The author has studied milk culture in Afro-Eurasia (Hirata, Reference Hirata2020). As one conclusion of the milk cultural study, the author hypothesized the history of milk processing on the Eurasian continent as the Monogenesis-Bipolarization of milk culture. Milking and milk processing originated in West Asia, giving rise to a new subsistence of pastoralism that relies on milk culture (Umesao, Reference Umesao1976; Vigne and Helmer, Reference Vigne and Helmer2007; Evershed et al., Reference Evershed, Payne, Sherrat, Copley, Coolidge, Urem-Kotsu, Kotsakis, Özdoĝan, Özdoĝan, Nieuwenhuyse, Akkermans, Bailey, Andeescu, Campbell, Farid, Hodder, Yalman, Özbaşaran, Biçakci, Garfinkel, Levyan and Burton2008; Zeder, Reference Zeder2008). Pastoralism that was accompanied by milking and milk processing was thought to have transmitted from West Asia to the surrounding regions when its milk processing technique had developed to West Asian type of fermentation processes which were able to preserve milk for a long period. And then, milk culture developed into the northern milk cultural sphere and the southern milk cultural sphere mainly influenced by local environments (Hirata, Reference Hirata2020). The West Asian-style fermentation processes is one in which the raw milk is first fermented before sour milk is churned to make butter. Butter is heated to make butter oil and soured buttermilk is heated, curdled, drained and sun-dried to make non-matured dry cheese. Butter oil and non-matured dry cheese can be stored for several years. Mongolia is located in northeastern Eurasia which is one final region reached by the transmission of milk culture from West Asia. It is an important case study in the consideration of cultural transmission to analyze how the milk processing technique from West Asia changes to accommodate the cooler climate of Mongolia.

A number of archaeological studies have reported on the origin and the history of milking and its utilization. The domestication of sheep and goats was reported to start in the middle of the 9th millennium BC, followed by cattle within a few hundred years in West Asia (Zeder, Reference Zeder2008; Hongo, Reference Hongo2013). Compound-specific stable carbon isotope analysis of organic residues on excavated pottery vessels provided the material evidence that milking from sheep and goats began in West Asia at least in the 7th millennium BC (Evershed et al., Reference Evershed, Payne, Sherrat, Copley, Coolidge, Urem-Kotsu, Kotsakis, Özdoĝan, Özdoĝan, Nieuwenhuyse, Akkermans, Bailey, Andeescu, Campbell, Farid, Hodder, Yalman, Özbaşaran, Biçakci, Garfinkel, Levyan and Burton2008) although analysis of animal bones from archaeological sites by animal type and age suggested that milking possibly started also in West Asia as early as the first half of the 8th millennium BC (Vigne and Helmer, Reference Vigne and Helmer2007). In the earliest estimate of the utilization of dairy products in Central and North Asia, Wilkin et al. (Reference Wilkin, Miller, Taylor, Miller, Hagan, Bleasdale, Scott, Gankhuyg, Ramsoe, Uliziibayar, Trachsel, Nanni, Grossmann, Orlando, Horton, Stockhammer, Myagmar, Boivin, Warinner and Hendy2020) reported that mass spectrometry analysis of proteins extracted from dental plaque on remains at the site dating to 3000 BC in central Mongolia, south of the Khangai Mountains, confirmed the presence of milk in it. Regarding the milk processing technique, it was speculated from the perspective of lactose intolerance that ancient nomads processed yoghurt and cheese as early as the start of milk utilization in order to reduce lactose concentrations in milk (Curry, Reference Curry2013). Yang et al. (Reference Yang, Shevchenko, Knaust, Abuduresule, Li, Hu, Wang and Shebchenko2014) reported that mass spectrometry analysis of the ornaments on the necks of mummies excavated from the Xiaohe cemetery from 1980 BC to 1450 BC in Xinjiang Uygur Autonomous Region identified milk peptides degraded by Lactobacillus kefiranofaciens and other lactic acid bacteria and yeasts. Thus, there is a limitation to reveal about specific dairy products and milk processing techniques by the archaeological approach. The results of cultural anthropological research studies are required to examine how milk processing techniques have transmitted and changed in Eurasia.

Many reports have been published on Mongolian milk culture, mainly by Japanese researchers (Umesao, Reference Umesao1955; Nakae, Reference Nakae1976; Ochi, Reference Ochi1990; Konagaya, Reference Konagaya, Ishige and Wani1992; Miaki, Reference Miaki1996; Ishige, Reference Ishige1997; Ishii, Reference Ishii1997; Hino, Reference Hino1998; Hirata, Reference Hirata2002, Reference Hirata2020). It is the region where the cultural anthropological research on the subject is most advanced, including the classification and characterization of milk processing techniques, uses of alcoholic sour horse milk, and the subsistence study on the use of dairy products. It has been reported that cream is first separated from raw milk, and alcohol is made from raw milk whilst rennet, a milk coagulating enzyme, is not used in cheese processing in the region (Hirata, Reference Hirata2020). The milk processing techniques are extremely developed and complicated in Mongolia, which are diversified in each region. Su'qbaatar and Dornod Provinces are located in eastern Mongolia, which is the furthest from West Asia. The case studies have not been sufficiently reported yet in eastern Mongolia.

Hence, the purpose of this paper is firstly to understand the milk processing system practiced in the Mongolian nomadic Khalkha groups of Su'qbaatar and Dornod Provinces in eastern Mongolia through a field survey and, secondly, to identify the characteristics of the milk processing techniques by comparing cases in surrounding areas of Qentiy and Dundgowi Provinces and, finally, to analyze the transition of milk processing technique in eastern Mongolia by comparing the cases of Syria, Jordan, Iran and Iraq in West Asia.

