Introduction

During the 1960s, two Iron Age shipwrecks were discovered in the western Mediterranean with unusual objects in their cargoes: lead ingots that had been cast in the large shells of Pinna nobilis molluscs endemic to coastal waters. These shipwrecks, known as Agde K (Brescou Island, France) and Cabrera B (Balearic Islands), yielded seven examples of these rare Pinna nobilis-cast ingots. All seven have since been traced to production centres in south-eastern Iberia through lead isotope analysis (Trincherini et al., Reference Trincherini, Domergue, Manteca, Nesta and Quaranti2009: table 2). Both shipwrecks and their ingots have been presented as windows into the long-distance trade in metals during the third century bc, a time when Punic merchants were dominant in western Mediterranean trade networks.

In addition to providing insights into trade, I argue in this article that the ingots are a key source for understanding coastal resource exploitation in south-eastern Iberia during the Iron Age and for disentangling the economic implications of reuse. They reveal aspects of the organization of pre-Roman mining and metallurgy, a time for which little direct archaeological evidence survives. The reuse of Pinna nobilis shells also suggests that coastal industries linked to the molluscs’ by-products—sea silk weaving (fibres from molluscs woven to produce a type of textile), crafts using pearls and nacre, and meat consumption—were practised simultaneously. This is potentially the earliest attestation of Pinna nobilis crafts in Iberia.

Beyond these implications for each industry, the ingots provide a peculiar example of cross-industry reuse in an Iron Age coastal context. This is of local environmental and economic significance as well as of importance for understanding reuse, recycling, and the spread of technology in the ancient Mediterranean. I suggest that reuse was a circular economic strategy, which allowed for sustainable repurposing of materials and, perhaps, reduction of labour through cross-industry exchange. This strategy was relatively short-lived, as Pinna nobilis shell-casting was abandoned when ingots became standardized after the Roman conquest of Iberia and the subsequent expansion in the scale of metal production. Although it fell out of use, this technology reveals locally specific economic strategies in coastal contexts where both metals and Pinna nobilis were available during the Iron Age. Other examples of similar ingots presented here suggest that this same practice was employed in several Mediterranean locales; moreover, additional ingots may have gone largely unrecognized. Other better-known examples of reuse in Mediterranean Iron Age coastal contexts, such as burning murex shells to make lime after purple dye production, provide a context for the casting of ingots in Pinna nobilis shells. Ultimately, further investigation of our ingots and others like them will reveal how local environments shaped production practices, economic decision making, and the spread of technology in the Iron Age Mediterranean.

Shipwreck Evidence for Iberian Pinna nobilis Shell-Cast Ingots

The Pinna nobilis-cast ingots came from the Cabrera B and Agde K shipwrecks, which sank in the western Mediterranean, probably during the third century bc (Figure 1: Agde in Hérault, France, and Cabrera off Mallorca (inset B)).

Figure 1. Pinna nobilis distribution in the Mediterranean alongside the shipwrecks, sites, and mining districts mentioned in the text (map by Daniel Plekhov).

The Cabrera B shipwreck

In the 1960s, archaeologists Cristóbal Veny Melià and Damián Cerdà fortuitously came across some well-preserved ancient pottery on display in a house in Palma de Mallorca. They traced the origin of the pieces to a shipwreck off the coast of the Balearic Island of Cabrera and, eventually, retrieved other finds from the same site that had been purchased or given to private collectors (Veny Melià & Cerdà, Reference Veny Melià and Cerdà1972: 310–11). This shipwreck, located on the western side of the harbour of Cabrera at a depth of 30–35 m, came to be known as Cabrera B or Cabrera II (because it is one of several shipwrecks at Cabrera). It was never systematically excavated, and no remains of the hull were found in a survey of the harbour (Guerrero Ayuso & Colls y Puig, Reference Guerrero Ayuso and Colls y Puig1982: 6). However, the chronologically uniform group of materials recovered from looters between 1965 and 1970 was published in articles detailing the pottery and metal objects, including four lead ingots and a fragmentary iron anchor (Veny Melià & Cerdà, Reference Veny Melià and Cerdà1972; Cerdà, Reference Cerdà1979).

The ceramic finds included amphorae, common ware, and black gloss fine ware characteristic of western Mediterranean types of the fourth to second centuries bc. The transport amphorae were Greco-Italian and Punic forms (Mañá A, B, D, and E), mainly Mañá D, dating to the third and second centuries bc (Veny Melià & Cerdà, Reference Veny Melià and Cerdà1972: 311–15; Cerdà, Reference Cerdà1979: 93–97). Plates, small jars, and a louterion constituted the common ware assemblage, which came primarily from the island of Ibiza. Black gloss pottery included cups, plates, a jug, and a distinctive guttus that helped to narrow the ship's chronology (Veny Melià & Cerdà, Reference Veny Melià and Cerdà1972: 316–22; Cerdà, Reference Cerdà1979: 90–93). Based on this assemblage, Cabrera B was identified as a Punic vessel of the later Iron Age, variously dated to the fourth or third century bc (Veny Melià & Cerdà, Reference Veny Melià and Cerdà1972: 322), 300–225 bc (Parker, Reference Parker1992: 81), around 210–190 bc (Ramon Torres, Reference Ramon Torres1995: 62), and—most recently—‘sometime before 200 bc' (Ramon Torres, Reference Ramon Torres, Prados Martínez, Jiménez Vialás and Martínez Garcia2017: 49). It seems reasonable to assume a date in the later third century bc. The wreck was likely to have been a merchant ship sailing the western Mediterranean during the time of Punic commercial dominance (Guerrero Ayuso, Reference Guerrero Ayuso, Devijver and Lipinksi1989: 112–13; Parker, Reference Parker1992: 80–81; Ramon Torres, Reference Ramon Torres, Prados Martínez, Jiménez Vialás and Martínez Garcia2017: 49).

