No CrossRef data available.

Article contents

Modelling and analysis of an endothermic reacting counter-current flow

Published online by Cambridge University Press: 29 September 2022

Abstract

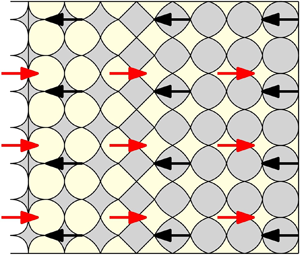

We study the endothermic reaction and flow of a granular solid reactant, where energy for the reaction is provided by a counter-current flow of hot gases through the porous reactant bed. Research into reacting flows typically focusses on exothermic combustion processes. However, endothermic processes are common in the metallurgy industry, including the production of cement, silicon and rutile titanium dioxide. Several common features are observed in experimental and numerical studies of these processes, including critical temperatures of the reactant at which the chemical reaction begins, and regions of the reactor with uniform reactant temperature. Motivated specifically by the processes in a silicon furnace, we analyse a model of endothermic, reacting counter-current flow using the method of matched asymptotic expansions. Assuming the Péclet number in the solid is large, we explore the full range of values for the dimensionless inter-phase heat-transfer rate, finding six distinguished limits. In all limits, we find a diffusive boundary layer in which there is a fast chemical reaction rate due to the high temperatures, analogous to exothermic flame fronts. Outside this region, the counter-current flow is crucial to the chemical processes. For intermediate values of the heat-transfer rate, we find the same qualitative properties as those observed across the metallurgy industry, and we quantify the dependence of these properties on the flow rate and heat-transfer rate. In the limit of large heat-transfer coefficient, we derive the single-temperature limit, in which the solution structure is dependent on the direction of net heat flux through the domain.

JFM classification

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2022. Published by Cambridge University Press