Material and methods

Survey households and survey methodology

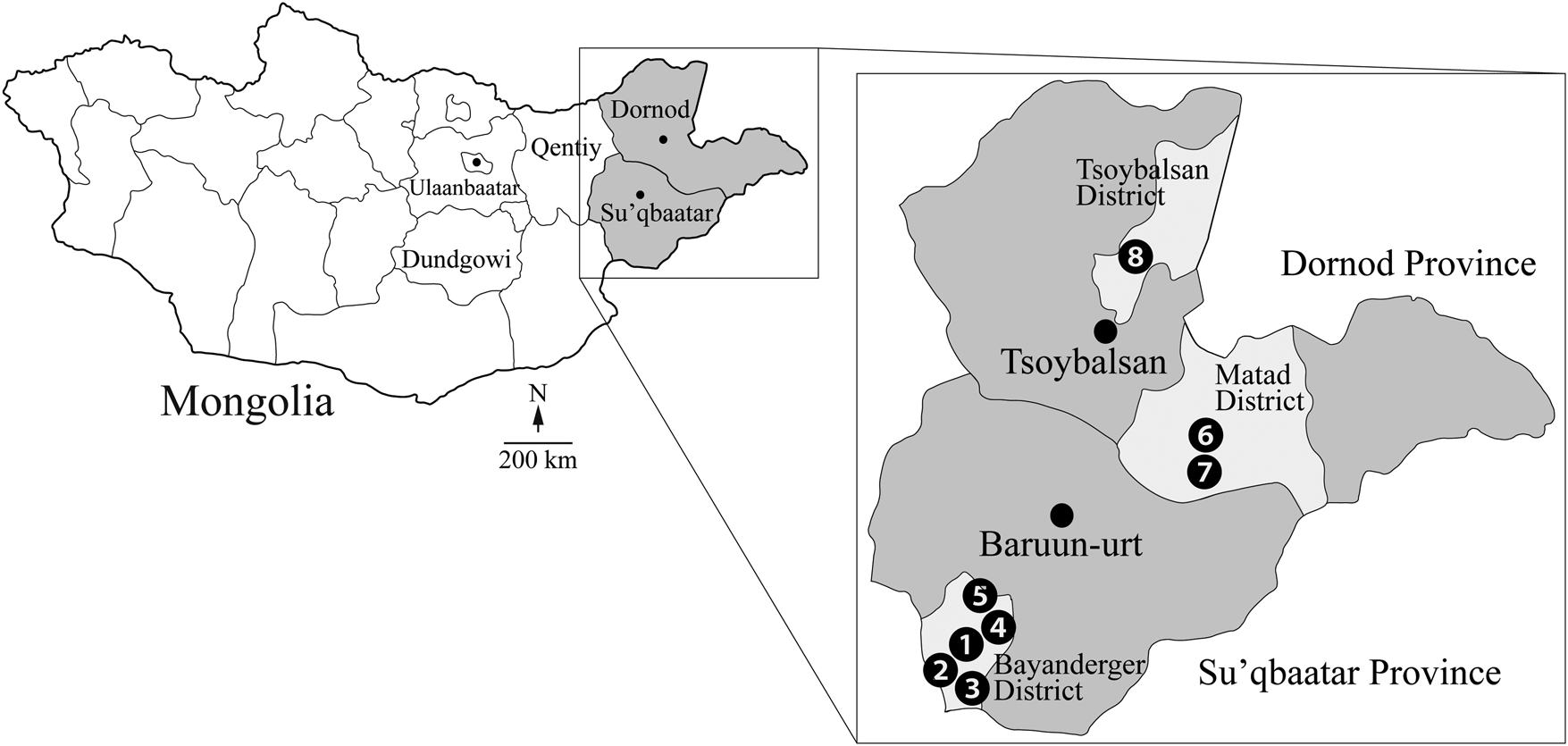

The survey sites are Bayanderger District, Su'qbaatar Province, and Matad District and Tsoybalsan Distric, Dornod Province, located in approximately 600 km east of the capital, Ulaanbaatar (Fig. 1). Annual precipitation is about 200 m in Bayanderger District, and 250 mm in Matad and Tsoybalsan Districts (Canty and Associates LLC, 2024), located in the vegetation zones of desert steppe and dry steppe, respectively (Environmental Information Center, 2018). The field survey was conducted on a total of eight households of Mongolian nomadic Khalkha groups, five households in Su'qbaatar Province and three households in Dornod Province, in August 2022. The survey households were randomly selected in Sukhbaatar and Dornod Provinces. In households 2, 4 and 6, milk processing was observed while staying in the ger, or nomadic tent, and interviews were conducted on related issues. In households 1, 3, 5, 7 and 8, females responsible for milk processing were interviewed. The interviews were conducted in Mongolian, and the Romanization of the Cyrillic alphabet basically follows Ozawa (Reference Ozawa1994).

Figure 1. Administrative divisions of Mongolia and survey sited in eastern Mongolia.

❶ – ❽: Surveyed households.

