Greek yoghurt is rich in nutrients, flavour, texture, and taste compared to regular yoghurt and these favourable factors have increased consumer demand. The higher solids content, protein content and acidity in Greek yoghurt are responsible for its unique thicker, creamier and moderately acidic flavour. Most of these unique physicochemical and nutritional properties in Greek yoghurt have been attained through straining of the gels after fermentation. However, straining releases acid whey as a discharge which contains a high amount of lactic acid. These acidic discharges can be harmful to the environment unless they are disposed of with proper treatments (Jelen, Reference Jelen2011; Chandrapala et al., Reference Chandrapala, Duke, Gray, Zisu, Weeks, Palmer and Vasiljevic2015). Moreover, acid whey contains many vital nutrients such as water soluble vitamins (vitamin C, thiamine, riboflavin, vitamin B12, vitamin A) and a small fraction of caseins is also lost with the discharge (Moore et al., Reference Moore, Horti and Fielding2018). To overcome these disadvantages, scientists are in search of novel approaches with the main emphasis on minimizing the generation of acid whey during the production of Greek yoghurt. Also, there is a desire to simultaneously increase the retention of nutritional components in the gels during the straining process. Thus, the current work aimed to address these two issues with the help of ultrasonication technology. This is considered to be an emerging, non-thermal and environmental-friendly processing technique and has shown potential to use as a dairy processing technique in the future.

Material and methods

Initially, three sets of skim milk solutions (14% w/w) were prepared by dissolving skim milk powder (Tatura milk industries limited, Victoria, Australia) in MilliQ water at 40 °C for 1 h and kept overnight at 4 °C. On the following day, milk solutions were heated at 90 °C for 10 min using a water bath and subsequently cooled to 43 °C. Three types of yoghurt samples; (a) untreated milk Greek yoghurt (MY), (b) sonicated milk Greek yoghurt (SMY), and (c) sonicated Greek yoghurt (SY) were prepared (detailed in online Supplementary Fig. 1). To prepare SMY, 50 ml aliquot of skim milk solution was sonicated using a 20 kHz low-frequency ultrasonic unit (Q Sonica, Bandelin electronic, Berlin, Germany) at 40% amplitude for 7 min at <10 °C corresponding to an energy density of 52.92 J/ml. MY and SY yoghurt samples were prepared without applying any ultrasound treatments to the skim milk. Then, the sonicated milk sample and the other two sets of untreated milk samples were inoculated with mesophilic homofermentative culture containing Lactococcus lactis sub. Lactis and Lactococcus lactis sub. cremoris (freeze-dried lactic culture from Chr. Hansen, Bayswater, Victoria, Australia) and incubated at 45 °C for 2 h. Once the pH of the samples reached 4.6, they were cooled to room temperature. One of the fermented yoghurt samples prepared with untreated skim milk was labelled as MY, whilst the other was sonicated to obtain the SY using the same sonication conditions that were used to sonicate milk. After that, all three yoghurt samples (MY, SMY, SY) were strained to obtain Greek yoghurt.

The pH of the yoghurt gels was measured after the fermentation using a pH meter (lab cHem, Australia) at 25 °C with probe calibration (Shanmugam and Ashokkumar, Reference Shanmugam and Ashokkumar2014). The volume percentage of the acid whey generated after the straining was measured and the acid whey was left for a few hours and the observations were taken for any layer separations. The microstructure of the gels was observed under an optical microscope (Nikon, Eclipse Ci-POL, Nikon Inc., Japan) equipped with a camera (Nikon D610, Nikon Inc., Japan) at 10 × magnification. The hardness and the adhesiveness of the Greek yoghurt samples were measured as described by Chandrapala et al. (Reference Chandrapala, Zisu, Kentish and Ashokkumar2013) using a texture analyser (Stable Micro System Ltd., Godalming, Surrey, UK). All experiments were performed at least two times and the results were presented as average ± standard deviation. Statistical analysis was performed using SPSS version 26 software (SPSS, IBM) at 95% confidence level.