Four ingots were recovered from the site, three of which are now at the museum of the monastery of Lluc in Mallorca. One remains in a private collection (Figure 2). From their earliest publication, Veny Melià and Cerdà recognized the shape of the ingots—elongated with a flat surface on one face and a curved surface on the other—as identical to that of Pinna nobilis shells. They suggested that empty specimens had been used as moulds to cast molten lead into a form suitable for maritime transport (Veny Melià & Cerdà, Reference Veny Melià and Cerdà1972: 322). All four examples had similar dimensions and weights. Published weights exist for two: 38.6 kg and 40.0 kg.

Figure 2. Cabrera B ingot held in a private collection. Reproduced by permission of Claude Domergue.

In his seminal publication on mining in the Iberian Peninsula, Claude Domergue (Reference Domergue1990) discussed these ingots, surmising that they came from south-eastern Iberia. He noted that the mining districts of Cartagena-Mazarrón, Sierra de Gador (Almeria), and Sierra Almagrera (Almeria) were all located reasonably close to the coast for the use of Pinna nobilis to be practical at metallurgical production sites, which were also active during the fourth and third centuries bc (Domergue, Reference Domergue1990: 167–68). The mines of s'Argentera (Ibiza), exploited from the seventh century bc onwards (Hermanns, Reference Hermanns2014, Reference Hermanns and López Ballesta2015), could have been another possibility, unknown to Domergue in 1990. More recently, Trincherini and colleagues tested samples from the ingots using lead isotope analysis. Their probable origin was pinpointed to Cartagena (Trincherini et al., Reference Trincherini, Domergue, Manteca, Nesta and Quaranti2009: 137–38), providing confirmation of Domergue's hypothesis and further insights into the production locale and distribution network of these ingots.

The Agde K shipwreck

A shipwreck with a similar cargo, known as Agde K, was discovered in 1960 in Hérault in southern France. It was located near Brescou Island, a small island just off the coast of Agde, one of a series of shipwrecks found in the vicinity and named Agade A–K in alphabetical succession (Parker, Reference Parker1992: 42–46). This area was published as ‘Gisement E’ (Gallet de Santerre, Reference Gallet de Santerre1962: 622). As with the Cabrera B wreck, no hull was recovered, but a group of ingots was reported. Italic, Dressel 10, and Dressel 45 amphorae were found near the site but not associated securely with the ingots (Bouscaras, Reference Bouscaras1960, Reference Bouscaras1961; Gallet de Santerre, Reference García-March, Hernandis, Vázquez-Luis, Prado, Deudero, Vicente and Tena-Medialdea1962: 622; Laubenheimer-Leenhardt & Gallet de Santerre, Reference Laubenheimer-Leenhardt and Gallet de Santerre1973: 145–61, 169–72).

Eight lead ingots of various shapes and sizes, weighing between 15 and 66 kg, were recovered. Three were cast in Pinna nobilis shells, while others were oblong, plano-convex shapes cast in an ad hoc manner in depressions in the earth—a more typical ingot-casting technique for the Iron Age (Gale Brown, Reference Gale Brown2011: 92–94; Rothenhoefer & Hanel, Reference Rothenhoefer, Hanel, Burmeister, Hansen, Kunst and Müller-Scheeßel2013: 273). In the early publications, the Pinna nobilis-cast ingots are described as being produced in the form of a ‘grand coquillage’, i.e. a large shell (Gallet de Santerre, Reference Gallet de Santerre1962: 622). André Bouscaras, the excavator, suggested that they were made in Pinna nobilis shells and could be from Cabrera or Cartagena because of the need for easily accessible coastal resources near the production site (Bouscaras, Reference Bouscaras1960: 29; Reference Bouscaras1961: 17–18). Like the Cabrera B ingots, the Pinna nobilis-cast ingots from Agde K were examined by Trincherini and colleagues decades later by lead isotope analysis and found to match the isotopic signature of the mining district of Cartagena (Reference Trincherini, Domergue, Manteca, Nesta and Quaranti2009: 137–38, table 2).

