INTRODUCTION

In the transatlantic transfer of scientific management, the German case stands as a notable example of adaptation. Rather like their European counterparts, German industrialists and engineers were fascinated by the development of American technology and industrial practice in the early twentieth century. However, Germany's strong labour movement and the limited markets of the German industrial world amounted to twin prominent differences between the two industrial contexts that prevented wholesale adoption of American methods by the Germans. That situation challenged German enthusiasts of scientific management to secure peace and discipline on the shop floor in the absence of mass consumption.Footnote 1 The outcome was a specific form of scientific management that came to be known as Rationalisierung and entailed a corporatist response to economic and political liberalism.

The juxtaposition of the two different industrial contexts offers a fine vantage point for fruitful study of divergent national paths during the interwar period. In the present article, I shall broaden the view from that vantage point by introducing a third and totally different industrial context that was part of a transnational movement within the German scientific movement in the 1930s. My main question is what happened to this specific German form of scientific management, developed in an industrial context of craft control of the labour process, predominance of skilled labour, and a strong labour movement when it was transferred to a completely different context of industrialization in the recently established Turkish Republic that had emerged from long years of war and economic destruction with a new developmentalist plan. Only a decade after the establishment of its Republic and in the wake of the Great Depression, Turkey embarked on an ambitious import substitution model of national industry building.

Most studies of the emergence and development of scientific management in contexts of late industrialization have focused on the flow and reception of American management ideas after World War II, and Turkey is no exception.Footnote 2 However, the case presented here represents an earlier effort by the Turkish state to solve its crisis of industrial productivity. In 1931, Muhlis Ete, one of the founding fathers of business education in Turkey, complained that rationalization “has not arrived here yet”, but at the Turkish Economic Congress seventeen years later he found himself in the pleasing position of being able to report that many state factories were now operating on rational lines.Footnote 3 Between those two dates, the terms “rationality” and “efficiency” penetrated the discourse of Turkish national industrial development to such an extent that people were even talking about them at home.Footnote 4 Until now, the role in this development of a group of German industrial experts has been completely overlooked, but we can now see that the increasingly repressive political climate in Germany after 1933 presented the Turkish state with an opportunity to offer Germans with industrial management experience the chance to leave Germany to apply their expertise to the rational organization of Turkey's industrial production.

During the early years of industrialization, working-class politics posed no threat to the Turkish state. In the absence of craft control of the labour process or labour organization, and with no strong employment relations institutions, the improvement of industrial production was regarded as a chiefly technical matter. How did the German scientific management experts respond to such a contrasting industrial context? What elements and mechanisms of Rationalisierung and Humanisierung did they retain and which did they redesign? How did they adapt to local traditions of management organization and practice? The answers can be found in the fourteen reports written by four German industrial experts on their return from visiting state-owned textile and shoe factories in Turkey between 1934 and 1939.Footnote 5 Originally written in German and later translated into Turkish, the reports were addressed to the General Directorate of Sümerbank, the holding company in charge of state factories. They sketch a picture, even if incomplete, of the conditions of the textile and shoe workers in Turkish state factories in the 1930s. Based on their observations on the shop floor, the German experts made a wide variety of suggestions to rationalize technical and organizational aspects of industrial production, and proposed new schemes to link incentive funds to performance in an effort to fight the problem of low labour productivity. The experts’ observations and suggestions underline the stark contrast between the spatio-temporal milieus of the two countries. Scientific management had recently created a new epistemic community of industrial experts: the engineers.Footnote 6 German and Turkish engineers interacted as members of a community on the basis of shared knowledge and experience of the industrial workplace. In the comparisons the German experts made between what they saw on the shop floors of Germany and Turkey, the factory assumes the role of transnational meeting ground. Long expertise and deep knowledge of the factory, its manufacturing processes and organizational workings had gone hand in hand with the development of modern mass-production methods. In that regard, James Scott defines mētis as the personal interpretative accounts of practices, routines, and interactions based on direct experience, and techne as systematically derived and analytically organized scientific knowledge. We may say therefore that the replacement by the new class of engineers of the local knowledge embodied in the workers by a priori and science-based knowledge, and their scientific management of the whole process, is a historical example of the subordination of mētis to techne. Indeed, as Scott himself argued, the genius of the American mechanical engineer Frederick Taylor stemmed from his recognition of the need to transform the essentially artisanal or mētis knowledge of workers into a standardized system.Footnote 7

The limited coverage of interactions between the German engineers and their Turkish colleagues on matters such as industrial waste management and piece-rate implementation reveals that at times there was a certain amount of friction, although perhaps only concerning technical matters. However, the national specifics of capital accumulation became most obvious in their effects on practical solutions. There were already enormous differences in historically determined conditions of capital investment, technological transfer, and market conditions, to say nothing of wage labour itself, while the manifest differences in management objectives and practices between the sending and receiving contexts resulted from different class and labour market dynamics. In contrast to the state of affairs in their home country, the German engineers working in Turkey were not obliged to make compromises to secure the support of labour. To put it another way, there was no need to transform the essentially artisanal or mētis knowledge on the shop floor and turn a resistant, quasi-autonomous artisan population into obedient workers.Footnote 8 Instead, the fact that the available army of labour was unskilled, cheap, and unorganized was something the newly arrived experts were able to take advantage of to intensify work requirements without having to secure class collaboration. Rather like the case with transatlantic transfer, the transfer of scientific management from Germany to Turkey was directed by the general logic of capital accumulation, but its proponents made sure to exploit the local dynamics historically produced by that logic. As we shall see later in this article from the incident at the Beykoz Shoe Factory, the result was not a conflict between techne and mētis but cross-fertilization between them. In what follows, I shall first explain the two industrial contexts and the context of migration between them, then discuss the German experts’ factory reports. My focus will be on the solutions suggested by the Germans to reduce labour costs, as seen against the background of the main debates and trends in German scientific management.

TURKISH ETATISM: A HOME-GROWN PLANT IN CONSTANT NEED OF FOREIGN HELPFootnote 9

Having inherited a mostly agrarian economy battered by the recent Great War, debts from its lost empire, significant losses by most of its business and artisan classes, right from its beginning in 1923 the postwar Turkish Republic suffered from lack of capital accumulation, entrepreneurship, and no established industrial workforce.Footnote 10 The ruling Republican People's Party (RPP) chose to pursue liberal economic policies which it maintained until the Great Depression, so that 1920s Turkey amounts to a near-perfect example of a dependent economy in which the intervention of the state had been minimal. The extremely restrictive rules of the Lausanne Treaty dictated that Turkey lived under the Ottoman trade regime until 1929, which effectively hamstrung the Turkish state. Plummeting returns from the agricultural products that were Turkey's primary exports heightened the new regime's economic vulnerability and forced the government to re-examine and reorient economic policy.Footnote 11

The worldwide economic circumstances were therefore quite pressing enough, but there were more than economic considerations behind the Turkish government's policy choice. The Republican state elite had been at pains to break free from its imperial socioeconomic chains but had neither the autonomy nor economic institutions to do so.Footnote 12 It had spent the 1920s trying to impose super-structural reform – which had faced substantial opposition – and to overcome threats to territorial integrity such as the 1925 Kurdish rebellion. There were attempts to nationalize the economy, by allowing only Turkish vessels to transport goods by sea for example, by making Turkish the official language for business correspondence, and by nationalizing all foreign railway companies.Footnote 13 Nevertheless, by the end of the decade it was clear that the regime would not be able to succeed in forging central authority either economically or politically.