Results and discussion

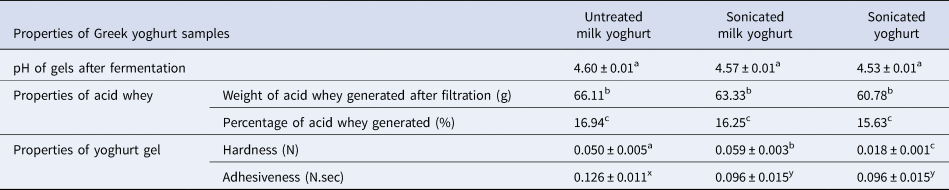

As shown in Table 1, no significant difference (P > 0.05) was observed in the pH values of the Greek yoghurt samples. It is clearly evident that sonication of milk before or after the fermentation hadn't significantly affected the pH of the samples. It is indicated that the shear and mechanical forces generated through acoustic cavitation (a consequence of sonication) did not significantly influence the mass transfer of minerals from the casein micelles. Similarly, it has previously been observed that pH of skim milk (Chandrapala et al., Reference Chandrapala, Martin, Zisu, Kentish and Ashokkumar2012) or milk protein mixtures containing caseins and whey proteins (Silva et al., Reference Silva, Chandrapala and Zisu2018) were also unaffected by sonication (20 kHz) under controlled temperature (within 10 °C) conditions. Therefore, only acid gelation process-related pH has dropped within the Greek yoghurt systems during fermentation. As the pH of the milk reduces to 4.6, negative charges on the casein micelles decrease which increases the rate of solubilization of colloidal calcium phosphate leading to the removal of the hairy layer of k-casein. Consequently, electrostatic repulsion and stearic stabilization are decreased, increasing casein–casein interactions leading to the formation of the three-dimensional network which consists of casein clusters, chains and strands (Ozer et al., Reference Ozer, Robinson, Grandison and Bell1998; Lee and Lucey, Reference Lee and Lucey2010; Marafon et al., Reference Marafon, Sumi, Granato, Alcântara, Tamime and de Oliveira2011; Patel, Reference Patel2011).

Table 1. pH and the properties of acid whey and yoghurt gels of Greek yoghurt samples prepared from untreated milk (MY), sonicated milk (SMY) and sonicated yoghurt (SY), Values are means of at least 3 replicates (N > 3) and the results are presented as means ± standard deviation; values in the same row with different English letters are statistically different