All households have about 1000 head of livestock, which is basically managed by husband and wife. All of the households kept sheep, goats, cattle and horses, and household 2, 3 and 8 kept also camels. Camels have been used to transport household belongings during seasonal migration. Since almost all households currently used automobiles for transportation, the camel's role as a pack animal has almost ended. Camels are not milked in eastern Mongolia. The most common livestock is sheep, with 500–1400 head/household. Milking is currently practiced only from cows in Su'qbaatar and Dornod Provinces. Sheep and horses were milked until the socialist era in 1989. The number of cows in the household currently increases to 17–200 cows/household, 93 in average, and the situation of supplying milk and dairy products from cows alone are enough for the household consumption, gifts to relatives and friends, and sale. Since they say horse milk does not ferment well into alcoholic sour milk in Su'qbaatar and Dornod Provinces, milking of horses is no longer practiced.

An interview was also conducted in August 2022 in one household of the Khalkha group in Delgerqaan District, Qentiy Province, for understanding the characteristics of the milk processing system in eastern Mongolia. Qentiy Province is bordered by Su'qbaatar and Dornod Provinces. Furthermore, a comparative analysis of milk processing systems in eastern Mongolia was conducted using the case of Sayntsagaan District, Dundgowi Province, central Mongolia, where the author conducted identical observations and interviews (Hirata, Reference Hirata2002).

This research was approved by the ethics board of Chubu University (20220052).

Model for analyzing milk processing system

The analysis of milk processing system in this paper was conducted according to the Nakao's model used to categorize the world's milk processing techniques (Nakao, Reference Nakao1972). Nakao categorized the world's milk processing techniques into the following four types: (1) Fermentation processes, which start out by making fermented milk from raw milk, (2) cream separation processes, which start out by separating cream from raw milk, (3) additive coagulation processes, which involve adding a coagulant to raw milk to make cheese, and (4) heat condensation processes, which are based on heating and condensing raw milk. The coagulants include rennet (enzyme synthesized in the abomasum or fourth stomach of ruminants), sour milk, plant-based organic acid, and plant enzyme. This paper described the cases of milk processing systems in eastern Mongolia and discussed those characteristics using Nakao's model.

Results

Milk processing system in Bayanderger District, Su'qbaatar Province

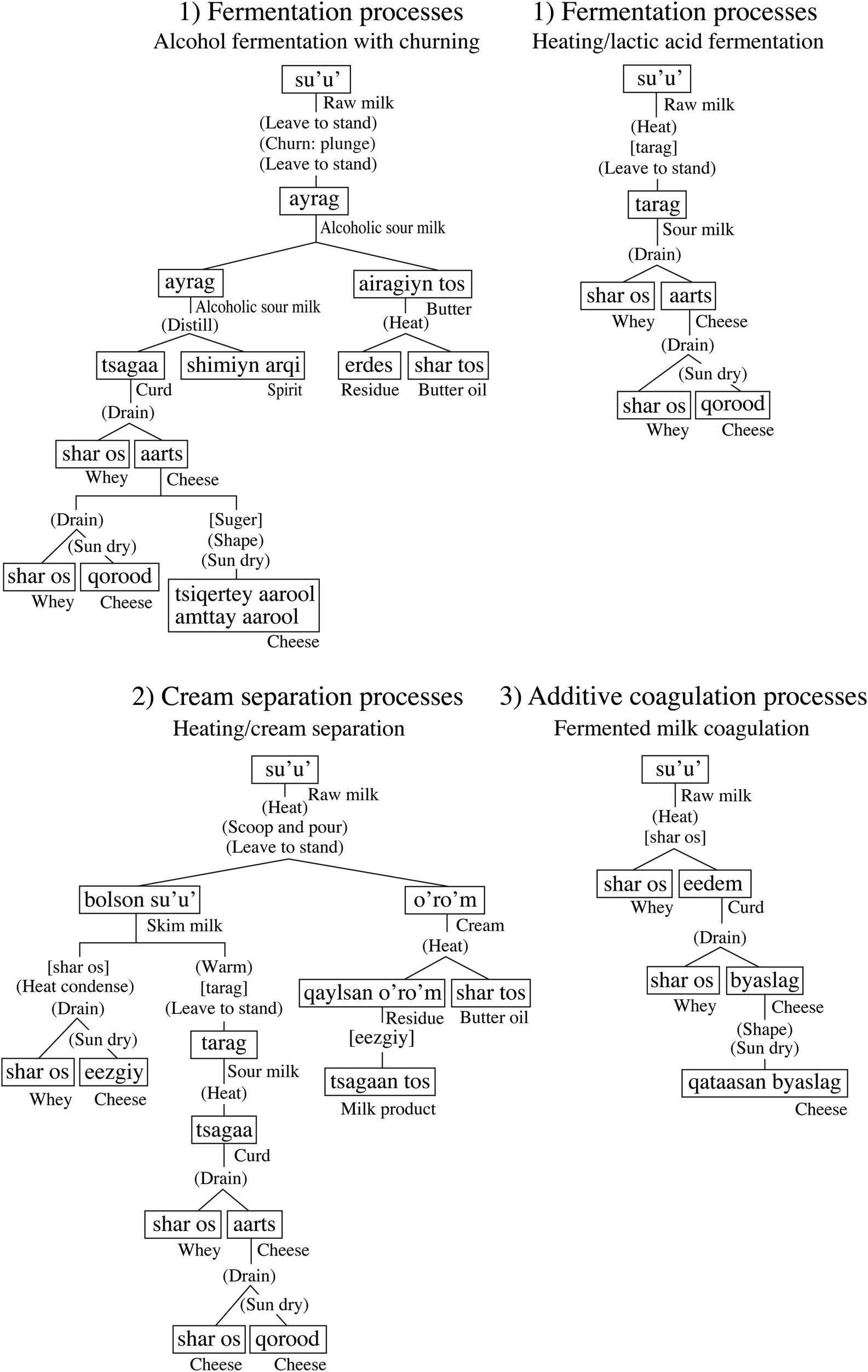

The milk processing techniques of fermentation processes, cream separation processes and additive coagulation processes are used in Bayanderger District, Su'qbaatar Province (Fig. 2).

