Introduction

Rice (Oryza spp.) is the staple food of more than half of the world’s population. Most of the rice cultivated in sub-Saharan Africa (SSA) is produced by low-resource smallholder farmers in rainfed lowland and upland environments (Saito et al., Reference Saito, Nelson, Zwart, Niang, Sow, Yoshida, Wopereis, Wopereis, Johnson, Ahmadi, Tollens and Jalloh2013). Rainfed lowland rice is cultivated on level to slightly sloping fields, whether bunded or unbunded, situated in the lower sections of the toposequence, while rainfed upland rice is grown on level or sloping fields, typically unbunded, without water accumulation throughout the crop cycle in hilly regions characterised by undulating landscapes and low groundwater tables (Niang et al., Reference Niang, Becker, Ewert, Dieng, Gaiser, Tanaka, Senthilkumar, Rodenburg, Johnson, Akakpo, Segda, Gbakatchetche, Jaiteh, Bam, Dogbe, Keita, Kamissoko, Mossi, Bakare, Cissé, Baggie, Ablede and Saito2017); both rely only on rainfall. Madagascar is the second largest producer of rice in SSA, after Nigeria, with 1.3 million hectares cultivated by more than 2 million farmers, most of whom are smallholders (<2 ha landholding) accounting for 60% of the arable land (MinAgri, 2015). More than one third of the rice in the country is produced in the central highlands; however, access to irrigated fields is becoming increasingly limited, leading to expansion of rice into uplands. Rice yields are generally low – averaging around 2.7 t ha–1 across all rice-growing environments (MAEP, 2019), and much lower in the rainfed uplands (1.8–2.7 t ha–1) than the irrigated lowlands (3.9–4.3 t ha–1) (Senthilkumar et al., Reference Senthilkumar, Rodenburg, Dieng, Vandamme, Sillo, Johnson, Rajaona, Ramarolahy, Gasore, Abera, Kajiru, Mghase, Lamo, Rabeson and Saito2020; Tanaka et al., Reference Tanaka, Johnson, Senthilkumar, Akakpo, Segda, Yameogo, Bassoro, Lamare, Allarangaye, Gbakatchetche, Bayuh, Jaiteh, Bam, Dogbe, Sékou, Rabeson, Rakotoarisoa, Kamissoko, Mossi, Bakare, Mabone, Gasore, Baggie, Kajiru, Mghase, Ablede, Nanfumba and Saito2017). Under rainfed conditions, the prevailing weather conditions such as temperature and rainfall significantly influence the growth and yield of rice production (Pheakdey et al., Reference Pheakdey, Xuan and Khanh2017). Temperature fluctuations can impact the physiological processes of the rice plant. The amount and distribution of rainfall determine water availability, which is crucial for crop yield in rainfed systems (Korres et al., Reference Korres, Norsworthy, Burgos and Oosterhuis2017).

Mechanisation options increase agricultural productivity mainly by improving labour productivity (Rodenburg et al., Reference Rodenburg, Saito, Irakiza, Makokha, Onyuka and Senthilkumar2015). Three levels of mechanisation can be distinguished according to their power sources: human, animal, and mechanical (MMP, 2018). However, limited progress has been made on mechanisation options, especially in SSA which has the world’s lowest level of agricultural mechanisation – 65% of farm power is provided by human muscles without the support of animals or machinery (Sims and Kienzle, Reference Sims and Kienzle2016, Reference Sims and Kienzle2017). In addition, mechanisation enables farmers to achieve tasks that are difficult without such aid. Meanwhile, subsistence smallholder farming systems dominate in SSA, producing more than 50% of the food (Herrero et al., Reference Herrero, Thornton, Power, Bogard, Remans, Fritz, Gerber, Nelson, See, Waha, Watson, West, Samberg, van de Steeg, Stephenson, van Wijk and Havlík2017; Kienzle and Sims, Reference Kienzle and Sims2014; Maass Wolfenson, Reference Maass Wolfenson2013). Smallholders’ fields are mostly small and dispersed, with irregular shape and thus unsuitable for large machines (Harman, Reference Harman2016; Krupnik et al., Reference Krupnik, Shennan and Rodenburg2012; Maass Wolfenson, Reference Maass Wolfenson2013). Such are most of the fields of Malagasy rice farmers, whose financial resources are limited; so, most farm activities such as land preparation, sowing, weeding, and harvesting are carried out manually, which is labour-intensive and time-consuming.