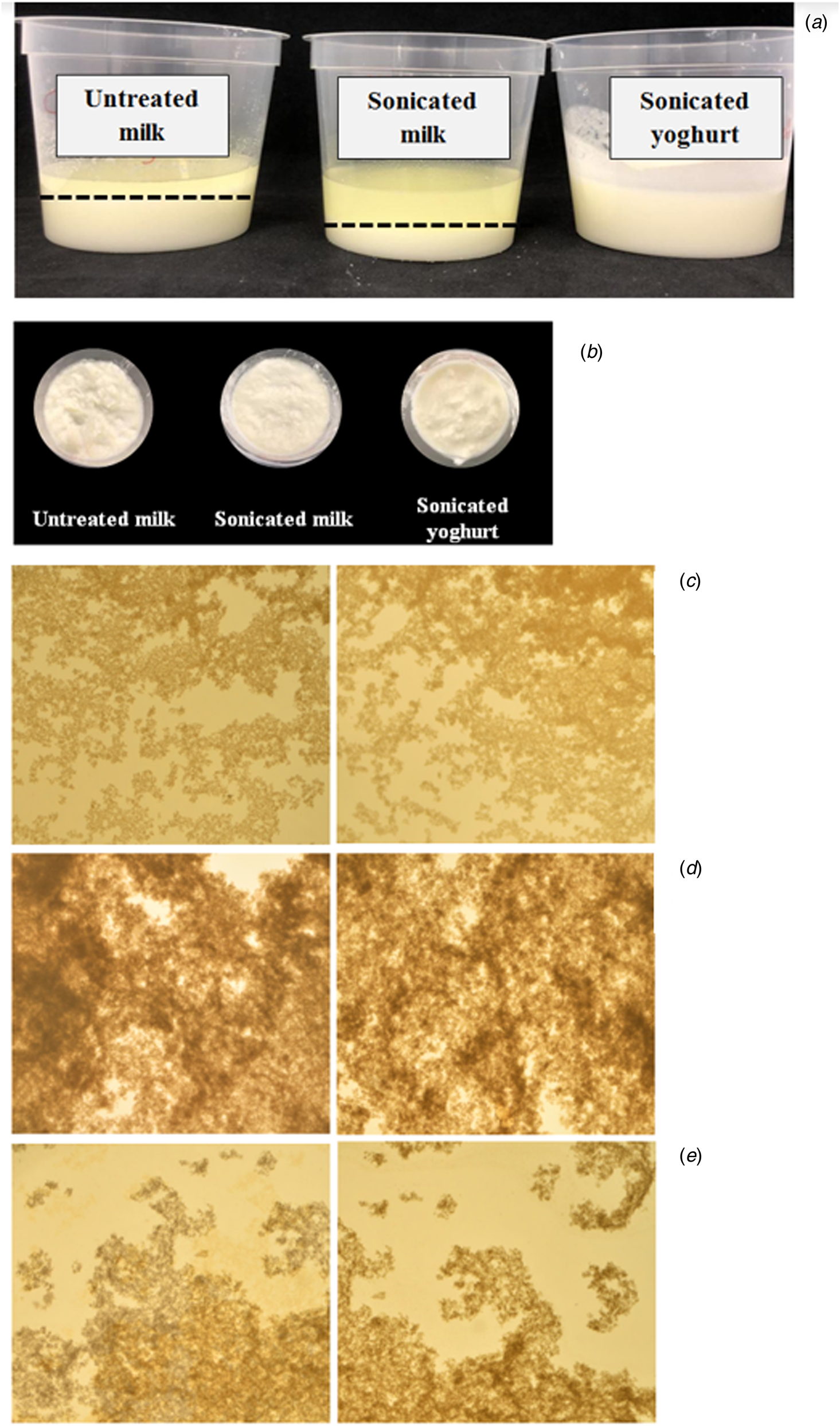

After fermentation, yoghurt gels were strained which is one of the critical steps during Greek yoghurt manufacturing as it increases the solids content in the final product by removing acid whey as a filtrate/liquid part (Uduwerella et al., Reference Uduwerella, Chandrapala and Vasiljevic2017). This step isn't generally used in other regular yoghurt manufacturing. Therefore, this gives higher viscosity with improved creaminess and moderate acidic flavour. As shown in Table 1, the percentage generation of acid whey was insignificant between samples (~16%). However, clear significant differences in the nature of the separated acid whey were observed after the settling period (Fig. 1a). Clear layer separations were observed in acid whey samples filtered from untreated milk and sonicated milk while no layer separation was observed in sonicated yoghurt samples. Moreover, yoghurt prepared from sonicated milk had a higher fraction of whey (top layer) and minor sedimentation (caseins and insoluble milk protein aggregates) compared to the filtrate obtained from untreated milk yoghurt (Fig. 1a). As the sediment layer may contain a significant amount of caseins, it can be concluded that the application of ultrasound to the milk increased the retention of caseins in the final product compared to the untreated yoghurt. This might have occurred through sonication-induced structural and/or bonding changes in milk proteins. According to previous reports, sonication of skim milk induces the denaturation of whey proteins leading to the formation of whey–whey/whey–casein aggregates and further interaction with casein micelles resulting in micellar aggregates in the system (Shanmugam et al., Reference Shanmugam, Chandrapala and Ashokkumar2012). Moreover, as stated by Silva et al. (Reference Silva, Chandrapala and Zisu2018), the application of ultrasound to skim milk like systems that contained casein to whey protein ratio of 80 : 20 resulted in the formation of more hydrophobically-mediated aggregates with a minor level of disulphide-mediated aggregation between whey protein–whey protein and whey protein–casein. The interactions formed between whey–whey and whey–k-caseins were responsible for the improved gel properties in Greek yoghurt (Uduwerella et al., Reference Uduwerella, Chandrapala and Vasiljevic2018). It is likely that sonication-induced aggregations between whey–whey and whey–caseins, even at a minor level, had a positive impact on the compositional and nutritional properties of the sonicated milk Greek yoghurt (SMY) due to the retention of more caseins within the gel network. In contrast, the application of sonication after fermentation (SY) may have significantly reduced casein retention in the final product. This conclusion is supported by the nature of the acid whey filtrate which contained a larger amount of caseins and whey proteins in a semi-solid state, explaining why no layer separation was observed.