Figure 2. Milk processing system in Bayanderger District, Su'qbaatar Province, Mongolia.

![]() : Product [ ] : Additive ( ) :Treatment.

: Product [ ] : Additive ( ) :Treatment.

Fermentation processes: alcohol fermentation with churning

Raw milk is called su'u’. Raw milk is mainly processed into alcoholic sour milk, and non-matured dried cheese and butter oil in Su'qbaatar Province. The author categorizes this milk processing technique as a fermentation processes: alcohol fermentation with churning.

A small amount of the previous alcoholic sour milk is left in the wooden cylinder called dombo. Raw milk is added, and lactic acid fermentation and alcoholic fermentation take place in dombo. The small amount of the previous alcoholic sour milk left over is used as a fermentation starter called qu'ru’ngu’. Freshly milked, still warm raw milk is not put into dombo. Raw milk is left to stand in another container and then added to dombo after it has cooled down. In most cases, cooled raw milk is poured into dombo in the morning and allowed to stand until evening. The mixture is churned up-and-down with a plunger called bu'lu’u'r for about an hour in the evening. The number of plunging amounts to about 3000 times. After churning, it is left to stand until the next morning. It becomes alcoholic sour milk with an alcohol content of about 1% by the next morning. Alcoholic sour milk is called ayrag.

Since there is churning treatment in the processing procedure of ayrag, butter rises up to the surface. This butter is called airagiyn tos, literally meaning ‘oil of airag’. Airagiyn tos is scooped out and stored in a container, and heated in the beginning of winter to process into butter oil called shar tos, literally meaning ‘yellow oil’. Butter oil can be stored over a long period at room temperature. Brown residue remains when airagiyn tos is heated. It is called erdes. Erdes is eaten as it is or fried with wheat flour.

There is no heating in the processing from raw milk to ayrag, which is rarely drunk. Ayrag is distilled to produce spirit called shimiyn arqi. Ayrag is poured into a large pan, covered with a metal roll called a bu'rqeer, and heated with livestock dung for distillation. A cooling pan called shalawts is placed over the roll and filled with cold water to cool alcohol-containing steam. A cloth called oroolt should be tightly wrapped around the pan filled with cold water to prevent steam from leaking out. A plate called tosguur inside of the roll is hung to receive spirit that drips as drops liquefied by cold oroolt. Tosguur is connected to the outside of a container by a pipe to collect the shimiyn arqi. Shimiyn arqi is drunk when guests arrive or used as a gift to relatives and friends.

Curd called tsagaa remains in the large pan after the distillation. It is cloudy white and sludgy, and extremely sour taste due to over-adequate lactic acid fermentation. Local Mongolian nomads sometimes drink tsagaa directly. The drink mixed with tsagaa, a small amount of shimiyn arqi and shar tos is called qarnu'den. Local Mongolian nomads prepare hot qarnu'den especially in winter when they catch a cold or try to warm up their body. The most part of tsagaa is used for processing non-matured dry cheese. Tsagaa is placed in a cloth bag and hung for several hours to process cheese called aarts by draining whey called shar os, literally meaning ‘yellow water’. Aarts is removed from the bag, formed into thin strips of 5 to 10 mm using a thread, and dried in the sun to produce non-matured dry cheese called qorood. Qorood can be stored over a long period at room temperature. Aarts, which is still moist, is also mixed with sugar, formed into various small shapes, dried in the sun, and processed into cheese called tsiqertey aarool 4 or amttay aarool 5, literally meaning ‘sugared aarool’ or ‘delicious aarool,’ respectively. Tsiqertey aarool and amttay aarool have been processed since the 1990s, when sugar became readily available in Mongolia.

Thus, raw milk of cow is mainly processed to alcoholic sour milk, and then further processed to butter oil and non-matured dry cheese using the technique of fermentation processes: alcohol fermentation with churning in Bayanderger District, Su'qbaatar Province.

Fermentation processes: heating/lactic acid fermentation

In fermentation processes, the technique of heating/lactic acid fermentation is also used to process sour milk and non-matured cheese after pasteurizing raw milk by heating. Raw milk is firstly pasteurized by heating, cooled down to body temperature, and then added with a small amount of a starter culture consisting of sour milk from an earlier batch, and left to stand in a warm place in the tent for several hours for lactic acid fermentation. Sour milk is called tarag. Tarag is served as it is for eating, especially at night. Tarag is heated to process curd (tsagaa), which is used to produce cheese (aarts) by draining whey. Aarts is formed and dried in the sun to produce non-matured dry cheese (qorood). Tarag is also processed in the technique of cream separation described next, but tarag is better tasting from whole milk by fermentation processes: heating/lactic acid fermentation.