A politically directed national economy therefore arose, in answer to the economic and bureaucratic problems created simultaneously by the Great Depression worldwide and by domestic developments in the Turkish political economy.Footnote 14 In July 1932, the Turkish government officially adopted a new policy of state-led import-substituting industrialization, which came to be known as etatism. Together with revolutionism and secularism, it was added to the party's first three principles – republicanism, nationalism, and populism. In 1937, all six principles were added to the Turkish Republic's constitution.

As the decade progressed, an increasingly national identity attached itself to the RPP as it came to be fully identified with the Turkish state. Nationalism grew into Turkey's official ideology, and the Kemalist regime was consolidated to such an extent that the 1930s have been called the decade of “High Kemalism”.Footnote 15 The regime's projection of its desired society was based on a reflection of the War of Liberation as a classless national revolution. Its statist and inward-oriented industrialization programme befitted that projection by displacing class antagonism through an ideology of citizens in the service of national development. Indeed, the key idea of national unity was reflected in the RPP's programme for 1935. Written three years after the inception of etatism, the 1935 programme had been formulated against a background of heavy criticism of the RPP's economic policies and included the blueprints of the Labour Law enacted the following year. To refute the criticism, the Party Secretary resorted to arguing the particularity of Turkey's situation, insisting that Turkey was neither liberal, nor class based. He acknowledged the dangers of rapid industrialization, which risked creating a sizeable working class, then seeing it “poison[ed] […] with ideas such as class conflict”. The party programme therefore dictated agreement and harmony between the workers and employers and appointed the state as arbitrator. When the Secretary announced that under the programme strikes and lockouts were to be banned, his audience replied with an enthusiastic “Bravo!” before he added that it would also guarantee that no capitalist would be able to put unfair pressure on any worker, because, after all, populism dictates that, “they are both sons of the country”.Footnote 16 The next year, full congruency between state administration and party organization was declared and the government enacted the Labour Law, which was modelled on Italian fascist legislation. Although the Labour Law brought a number of protective working regulations at individual level, its defining feature was the authoritarian measures it contained at the collective level. The 1935 Penal Code had already imposed punitive sanctions on strikes; the Labour Law now made them illegal. Activities aimed at “establishing the hegemony or domination of a social class over the other social classes, or eliminate a social class or overthrow any of the fundamental economic or social orders established within the country” were declared illegal in the Penal Code, while the final blow came in 1938 with the revised Law of Associations, which banned all forms of “organizations based on social class”.Footnote 17

In the meantime, state industrialization went into action at full swing. A holding company named Sümerbank was established in 1933 to take over the Ottoman textile plants in Istanbul and build spinning and weaving factories in different parts of Anatolia. Meanwhile, the share of industry in Turkish GNP increased from 10.8 per cent between 1925–1929 to 17.8 per cent in 1933–1941.Footnote 18 Factory production doubled between 1929 and 1938, and the share of industry and construction in national income rose from thirteen to sixteen per cent.Footnote 19 The primary goal of state-led industrialization, as stated in the first Five-Year Plan in 1933, was to create the industrial capacity to produce consumer goods and, because textiles were a major import item, heavy investment was made to establish a domestic textile industry. Of the five industries covered by the plan, textile and mining were respectively assigned 50.7 and 26.9 per cent of total expected investment, while cotton received the biggest share with 42.2 per cent of total investment.Footnote 20 By 1947, Sümerbank became the top producer of cotton textiles, controlling 47 per cent of all spindles, with 47 per cent of the entire textile sector workforce in its employ and responsible for 68 per cent of all textile production.Footnote 21

The project of state-led industrialization was closely connected to the ideological core of Kemalist nationalism, which it buttressed through the narrative of Turkish capital enabling Turkish people to work to produce goods for the Turkish homeland. The social implications of industrial investment decisions were mentioned quite openly as political priorities were built into economic plans.Footnote 22 The factories, many of which were located in underdeveloped areas, received enormous media attention as national spaces exemplifying Turkey's modern development project. Unfortunately, and in spite of the nationalist propaganda, from the very beginning serious and chronic problems of poor efficiency and low productivity characterized the factories’ operations. With actual production levels consistently less than yearly goals, the etatists came under increasing pressure from the more economically liberal-minded state elite.

A prominent figure belonging to that second group was the Minister of Economy, Celal Bayar. Although the national economy had actually benefited from protective measures, he argued in 1937 that it also increased the cost of living, so it was time to lift at least some of those measures and restructure the economy.Footnote 23 Bayar argued for rationalization as the key feature of the restructuring, saying that it should be applied to a redesign of the administration and inspection of state enterprises as well as to actual production. Ever more criticism of state factories continued to appear on the agendas of parliamentary meetings, with a member of parliament in 1940 for example comparing two possible ways to think about state investments. In terms of the profit-to-investment ratio, they were certainly not profitable, but given that industrial investment was something “we did not know at all”, such enterprises had actually been hugely successful, he said.Footnote 24 The state's simple solution to its problem of “not knowing at all” was to invite foreign experts to visit Turkish factories. Already key sites for entanglements of state-making, class formation, and modernization, state factories would now become spaces of encounter between different ideas of industrial development and modes of governance.

THE POLITICS OF FOREIGN EXPERTISE

The young post-1929 Turkish state resorted to the help of foreign experts in its search for an economic policy free from economic liberalism and leaning instead towards a planned economy.Footnote 25 The regime's rulers were impressed by the performance of the planned economy of the 1920s Soviet Union, noting specifically the extraordinary growth of Soviet heavy industry and the technological development of its textile industry. Interest was mutual, and in 1932 Turkish industrialists accompanied the Turkish Prime Minister and Minister of External Affairs on a visit to Moscow and Leningrad. The visit proved successful, with the two countries declaring that as the first step towards economic cooperation the Soviets were to provide a loan worth eight million dollars to pay for the import of industrial machinery to Turkey.Footnote 26 Later the same year, a group of Soviet experts visited Turkey to make a preliminary study of the establishment of textile factories,Footnote 27 while a council of Soviet planning experts was involved in preparations for Turkey's First Industrial Plan in 1933. From the mid-1930s onwards, however, Turkish-Soviet relations began to deteriorate until, by the Montreux Convention of 1936, tensions had escalated so much that the Soviet Union no longer supported the Turkish cause. However, that was only part of why Turkey moved away from the Soviet economic model, for as the decade progressed disagreements within the RPP over state involvement in the economy continued to grow.

Beginning with the policy discussions in 1931, the very meaning of etatism provoked intense discussion within the RPP, with the crux of the matter being the role of private enterprise. In simple terms there were two factions within the party: a bureaucratic group arguing for active state involvement and government regulation of private enterprise, and a liberal-minded interest group led by Celal Bayar who argued for a limit to the state's role in the economy.Footnote 28 Disagreement on the scope and ultimate goal of etatism was further complicated by escalating tension in international politics, so that the question of whom to turn to for technical know-how became highly politicized. The shift from a more radical etatism and extensive economic planning to a model mixing state and private investment was reflected, among other things, in the appointment of a new Minister of Economy.Footnote 29 When the more liberal Celal Bayar became Minister of Economy he turned to the expertise of the American expert Walter D. Hines and his colleagues to balance the predominance of the Soviet experts.Footnote 30 In the meantime, the American Embassy in Ankara was vehemently warning the US Secretary of State about the “strings attached” to the Soviet Union's generosity to Turkey. The planned productive enterprises offered a market for considerable amounts of capital goods, the ambassador wrote, and he urged American contractors to participate in the industrialization of Turkey.Footnote 31 By the end of 1932, Bayar, for his part, set about finding six suitable American individuals to fill positions at the Ministry of the Economy. Along with four experts in commerce and mining, he wanted an economic specialist to supervise the preparation of a detailed economic survey report, and a general economic advisor to implement the recommendations of the survey.Footnote 32 By March 1933, Bayar had found Walter D. Hines for the former position, but despite diligent efforts by the Division of Near Eastern Affairs at the request of the Turkish Embassy in Washington, the latter post remained unfilled. On 5 May 1933, the Chief of Division wrote that they had, “found it much more difficult than we had expected to find qualified persons to suggest to the Turkish Ambassador for these positions, particularly for the position of General Economic Adviser”. By June 1933, the enthusiasm of the Turkish government seems to have faded away to the extent that in September the Turkish ambassador's reply to a letter indicating interest in the position was that, “[the Ministry of the Economy] does not contemplate engaging the services of a specialist immediately”.Footnote 33 Eventually, in autumn 1934, a German expert was employed as chief consultant to the Ministry of the Economy. We shall meet him later.