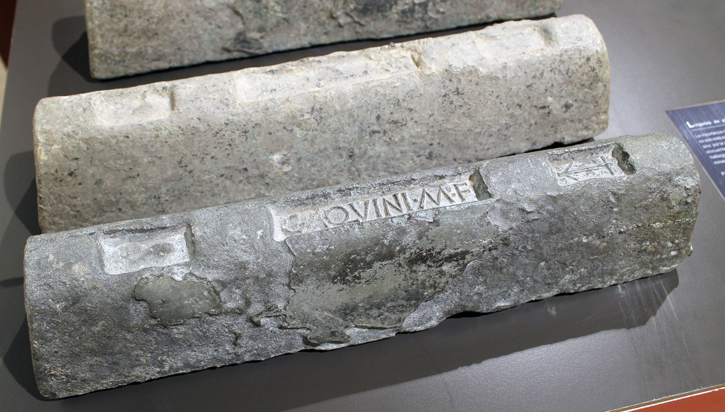

The three Pinna nobilis-cast ingots were dated to the third century bc because they are morphologically similar to those recovered from the Cabrera B shipwreck (Parker, Reference Parker1992: 46). One is now held in the Musée du Vieux Biterrois (Béziers, France) and two are in the Musée de l'Éphèbe in Agde. Two of the ingots are well preserved and various markings are visible on their surface (Figure 3). Both show a symbol made up of three lines, one executed freehand and the other punched or stamped. One also has a vertical line punched four times on the flat surface. The surface of the final ingot is too deteriorated to preserve any markings, if ever present.

Figure 3. Ingot from the Agde K shipwreck showing markings (after Laubenheimer-Leenhardt & Gallet de Santerre, Reference Laubenheimer-Leenhardt and Gallet de Santerre1973: fig. 37 with modifications).

The markings have been variously interpreted as a Greek pi, an archaic Latin P, or an Iberian character. Domergue argues convincingly that the latter is most probable, given the then-hypothesized and later confirmed origin of the ingots (Reference Domergue1990: 168). Perhaps significantly, the other five ingots recovered from Agde K—those not cast in shells—also had similar markings, with the three-line letter common to all of them (Laubenheimer-Leenhardt & Gallet de Santerre, Reference Laubenheimer-Leenhardt and Gallet de Santerre1973: 145–61, 169–72; Gale Brown, Reference Gale Brown2011: 203–5). Since this was likely to have been a notation related to the production or commodification of the ingots, the Agde K assemblage hints that Pinna nobilis shells were used alongside other casting processes that did not utilize shells. These could have been carried out by the same producers or different producers operating within the same region or economic system, a point addressed below.

Coastal Resources and Industries in Iron Age South-Eastern Iberia

The ingots have been mentioned cursorily in publications about the two shipwrecks, as well as in discussions of mining and metallurgy (Triester, Reference Triester1996: 347–51; Rothenhoefer & Hanel, Reference Rothenhoefer, Hanel, Burmeister, Hansen, Kunst and Müller-Scheeßel2013: 274), but their implications for understanding coastal resource use and the integration of production strategies have not been fully explored. The distinctive form of these ingots suggests that workers in mining and metallurgy in south-eastern Iberia had access to Pinna nobilis shells and chose to use them for casting, perhaps to streamline production and make expedient use of a readily available material. In the following, I discuss the integration of Pinna nobilis exploitation and mining in Iron Age south-eastern Iberia: I first address the evidence for mining and metallurgy, then outline the Pinna nobilis-based crafts that may be attested by the presence of the shells, and finally consider how and why these ingots were repurposed for lead casting and the economic implications of this cross-industry exchange.

Mining and metallurgy

The ecological and geological conditions of south-eastern Iberia meant that many mines and foundries for extracting and processing argentiferous galena, from which lead and silver were derived, were located close to the coastal exploitation of Pinna nobilis molluscs. Many of the areas with mines and/or foundries were visible and accessible by foot from the coast. These include the extensive mining districts of Cartagena-Mazarrón, Sierra de Gador, and Sierra Almagrera—all regions identified as possible locations from which the ingots derived (Domergue, Reference Domergue1990: 62–64, 189–97). Several coastal mines preserve evidence for Punic-period exploitation (e.g. Cala Cocón; Bellón Aguilera, Reference Bellón Aguilera2013) (Figure 4; location on Figure 1, inset A). The coastal settlement of Punta de Gavilanes also has evidence for Punic silver smelting (Ros Sal, Reference Ros Sal, Ramallo Asensio, Muñoz Amilibia, Ros Sal and Castillo1993). Iron Age mining, however, is generally not well documented because of the large scale of mining operations that have taken place across the region in subsequent periods, particularly during the second and first centuries bc and more recently, often obliterating earlier evidence (Orejas & Sánchez-Palencia, Reference Orejas and Sánchez-Palencia2002: 582–89; Antolinos Marín & Noguera Celdrán, Reference Antolinos Marín, Noguera Celdrán, Fiches, Planta-Mallart and Revilla Calvo2013). It is therefore constructive to use the Pinna nobilis-cast ingots as indirect evidence for metal extraction and processing in the region during the Iron Age.

Figure 4. Punic mine of Cala Cocón in its setting and detail of a subterranean shaft (inset).

Reproduced by permission of Jesús Bellón.