Cream separation processes: heating/cream separation

Raw milk is dominantly processed to airag. When the amount of raw milk increases more than the need for airag processing, raw milk is also used for cream separation. In the summer, cream is produced almost every day because of the high milk yield. Raw milk is brought to the boil in a large pan heated with dung as fuel and then scooped up with a ladle and poured back into the pan from around shoulder height. After about 30 repetitions, the surface of the milk is covered in froth, and the scooping is stopped, while gentle heating continues for one hour at least. During this time, the bubbles burst with popping sounds. Wheat flour is often added to the milk to promote the formation of cream during the scooping. About 100 g of wheat flour is added to 5 liter of the milk. The pan is then left undisturbed overnight, and cream collects on the surface. The following morning, the cream in contact with the air forms a firm, yellowish skin with tiny indentations left by bursting bubbles. If the scooping and pouring are done in the morning, the milk is left to stand until the evening. This cream called o'ro’m is spooned out onto a plate. With its soft, rich flavor, cream is a superior dairy product. O'ro’m is used in milk tea and as a garnish for dishes. O'ro’m is eaten fresh, and also what remains is heat-treated to make butter oil called shar tos. O'ro’m is pooled little by little in wooden tubs through the summer and kept until the beginning of winter. The accumulated o'ro’m is heated gently with constant stirring. Yellow butter oil (shar tos) begins to surface through heating, and this is spooned into a small bottle. The residue mainly of scorched cream produced by heating is called qaylsan o'ro’m, literally meaning ‘melted o'ro’m’. Qaylsan o'ro’m is mixed with cheese called eezgiy, which is described later, to produce into a dairy product called tsagaan tos, literally meaning ‘white oil’. Tsagaan tos is an important food resource in winter and spring, when milk production is low.

The skim milk remaining after the cream has been separated is called bolson su'u’, literally meaning ‘milk produced after separating cream’. It is processed by two methods: one beginning with fermentation to produce sour milk, and one beginning with the addition of fermented whey to promote acid coagulation of milk protein. Lactic acid fermentation begins with warming skim milk in a pan to around body temperature and adding a small amount of a starter culture consisting of sour milk from an earlier batch. The mixture is kept warm and left to stand overnight for producing the sour milk (tarag). Tarag was coagulated by heating, then dried in the sun to produce non-matured dry cheese (qorood). The second method of processing skim milk into non-matured dry cheese begins with acid coagulation. Acidification by adding fermented whey (shar os) causes protein in skim milk to coagulate, and heating denatures the milk protein and further promotes coagulation. The coagulated milk protein is processed for storage by ladling off whey from the surface and concentrating the curd by low heating for about a few hours. Concomitantly, the heating caramelizes lactose, which is present in high concentration, and colors the product, which is finally sun-dried to make a rock-hard cheese called eezgiy.

Thus, the technique of cream separation processes: heating/cream separation is adopted, in which the cream is first separated while heating raw milk. It is more frequently employed after fermentation processes: alcohol fermentation with churning.

Additive coagulation processes: fermented milk coagulation

Cheese called byaslag is processed from raw milk using fermented whey as a coagulant. Raw milk is heated and then added by fermented whey (shar os) for acid coagulation. Curd is called eedem. Eedem is poured into a cloth bag, sandwiched between wooden boards, and weighted by a heavy rock placed on top to drain whey. This non-matured dry cheese produced here is byaslag. Byaslag is formed by slicing thinly with a kitchen knife. Byaslag with some water remaining is consumed within a week. Sliced byaslag is also dried in the sun to produce a dry cheese, which can be stored for a long period. This dry cheese is called qataasan byaslag, literally meaning ‘dried byaslag’.

Thus, the milk processing technique of fermented milk coagulation is also conducted in the eastern part of Mongolia. The technique of using fermented whey as the coagulant is also utilized to process eezgiy from skim milk (bolson su'u’) in the procedure of cream separation processes.