German political and economic thought had already penetrated the Ottoman Empire by the late nineteenth century.Footnote 34 Germany had courted the Ottoman Empire with a policy of providing generous loans, weapons, and German officers to train the Ottoman army in return for the favouring of German firms in railway concessions and other public works. The agreement included cooperation in technical and scientific education, which led to an influx of German civil and mining engineers, agronomists, and forestry experts, while Ottoman engineering students were sent to Germany.Footnote 35 For the Young Turks, Germany was the role model for the technical and organizational aspects of modernization. After it seized power in 1913, the Committee (later, the Party) of Unity and Progress, the organization from which the Republican state recruited many for its cadre, endorsed a national economic programme called Milli İktisat, which was directly inspired by German economic nationalism.Footnote 36 In 1917, the US vice consul reported that the Turkish rulers “point consistently to Germany as the country, which, being already pledged, will show herself capable of giving them their future economic salvation […]” and referred to “German penetration on all the inner fabric of Turkish national life […]”, which he called “an astonishing fact”.Footnote 37 Finally, the German economic recovery during the 1920s added to the Turks’ fascination with German economic and industrial ideas.

That, then, was the background against which the Turkish state immediately seized the opportunity to take advantage when political repression began to escalate in Germany. The Nazi regime's arrival in 1933 opened a new window of opportunity for the Turkish state to seek foreign expertise from somewhere other than either the US or the Soviet Union. Two months after Hitler gained power, under a new Law for the Restoration of the Professional Civil Service even established civil servants were banned from all civil service positions if they happened to be members of certain groups such as Jews, other non-Aryans – or political opponents.

Later, in 1933, a colony of German intellectuals formed in Zurich, where Philipp Schwartz, a renowned pathologist from the University of Frankfurt, founded the Notgemeinschaft deutscher Wissenschaftler im Ausland [Emergency Association of German Scientists Abroad]. Through his connection with Albert Malche, a Swiss professor of education who had been involved in Turkish university reform from 1932 onwards, Schwartz went to Ankara in July 1933 to advocate the recruitment of German scientists. By November of that year, refugee academics had begun working at Turkish universities,Footnote 38 and in March 1934 Bayar told Schwartz that the Turkish state was so pleased with the work of its German academics that it wished to attract more Germans, especially experts in economics.Footnote 39 Germany's Ambassador Rosenberg reported on 4 December 1934 that the General Director of the Ministry of the Economy's Commerce Office had personally visited Zurich to select nine experts to be sent to Turkey.Footnote 40

While much modern research has been done on German refugee academics and their influence on Turkish university reform during the 1930s, with the single exception of one, Max von der Porten, very little is known about the role of individual German experts in the conceptualization and implementation of state-led industrialization.Footnote 41 Von der Porten was the chief consultant at the Ministry of the Economy between 1934 and 1939,Footnote 42 a length of service for which he stands out from Ivor Bauer, Emil Mundorf, and Ewald Sachsenberg, who were the other three German experts considered here and who seem to have made only short visits.

Max von der Porten was born in 1879 as Moses von der Porten, a name he changed first to Moritz von der Porten in 1919 and then to Max von der Porten in 1931. During World War I, Von der Porten worked for the Prussian Ministry of War as a consultant to the metal industry. He was then appointed first as State Commissioner in the Kriegsmetall AG, a management agency for war-important metals, and then General Director of the aluminium corporation Vereinigte Aluminium-Werke AG in 1920. A year later, the Technische Universität Braunschweig gave him the honorary title, Dr.-Ing. E.h. – “E.h.” meaning Ehren halber.Footnote 43 Before it ended, he worked in the Weimar Republic as an industrial consultant in Heinrich Brüning's government, but immediately after Hitler's seizure of power Von der Porten came under threat of persecution by the new regime, for although himself an Evangelical Christian he was denounced as a “baptized Rassejude” (a “Jew by race”). Ousted from his many economic posts, he was eventually obliged to leave Germany in 1933.

The exact date of Von der Porten's arrival in Turkey is unknown. Tekeli and İlkin mention a letter from him addressed to the Ministry on 4 October 1934,Footnote 44 while his earliest appearance in the media was on 20 March 1935, when he was referred to as “one of the most famous industrial managers and a powerful person”.Footnote 45 Throughout 1936, 1937, and 1938, his activities were widely reported in the newspapers (Figure 1) under a wide range of headings on topics and sectors, including docks and harbours, maritime commercial activities and education facilities, coalfields and warehouses, and iron and steelworks. Von der Porten worked on the improvement of cooperatives in 1935, education reform in economics and commerce in 1936, the evaluation and inspection of industrial enterprises from the second half of 1936 onwards, and the development of new administrative and control mechanisms of state economic enterprises in 1937.

Figure 1. Cumhuriyet, 26 April 1936. Von der Porten must be the second one on the left, in view of the following description by another German refugee professor in Turkey, Prof Fritz Neumark: “Doubtlessly, he was an excellent specialist, particularly of heavy industry, and in his view of these capabilities one should not be too critical with respect to certain human weaknesses of his, for example, to show off his monocle or to shout at the head waiter who might have served the Burgundy wine one or two centigrade too cool.” (Quoted in: Tekeli and İlkin, p. 5.)

Tekeli and İlkin managed to assemble thirty-three of the total of seventy-one known reports by Von der Porten, most of which dealt with the establishment and auditing of state industrial enterprises.Footnote 46 Regrettably, however, there is no trace in print media of his work on the textile industry, nor records of the factory visits he made. Von der Porten's departure from Turkey was mentioned in only a short article on 22 April 1939, which reported that “The Chief Consultant of Economy is leaving for the USA”, stating that his contract had not been extended.Footnote 47

“A professor of engineering with close ties to industrial circles” and “a German pioneer in psychotechnics”Footnote 48 are the words used to describe Friedrich Eduard Ewald Sachsenberg in Visions of Modernity.Footnote 49 Sachsenberg was born on 16 June 1877 in Roßlau. After studying naval architecture and mechanical engineering at the TH Berlin-Charlottenburg, he worked as a design engineer at Friedrich Krupp AG Germaniawerft in Kiel. In 1907, he received his doctorate to give him the title “Dr.-Ing. PhD”. For the next sixteen years, Sachsenberg held posts in various companies, from 1920 lecturing on shipyard operations and organization. In 1921, he was appointed Full Professor of Betriebswissenschaften [Business Administration] at the Technische Hochschule Dresden and Chairman of the Arbeitsgemeinschaft deutscher Betriebsingenieure [Association of German Plant Engineers]. By now a key player in the rationalization of German industry after World War I, Sachsenberg wrote numerous books on factory organization and performance measurement and was involved in the establishment of the Psychotechnical Institute in 1922 as well as the founding of the Institute for Machine Tool Examinations and Manufacturing in 1923. He also acted as Chairman of the Ausschuss für Wissenschaftliche Fertigung [Committee for Scientific Production].Footnote 50 Nevertheless, when the National Socialists came to power in 1933, being a liberal-minded freemason, Sachsenberg's position soon came under threat, and although he signed the Vow of Allegiance of the Professors of the German Universities and High Schools to Adolf Hitler and the National Socialistic State, he was forced to take leave of absence for his failure to meet the conditions of the Civil Service Act. Eventually, in 1940, he was dismissed from the university, an experience which was perhaps his point of connection with the Zurich group, and as such offers a plausible explanation for Sachsenberg's visit to Turkey, where, in March and April of 1937, he inspected four textile factories.Footnote 51

