wavenumber structures in the high-shear region near the pipe wall, whereas at the downstream front tip is via low-azimuthal-wavenumber structures in the low-shear region near the pipe centre. This difference is possibly responsible for the asymmetric speed scalings between the upstream and downstream fronts.

Visualisation of the downstream front in a co-moving frame of reference at Re=25000. The transverse velocity is color-coded in a cut-plane along the pipe axis. The flow is from left to right and the domain shown in the movie is eight-diameters-long in the axial direction.

Visualisation of the upstream front in a co-moving frame of reference at Re=25000. The transverse velocity is color-coded in a cut-plane along the pipe axis. The flow is from left to right and the domain shown in the movie is eight-diameters-long in the axial direction.

Visualisation of the downstream front tip in a co-moving frame of reference at Re=25000. The transverse velocity is color-coded in a cut-plane along the pipe axis. The flow is from left to right and the domain shown in the movie is five diameters-long in the axial direction. The flow is damped at the left end of the domain in order to isolate the front tip.

Visualisation of the upstream front tip in a co-moving frame of reference at Re=25000. The transverse velocity is color-coded in a cut-plane along the pipe axis. The flow is from left to right and the domain shown in the movie is five diameters-long in the axial direction. The flow is damped at the left end of the domain in order to isolate the front tip which is at the right end of the domain in the movie.