Milk processing system in Matad and Tsoybalsan Districts, Dornod Province

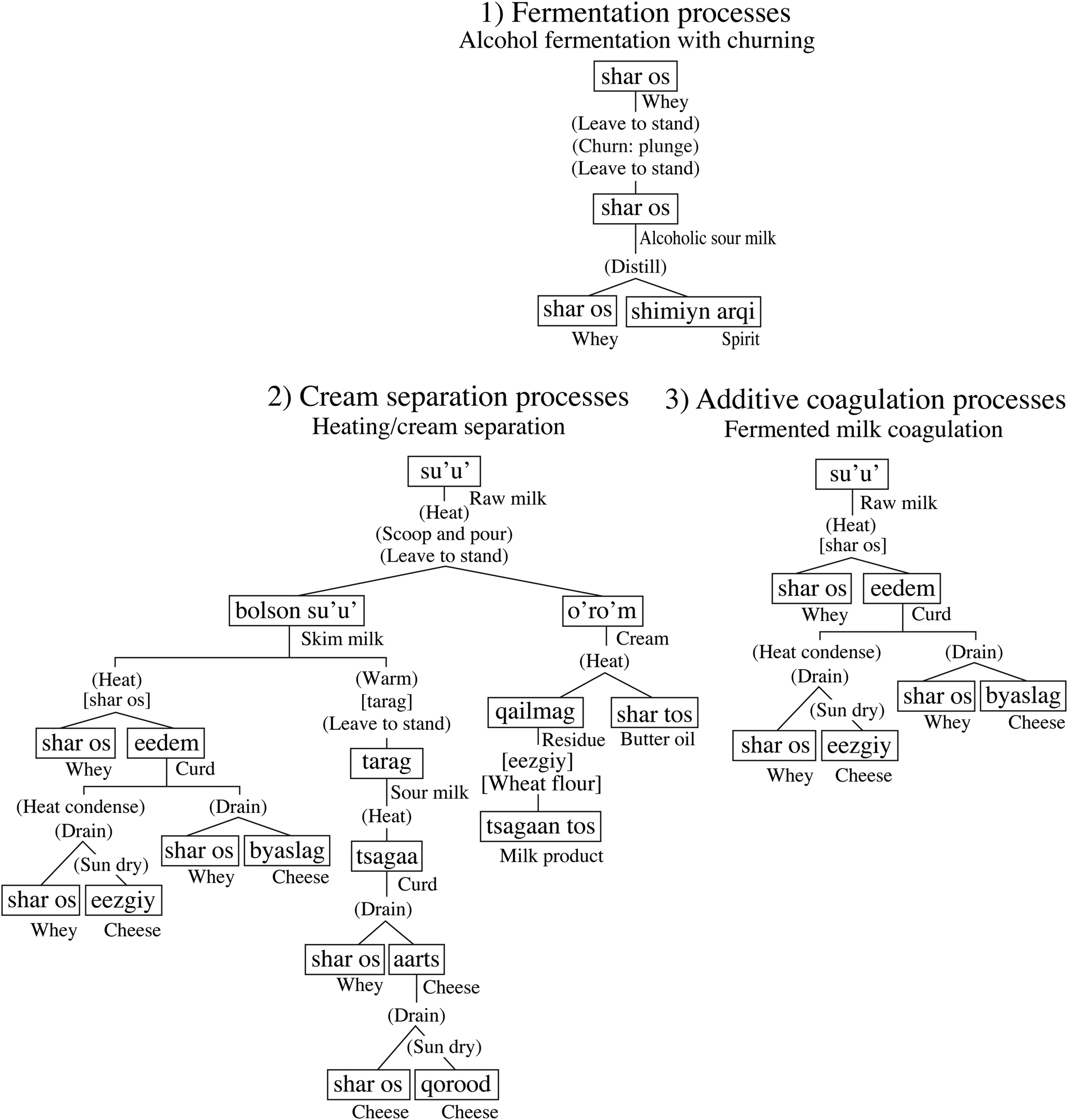

The milk processing techniques of fermentation processes, cream separation processes and additive coagulation processes are also used in Matad and Tsoybalsan Districts, Dornod Province (Fig. 3).

Figure 3. Milk processing system in Matad and Tsoybalsan Districts, Dornod Province, Mongolia.

![]() : Product [ ] : Additive ( ) :Treatment.

: Product [ ] : Additive ( ) :Treatment.

Fermentation processes: alcohol fermentation with churning

The fermentation technique, such as processing alcoholic sour milk or sour milk from raw milk, are basically not used in Dornod Province. However, there are many guests and spirits are needed to celebrate the New Year together on tsagaan sar, which is New Year's Day in Mongolia. For tsagaan sar in winter, the lactic acid fermented and alcoholic fermented whey (shar os) is stored until winter and distilled to produce the spirit (shimiyn arqi) in winter. The spirit is not processed from milk in the summer when raw milk is abundant.

Thus, the technique of fermentation process is basically not used, but when spirit needs, it is temporarily applied to the technique belonging to fermentation processes: alcohol fermentation with churning in Dornod Province.

Cream separation processes: heating/cream separation

The majority of milk processing practice involves the technique of cream separation processes in Dornod Province. Once raw milk is obtained, the technique of cream separation processes: heating/cream separation is used to process cream (o'ro’m) and non-matured cheese (qorood and eezgiy). The technique of cream separation process is almost identical to the one in Su'qbaatar Province. In the case of the Dornod Province, byaslag is also processed along with eezgiy from the skim milk (bolson su'u’).

Additive coagulation processes: fermented milk coagulation

Non-matured dry cheese is also processed using fermented whey as the coagulant in the technique of additive coagulation processes in Dornod Province. Only byaslag is processed from raw milk in Matad District, and byaslag and eezgiy are both processed in Tsoybalsan District. Raw milk becomes byaslag by adding the coagulant of fermented whey, heating and dehydrating, and results in eezgiy by continued heating and concentrating whey. The technique of fermented milk coagulation is almost identical to the one in Su'qbaatar Province. The frequency of processing byaslag from raw milk is not as high as the technique of cream separation processes.

Discussion

Characteristics in the eastern part of Mongolia

Cream separation processes (heating/cream separation) and additive coagulation processes (fermented milk coagulation) are commonly adopted in Su'qbaatar and Dornod Provinces. In the cream separation processes, cream is firstly separated from raw milk and used as the important food in the summer when raw milk is abundant, and the cream is processed into butter oil in the early winter as the valuable preserved ingredient. Skim milk is finally processed into non-matured dry cheese through sour milk processing. This technique is common in Delgerqaan District, Qentiy Province and Sayntsagaan District, Dundgowi Province, central Mongolia. The additive coagulation processes are also used in Qentiy and Dundgowi Provinces. Hence, the techniques of heating/cream separation and fermented milk coagulation are widely shared in the eastern Mongolia.

Fermentation processes (alcohol fermentation with churning) in Su'qbaatar Province and cream separation processes (heating/cream separation) in Dornod Province are mainly adopted for the practice of milk processing during the summer when raw milk is abundant. Raw milk is firstly processed into alcoholic sour milk and distilled to spirit in the fermentation processes in Su'qbaatar Province. On the other hand, cream is dominantly separated from raw milk, and the technique of fermentation processes is not used as the daily milk processing technique in Dornod Province. Since spirit producing is only processed in the occasion of summer festival (naadam), New Year's Day (Tsagaan sar), and the visiting of close friends also in Delgerqaan District, Qentiy Province, the technique of fermentation processes is not daily practiced. The milk of cow, sheep and goat is processed using the technique of cream separation processes in Sayntsagaan District Dundgowi Province, central Mongolia. Only mare milk is processed to alcoholic sour milk (ayrag) in Sayntsagaan District. Airag processing from mare milk also involves churning treatment, the same as the case of cow milk. Spirit processing is not distilled from airag in Sayntsagaan District. Hence, it is the characteristics in Su'qbaatar Province that the processing of cow milk is dominanted by the technique of alcohol fermentation with churning. However, since this technique is also found in the Tariganga, Buryat and Hamingan groups (Badamkhatan, Reference Badamkhatan1996), alcohol fermentation by churning is a widely shared technique in eastern Mongolia.