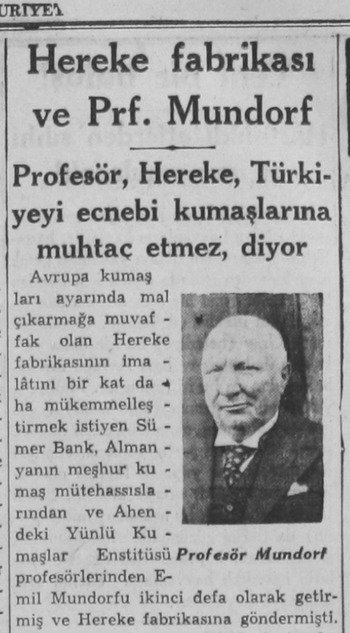

The Turkish newspapers used the following words to announce Prof. Emil Mundorf's second visit to the country (Figure 2): “In order to further excel production at the Hereke Factory – which is already capable of producing material of European quality – Sümerbank has brought in the famous German expert on fabrics Professor Emil Mundorf, founder of the Woollen Fabric Institute in Aachen”.Footnote 52

Figure 2. “Hereke Factory and Prof Mundorf: Professor Says Hereke Would End Our Dependency on Imported Fabric”, Cumhuriyet, 9 July 1935.

Mundorf was born in 1866, but my own research in German and Turkish archives has not yet yielded any information on his education nor his professional career, apart from revealing that between 1908 and 1936 he made sixteen applications to the Deutsche Patent und Markenamt [German Patent and Trade Mark Office] for patents for industrial machines and methods, and that he applied too for patents in France, the UK, and the US. In an application in 1910, he described himself as “Technical School Superintendent” in Boxgraben, Aix-la-Chapelle; in later applications that had changed to “Professor, Boxgraben, Aachen”.Footnote 53

Although there is no trace of it in the archives, Mundorf himself mentioned at least one earlier visit to Turkey saying, “I had been there before to examine the Feshane and Hereke factories and to present to them the recent developments in rationalized operations, which will reduce production costs and increase fabric quality”. Mundorf's second visit lasted two months, its extensive newspaper coverage rather unusual, for there was rarely much reporting of such visits in print. Perhaps it was Mundorf's favourable comparison of Hereke to Western European factories – clearly apparent in the headline, “Prof. Mundorf says Hereke would stop Turkey's dependency on foreign fabric” – that brought him to public attention, for pro-government newspapers of the day tended to report such statements enthusiastically.

On the fourth and last German expert, Ivor Bauer, there is even less information in the Turkish archives. There is press coverage of his engagement and marriage in 1936 to “Miss von der Porten”, who turns out to be Max von der Porten's daughter,Footnote 54 and Bauer's name is mentioned again on 18 January 1939 in relation to his public appointment as erection engineer at the paper factory in İzmit.Footnote 55 In spite of the scarcity of solid information in the records, however, there are good reasons to believe that he lived in Turkey for some time at least between those dates.

How were such men chosen? Who first made contact with them? Was Von der Porten involved in the selection of the other experts? Did the men know each other from Germany, or did they meet during or after their visits to Turkey? Were they familiar with each other's work on Turkish factories? How many times did each of them actually visit Turkey, and how long did they spend there? Important questions all, of course, but they lie beyond the scope of the current article. However, the transnational experiences of that group of exiles and their families are still to be traced in the German and Turkish archives – and perhaps other archives too. The Turkish archives certainly provide an answer to one question relevant to this article, which is how their activities were perceived in Turkey. Suspicion of the figure of the “foreign expert” had already begun to grow in the 1930s and was obvious by the 1940s as Turkish industrialists and professionals began to appear in greater numbers.Footnote 56 In 1949, the archives were said to be full of reports by all sorts of experts, all of them gathering dust, many already lost and many untouched, having been “put to sleep or ignored by those who were supposed to act on them”.Footnote 57 Writing in a textile-engineering journal in 1951, two Turkish engineers complained about the current situation of the textile industry. One criticized the popular use of the term “rationalization” despite the many failed attempts to achieve it,Footnote 58 while the other was disappointed in the high production costs resulting from the lack of standardization.Footnote 59 Were the German experts’ reports among those “put to sleep or ignored”? In fact, the many scribbled – many of them albeit illegibly – Turkish comments in the margins of Mundorf's and other experts’ reports suggest that they were read repeatedly and carefully. Indeed, in 1948, an article in the abovementioned engineering journal on the fulling of wool was based on Mundorf's notes.Footnote 60

From 1939 onwards, annual factory reports by Turkey's Supreme Audit Board revealed that the industrial problems pointed out by the German experts were continuing to create bottlenecks in production into the 1940s. However, other than such sporadic references, there is no mention in the archives of any results of suggestions by any of the German experts actually being applied. Meanwhile, the reports by Turkish state inspectors from 1939 onwards do not refer to the earlier reports by foreign experts and were anyway of a quite different tone and focus from the reports I analysed for this article. I could therefore make no systematic evaluation of the implementation of German experts’ suggestions, although where possible I have referred to later developments in state factories as they proved relevant to the main problems indicated by the German experts.

But what exactly were those problems? What were the recurrent themes and recommendations filling the pages of the reports gathering dust in the archives? What ideas and practices did these Germans in important industrial and academic positions bring to the Turkish shop floor? Moreover, what were the peculiarities of the German industrial context and scientific management in the 1920s and early 1930s? It is with these questions in mind that I now turn to the German context of industrial rationalization.

THE GERMANIZATION OF SCIENTIFIC MANAGEMENT

Although scientific management first appeared in large German workshops about the turn of the twentieth century, major companies had already developed systematic factory organization based on earlier German bureaucratic traditions that emphasized written instructions, precision, and standardization.Footnote 61 With increasing numbers of business academies, polytechnics, and technical colleges from the 1850s onwards, academically trained men began to gain footholds in industry until, from roughly the 1890s, engineers began to replace the purely empirically trained directors in workshops and production plants,Footnote 62 and academics began to become involved in the implementation of scientific management through their work in industrial research laboratories.Footnote 63

Public discussion of Taylorism began as early as 1907, just three years after the German translation of Taylor's Shop Management was published.Footnote 64 In 1907, a new journal called Werkstattstechnik [Workshop Techniques] made terms such as “efficiency”, “unpunctuality”, “inaccuracy”, and “imperfection” increasingly familiar.Footnote 65 After the Great War, more than a thousand books and articles on scientific management were published,Footnote 66 but it was the exigencies of war rather than the impact of Taylorism itself that gave European scientific management its practical value. As war had increased the pressure for industrial expansion and efficiency, Taylorismus and Fordismus emerged as cults; the German version of Taylor's Die Grundsätze wissenschaftlicher Betriebsführung sold more than 30,000 copies, while Henry Ford's Mein Leben und Werk was reprinted over thirty times between 1923 and 1939.Footnote 67 Pressure for efficient utilization of resources increased along with efforts to reduce waste and recruit new sources of labour, such as women and disabled workers. Although further organizational and technical changes were introduced between 1914 and 1918, especially in the sectors most involved in the war economy, they did not amount to systematic and sustained modernization of industrial production.Footnote 68