Argentiferous galena was typically extracted by subterranean mining techniques, excavating shafts and galleries to access deposits of minerals and bringing the ore to the surface for processing. Once mined, the ore had to be processed in foundries to separate the silver and lead (Ramallo & Berrocal, Reference Ramallo, Berrocal and Vaquerizo Gil1994; Bellón Aguilera, Reference Bellón Aguilera2013). It was smelted to produce mixed lead and silver, then reheated to separate the two metals through a process called cupellation (Craddock, Reference Craddock1995: 221–28). Silver was destined for minting coinage, probably to pay soldiers who were fighting in the Punic wars, and to craft jewellery and other luxury items (Mangas & Orejas, Reference Mangas, Orejas, Rodríguez Niela, Cristóbal González, Mangas and Orejas1999: 220; Ripollès, Reference Ripollès and Metcalf2012). Lead was used for utilitarian purposes including pipes, tableware, architectural elements, and shipbuilding. The molten lead was cast into ingots that were portable enough to carry in the hulls of ships for long-distance trade, as demonstrated by Cabrera B and Agde K. During the later Iron Age, the primary purpose of casting lead ingots in plano-convex shapes seems to have been for portability rather than to replicate a standard weight. Pinna nobilis ingots were not standardized, nor were other iron ingots of this period cast by other techniques (Rothenhoefer & Hanel, Reference Rothenhoefer, Hanel, Burmeister, Hansen, Kunst and Müller-Scheeßel2013: 273–374).

During this final stage of production, Pinna nobilis shells were collected and used as moulds into which the molten lead was poured. These were probably single-use shells that were destroyed or dismantled in the process. The shells have not been recovered—or perhaps not recognized—archaeologically. Another possibility is that shells were recycled and burned for lime, an ingredient in plaster. The molluscs were likely to have been first collected for other primary purposes.

Pinna nobilis exploitation

The Pinna nobilis mollusc, also called the pen shell or fan mussel, is a bivalve that grows durable shells of elongated triangular shapes ranging in size from c. 50 to 120 cm (Figure 5). They anchor themselves to shallow ocean floors along Mediterranean coasts with ‘byssus’ fibres, or strong, golden-brown filaments. Modern distribution of the shells provides the best proxy for their possible ancient distribution (marked red on Figure 1), with the caveat that the Pinna nobilis has become threatened by human and environmental causes as well as parasites in contemporary periods (Carella et al., Reference Carella, Antuofermo, Farina, Salati, Mandas and Prado2020; Öndes et al., Reference Öndes, Kaiser and Güçlüsoy2020). They are found across the Mediterranean coastline, with abundant populations in the Aegean Sea, the western Mediterranean islands, and the coasts of Spain, Italy, France, and Tunisia.

Figure 5. Pinna nobilis in their underwater habitat (photograph by Arnaud Abadie 2019 licensed under CC BY 2.0).

In antiquity, these molluscs were harvested to produce a luxury textile called ‘sea silk’, brown pearls, mother of pearl inlays, and for consumption. Given that these were specialized crafts with products that were either ephemeral, consumable, or unlikely to survive in archaeological contexts, no direct evidence for them has been found in south-eastern Iberia. The potential value of products directly derived from the Pinna nobilis in antiquity nevertheless suggests that the large shells were not harvested specifically for mining but for other primary purposes. Mining thus repurposed waste that was not useful to the producers of these luxury goods or as food.

The byssus filaments were harvested, dried, combed, and then spun into fibres for weaving sea silk (Maeder, Reference Maeder, Alfaro and Karali2008: 109; Pes & Pes, Reference Pes, Pes, Landenius Enegren and Meo2017) (Figure 6). This industry has been studied by Felicitas Maeder (Reference Maeder2021), who has recorded over sixty sea silk textiles dating primarily between the fourteenth and twentieth centuries ad. Unfortunately, ancient examples have proved elusive because of the craft's small scale and because the delicate material survives only in exceptional circumstances. The earliest piece comes from a fourth-century ad elite female burial at Aquincum (Budapest, Hungary; Maeder, Reference Maeder, Alfaro and Karali2008). Tertullian (De Pallio 3.6), who lived in the late second and early third century ad in Carthage, also described sea silk. Hence, while rare, the textile was produced in the Roman central and western Mediterranean (Marzano, Reference Marzano2013: 168–69).

Figure 6. Sea silk fabric woven by Chiara Vigo in Sant'Antioco, Sardinia (photograph by Giulio Gigante licensed under CC BY-SA 2.0).

Figure 7. Stamped lead ingot of the Roman Republican period at the Museo Arqueológico Municipal de Cartagena.

Although no direct evidence for ancient sea silk exists from Iberia, the use of shells in lead casting during the Iron Age suggests that sea silk production could have been practised simultaneously. Indirect archaeological evidence for ancient sea silk from outside Iberia lends further support. One compelling instance of a sea silk workshop of the seventh–fifth centuries bc has been found at Aetolian Chalkis in western Greece. Specialized weaving implements, including small pyramidal and conical loom weights and micro-blades, were found alongside Pinna nobilis shell fragments (Houby-Nielsen, Reference Houby-Nielsen, Landenius Enegren and Meo2017: 48–55). It is plausible that sea silk could also have been produced in coastal south-eastern Iberia because the Pinna nobilis shells and the weaving technology required to craft fine textiles (e.g. spindle whorls, looms, technical weaving knowledge) co-existed there and because the ingots show that Pinna nobilis molluscs were being actively exploited (Alfaro Giner, Reference Alfaro Giner1984; Marín-Aguilera & Gleba, Reference Marín-Aguilera and Gleba2020).