The labour cost for sowing accounts for 9% of the total seasonal labour cost in rice cultivation (Mujawamariya and Kalema, Reference Mujawamariya and Kalema2017). In rainfed lowlands and uplands, rice is dibbled manually. In the distribution of tasks in agriculture, hand sowing is mainly done by women and consists of bending over to plant the seeds. Such work can cause back pain in addition to the drudgery in carrying out this work (Nag and Nag, Reference Nag and Nag2004; Vanderwal et al., Reference Vanderwal, Rautiainen, Kuye, Peek-Asa, Cook, Ramirez, Culp and Donham2011). Small-scale mechanisation options such as mechanical seeders, if available, will improve the working conditions for labourers and, moreover, both men and women could undertake such operations. During the peak labour demand periods, the labour scarcity delays coverage of land area with manual sowing whereas mechanised sowing can optimise labour usage. Many studies have shown the yield penalty incurred by delayed sowing under rainfed rice production (Tiwari et al., Reference Tiwari, Tiwari, Tiwari and Yadav2018), especially in high altitude areas where cold temperatures adversely affect rice yields (Abera et al., Reference Abera, Stuerz, Senthilkumar, Cotter, Rajaona and Asch2020). This can be as high as 1% reduction of yield per day of delay in planting for many crops (Baudron et al., Reference Baudron, Sims, Justice, Kahan, Rose, Mkomwa, Kaumbutho, Sariah, Nazare, Moges and Gérard2015; Singh, Reference Singh2006). In Madagascar, research conducted by Shrestha et al. (Reference Shrestha, Asch, Dusserre, Ramanantsoanirina and Brueck2012) revealed an average reduction in rice yield of up to 48% when sowing was delayed by one month in high altitude areas. Having access to the right machinery and equipment at the right time can help manage farm inputs effectively and improve productivity (Ayodele, Reference Ayodele2012). Srivastava et al. (Reference Srivastava, Goering, Rohrbach and Buckmaster2013) state that completion of certain agricultural operations such as timely planting increases yields and improves profitability. Thus, development of appropriate small-scale mechanisation options for sowing would be a cost-effective alternative for smallholder farmers to improve labour use efficiency, sow seeds accurately, compensate for seasonal labour shortages, reduce drudgery of farmers during sowing and, most importantly, increase rice productivity.

Micro-dosing of fertilizers, mainly phosphorus (P), together with seeds in planting holes increases rice productivity in East African direct-sown conditions, especially in Madagascan uplands (De Bauw et al., Reference De Bauw, Smolders, Verbeeck, Senthilkumar, Houben and Vandamme2021; Vandamme et al., Reference Vandamme, Ahouanton, Mwakasege, Mujuni, Mujawamariya, Kamanda, Senthilkumar and Saito2018). One of the main agricultural constraints in the highlands of Madagascar is the low fertility of ferralitic soils due to P deficiency. Limited use of fertilizers because of their high cost poses a significant obstacle for farmers. Efficient P fertilizer management to improve P availability and crop production while lowering fertilizer costs could be a solution. Adopting the micro-dosing technique increased productivity in areas where high costs posed a challenge for small-scale farmers to use fertilizers (Ibrahim et al., Reference Ibrahim, Abaidoo, Fatondji and Opoku2015). However, manual micro-dosing is very laborious and time-consuming, especially when sowing and micro-dosing are carried out in separate operations (Vandamme et al., Reference Vandamme, Ahouanton, Mwakasege, Mujuni, Mujawamariya, Kamanda, Senthilkumar and Saito2018). Thus, using appropriate small-scale machines for simultaneous seed sowing and fertilizer application could further increase the labour use efficiency and land productivity of farmers who direct sow rice.

In this study, appropriate small-scale mechanisation options refer to affordable, portable, user-friendly seeders (equipment for dibbling seeds), and fertiseeders (equipment for simultaneous dibbling of seeds and fertilizer) adapted for smallholder fields and local agronomic circumstances (Mottaleb et al., Reference Mottaleb, Krupnik and Erenstein2016; Van Loon et al., Reference Van Loon, Speratti and Govaerts2018). Such mechanical seeders and fertiseeder should be easily fabricated, can be locally repaired and spare parts can be made by local blacksmiths.

This study aimed to (i) compare the effectiveness and time requirements of seeders and fertiseeder for sowing or sowing plus di-ammonium phosphate (DAP) application with manual sowing or manual sowing plus DAP; (ii) determine farmers’ preferences and feedback on the different types of seeders and fertiseeder tested through a farmer participatory approach; and (iii) evaluate the economic cost of different mechanical and manual sowing methods. The study was conducted for two consecutive rice-growing seasons with participatory on-farm testing. Information obtained from farmers during the first season was used to further improve the implements for the second season testing.

Materials and methods

Study area

The on-farm participatory testing was conducted for two consecutive rice-growing seasons in November 2018 to May 2019 (season 1) and December 2019 to May 2020 (season 2) in rainfed rice-growing environments in four villages per season in the central highlands of Madagascar. The four villages were: Ampahitra (19°51′26.57″S; 47°00′47.47″E), Belanitra (19°43′26.98″S; 46°36′20.39″E), Ankazomiriotra I (19°39′59″S; 46°32′16.3″E), and Mahitsy (18°45′ 8.74″S; 47°20′32.92″E) in season 1 and Ampahitra, Belanitra, Ankazomiriotra I, and Ankazomiriotra II (19°39′38.13″S, 46°32′46.96″E) in season 2. The altitude ranged between 1064 and 1501 masl. The average annual temperature ranges from 13.9 to 26.4°C with an annual rainfall of 1084 to 1381 mm. The predominant soil type is ferralsol.