That change finally became permanent in the 1920s, as pressure to increase production and reduce costs remained high throughout the decade despite German industry's successful expansion between 1873 and 1913.Footnote 69 Currency stabilization and the agreement of a staggered payment plan for war reparations kindled hopes for German economic recovery, so that with “an unusual coalition of industrialists, labour unionists, engineers, and a state convinced of the importance of improving work organization methods to modernize the country”,Footnote 70 the “rationalization boom” resounded through the 1920s.Footnote 71

German management intellectuals had invented the term Rationalisierung sometime after 1917 to denote a series of ideas that were essentially a corporatist response to economic and political liberalism.Footnote 72 Although sometimes used interchangeably with scientific management, Rationalisierung's social and political implications were, in fact, different. As a broad concept, Rationalisierung covered factory operations, economic planning, cartel negotiations, and corporatist political arrangements.Footnote 73 The Reichskuratorium für Wirtschaftlichkeit [National Productivity Board] specified its three forms as technical, commercial, and politico-economic. Pertaining to economic policy, it was defined as the best method to promote national prosperity “by way of bringing the well-being of society and the striving of entrepreneurs after profits into conformity with each other”.Footnote 74 In Brady's words, rationalization added direction to scientific management by implying “a balance and coordination which is not comfortable with exploitation of resources for the exclusive benefit of a selected few”.Footnote 75 The Deutsches Institut für technische Arbeitsschulung, DINTA [German Institute for Technical Labour Training], the “most vocal, visible, and influential practitioner of human rationalization in the 1920s”, promoted a particular German path to rationalization without Americanizing the worker. The peculiarities of the German path were best captured in its project for the industrial leadership of man (industrielle Menschenführung), which had a significant influence on Weimar engineers and industrialists.Footnote 76

Interest in the human factor in production led to increased problematization of power relations in the workplace, especially in the relationship between managerial control and workers’ own responsibility for themselves.Footnote 77 Arguing for a need to reconcile rationalization with the “humanizing” of industrial life, a broad movement of engineers, scientists, and industrialists supported menschliche Rationalisierung, “human rationalization”.Footnote 78 To some, menschliche Rationalisierung was the key to an especially German form of economic modernization that they believed ought to be developed independently of the American influences of Taylorism and Fordism.Footnote 79 By the late 1920s, approximately 600 private and state institutions were working on the problems of rationalization.Footnote 80 The teaching of scientific management in many engineering schools, and the increasing availability of industrial psychology research, hastened the implementation of incentivized wage plans, collective bargaining, and increased production planning and coordination.Footnote 81 The results were impressive as productivity per worker and overall productive capacity rose considerably while working hours decreased.Footnote 82 Mechanization and intensification of work led to steady loss of Arbeitsfreude – “job satisfaction” or “joy-in-work” as it later came to be more widely understood. Loss of Arbeitsfreude was to become a major concern for German industrialists,Footnote 83 with one influential German economist-cum-sociologist noting that German workers began to refuse to be treated purely as factors in production.Footnote 84 Meanwhile, another German academic argued more pragmatically that if the new methods of work were not accompanied by gains for labour such as reductions in their working hours, national industry would be in danger of using up its labour supply too quickly.Footnote 85

Thanks to the important gains German workers made after 1918, the labour movement secured a strong voice in debates over methods of increasing productivity. Protective bouts of labour legislation followed one another under successive Weimar governments. New laws were applied to wages and hours, pensions, and unemployment insurance, along with the institution of a system of labour courts, and to a large extent all of that secured the endorsement of Rationalisierung by both capital and labour.Footnote 86 The labour movement also secured representation in debates and decision-making on rationalization. An example of that is the membership of the Chairman of the Allgemeiner Deutscher Gewerkschaftsbund [General Confederation of German Trade Unions], Theodor Leipart, on the managerial board of the Kaiser-Wilhelm-Institut für Arbeitsphysiologie [Kaiser Wilhelm Institute for Labour Physiology].Footnote 87 Brady defines labour's position on rationalization as simple and to the point: “Rationalization must increase efficiency, and at the same time increase the purchasing power in the hands of workers who buy the goods produced by rationalized plants”. Labour was willing to cooperate as long as it had a hand in all studies on rationalization and was satisfied that workers would share in the gains they brought about, as in the case of the reduction of working hours.Footnote 88 Moreover, the gains had to do with time and money, the twin sources of major struggles within capitalist production relations, as opposed to the physiological and spiritual elements of the Arbeitsfreude. In 1931, Leipart put the matter succinctly:

Keeping up this speed (of rationalization) would deplete public health if reducing working hours does not create the necessary balance. Neither flowers in the windows nor lawns between the factory buildings, nor joint swimming exercises, nor the idea of a shop-floor community [Werksgemeinschaft] will sustain the worker for the factory and his labour; but adequate wages for his physical and sufficient leisure for his spiritual needs will. Because the worker feels like a human being not during but only after his work is done.Footnote 89

Expelled from Nazi Germany, our quartet of German experts had left an industrial context where a strong labour movement was able to wrestle with terms and benefits of rationalization, but were confronted with a completely different context waiting for them at their destination. They now found themselves in an authoritarian state which had just launched an ambitious programme of industrialization but with neither the highly skilled craft-based workforce nor the labour movement they expected.

RATIONALIZING THE TECHNICAL AND BUREAUCRATIC ORGANIZATION OF PRODUCTION

By the early 1930s, Germany stood out for its rapid progress in production simplification and standardization,Footnote 90 the two themes most often repeated by German experts. To the German experts the problem of productivity in Turkish industry appears to have been first and foremost a technical one. They thoroughly covered the reasons and solutions for “technological idiosyncrasies” of the production process,Footnote 91 giving detailed information on the state of machinery and the appropriate technological investment needed. Their reports strongly advocate production standardization, along with rationalized accounting and management of wastage. Comparisons favouring German factories were made to illustrate the extent of the insufficiency in Turkey of factory-level specialization and product standardization.

Problems with machinery appeared to be of two kinds. On the one hand, there might be lack of investment in new machines or inadequate maintenance; on the other hand, there might be inefficient use of existing machinery. The old imperial factories suffered from ageing machinery, with Von der Porten for example complaining in a 1936 report about the lack of care for the old looms at the Bakırköy Factory, where he found that of a total of 340 looms, sixty needed immediate replacement. However, from a later state inspection report we learn that those same looms were still in use in 1940, when the worn-out machinery at the Bakırköy Factory was unfavourably compared with that in three newly built cotton factories.Footnote 92 The source of the machinery in Turkish factories also changed during the 1930s. For example, a German visitor to the Beykoz shoe factory in 1917 wrote that the factory had modern installations and was equipped throughout with German machinery.Footnote 93 However, the Soviet loan of 1934 was used to buy new machinery for the sugar and textile factories, which were built in the 1930s and included the three factories that performed better than the Bakırköy Factory. In a 1939 report, Von der Porten criticized the factory investment projects for relying on the latest technology in the face of skill shortage.Footnote 94 For according to the German experts, the solution lay not in technological investments but in control and training of the workers, as exemplified by Bauer's 1934 report on the spindles in the Bakırköy Cloth Factory. Focusing on problems of cleaning, maintenance, and ventilation in the workshops and their effects on the quality of yarn, Bauer made simple suggestions to eliminate production stoppages resulting from technical failure, such as placing a signboard with instructions on the machines for the foremen to follow when changing the bobbins. Bauer argued that technical reorganization could be no more than a partial solution, for the real answer to a variety of problems causing interruption of production and low yarn quality lay in the establishment of a control mechanism to compare the productivity of each machine and worker.