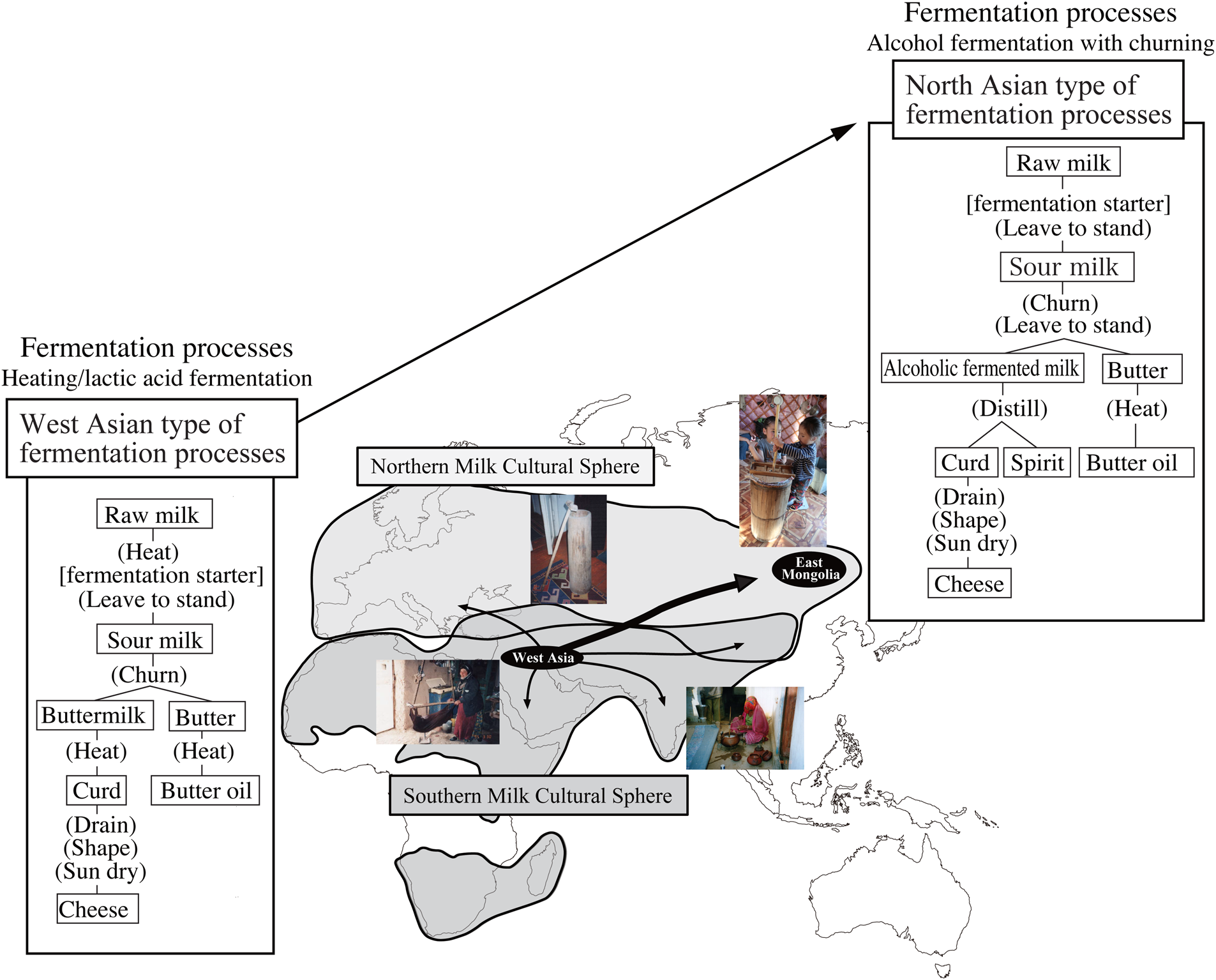

Cultural transition from churning for butter processing to churning for alcoholic sour milk processing

Within the fermentation processes, the treatment of heating/lactic acid fermentation is well developed in West Asia, including Syria, Jordan, Iran and Iraq (Musil, Reference Musil1928; Dickson, Reference Dickson1959; Hansen, Reference Hansen1961; Weir, Reference Weir1976; Mortensen, Reference Mortensen1993; Hirata, Reference Hirata1999). Sheep and goat milk is pasteurized, added with the small amount of the previous sour milk left over as a fermentation starter, and left to stand for several hours at room temperature to make sour milk. Sour milk is churned using a skin bag to produce butter, and then butter is heated to process butter oil (Fig. 4). Soured buttermilk that remains after the butter is scooped out is heated to coagulate, and then curd is drained, formed and dried in the sun to produce non-matured dry cheese. Butter oil and non-matured dry cheese can be stored at room temperature for several years. The separation of lipid and protein from raw milk, which enables them to be stored over long periods is achieved by heating, leaving to stand, churning by a skin bag, draining and dehydrating. It is assumed that the technique of heating/lactic acid fermentation, invented in West Asia, spread widely throughout Afro-Eurasia and became the basis of milk processing technique over Afro-Eurasia (Hirata, Reference Hirata2020).