Figure 1. Photographs of (a) Layer separation of filtered acid whey after standing for few hours; the dotted line separates the liquid (upper) phase from semi-solid phase (below), (b) Comparison of the appearance (top surface) of Greek yoghurt prepared from untreated milk (MY), sonicated milk (SMY) and sonicated yoghurt (SY) Microstructure of yoghurt gels prepared from (c) untreated milk – MY, (d) sonicated milk – SMY and (e) sonicated yoghurt – SY.

Consequently, the properties of removed acid whey should influence the textural properties of the final product which is one of the key factors determining consumer perception. Among these properties, visual appearance of the yoghurt also plays an important role. As shown in Figure 1b, Greek yoghurt prepared from sonicated milk (SMY) had a smoother textural appearance compared to the other two types, signifying the beneficial effect of sonication on the sensorial properties of Greek yoghurt. Similarly, more compact and denser microstructure with an evenly distributed pore structure can be observed in the Greek yoghurt prepared from sonicated milk (SMY: Figure 1d). However, sonicated yoghurt (SY: Figure 1e) had a microstructure with clustered particles, denoting a comparatively weak distribution of caseins and/or whey molecules within the network. Therefore, both untreated milk yoghurts (MY) and sonicated milk yoghurts (SMY) had relatively strong and smoother microstructures which in turn helped to produce yoghurt with better textural properties.

In line with the microstructure, sonicated milk yoghurts (SMY) showed the highest hardness among all the samples (Table 1) while the lowest hardness was observed in sonicated yoghurt (SY) samples. Draining a relatively higher amount of whey and a lesser amount of caseins from the gels increased the casein to whey protein ratio in the yoghurt compared to the untreated samples. An increased casein to whey ratio reduces the viscous nature of yoghurt gel (Sauer et al., Reference Sauer, Doehner and Moraru2012) and strengthens the gel network. It can be observed that a larger portion of free water had removed in SMY during the straining compared to MY and SY which contains more total solids with a higher amount of caseins. As free water is removed, more casein aggregations develop in the gel via non-covalent interactions resulting in higher gel strength (Phadungath, Reference Phadungath2005). The hardness or strength of the gels can be further improved during the acidification where remaining thiol groups in the whey proteins can participate in thiol-disulphide interchange reactions (Vasbinder et al., Reference Vasbinder, Alting, Visschers and de Kruif2003). Similarly, Uduwerella et al. (Reference Uduwerella, Chandrapala and Vasiljevic2017) observed that the increase in casein concentration in yoghurt gel by fortification with milk protein concentrate followed by straining also improved the gel strength due to the formation of non-covalent interactions. Therefore, sonication of milk prior to fermentation enhanced the physicochemical properties in Greek yoghurts as a result of the formation of more hydrophobically mediated aggregates with a minor amount of disulphide mediated aggregation between caseins and whey proteins. In contrast, the application of ultrasound after the fermentation resulted in poor gel properties. The casein-whey network formed during the fermentation is the backbone of the yoghurt gel which influences the gel properties such as hardness (Bong and Moraru, Reference Bong and Moraru2014). However, intense shear and mechanical forces generated during the sonication may lead to the breakdown of the gel network and as a result, entrapped casein molecules can leach out from the network. Therefore, the gel network becomes weaker and a higher portion of caseins together with whey proteins can filter out during the straining as acid whey. Therefore, the application of ultrasound after the fermentation is not a good practice to reduce the acid whey generation.

In conclusion, application of low frequency ultrasound to skim milk prior to fermentation enhanced the properties of Greek yoghurt gel such as gel hardness (texture) and microstructure (appearance) and improved the retention of caseins within the gel network in the resulting final product compared to Greek yoghurt prepared from untreated skim milk. Shear and mechanical forces generated through acoustic cavitation produced more hydrophobically mediated aggregates with a minor amount of disulphide-mediated aggregates between casein and whey proteins and resulted in improved gel properties. Moreover, an increase in casein-involved aggregation within the system reduced the draining of caseins with acid whey to the filtrate. However, the application of ultrasound to the Greek yoghurt gel after fermentation was not a viable option as it breaks the three-dimensional gel network, weakens the gel properties and increases the draining of caseins and whey protein during straining. However, it should be noted that neither sonication before fermentation nor after fermentation reduced the amount of acid whey generation during Greek yoghurt production.

Supplementary material

The supplementary material for this article can be found at https://doi.org/10.1017/S0022029923000328.

Acknowledgements

The research was financially and technically supported by the Royal Melbourne Institute of Technology (RMIT), Australia.