The matter of labour supervision came up in relation to industrial waste management and bookkeeping too. Sachsenberg criticized workshop managers for their lack of interest in reducing waste and with it the much complained of general overhead costs. The large amount of waste in the Bakırköy cotton mill, he wrote, remained unaddressed mainly because of accounting errors, the elimination of which he identified as the first step towards general organization of production: “It allows you to calculate the actual cost of your product and lays the basis for the second step on the organization. This second step is rationalization, that is, the totality of all the measures taken to reduce the cost”.Footnote 95 Bauer made detailed comparisons between the operational and labour costs of German factories with those of the Bakırköy and Beykoz factories, and although he found that the labour costs were considerably lower in Turkey, the general overhead costs differed greatly due to a combination of accounting mistakes and lack of effort.Footnote 96

It is obvious from the reports that the operation of Turkish state factories in the 1930s was squeezed between the rock of centralized planning and the hard place of the shop floor. “Turkish planning was a hit-or-miss affair”, wrote A.H. Hanson at the end of the 1950s; there was a considerable gap between formal planning and practical execution.Footnote 97 Accordingly, problems in decision-making and implementation were given extensive coverage in the reports by the German experts, who all reiterated the need to streamline national economic development and central planning on the one side, and execution and inspection on the other. The reports also hint at a chasm between the official definition and actual practice of central planning and management during those formative years of Turkish etatism, thereby validating our analysis of planning and centralization as open-ended processes rather than top-down implementation. This analysis could thus be read as a corrective to the tendency of historians to mistake management objectives for what actually happened inside workplaces.Footnote 98 The blueprints of the plan – as they were presented in the laws on state enterprises, parliamentary discussions, and other official documents – existed perhaps somewhat uneasily somewhere between the decision-making processes and everyday practices. As such, the reports perfectly exemplify the “piecemeal, uncoordinated and empiricist” character of much management policymaking and execution, and reveal the contentions and conflicts within central planning.Footnote 99

RATIONALIZING THE LABOUR PROCESS AND ITS REMUNERATION

The redesign of the labour process along rational lines and remuneration for that labour were the other matters that the German engineers wrote about extensively. Von der Porten pointed out again and again that labour is the largest component of production costs, so that any effort to reduce production costs must begin with labour management.Footnote 100 The German experts had two main solutions to the problem, namely vocational training and the piece-work system. However, in terms of the availability of skilled workers, the German and Turkish industrial contexts were worlds apart. While deskilling due to rationalization was the main concern for the labour movement in Germany, the Turkish situation was characterized from the very beginning by a severe lack of skilled workers, partly as the result of the political exigencies of nation-building after World War I. During the first two decades of the twentieth century, much of the Ottoman industrial labour force was removed by deportation and emigration. As late as 1915 Turkish workers made up only fifteen per cent of the industrial workforce,Footnote 101 although that proportion did increase. Finally, the 1923 population exchange with Greece led not only to the loss of an important source of cheap labour but to the loss of artisanal skills too, especially in urban areas.Footnote 102 The “deep sickness” of skill shortage was so acute, wrote Von der Porten, that it stood in the way of almost every attempt to streamline and rationalize the production process. At the Feshane, Hereke, and Bakırköy factories, for example, workers had only extremely superficial knowledge of the spinning, weaving, and finishing that was done there.

It is worth noting that the problem was defined as a lack of skill rather than any kind of cultural unsuitability. Most other European industrialists tended to explain low productivity in non-European settings by reference to cultural factors such as lax discipline, and general laziness and dilatoriness. British colonial observers, for example, attributed practices of shared work and excess employment in Bengal jute mills to the prevalence of the workers’ premodern habits.Footnote 103 However, such negative cultural readings are strikingly absent from the German experts’ Turkish reports, and there is no mention of the “soldiering on the job” which, according to Fredrick Taylor, was the greatest – indeed almost universal – phenomenon impeding higher productivity. On the contrary, the German experts praised Turkish workers, with Mundorf for example stating quite clearly that the problem of low productivity was nothing to do with any inability on the part of the workers. “The worker of this country is diligent, dexterous, and hardworking”, he wrote, but “he should be given jobs appropriate for his skills and qualifications”, and receive “systematic and scientific training”.

Von der Porten went even further in complimenting the Turkish worker:

It should be considered by no means fulsome praise if I report that the workers I have so far seen in Turkish factories are no less intelligent than Germans; if anything they are cleverer. But their cleverness comes with less patience. A German worker might have more difficulty learning a task, but he uses his greater persistence to improve his skill. The Turk learns quicker; but as soon as he has mastered it he wants to be away to a different department, or to operate a different machine.Footnote 104

Obviously, these men were not colonial observers. In fact, they were quite the opposite, for they had been employed by the Turks to report on their state factories, which were the source of so much national pride. In that light then, the German experts’ tendency to refrain from making condescending remarks is perhaps only to be expected. The Germans even used inclusive language, referring to “our economy […] our peasant […] our country”.Footnote 105 But there was perhaps more behind such words of praise than a diplomatic wish to please a demanding employer; perhaps the German engineers were keen in turn to convince the Turkish bureaucrats of the importance of the vocational training which was an important element in Rationalisierung.

The notes of a conversation between Bauer and the Director of the Bakırköy Factory, Fazıl Turga, nicely illustrate the gap between the theories of the central planners and the realities of the men on the shop floor. The two engineers talked enthusiastically about the importance to productivity of well-trained workers. Here, it is interesting to speculate whether during his talk with the factory director Bauer mentioned anything about the German debates. Or, perhaps Turga was already following them, for, after all, he had studied at the Textilfachschule in Brünn during World War I.Footnote 106 Unfortunately for us, the reports are silent on such social transactions and Bauer's own notes end with a reference to a promise he made to Turga to provide further information on vocational training. That information supplied by Bauer would then need to be adapted to the conditions of the shop floor by means of psychotechnical devices to measure the intelligence and dexterity of the workers,Footnote 107 but, unfortunately, again, the archive did not allow us to follow up on the two men's conversation. All we do know is that Bauer's and Turga's optimistic plans did not materialize, at least not before the end of the war, as we can infer from the Minister of Labour's complaints in 1946 about the lack of psychotechnical studies in Turkish industry.Footnote 108

For the most part, before World War I, German workers acquired skills by serving apprenticeships in small and technologically backward shops and firms known as Handwerk. By the mid-1920s engineers, vocational educators, and industrialists were increasingly criticizing the system for its inadequacy in addressing the changing needs of the industry. Despite the labour movement's concern at deskilling, the prevalent belief was still that skilled workers would remain pivotal even under rationalization, so that there was widespread fear of an impending shortage of skilled workers.Footnote 109 Despite that, however, agreement on the need to upgrade technical education stopped short of delineating its scope. In the textile industry, for example, the existence of a large pool of unemployed skilled workers prompted a shift of interest to specialized training.