Figure 4. Spread and transition of fermentation processes.

Source: Modified from Hirata (Reference Hirata2020).

The technique of alcohol fermentation with churning is used in Su'qbaatar Province, eastern Mongolia. Cow milk is added with the small amount of the previous alcoholic sour milk as a fermentation starter, and left to stand for several hours at room temperature to promote lactic acid fermentation. Then, the mixture is churned by the wooden cylinder with the plunger to feed oxygen for growing yeast, and left to stand to produce alcoholic sour milk. The butter produced during churning is scooped up and heated to process into butter oil. The alcoholic sour milk after scooping out butter is distilled into spirit, and the curd is drained, formed, and dried in the sun to produce non-matured dry cheese. Churning is also used in the cases of Dornod and Dundgowi Provinces, both of which are applied for processing into alcoholic sour milk.

Comparing West Asia with eastern Mongolia, the procedure on sour milk processing of raw milk, churning of sour milk, butter and butter oil processing, as well as non-matured dry cheese processing by heat coagulation, dehydration, formation and sun drying of buttermilk or alcoholic sour milk after scooping out butter are the exactly same milk processing steps in both areas. The case of eastern Mongolia differs from West Asia with regard to the alcoholic fermentation process with churning. Since yeast undergoes alcoholic fermentation under aerobic conditions (Cook, Reference Cook1958), a treatment to supply oxygen into sour milk is necessary for promoting alcoholic fermentation. Churning for the purpose of butter processing simultaneously results in supplying oxygen into the sour milk. Churns are different in each Afro-Eurasian region; a skin bag in West Asia, an earthen pot and stirrer in South Asia, and a wooden cylinder and a plunger in Central Asia and Mongolia, which are all used for churning to produce butter (Hirata, Reference Hirata2020).

Yeasts such as Saccharomyces cerevisiae, Saccharomyces pastrianus, Candida kefyr, Candida versatilis, Candida pseudotropicalis, Kluyveromyces fragilis have also been isolated from sour milk in West Asia (Suriyarachchi and Fleet, Reference Suriyarachchi and Fleet1981; Tantaoui-Elaraki et al., Reference Tantaoui-Elaraki, Berrada, El-Marrakchi and Berramou1983; Guizani et al., Reference Guizani, Kasapis and Al-Ruzeiki2001; Yasuda, Reference Yasuda and Kitamoto2017). Baroudi and Collins (Reference Baroudi and Collins1975) showed that K. fragilis and S. cerevisiae were responsible for the production of ethanol in traditional Lebanese sour milk called laban. Tantaoui-Elaraki et al. (Reference Tantaoui-Elaraki, Berrada, El-Marrakchi and Berramou1983) suggested that yeasts may activate the growth of lactic acid bacteria and contribute to the development of characteristic flavors of laban. Their absence in commercial laban suggests that they may not play an effective role in the development of the organoleptic characteristics of the product in West Asia. On the other hand, in the cooler environment in Mongolia, North Asia, yeast plays an important role in the processing of fermented milk.

A cool environment is needed to produce alcoholic drinks. Local alcoholic liquors and fermented milks are processed at lower temperatures. For instance, it is less than 10°C in Japanese rice wine called sake for the period during lactic acid fermentation before alcoholic fermentation by yeast (Wada, Reference Wada2015), at or below 15°C for white wine (Reynolds et al., Reference Reynolds, Cliff, Ginard and Kopp2001), at 18–22°C for commercial kefir for fermentation and 10°C for ripening (Kosikowski, Reference Kosikowski, Kosikowski and Mistry1982; Masuda, Reference Masuda and Kitamoto2017), and at 17°C for commercial koumiss from cow's milk (Kosikowski, Reference Kosikowski, Kosikowski and Mistry1982). The temperature is too high for successful alcohol fermentation in West Asia, but suitable in Central and North Asia. Hence, it is presumed that the technique of churning sour milk transmitted from West Asia to eastern Mongolia, and then the function of churning originally for butter processing was converted to for alcohol fermentation under the cooler environment in North Asia.

We can conclude by saying that the first purpose of this paper was to understand the milk processing system practiced in the Mongolian nomadic Khalkha groups in eastern Mongolia. It became clear through the field survey that the processing of cow milk was dominated by the a cream separation process, namlely the technique of heating/cream separation. It is characteristic in West Asia that raw milk is firstly pasteurized, and then processed to sour milk by lactic acid fermentation (Hirata, Reference Hirata1999). There has been a shift to separation of cream first with heating treatment of raw milk in North Asia. Fermentation processes especially alcohol fermentation with churning was also found in eastern Mongolia. The second purpose was to analyze how the milk processing technique from West Asia has transited in eastern Mongolia. As the result of comparing the techniques and local natural environments in both West Asia and North Asia, we can propose that the fermentation process of heating/lactic acid fermentation was transmitted from West Asia to eastern Mongolia, and then it was converted to alcohol fermentation with churning under the cooler environment in North Asia. Fermentation processes had changed to include alcohol fermentation along with butter producing by churning in eastern Mongolia. Alcoholic fermentation is the technique that progresses bunder the cooler temperatures.

Acknowledgements

The author owes a great deal of thanks to the local nomads in Mongolia for offering their hospitality and kindness. We also thank Dr Damdin B., General Agency for Specialized Inspection, Regulatory Agency of the Government of Mongolia, for supporting the field survey.

Financial support

This research was funded by the 2022 fiscal year's Grant-in-Aid from the Japan Society for the Promotion of Science, Japan (Project Number: 20KK0150).