Seeder and fertiseeder description

The technical characteristics and technical drawings of the tested seeders and fertiseeders are presented in Table 1. In season 1, three single-row seeders were tested: ‘CFFAMMA seeder’ from Centre de Fabrication de Formation et d’Application du Machinisme et de la Mécanisation Agricole (CFFAMMA), Madagascar; a ‘New seeder’, a newly designed seeder; and a ‘single row fertiseeder’, a new design that places a micro-dose of fertilizer together with seeds in the planting hole. There are two drums side-by-side holding seeds and fertilizers separately in the fertiseeder. All these machines were manufactured by CFFAMMA. Two additional seeders, named African and Brazilian seeders, were tested; however, they are not included in this analysis as they were used for only one season. Based on farmers’ suggestions from testing in the first season, the fertiseeder (Fertiseeder 1) was improved (Fertiseeder 2). The improvements were: (1) making the seed and fertilizer tanks transparent so that the user can see the quantity of seeds and fertilizers inside; (2) making the fertiseeder lighter by fabricating it using lightweight material, especially because women farmers expressed the need for a seeder that is not too heavy for them to handle; (3) addition of a system to cover seed with soil; and (4) attachment of a tracer for fixing line/row spacing. Two seeders (CFFAMMA seeder, New seeder) were again tested along with the improved fertiseeder in season 2. Additional technical details of these five seeders and fertiseeder are available (AfricaRice, nd).

Table 1. Technical characteristics and technical drawings of the seeders and fertiseeders used in on-farm experiments in central highlands of Madagascar

On-farm experiments

Demonstration and testing in farmers’ fields compared seeders and fertiseeder with manual sowing. In both seasons, four on-farm experimental fields were used, treating each field as a replication and testing the same treatments on homogeneous soils. The average field size was 700 m2, and the size of each treatment plot was 100 m². Between- and within-row spacings for all treatments were set at 20 cm.

Each seeder/fertiseeder operated by one adult male was used to sow a plot. Two manual sowing plots, one with and one without micro-dose DAP application, were set up as reference treatments. In each planting hole, 5–8 seeds were dibbled. For manual sowing + DAP micro-dose, seeds were placed in the planting hole together with the fertilizer. The number of DAP granules dropped per planting hole was two large (4–5 mm in size) or three small granules (2–3 mm in size). For manual sowing plots, two adult females and one adult male performed the sowing during the testing. The sowing time required to cover each treatment plot was recorded. A seventh plot was used as a test plot for all participating farmers to become familiar with the seeders before using them in the designated main treatment plots. Different rice varieties were selected according to farmers’ preferences and to test the seeders’ compatibility with different grain sizes (Table S1). For land preparation, each field was tilled by hand ploughing followed by levelling using a hand hoe by male labour. No additional fertilizer was applied in any of the treatments during the cropping season. Other agronomic practices, such as weeding and pest management, followed farmers’ normal practices.

Farmer participatory testing of seeders and fertiseeders

In each location, the participating farmers from nearby villages were assembled. From four villages, a total of 222 participants for season 1 and 91 participants for season 2 tested each seeder and fertiseeder on one or two rows of the field at the beginning of the cropping season. Overall, 58% were women and 42% were men, with 55% being youth under 35 years of age (56% female, 44% male). At the sowing time, immediately after testing the seeders, farmers’ feedback on the seeders and fertiseeder was collected through a mixed methods approach combining individual interviews using a structured and systematic questionnaire and qualitative enquiries. The main questions asked were on (1) the method of crop establishment for rainfed rice cultivation in general and the associated costs; (2) their willingness to use the seeder in future and why; (3) the rating and preferences given for each seeder and fertiseeder by the farmer; and (4) the price that each farmer was willing to pay for each seeder. The cost price of the seeders was not communicated to the farmers to avoid biasing their responses.

Data collection and analysis

Weather data were collected from an automatic weather station located 50 m from the experimental field in Ankazomiriotra II. The daily average temperature (°C) and daily cumulative rainfall (mm) during the rice-growing seasons for both years were calculated (Figure 1). Weather data for other locations were not available.

Figure 1. Mean daily temperature and daily cumulative rainfall during rice-growing seasons 2018/19 and 2019/20 from sowing to harvesting time at the experimental location in Ankazomiriotra II, central highlands, Madagascar.

During sowing, the performance and efficiency of each seeder and fertiseeder were assessed based on the seeding and DAP application rates, as well as the time required to seed a specific area, compared with both manual sowing and manual sowing combined with DAP. The number of hills and missing hills per m², and the number of seedlings per hill were recorded five weeks after sowing to determine the uniformity of sowing using different methods. Four representative 1 m² areas, excluding the border rows, were randomly selected for data collection from each treatment plot. The average number of seedlings (Ns) per hill was calculated using the formula:

Where Σ(xi) is the sum of the observed number of seedlings on n hills, and n is the total number of hills. Missing hills were also quantified from each treatment plot.

At maturity, the number of panicles was counted from two 1 m² areas in each plot. The panicles were then harvested, threshed, and winnowed and the filled grains were weighed. The grain moisture content was measured during weighing using a grain moisture meter (SATAKE Moistex Model SS-7) and the yields were expressed at 14% moisture content.