The use of the flesh of Pinna nobilis molluscs as food cannot be discounted. It is eaten today in coastal Turkey, an area with a history of exploitation of the molluscs (Tekin, Reference Tekin, Arslan and Baz2018: 190). During the fourth and third centuries bc, for instance, coins were minted at Gyrneum, an Aeolian port city near modern Bergama. These coins have the image of a Pinna nobilis shell, suggesting that this city was linked to their exploitation. In Aetolian Chalkis, consumption has been interpreted as secondary to the Pinna nobilis function in textile manufacture (Houby-Nielsen, Reference Houby-Nielsen, Landenius Enegren and Meo2017: 52). It is therefore possible that the mollusc's flesh was also consumed in south-eastern Iberia.

Pinna nobilis may also have been exploited for its pearls and mother of pearl (nacre), the shell's iridescent interior. Fine white pearls from the oyster species Pinctada margaritifera and Pinctada radiata were sourced from the Indian Ocean and the Red Sea in Roman times (Schörle, Reference Schörle, de Romanis and Maiuro2015: 44–46). Lesser-quality pearls came from Britain (Marzano, Reference Marzano2013: 170; Bustamante-Álvarez et al., Reference Bustamante-Álvarez, Bernal-Casasola and Castellano-Hernández2021: 2–5). In the Roman period, white pearls have been found across the Iberian Peninsula and the Balearic Islands, with many examples, mostly from jewellery, found in south-eastern coastal areas. These pearls were not from fan molluscs (Bustamante-Álvarez et al., Reference Bustamante-Álvarez, Bernal-Casasola and Castellano-Hernández2021). Before Roman commerce made long-distance pearl trade feasible, however, local use of the brown, oblong pearls of the Pinna nobilis for jewellery in Iron Age Iberia is not out of the question, though this has not been identified archaeologically.

Examples of nacre from other parts of the Mediterranean in the Bronze and Iron Ages and from Roman Iberia show that this material was used widely in antiquity. Cut and polished Pinna nobilis nacre has been found in inlays in Aegean Bronze Age contexts (Houby-Nielsen, Reference Houby-Nielsen, Landenius Enegren and Meo2017: 51). Roman nacre plaques have been found in Iberia, though the species of bivalve that they came from has not been identified. One first–second-century ad burial at Augusta Emerita (Mérida) contained plaques once fitted to a wooden box. Another plaque from the villa of Roceipón (Vera, Almeria) may come from a piece of furniture (Bustamante-Álvarez et al., Reference Bustamante-Álvarez, Bernal-Casasola and Castellano-Hernández2021: 18). Other nacre pieces identified as that of the Pinctada margaritifera formed part of an opus sectile wall decoration at the villa of Las Pizarras (Segovia) (Reyes Hernando et al., Reference Reyes Hernando, Pérez González, Bragado Álvarez, Araujo Armero and de Andrés Cobeta2016). Given this evidence, the use of Pinna nobilis mother of pearl in Iron Age south-eastern Iberia is plausible. The shells, which were dismantled for their nacre, were probably no longer suitable for casting, unlike the shells used for sea silk, consumption, and pearl harvesting.

Reanalysis of archaeological assemblages containing shells, jewellery, and plaques could help identify local uses of Pinna nobilis in Iron Age Iberia. Whatever these were, harvesting the Pinna nobilis typically produced large, empty shells as waste. The lead ingots under consideration demonstrate that this discarded material was repurposed for metallurgy.

Discussion

The ingots recovered from Cabrera B and Agde K reveal processes of production in mining and metallurgy and Pinna nobilis exploitation. Further, they provide a clear example of cross-industry reuse, which I suggest is evidence for a circular economic strategy in coastal resource exploitation.

Cross-industry reuse and recycling

Drawing from longstanding work in anthropology (e.g. Schiffer, Reference Schiffer1987; Downs & Medina, Reference Down and Medina2000; Rathje & Murphy, Reference Rathje and Murphy2001; Zimring & Rathje, Reference Zimring and Rathje2012), Peña has recently laid out clear definitions of reuse and recycling in the archaeological record: recycling occurs when refuse or discarded items (recyclables) are ‘taken up and utilized as a raw material in a productive process of some kind’ (Peña, Reference Peña, Duckworth and Wilson2020: 11). Materials such as metals, glass, ceramics, and textiles are reprocessed so that they can be used again in another form. Reuse is a broader concept that includes ‘employing objects recovered from provisional discard, de facto discard, and/or the refuse stream either for their original purpose or for some other application’ (Peña, Reference Peña, Duckworth and Wilson2020: 12). Following Peña's definition, Pinna nobilis shells were recovered and repurposed for metallurgy, a clear example of cross-industry reuse. Although cross-industry reuse is most studied for the Late Roman period in the Mediterranean, metal recycling, i.e. remelting metal objects to make new ones, has long been part of a separate discourse in archaeometry and archaeology across ancient periods (e.g. Jennings, Reference Jennings2014; Pernicka, Reference Pernicka, Roberts and Thornton2014; Bray et al., Reference Bray, Cuénod, Gosden, Hommel, Liu and Pollard2015).