Mundorf's advice to prioritize the training of foremen and assistant foremen by sending them to evening classes reflects the increasing popularity in Germany of specialized worker training. Von der Porten agreed with the point about specialization, but considered the training of the rank-and-file much more urgent. He therefore criticized plans for a polytechnic-style textile school in Istanbul, arguing that such an institution could never supersede factory schools for it would take at least three or four years before workers actually began learning the job in practice. Instead of people with a broad range of knowledge, the textile industry needed specialists, and factory schools, said Von der Porten, were the best institutions to train them.Footnote 110 However, it seems Turkish bureaucrats were unconvinced, for the polytechnic school was opened the following year according to plan. Ironically, barely twenty years later, a Turkish engineer criticized it for lagging behind the development of the Turkish textile industry, with only fifteen graduates a year.Footnote 111

What Von der Porten meant by “factory schools” was the type of apprentice school affiliated to almost every large factory in Germany. Such schools combined rigorous training in working techniques with “far-reaching propaganda campaigns designed to attach the younger generation to the interests of the respective companies”.Footnote 112 It was from such schools that companies recruited skilled workers and sometimes even supervisory and executive staff. Having the control over the training of apprentices had political motivations too since skilled workers were central to the workers’ movement.Footnote 113 In the Turkish context of course that was of no concern, for an entirely different impediment stood in the way of Turkish workers’ acquisition of skills. During his later visits to Anatolian factories, Von der Porten learned that workers’ continuing rural ties tended to undermine their motivation to undergo training. Von der Porten later concluded that what was causing the high rate of labour turnover in the factories was not “the lack of training […]” but, “[…] difficulty of changing the centuries old habits… training people who had been doing agriculture until now, as industrial workers”.Footnote 114

At first glance, Von der Porten's words might appear to have a colonial tone. But there are two important nuances here. The first is that Turkish industrial experts too referred to workers’ continuing rural ties as the main reason for the unstable and low-skilled labour force. In fact, the point was made so often that in a report from 1950 on labour turnover, a Turkish expert disputed it by referring to other factors such as workers’ distaste for repetitious, monotonous jobs and being confined indoors all day.Footnote 115 The second nuance separating Von der Porten's observation and “colonialist” remarks concerns the workers’ capacity for actual labour. Consider the following example from Britain: the 1890 Factory Commission on Indian Factories reported that “The Indian factory worker is, in general, incapable of prolonged and intense effort; he may work hard for a comparatively short period, but even in such cases the standard attained is much below what would be expected, in similar circumstances, in any European country.”Footnote 116 By contrast, German experts approvingly observed that while on the shop floor, the Turkish workers worked well. The problem seemed to be finding the right method and incentives for vocational training.

At the Feshane Factory vocational training was raised in relation to the most obvious incentive: wages. Von der Porten advised the Turks to start a factory school where foreign textile technicians would teach young workers how to maintain and repair the machinery. Stoppages due to technical problems were quite common at all the factories and, quite naturally, adversely affected the morale of piece-rate workers. Von der Porten pointed out that workers who could keep their own machines running would not be dependent on technicians, which, in turn, meant they would be encouraged to work harder thanks to the wage incentive. Another important point concerned the training of apprentices, whom Von der Porten said should receive training commensurate with their abilities. After spending three months in the various departments of the cotton mill, those successful would receive training at the factory school for another six months during which they would be paid low wages. The same training should be open to older workers too who might wish to become foremen, although again the priority should be the training of the rank and file. The investment made in the factory school would pay off when the graduates were employed full time at Feshane for they would increase its productivity. Furthermore, the factory school could train apprentices for other factories. Von der Porten claimed that within three years home-grown Turkish experts would replace foreign teachers.Footnote 117

Vocational training attracted increasing attention in both public debates and bureaucratic circles. A pro-government newspaper made clear the connection between the presence of the foreign experts and the training of workers. “The most perfect engineer cannot be successful without experienced and skilled workers. We do not benefit enough from the European experts for whose services we spend a considerable amount because we do not have enough employees who can implement the programmes they devise.”Footnote 118 In 1938, the Turkish Parliament decided to set up occupational courses in industrial enterprise and mining,Footnote 119 while the Supreme Audit Board reports from 1939 recommended further improvements and wider implementation in order to keep the trained workers at the factories.Footnote 120 All the same, despite repeated warnings and efforts at piecemeal solutions, the problem persisted until the 1950s.

PIECE RATES AND GENDER STEREOTYPING

When piecework was implemented in large German enterprises in the 1920s, the labour movement's reaction was strong: “Akkord ist Mord!”Footnote 121 However, the German experts had no need to worry about such “problems” in Turkey, an industrial context where state repression prevented collective action. Indeed, even before German experts began to visit Turkish factories, piece-rate systems had already been implemented to some extent, even if there were many problems along the way. I have written elsewhere about sporadic individual objections lodged during the second half of the 1940s to incentivized wages.Footnote 122 In many respects, however, the 1930s were light years away from the postwar period. In 1936, Von der Porten wrote: “Piece rate is a better wage system for a mechanized factory like Bakırköy, where the labour movement has little effect, and hard work and attention are of the utmost importance for productivity”. Other than that remark, Von der Porten made no mention of even the possibility that workers might have any significant reaction to the imposition of piece rates. The lengthy sections in the reports on piece-rate systems are either evaluations of existing implementation methods or recommendations for expanding their scope.

One of the very few positive remarks about the existing piece-rate practices in the reports concerned the carding department at the Feshane Factory. There, the rate was determined not on the basis of the weight of carded wool but the weight of the yarn spun from it, a piece-rate application Von der Porten praised for its value as a quality control mechanism. At the Feshane and Hereke factories, he wrote, “[piece rate] was implemented everywhere possible” – except for in the sorting department for fear it would result in bad cotton becoming mixed up with good. That risk could be avoided without increasing the labour cost, he claimed, simply by using savings from poorly performing sorters to pay for quality controllers. Under such a system all workers would work on piece rates, labour costs would stay the same, and sorted wool would undergo quality checks twice. The productivity-piece-rate connection was therefore twofold, as piece-rate working would increase the production incentive while simultaneously improving shop-floor control. It might even eliminate the need for managerial supervision, as it had with wool sorters.

However, such cases of carefully determined and implemented piece-rate schemes were rare, while examples of faulty calculations and inconsistencies in the implementation of piece rates abound in the reports. In his explanation of the ten per cent difference between planned and actual labour costs in Bakırköy in 1937, Sachsenberg cites among other reasons mistakes in the determination of wage norms. Bakırköy's weaving shop operated under “best-practice” rules, with workers paid according to the number of shuttles they made instead of the weight or length of the fabric weaved, for that would have led to unfairly higher wages to those weaving coarser yarn or wider wefts. Best practice in the spinning shop, however, was an entirely different matter, and both Sachsenberg and Von der Porten were surprised by the situation they found there. “They think they are implementing piece rates”, wrote Von der Porten, “by paying the male and female workers according to the hank they produce”. He compared the counters attached to the machines to a goods-vehicle tachometer. Just as the tachometer counting the rotations of the wheels could not indicate the weight of cargo transported, a counter counting the rotation of the spindles could not indicate the amount of yarn spun. Not only that, the counters continued to rotate even when the yarn was broken, leaving the spindles running idle, a recurrent problem. Sachsenberg reported the same problem both with spinning machines and drawing frames a year later. All the same, it appears that Von der Porten's warning was not taken seriously. During his visit, Von der Porten's critical eye observed experiments with different pay systems and noted an incident that hints at the intricacies of the decision-making process in centrally planned production. A shop-floor engineer objected to Von der Porten's suggestion that workers be paid for the yarn they spun rather than the rotations of the spindles. The engineer claimed that the quality of spun yarn would be adversely affected. Von der Porten noted that after extended discussions the Director of the Sümerbank's Istanbul Office, Muhip Bey, intervened on behalf of the factory engineer and insisted that the then-current practice was wholly fair and accurate.

Factory inspection reports from later years also point to the slow and problematic implementation of piece-rate payment in spinning compared to weaving shops. In 1939, for example, of the 7,789 workers at four cotton textile factories (Nazilli, Kayseri, Ereğli, and Bakırköy), 4,303 were paid piece rates and worked mostly in spinning, weaving preparation, and weaving shops.Footnote 123 In 1943, of the 869 workers in the Bakırköy weaving shop, 583 were paid piece rates.Footnote 124 Von der Porten noted in 1939 that some spinners at the Kayseri Factory were being paid hourly wages, whereas all the weavers were paid piece rates. The insistence in the state inspection reports on the need to pay all workers piece rates continued into the 1940s, and the replies to those reports by Sümerbank indicate slow but steady progress in that direction.