Immediately following the testing in both seasons, farmer interviews and focus group discussions were conducted to gather feedback on the preferred seeder/fertiseeder, its effectiveness and desirability, farmers’ willingness to pay, and suggestions for further improvements.

In addition to the field experiments, an economic analysis was performed to compare the profitability of each sowing method. Production costs and net returns were calculated in USA dollars. An exchange rate of MGA 3700 per USA$1 was used. All variable cost including labour cost for various farming activities such as land preparation, sowing, fertilizer application, weeding, harvesting, and post-harvest processing, were considered for both seasons. Production income was estimated using the farm gate rice price of $270 t–1, using 2019–2020 prices.

The average initial acquisition cost of a seeder and fertiseeder was $68 and $81, respectively. The depreciation cost per hectare of the seeder/fertiseeder was calculated using the straight-line method and expressed as followsFootnote 1 :

Where D is the depreciation cost of the seeder/fertiseeder per ha (in USA$); Iv is the initial price of the seeder/fertiseeder (US$); Sv is the salvage value of the seeder/fertiseeder at the end of its life (US$) (the salvage value was estimated at about 20% of the purchasing cost); nY is the expected lifetime of the seeder/fertiseeder (years) (we assumed that the seeder/fertiseeder can be used for 10 years/seasons); dA is the area covered in a work-day of 8 hours (ha); dS is the number of days that the seeder can be used in a season (the sowing period in the region lasts from November to December, so we estimated the duration of use of the seeder/fertiseeder per season at 30 days). The benefit–cost (B:C) ratio was calculated by dividing the value of paddy yield by the total cost of production for each treatment.

The data were analysed using R software (version 4.2.3) analysis of variance (ANOVA). To compare the differences among treatments, a post hoc LSD (least significant difference) test by Fisher was conducted at a 5% probability level.

Results

Seeding efficiency of seeders and fertiseeder

Seed and fertilizer rate

The average seed rate ranged from 20 to 57 kg ha–1 in season 1, and 18 to 65 kg ha–1 in season 2 across sowing methods (Table 2). Statistical analysis showed that seed rate was not significantly different among the seeders and manual sowing in season 1, except the fertiseeder which delivered significantly lower seed rate (20 kg ha–1). However, in season 2 the seed rate differed between the sowing methods: only the CFFAMMA seeder delivered equivalent rates to the manual sowing methods; the New seeder and the fertiseeder delivered significantly lower rates due to the modifications made after the first season testing.

Table 2. Comparative analysis of agronomic and economic performance across various sowing methods in two rice-growing seasons

Means followed by the same letters within a row are not significantly different at p = 0.05.

LSD0.05, least significant difference at p = 0.05; ns = not significant. B:C ratio = benefit cost ratio; DAP = diammonium phosphate.

DAP micro-dosing rate did not differ significantly between manual and fertiseeder applications for the two seasons (Table 2). In season 1, the average DAP rates used were 24.1 kg ha–1 and 31.4 kg ha–1 with manual application and fertiseeder, respectively, i.e. an average application of 5 kg N ha–1 and 5.6 kg P ha–1; while in season 2 the DAP rates used were 47.2 kg ha–1 and 45.5 kg ha–1 with manual and fertiseeder application, respectively, equivalent to an average dose of 8.3 kg N ha–1 and 9.3 kg P ha–1.

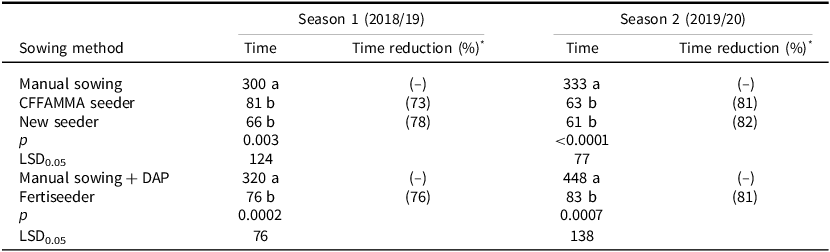

Labour saving

In both seasons, the sowing time was shorter with seeders and fertiseeder compared with manual sowing or manual sowing combined with DAP application (Table 3). In season 1, manual sowing required 300 h ha–1, while seeding with the New seeder and CFFAMMA seeder required 66 and 81 h ha–1, i.e. a time reduction of 78% and 73%, respectively. With the use of fertiseeder 1, a 76% reduction in labour time was observed compared with manual sowing and application of DAP fertilizer.

Table 3. Seasonal time requirements (h ha–1) of the six sowing methods tested in the central highlands of Madagascar

* Values in parentheses represent the percentage of reduction in time compared with the manual sowing for seeders and compared with the manual sowing + diammonium phosphate (DAP) application for fertiseeder.

Means followed by the same letters within a column are not significantly different at p = 0.05.

LSD0.05, least significant difference at p = 0.05.