There is no direct evidence for how the exchange of the material (shell) operated, but there must have been social or organizational integration, given the clear link in the supply chain between mining and Pinna nobilis exploitation. One potential scenario is that labourers worked seasonally or part-time in both mining and maritime exploitation, since their geographical proximity meant that both types of work were accessible. The scale of production during the Iron Age may not have required full-time engagement with either industry. Shared labour would have made it easier for supplies to be pooled, and for the waste materials of one industry to be recycled in another. Another option is that, if labour was not directly shared, the geographical proximity of the resources and corresponding production spaces provided the context for easy communication among workers and their communities to facilitate shell reuse. Alternatively, the refuse disposal practices of Pinna nobilis harvesters may have been conspicuous—it is not easy to hide shell middens—so these shells could have been acquired through scavenging by smelters rather than through a direct social or economic exchange.

While these interpretations must remain speculative without additional archaeological evidence, they have implications for reconstructing economic organization during the later Iron Age. The concept of the ‘circular economy’ derived from modern sustainability studies is useful for explaining the economic and environmental motivations for reuse and recycling. The circular economy has been defined as

‘a regenerative system in which resource input and waste, emission, and energy leakage are minimised by slowing, closing, and narrowing material and energy loops. This can be achieved through long-lasting design, maintenance, repair, reuse, remanufacturing, refurbishing, and recycling.’ (Geissdoerfer et al., Reference Geissdoerfer, Savaget, Bocken and Hultink2017: 759)

In south-eastern Iberia, using the waste from Pinna nobilis harvesting in metallurgy reduced the need for metallurgists to form their own moulds in the ground or out of new material through the expedient reuse of ‘waste’ shells. Shells were also portable and could therefore be used when ground conditions were not ideal for casting. This process created an economic loop that, at least in localized coastal production contexts, mitigated the environmental impacts of both industries by reducing the overall quantity of material consumed and waste produced. Economic benefits included reduced labour investment to acquire materials in metallurgy and dispose of waste in Pinna nobilis-related industries.

These possibilities also have implications for each industry. In metallurgy, shells of similar sizes may have been selected for casting to keep the shape and weight of ingots more regular for long-distance maritime shipping. Portability seems to have been the main objective, as shape was prioritized over weight (complete ingots range from 33 to 66 kg). Although there is evidence for standardization of weight earlier in the Late Bronze Age Aegean for some types of ingots (e.g. oxhide ingots) and later after the Roman conquest for lead ingots, there were no clear standard weights for Iron Age lead ingots from Iberia or elsewhere (Trincherini et al., Reference Trincherini, Domergue, Manteca, Nesta and Quaranti2009: 127; Sabatini, Reference Sabatini2016: 31).

The fact that ingots cast both in shells and in depressions in the sand were shipped together on the Agde K shipwreck suggests that metallurgists did not depend exclusively on the supply of shells to make their ingots. Rather, they may have chosen to use shells when they were available to streamline the casting process and produce convenient shapes. The markings on the Agde K ingots may provide further evidence for the organization of production in foundries. One possibility is that all the ingots—both shell- and sand-cast—were produced by the same group who had a common marking system to keep track of their output. Alternatively, this system could have been adopted in the region both by producers who used the Pinna nobilis shell casting technique and by those who did not, in order to integrate practices of production and to supply merchants, who acquired both types of ingots indiscriminately, if the Agde K wreck is any indication.

Both the standardization of shapes and the external marking of ingots using stamps and other notation later became common practice during the Roman Republic in south-eastern Iberia. During the second and first centuries bc, ingots were cast in purpose-made wood or ceramic moulds of regular sizes and weights (c. 1000 Roman librae or 32–33 kg), and stamped inscriptions marked the ownership of the mines or named the producers (Domergue, Reference Domergue1990: 508–09; Trincherini et al., Reference Trincherini, Domergue, Manteca, Nesta and Quaranti2009: 127; de Juan Fuertes & Domergue, Reference de Juan Fuertes and Domergue2013; Stefanile, Reference Stefanile2017). The use of moulds and markings may thus represent early organizational developments in the Iron Age that were implemented in more pronounced ways after Roman conquest, when the mining industry expanded in scale and organizational complexity.

Alternatively, the availability of large shells may have had more to do with industries linked to Pinna nobilis exploitation than it did with a selection process driven by metallurgical production. Perhaps full-grown molluscs were chosen to maximize the products harvested from each animal. This exploitation strategy would help maintain a sustainable population of growing molluscs, thus keeping supply available for the future. In a recent study of western Mediterranean Pinna nobilis populations, García-March and colleagues (Reference García-March, Hernandis, Vázquez-Luis, Prado, Deudero, Vicente and Tena-Medialdea2020) found that the speed of growth depends heavily on local environments; estuaries and coastal lagoons provide optimal conditions, and minor differences such as the depth of the water affect the maximum size and longevity of each animal. They suggest that a normal lifespan can exceed forty-five years and that the fastest growth is in the first five months (García-March et al., Reference García-March, Hernandis, Vázquez-Luis, Prado, Deudero, Vicente and Tena-Medialdea2020: 2). These aspects of the Pinna nobilis lifecycle would have been known to ancient harvesters, whose work depended on the successful long-term exploitation of this resource. Thus, the supply of cast-off shells for use in mining would have tended towards larger, fully-grown specimens, given the practices of producers in the Pinna nobilis-related crafts and the resulting nature of their waste.