Besides giving detailed information on such strikingly different shop-floor practices, the comparison between the labour processes in spinning and weaving shops suggests gendered processes of skill valorization and labour remuneration. Ethnic and gender stereotyping of jobs was quite common in German debates on productivity, although most ethnic examples concerned the workforce in the US, for it was gender stereotyping that had wider resonance with the German workforce. Nolan argues that the following quotation from a prominent trade unionist reflected the belief of nearly every industrial commentator: “[it was] the apparently unintelligent, female, and young workers who were especially suited for flow and assembly line work”.Footnote 125 Von der Porten's comparison of spinning and weaving offers a glimpse into how such stereotyping worked on the Turkish shop floor. He wrote that spinning is much easier than operating weaving looms; in fact, it was so easy that virtually anybody could master it. More to the point, if spinning were to be mechanized, as in the Kayseri Factory that Von der Porten was visiting at the time, all preparation work would be done automatically, which would leave no room for mistakes. The only skill needed would then be to tie the ends of the broken yarn as quickly as possible and with the minimum loss of material. Apart from that the productivity of the spinning workshop depended on the availability and quality of raw material, the quality of the spinning machines, the spindle gauge, and the technical knowledge of the managing engineer. Nolan's point on gender stereotyping is echoed in Von der Porten's conclusion that since the task required no intellect, women – or better still, girls – should be employed in the spinning shop. By contrast, both the quality of cloth and productivity depended on the weaver's skill: “There are factories [in Germany] where a weaver attends sixteen looms; we would be happy if a weaver attended eight looms because today, on average, a weaver attends only six. Both the volume and quality of production at every stage of weaving depends on the weaver”. Unsurprisingly, therefore, weaving in Turkish textile factories was almost exclusively a job for men.

THE ENGINEER AS ECONOMIST

With a threefold increase between 1924 and 1930, unemployment in all the rationalizing German industries was “a reality for an unprecedented number of workers and a threat to all”. While industry blamed trade union wage policy and depressed market conditions for the plight of the more than three million unemployed Germans in 1930, trade unionists and later historians pointed to rationalization as the main cause of the temporary displacement of workers as well as the high levels of new and long-term unemployment.Footnote 126 By direct contrast, Turkish state factories were celebrated as places of secure employment. Always in need of labourers, especially skilled ones, they had a fairly loose recruitment policy. Dismissals were quite rare and even workers who disappeared without notice were re-recruited. Moreover, managers pursued a strategy of labour hoarding to overcome the scarcity of labour due to fluctuations in demand. To Von der Porten, that was one of the main problems. He opened his report on the Beykoz Factory with a question: “How could we save on the pay of workers and clerks?” The answer was a rational work plan which in the leather workshop, for example, could reduce the workforce by half. The low productivity of the same workshop caught Sachsenberg's attention too. His comparison of the times taken to tan a kilogram of leather in Germany and Turkey was striking at twelve and thirty-seven minutes, respectively. Even more striking was the closeness of wages per kilogram of leather at 9 piasters and 9.9 piasters. Despite those numbers, the productivity gap caused a wide discrepancy between German and Turkish piece-rate wages, even taking into account the considerably longer working hours at Beykoz.

Another possible way to save labour costs was to reduce the size of the workforce. But which workers should be dismissed? Factory gates seemed to be wide open to skilled labour since Von der Porten had recommended incentive wage payments to attract skilled workers from private factories. From that point, Von der Porten's report takes an interesting turn and gives a vivid description of the labour process. Von der Porten observed that workers lost a few seconds every time they got up to collect a new pair of shoes from a nearby workstation before returning to their own. The managerial response was that such time loss had a negligible effect, but Von der Porten objected that, “My experience in the German factories gave quite different results […] no matter how short they are, these kinds of interruption in the workflow have detrimental effects”. He then asked the engineer on the shop floor, Mr Faruk, to calculate the possible increase in production if workers no longer needed to leave their places to fetch work. The calculation confirmed Von der Porten's suspicions: productivity would increase by ten per cent if workers could remain in their places.

Mr Faruk's corroboration was scarcely the end of the debate, however. Indeed, the story takes an even more interesting turn with the appearance on the shop floor of a rather unexpected figure, a foreman by the name of Roček – or “Roçek” as it was phonetically written in Turkish. Most probably a Czech, Roček had been sent from one of the Bata shoe factories in Europe to Beykoz – before the German occupation of Czechoslovakia, Jewish employees of Bata had been sent to various European branches of the company, which might explain Roček's presence in Beykoz. Whatever the reason for his presence, on observing the same problem Roček had his own solution to offer. As the largest boot and shoe business in Europe, the extraordinary growth of the Bata Company had been so much in the spotlight during the 1920s that in 1930 the International Labour Office undertook an investigation of why Bata was doing so well. The resulting report explained as follows the specificity of the shoe industry and the secret to Bata's productivity:

[H]and work is still far from being eliminated in boot and shoe factories. No machine yet invented can carry out an operation automatically as is the case in the textile and engineering industries; consequently, there is a vast field open to rationalisation. A small alteration in an existing machine, or the introduction of a new one, by reducing labour charges may sometimes substantially lower production costs. In this domain Bata has spared no effort, and it is largely to the technical progress that he has been able to achieve that the lowering of his production costs must be ascribed.Footnote 127

An important step in that technical progress was the introduction of the conveyor belt in 1923.Footnote 128 The Czech foreman had proposed an overhead conveyor belt with baskets hanging from it to carry shoes from one workstation to the next. “The Bata foreman”, wrote Von der Porten, “probably thought of the mechanical transportation belt in the Bata factory” and continued “I oppose this for two reasons”. The first reason concerned the specificity of the Beykoz Factory: “I am in complete agreement with the operation engineer: The use of engine power in shoe factories is profitable when machines are grouped together in order to economize on operational costs”. Fluctuations in demand made it impossible to have stable machine groups at Beykoz. Although the mechanical transport belt made perfect sense in the Bata Factory, to invest in mechanization at a factory like Beykoz, where production costs were already quite high, would not be rational. In explaining his second objection, Von der Porten revealed the main principle of the rational organization of labour process, which is that work should drive the worker, and not the other way round. The suggested belt would make each worker dependent on the previous one, in effect meaning that the “faster” worker would have to wait for “the lazy or unskilful worker”, with the latter determining the speed of the entire system.

Von der Porten's alternative to investing in mechanical labour was to use a specific kind of human labour:

Instead of [the conveyor], and in agreement with the management, I advise using a few children for this task. These children would bring the shoes to the workstations, thus enabling the worker to work without even the shortest interruption. This would mean not only a ten per cent increase in productivity, but also the opportunity to save electricity costs of [the conveyor].

Protective legislation against child labour in industry was first enacted in Prussia in 1839, and subsequent legislation banned the use of child labour in industry until Nazi decrees in 1938 practically abolished most of the protective measures. However, labour legislation in Turkey was considerably less protective of children in industrial employment. When Alexander Giesen, the editor of Frankfurter Zeitung, visited the Feshane Factory in 1917, he observed sadly the extensive employment of children and hoped their presence was merely a temporary necessity during the war.Footnote 129 But his hope did not materialize fully. The Law on Public Hygiene in 1930 set a minimum age for children in industrial work at twelve years; the Labour Law of 1936 came under increasing criticism in the 1940s for not raising it.Footnote 130 Under conditions of rapid industrialization therefore and in the absence of protective legislation, children were the cheapest reserve of labour and even as recently as the early 1950s made up more than twenty per cent of the industrial workforce.Footnote 131 According to Von der Porten's calculations, the recruitment of six children to transport material would cost barely more than the wage of one adult worker, while the proposed new system would make ten workers redundant.