In season 2, CFFAMMA (63 h ha–1) and New seeder (61 h ha–1) required a fifth of the manual sowing time (333 h ha–1), i.e. 81% and 82% time reduction, respectively. The use of fertiseeder 2 required 83 h ha–1 compared with 448 h ha–1 with manual sowing + DAP, a labour time saving of 81%.

Seedlings per hill and percentage of missing hills

Overall, the average number of seedlings per hill ranged from 5.3 to 7.1 in season 1 and 5 to 8.9 in season 2 (Table 2). There were significant differences in the number of seedlings per hill with the different sowing methods in both seasons. The fertiseeder and manual sowing had higher seedlings per hill in season 1, while CFFAMMA seeder, manual sowing, and manual sowing + DAP had higher seedlings per hill in season 2, compared to the other methods.

Season 2 had fewer missing hills overall, except for fertiseeder (Table 2). CFFAMMA seeder had a similar number of missing hills to manual sowing and manual sowing + DAP in both seasons, whereas New seeder and fertiseeder had more missing hills. In season 1, the manual sowing methods had 16–18% missing hills, while New seeder and fertiseeder had 38% and 34% missing hills, respectively. In season 2, fertiseeder had the most missing hills (46%), followed by New seeder (35%), while manual sowing and manual sowing + DAP had just 5% and 8% missing hills, respectively.

Effect of temperature and rainfall on yield and number of panicles

In rainfed rice production, the growth and yield of crops are influenced by the prevailing weather conditions. The four locations can be geographically grouped into two distinct regions. Ankazomiriotra I and II, and Belanitra were located in the same area and had available weather data, while no weather data were available for Ampahitra and Mahitsy.

For the Ankazomiriotra area (Ankazomiriotra I, II and Belanitra), Figure 1 illustrates the temperature and rainfall patterns during the two cropping seasons. In season 1, the daily mean temperature varied from 20.6°C to 24.7°C and in season 2, it varied from 20.5°C to 26.1°C. In season 1, some 1088 mm of rainfall was received during the rice cropping cycle, while it was only 536 mm in season 2 (2020 was a drought year in Ankazomiriotra). High temperature coupled with absence of precipitation occurred in the first two weeks after sowing in season 2 (Figure 1). In addition, severe drought affected the season 2 crop from 67 days after sowing (DAS) until harvest, coinciding with heading to grain maturity stages. Compared with season 1, rainfall distribution was not uniform during the crop cycle in season 2.

On average, the first season gave a higher yield (2.4 t ha–1) than the second season (1.9 t ha–1). ANOVA showed that in season 1, there was a significant difference in grain yield across the various sowing methods, with the manual sowing + DAP fertilizer application plot having the highest yield (3.8 t ha–1). The grain yields for the other treatments were not significantly different from each other (Table 2). However, in season 2, there was no significant difference in yield across the sowing methods.

Profitability analysis: production cost, net return, and benefit–cost ratio

The total production cost comprises cost for each activity from land preparation to harvest and post-harvest processing. The labour cost for each activity was considered the same except for sowing and fertilizer application cost for the treatment with fertilizer application. Sowing cost included labour cost and depreciation cost for the seeders and fertiseeder. We assumed that the equipment would be used only during the one-month planting season, resulting in an average depreciation of $1.6 ha–1, equivalent to one day’s labour wage. This assumption allows us to assess the economic viability of using seeders in the context of farmers’ operations.

In both seasons, using seeders or fertiseeders lowered production costs compared with manual sowing or manual sowing + DAP (Table 2). In season 1, the total cost of production per hectare was $195 with seeders and $203 with fertiseeder, compared with $222 and $248 for manual sowing and sowing + DAP, respectively. In season 2, the total cost of production per hectare was $168–185 with seeders and $194 with fertiseeder, compared with $220 and $267 for manual sowing and manual sowing + DAP, respectively. The lower production costs observed with seeders and fertiseeders can be attributed to their labour-saving potential for sowing, which averaged $10 per ha, significantly lower than the average labour cost of manual sowing and fertilizing (average $47).

This study used the benefit–cost ratio (B:C ratio) to assess the profitability of various sowing methods (Table 2). During season 1, manual sowing + DAP showed the most favourable B:C ratio (4.4), primarily due to its exceptional yield, while in season 2, the CFFAMMA seeder demonstrated the highest B:C ratio (3.0). Across the two seasons, the CFFAMMA seeder consistently yielded the highest B:C ratio among the machines used in the study.

Farmers’ feedback on seeders/fertiseeder

Among the participating farmers of both seasons, 95–96% expressed willingness to use the seeders on their farms (Table S2). The main reasons for their willingness to use the seeder or fertiseeder were its efficiency, with time and labour saving for sowing, ease of operation, and reduction of the drudgery associated with the use of human muscle power (Figure 2). The seeders and fertiseeder can do three operations in one go, i.e. making planting holes, sowing seeds (and placing fertilizer granules in case of fertiseeder), and covering the hole with soil, with one human labourer.

Figure 2. Reasons for willingness to use or not to use seeders in the future as expressed by the participating farmers, central highlands, Madagascar.