Other ingots: possible comparanda

One key question is whether this particular reuse strategy was unique to south-eastern Iberia. Domergue (Reference Domergue1990: 166–67) has pointed to other locations where mineral-rich areas exist close to coastal Pinna nobilis populations. These include Laurion (Attica, Greece) and Iglesias (south-western Sardinia), both exploited at the same time as the argentiferous galena mines of south-eastern Iberia. The recently discovered galena mines of Ibiza are another instance (Hermanns, Reference Hermanns2014). Unfortunately, very few examples of Pinna nobilis-cast ingots attributable to these alternative sources have been found and other possible examples are not usually published in a manner that identifies them as cast in this technique.

The Porticello shipwreck, in the Strait of Messina in southern Italy, provides one example of a Pinna nobilis-cast ingot from the Greek world. The wreck contained over twenty lead ingots (most of which were bun-shaped) alongside a cargo of wine, salted fish, bronze sculpture, and ink. The ship has been dated to c. 400–385 bc (Eiseman, Reference Eiseman1980: 42; Eiseman & Ridgway, Reference Eiseman and Ridgway1987; Parker, Reference Parker1992: 332). One ingot was inscribed with Greek letters (sigma, iota, and eta in ligature), suggesting that this practice of marking, seen later in the Agde K examples, was already established in the fourth century bc. Markings were not, however, found on other ingots from this shipwreck, though some were lost to looters and never examined closely. One of the fragmentary ingots (C26) was likely cast in a Pinna nobilis shell (Eiseman, Reference Eiseman1980: 43) (Figure 8). The lead has been traced to Laurion (Eiseman, Reference Eiseman1979), providing a single but significant indication that this method of casting was employed outside Iberia over a century earlier. If this is the case, one must question whether this technique emerged from multiple independent developments or spread through the maritime communication networks of the Phoenicians, Carthaginians, Greeks, and other merchants. The Porticello shipwreck has been interpreted as a Greek ship transporting lead from Laurion to the western Greek colonies. The use of this technique appears more tied to the availability of local resources than to culturally specific Greek, Iberian, or Carthaginian metallurgical practices.

Figure 8. Lead Pinna nobilis-cast ingot from the Porticello shipwreck. Reproduced by permission of the Penn Museum (image 170044_11).

No Pinna nobilis-cast ingots have been found from Sardinia. However, sea silk production has long taken place at Sant'Antioco in the south-west of the island, close to the Iglesiente mining district (Pes & Pes, Reference Pes, Pes, Landenius Enegren and Meo2017). It is unknown how early in antiquity sea silk weaving began, but it is probable that both metals and Pinna nobilis were exploited simultaneously. If metallurgists chose to use other methods of casting when Pinna nobilis shells were readily available, this may reveal something about the organization or scale of production of each of these industries, or of the lack of social integration between workers in maritime and terrestrial environments in Sardinia.

Finally, another shipwreck shows how the re-evaluation of existing ingots can enhance our understanding of where and how frequently shell casting was practised. Recently, forty orichalcum (a natural alloy of gold and copper) ingots of the sixth century bc were discovered at a shipwreck site near Gela in Sicily (Figure 9). At least one of the ingots (S22) resembles closely the Pinna nobilis-cast ingots from Iberia. The ingots in the assemblage, however, have been interpreted as having been cast in open-air pits in the ground (Caponetti et al., Reference Caponetti, Francesco, Chillura Martino, Saladino, Ridolfi and Chirco2017b: 12–15). Further comparative study between these ingots and the morphology of Pinna nobilis shells could change this interpretation and provide another instance of two types of ingots found on the same shipwreck, adding to the Agde K and Porticello shipwreck examples. The Gela group of ingots derive from a source in the eastern Mediterranean, perhaps from western Anatolia, and have been described as ‘Greek’ (Caponetti et al., Reference Caponetti, Armetta, Brusca, Chillura Martino, Saldano and Ridolfi2017a), providing another clue that this technique was not specific to the east or west or to Greek or Punic cultural contexts, but dependent on local resources and particular social interactions.

Figure 9. Orichalcum ingots from the shipwreck near Gela, Sicily, grouped by chemical similarities. Note the shape of S22 (from Caponetti et al., Reference Caponetti, Armetta, Brusca, Chillura Martino, Saldano and Ridolfi2017a: fig. 7). Reproduced by permission of Elsevier.

Circular economies in coastal environments

Beyond Pinna nobilis casting, other circular economic strategies involving reuse and recycling have been recognized in the ancient Mediterranean, though not always termed in this way and more commonly associated with urban building projects than coastal industries (e.g. Rous, Reference Rous2019; Duckworth & Wilson, Reference Duckworth and Wilson2020; Emmerson, Reference Emmerson2020: 92–123). The economic—rather than symbolic—aspects of ancient cross-industry reuse have only begun to be explored, especially before the Roman and late antique periods. The example discussed here adds an instance from the Iron Age.