Regarding effectiveness, the percentages for all parameters (sowing, facilitating weeding, plant growth, spacing, and time required) were lower in season 1 compared to season 2. For desirability, the percentages were similar across both seasons, with no significant difference between male and female participants (Figure 3). Among the 222 participants in the first season, 70% expressed preference for the fertiseeder over other seeders (Table S2). Farmers found it effective in sowing, spacing and time required for sowing (Figure 3). The CFFAMMA seeder was the least preferred machine (18%). According to farmers, it is the least effective for sowing because of its high sowing rate and it clogged easily. Regarding their desirability, farmers’ perceptions were similar for the three types of seeder. Over 75% indicated that the seeders are easy to operate, that is, easy to push and handle. When disaggregated by gender, the percentage of female participants was lower compared to male participants. Over 60% indicated the adaptability of the seeders to different varieties of rice. However, less than 25% reported the likelihood of the machines being replicated by other manufacturers (Figure 3). The total percentage exceeding 100 can be explained by some farmers selecting two seeders as their preferred choice.

Figure 3. Farmers’ feedback disaggregated by gender on effectiveness (a and c) and desirability (b and d) of the seeders and fertiseeders after testing during the two seasons in Madagascar.

After fixing the issues noted during the first season of testing (seeding rate and clogging), among the 91 participants in season 2, the CFFAMMA seeder was the most preferred: 40% of participants chose it (Table S2). New seeder (33%) was the second-best seeder. About 27% of participants chose the fertiseeder as best tool (Table S2).

Regarding farmers’ willingness to pay for each seeder and fertiseeder, none of the farmers expressed a willingness to pay the current or higher prices set by the equipment manufacturer, which are $68 per unit for CFFAMMA and New seeder, and $81 for the fertiseeder. The average willingness to pay stood at $8 for seeders and $11 for fertiseeder (Figure S1).

Discussion

Performance of seeders and fertiseeder – sowing and plant growth

In general, efficient seeders and fertiseeders can accurately place seeds and fertilizers, reduce sowing time, and increase crop yields. This study confirmed that the use of such technologies resulted in significant time and labour savings compared with manual sowing. The study showed that seeders and fertiseeder were able to reduce sowing time by up to 82% compared with manual sowing and manual sowing + DAP, respectively. In the study of Mujawamariya and Kalema (Reference Mujawamariya and Kalema2017), farmers also reported time savings as a major benefit of using mechanical equipment. Among the seeders and fertiseeders tested, the CFFAMMA seeder offered the best performance. It performed similar to the manual method in terms of crop establishment, growth, and yield, while providing the advantage of reducing labour time.

In previous research on P micro-dosing, fertilizers were applied manually, which can increase labour time by 50% with an additional cost of labour estimated to be $40 ha−1 (Vandamme et al., Reference Vandamme, Ahouanton, Mwakasege, Mujuni, Mujawamariya, Kamanda, Senthilkumar and Saito2018). The high labour cost associated with the micro-dosing is one of the reasons for its low adoption in SSA (Natcher et al., Reference Natcher, Bachmann, Pittman, Kulshreshtha, Baco, Akponikpe and Peak2016; Saweda et al., Reference Saweda, Sanou and Mazvimavi2015). Research has shown that labour shortage without suitable mechanisation can be a limiting factor for the adoption of micro-dosing (Aune et al., Reference Aune, Doumbia and Berthe2007; Aune and Bationo, Reference Aune and Bationo2008; Okebalama et al., Reference Okebalama, Abaidoo and Logah2016). Reports suggest that using mechanisation to apply seeds and fertilizers at the same time can be a solution for the adoption of fertilizer micro-dosing (Tabo et al., Reference Tabo, Bationo, Gerard, Ndjeunga, Marchal, Amadou, Garba Annou, Sogodogo, Taonda, Hassane, Diallo, Koala, Bationo, Waswa, Kihara and Kimetu2007; Sanogo et al., Reference Sanogo, Gaspart, Kabore, Taonda and Kestemont2020). The fertiseeder used in this study makes it possible to combine three tasks in one (making planting holes, placing fertilizers, and sowing seeds) with reduced labour time.

It should be noted, however, that the seeders used in this study were not perfect and still need design improvements to avoid variable seed rate, high percentage of missing hills, and lack of uniform sowing. These seeders were made from frugal materials and spare parts found locally to keep their cost low. Improved and more efficient versions of these seeders could be obtained with quality materials and parts.Footnote 2 Farmers commonly reported that the machines did not sow uniformly, and the operator needed to maintain a constant speed for uniform sowing – sowing uniformity was affected when the operator increased the pushing speed; the covering system sometimes dragged the dropped seeds instead of covering them; and the seeders were not suitable for wet and muddy soil, as they easily clogged. Generally, locally produced machines in SSA are low in quality and high in price (Sims et al., Reference Sims, Hilmi and Kienzle2016).

Effect of DAP micro-dose application on rice production under drought stress

Drought is a major abiotic constraint to rainfed rice production. It occurs when there is a prolonged period without rainfall, resulting in insufficient water in the soil. In addition, the weather conditions during droughts often lead to continuous water loss through evaporation from the soil surface and transpiration from the plants (Singh et al., Reference Singh, Kumar, Mehandi and Chandra2012). In the second season, rice crops in Ankazomiriotra faced a period of water shortage for two weeks after sowing, followed by drought stress from 67 DAS until harvest. In contrast, the first season had sufficient and uniform rainfall.

Despite the water shortage experienced during the second season in Ankazomiriotra I and II, and Belanitra, seedling emergence was not adversely affected. The number of seedlings per hill was actually higher than in the first season, indicating better germination and establishment of plants. Additionally, the percentage of missing hills was lower in the second season, except in the fertiseeder plot, where there was an equipment issue resulting in inadequate seeding or uneven seed distribution, leading to missing hills and fewer seedlings.

However, compared with season 1, significant reductions in grain yield were observed during the second season when drought stress occurred during the heading stage and persisted until maturity. Rice is particularly vulnerable to drought stress during the reproductive phase, specifically during the flowering stage (Korres et al., Reference Korres, Norsworthy, Burgos and Oosterhuis2017), which leads to decreased fertility of the spikelets and ultimately results in yield reduction (Liu et al., Reference Liu, Liao, Oane, Estenor, Yang, Li and Bennett2006). The application of a micro-dose of DAP during the second season did not lead to a substantial increase in yield compared with the first season. Several studies have shown that drought stress during the reproductive phase has a detrimental impact on rice plants (Kamoshita et al., Reference Kamoshita, Babu, Boopathi and Fukai2008; Palanog et al., Reference Palanog, Swamy, Shamsudin, Dixit, Hernandez, Boromeo, Cruz and Kumar2014; Yang et al., Reference Yang, Wang, Chen, Li and Cao2019). Moreover, Aune et al. (Reference Aune, Doumbia and Berthe2007) report that plants receiving DAP applications in the planting hole were more susceptible to late-season drought due to their increased vigour. The effect of micro-dosing on yield depends on the soil moisture regulated by rainfall under rainfed conditions (Aune et al., Reference Aune, Coulibaly and Giller2017). This explains the lack of significant yield differences between plots that received a DAP micro-dose and unfertilized plots during the second season in the drought-affected area. This aligns with the findings of Vandamme et al. (Reference Vandamme, Ahouanton, Mwakasege, Mujuni, Mujawamariya, Kamanda, Senthilkumar and Saito2018), which showed that the grain yield responds less to a micro-dose of P under drought conditions. Crop response to fertilizer micro-dosing has a positive correlation with rainfall amount. This means that as the level of rainfall increases, the effectiveness of fertilizer micro-dosing in enhancing crop growth and productivity also tends to increase (Ouedraogo et al., Reference Ouedraogo, Taonda, Sermé, Tychon and Bielders2020). Bielders and Gérard (Reference Bielders and Gérard2015) show that high rainfall around millet sowing in Niger gave a positive response to the placement of DAP or nitrogen–phosphorus–potassium (NPK) in the planting hole. Contra to our findings, Tabo et al. (Reference Tabo, Bationo, Gerard, Ndjeunga, Marchal, Amadou, Garba Annou, Sogodogo, Taonda, Hassane, Diallo, Koala, Bationo, Waswa, Kihara and Kimetu2007) state that fertilizer micro-dosing leads to rapid early growth and improved crop performance under drought conditions.

Farmers’ appreciation and profitability of seeder and fertiseeder technologies: addressing challenges and enhancing adoption

The survey results indicated that in season 1, the fertiseeder was the preferred choice among farmers due to its combined sowing and fertilizer application capabilities. However, in season 2, ‘improvements’ made to the fertiseeder based on farmers’ feedback were not as effective as expected, and the CFFAMMA seeder and new seeder were preferred due to their effectiveness in sowing. Given the role of women in sowing, another important factor explaining farmers’ preference for a seeder was its weight. Hence, the overall choice of the CFFAMMA seeder and new seeder that women can more easily manipulate. The fertiseeder was not properly adjusted during the testing, leading to a low seeding rate, but this issue was corrected afterwards. The fabricator can make technical improvements to meet the requirements of farmers, especially considering that the new seeder and fertiseeder have been newly designed, while the CFFAMMA seeder is already developed and fine-tuned. This is why the CFFAMMA seeder performed well in this study. Another common challenge faced by farmers in both seasons was clogging of seeders when working in moist plots. This issue highlights the limited suitability of seeders for wet or highly moist soils. Despite these challenges, farmers provided positive feedback on the use of seeders due to their time-saving and improved ease of sowing for both male and female farmers.