To contextualize cross-industry reuse, one must ask how widespread the practice of recycling or reusing shells and other waste from coastal industries was. Various bivalve shells have been used as containers and painters’ pallets, for example (Caley, Reference Caley1945). The purple dye industry, which produced materials (shells) to recycle and relied on recycled materials, provides a good illustration of coastal resource integration, reuse, and recycling. Purple dye is extracted from the glands of marine snails of various species including Murex brandaris, Thais haemastoma, and Murex trunculus. Pliny the Elder described the process (Natural History 9.124–142), which involved collecting the snails in baskets and removing the flesh by piercing or crushing the shell. Next, the meat was stored in salt and allowed to decompose. The resulting liquid was heated in vats to produce dye. Like the various products of the Pinna nobilis, purple dye was highly valued in the ancient world. This process produced empty shells as waste, which could be recycled.

Shells were crushed and used in floor pavements, as ceramic temper, construction fill, or burned to produce lime (Reese, Reference Reese1980: 92). Murex shells have been identified in plaster floors of Bronze Age eastern Mediterranean sites (e.g. Knossos, Akrotiri, Tell el-Dab'a, Hala Sultan Tekke; Brysbaert, Reference Brysbaert2007). Lime kilns were common in the Roman and late antique Mediterranean: for instance, a series of third-century ad kilns for converting murex shells into lime were uncovered in Berenice, Egypt (Reese, Reference Reese1980: 87–92). Purple dye production and other secondary uses of murex are well attested at prehistoric and Roman sites across the Iberian Atlantic and Mediterranean coasts (Cantillo Duarte et al., Reference Cantillo Duarte, Bernal Casasola and Muñoz2014). As with the Pinna nobilis, the high value of the dye derived from the snails suggests that these uses were secondary and a convenient way to recycle waste. Pinna nobilis and other marine shells could equally have been used in lime production (Ferraz et al., Reference Ferraz, Gamelas, Coroado, Monteiro and Rocha2019).

The purple dye industry also employed reused coastal materials. One intriguing example comes from the Phoenician settlement on Motya, a small island off the western coast of Sicily. Whale vertebrae were reused in purple dye production in the sixth and fifth centuries bc. These were reshaped for use as crushing platforms for the murex shells. Reese (Reference Reese2005: 108) has suggested that these vertebrae were collected from a beached or dead whale washed up in the Motya lagoon rather than from a hunted whale. Regardless, whale parts had myriad uses in antiquity (e.g. as oil for illumination, bone for tools, carving, and construction; Reese, Reference Reese2005: 110) On the whole, these instances illustrate the reuse of waste from whaling in another coastal industry.

The questions of how, why, and when reuse of coastal resources took place across industries in the ancient Mediterranean deserve future scrutiny.

Conclusions

The seven Pinna nobilis-cast lead ingots from the Cabrera B and the Agde K wrecks have been known since the 1960s and mentioned mainly as a curiosity of metal production and trade in the Iron Age Mediterranean. Their association with the mines of south-eastern Iberia is cause for a re-evaluation of their significance in their local context. Here, I argue that the ingots reveal previously unexplored aspects of the organization of production in coastal industries of third-century bc Iberia, specifically that luxury crafts were linked to Pinna nobilis exploitation and mining and metallurgy, with refuse (shells) from the former reused in the latter. This reuse can be explained as a circular economic strategy, which eliminated the waste from one industry and reduced the labour and supplies required in another. Many of these interpretations are speculative given the limited direct evidence, but they represent an important step in understanding how and why Pinna nobilis shell ingot casting was practised.

With this article, I hope to bring this particular—and peculiar—instance of coastal resource reuse and cross-industry integration to the attention of Mediterranean archaeologists so that the phenomenon of ingot casting in Pinna nobilis shells can be better recognized in the archaeological record. The discovery of additional archaeological evidence and further study of coastal environments will help answer whether the reuse of Pinna nobilis shells for metallurgy was a locally specific adaptation of coastal resource use in south-eastern Iberia or whether this practice was more widespread in the Iron Age Mediterranean world. The answer to this question has implications for the history of metallurgical and coastal resource exploitation, especially for the mechanisms of the spread of technology in the Iron Age.

Acknowledgements

This article emerged from research initiated during a postdoctoral fellowship with the Michigan Society of Fellows. This work was supported, in part, by a Bruce Frier Fund grant from the Department of Classical Studies at the University of Michigan, Ann Arbor, which allowed me to travel to Cartagena for a research trip. I thank my Women's Faculty Writing Group at Texas Tech University for writing support. I have also benefitted from conversations with and feedback from Katherine Harrington, Felicitas Maeder, Damià Ramis, Catherine Steidl, Katie Tardio, and three anonymous reviewers. I am grateful to Jesús Bellón, Claude Domergue, and Alessandro Pezzati for generously providing images for publication, and to Daniel Plekhov for preparing the map.