Profitability is a crucial factor in the adoption of agricultural techniques and equipment, and farmers often compare the relative profitability of different techniques. A benefit–cost ratio of 2 is the acceptable profitability level and critical threshold for fertilizer adoption by farmers in SSA (Kelly, Reference Kelly2005). However, absolute profit margins should also be taken into account (Fermont et al., Reference Fermont, Tittonell, Baguma, Ntawuruhunga and Giller2010). Based on our findings, during season 1, all treatments showed a B:C ratio exceeding 2, indicating favourable profitability level in the absence of drought. During season 2, manual sowing with and without DAP micro-dosing resulted in a B:C ratio equal to or lower than 2 (Table 2). It has been suggested that a B:C ratio of >4 was sufficient incentive for farmers in the face of price and climate risks (Guo et al., Reference Guo, Koo and Wood2009); rainfed rice production is mainly dependent on weather conditions. In our study, a B:C ratio of >4 was obtained only with manual DAP micro-dosing application in season 1. Vandamme et al. (Reference Vandamme, Ahouanton, Mwakasege, Mujuni, Mujawamariya, Kamanda, Senthilkumar and Saito2018) found that DAP micro-dose placement that gave a B:C ratio of up to 10 without considering the additional cost of labour and below 3 when considering the additional cost of labour.

While farmers expressed their appreciation for seeders and the benefits they bring, the high initial investment cost for purchasing these technologies posed a significant obstacle, with farmers proposing an average price significantly lower than the minimum unit price set by CFFAMMA. This price gap made it unaffordable for individual Malagasy farmers, particularly those with limited resources, to invest in seeders. For the future acquisition of the equipment by the farmer, it is obvious that the high initial investment cost for the purchase of seeders is not within the reach of resource-poor farmers (MinAgri, 2015) even though the additional costs associated with its use are lower compared with motorised machinery. The issue of high purchase costs for mechanisation equipment is a common challenge faced by farmers, as highlighted by previous studies (e.g. Mujawamariya and Kalema, Reference Mujawamariya and Kalema2017; Sims and Kienzle, Reference Sims and Kienzle2017). Smallholder farmers often find the initial investment and subsequent maintenance and operation costs beyond their means (Guthiga et al., Reference Guthiga, Karugia and Nyikal2007; Madhukar et al., Reference Madhukar, Reddy, Lakshmi and Ramu2021). Financial support and subsidies are limited, making it even more difficult for smallholders to acquire such equipment.

To address this challenge, one potential solution for farmers to benefit from the advantages of mechanisation technology is through rental or service provision, which would reduce the costs associated with purchasing and maintaining the equipment (Sims and Kienzle, Reference Sims and Kienzle2017). Alternatively, a service provision by youth entrepreneurs presents another avenue that provides business opportunities for them but also addresses the machinery needs of local farmers. By making the investment in seeders and offering rental services to other farmers, those who can afford the equipment would have the opportunity to profit from it, while marginal farmers could benefit from access to mechanisation without the burden of high costs. Another option could be the establishment of formal farmer groups to collectively purchase, own, and maintain a machine. This shared ownership model promotes cost efficiency and improves the efficient use of resources within the group (Theis et al., Reference Theis, Sultana and Krupnik2018).

Conclusion

Our study demonstrated that the use of seeders and fertiseeder for rainfed rice sowing offers several advantages. These machines save time, reduce labour-intensive work, and allow for timely completion of sowing. Farmers found the equipment easy to operate with just one labourer and appreciated its ability to facilitate mechanical weeding through in-line sowing. Additionally, the equipment requires less maintenance than an engine-driven machine. The use of a CFFAMMA seeder gave a benefit–cost ratio of up to 3.2, indicating significant profitability for farmers. It enabled similar yield and seed rate to manual sowing, while significantly reducing labour input over two years. However, the new seeder and fertiseeder as used in this study require further improvements to their performance. Although farmers recognised the positive impact on labour productivity, the main constraint to widespread adoption remains the high initial purchase cost of the equipment which is beyond the means of most smallholder farmers. As individual possession of the equipment is difficult, service provision models could be explored for improved adoption.

To address this challenge, policy interventions should encourage rental services and youth entrepreneurship in providing mechanisation services. Additionally, promoting the formation of formal farmer groups for collective ownership and maintenance of machinery can enhance its use efficiency and reduce cost per farmer. Governments could also consider offering subsidies or tax incentives to lower the initial purchase cost of the tools for smallholder farmers.

Supplementary material

The supplementary material for this article can be found at https://doi.org/10.1017/S0014479724000188

Acknowledgements

The authors would like to express gratitude to Jemima Amielle Ramarolahy for her contribution on seeder trial during the first season of testing. We also thank CFFAMMA as partners for designing and manufacturing seeders, FY VARY project for sharing data from weather stations in Ankazomiriotra, and interviewers and rice farmers for their generous support for interview and fields experiments.

Author contributions

Study design: Senthilkumar K; Methodology: Senthilkumar K and Mujawamariya G; Conducting the study: Andriatsiorimanana A, Harison N F; Data collection: Andriatsiorimanana A, Tefy I A, Harison N F; Data curation and analysis: Andriatsiorimanana A; Writing and reviewing: Andriatsiorimanana A, Senthilkumar K, Mujawamariya G, and Saito K.

Funding statement

This research was supported by the CGIAR Research Program on Rice (RICE) and Excellence in Agronomy (EiA) initiative.

Competing interests

The authors declare no conflicts of interest regarding the publication of this paper.