Implications

Fouling is a multifactorial problem affected by both the thermal climate, the space allowance, the flooring design and the pigs’ earlier experience. The most important factor to consider to prevent fouling is the climate of the pen, and especially ensuring the highest comfortability in the designated lying area. This can be accomplish through, for example, floor cooling of the lying area, sprinklers above the dunging area or by ensuring a more optimal ambient temperature curve that better fits the weight of the pigs in different stages of the production.

Introduction

Fouling of the pen happens when pigs change their excretory behaviour from occurring in the designated dunging area to the lying area. This can result in a lower hygiene, bad air quality, extra work for the farmer, disturbance of the pigs’ resting behaviour and an increase in agonistic interactions (Aarnink et al., Reference Aarnink, Wagemans and vandenBerg1996; Hillmann et al., Reference Hillmann, Mayer, Gygax and Schrader2004; Smulders et al., Reference Smulders, Verbeke, Mormede and Geers2006). Thus, there is a need for prevention of fouling. However, fouling is a multifactorial problem and thus, prevention is not a straightforward task. Conventional slaughter pigs are often housed in indoor pens with fully or partly slatted floors. The partly slatted floor pens offer a solid lying area that is more comfortable to rest on and aims at encouraging pigs to differentiate between the solid and slatted floor when resting. However, some pen designs work better than others to ensure this differentiation. Also, Randall et al. (Reference Randall, Armsby and Sharp1983) mention that pigs usually eat, drink and then excrete in that order which is why the feeder is often placed close to the lying area and the drinker close to the dunging area. Actually, pigs are known as clean animals in the sense that they keep their lying and dunging areas separate (Aarnink et al., Reference Aarnink, vandenBerg, Keen, Hoeksma and Verstegen2006). In a study by Stolba and Wood-Gush (Reference Stolba and Wood-Gush1989), pigs kept in a semi-natural environment rarely defecated closer than 5 m from their nest site. This is supported by the findings of Salomon et al. (Reference Salomon, Akerhielm, Lindahl and Lindgren2007) for organic pigs housed outdoors, who also saw that the area close to the nest was kept free of dung, and the findings by Olsen et al. (Reference Olsen, Dybkjær and Simonsen2001) where most of the excretory behaviour were performed in the outside runs. This suggests that pigs may change their lying behaviour and thereafter their excretory behaviour to the area previously used for resting, or that pigs change their lying behaviour after a change in excretory behaviour. Pigs only have very few sweat glands, mainly on the snout, and thus they must change their behaviour in order to cool themselves (Sumena et al., Reference Sumena, Lucy, Chungath, Ashok and Harshan2010; Olczak et al., Reference Olczak, Nowicki and Klocek2015). This includes changing from sternal to lateral lying posture to maximise heat loss, avoiding contact with pen mates, wallowing and lying in cooler and/or more draughty areas (Olsen et al., Reference Olsen, Dybkjær and Simonsen2001; Ekkel et al., Reference Ekkel, Spoolder, Hulsegge and Hopster2003; Spoolder et al., Reference Spoolder, Aarnink, Vermeer, van Riel and Edwards2012). If the pigs, on the other hand, are cold, they will huddle more, lay in a sternal posture to minimise heat loss and seek away from draughty and cold areas (Hillmann et al., Reference Hillmann, Mayer, Gygax and Schrader2004; Huynh et al., Reference Huynh, Aarnink and Verstegen2005a; Aarnink et al., Reference Aarnink, vandenBerg, Keen, Hoeksma and Verstegen2006). Further, pigs lie down for at great part of the day (Ekkel et al., Reference Ekkel, Spoolder, Hulsegge and Hopster2003), but there is a tendency for more pigs to lie down when temperatures increase (Huynh et al., Reference Huynh, Aarnink and Verstegen2005a; Spoolder et al., Reference Spoolder, Aarnink, Vermeer, van Riel and Edwards2012). The same is seen when humidity increases (Huynh et al., Reference Huynh, Aarnink and Verstegen2005a). More pigs lying in the pen means that more of the total floor space will be occupied as a lying pig takes up more space than a standing or sitting one. Also, a pig exposed to heat stress will seek to lie without contact with pen mates but with as much contact to the floor as possible. This, once again, takes up even more floor space (Hillmann et al., Reference Hillmann, Mayer, Gygax and Schrader2004 and Reference Hillmann, Mayer and Schrader2005). When a smaller part of the floor is available for moving around at high temperatures, a pig may be restricted in getting to and using the dunging area, and instead being forced to use the area it is currently in for defecation; or the pig may be forced away from its designated lying area to perform thermoregulatory behaviour. Pigs need both static space (occupied by the body of the pig), activity space (feeding and excretion separated) and social space (for social behaviour) (Spoolder et al., Reference Spoolder, Aarnink, Vermeer, van Riel and Edwards2012). If the space requirement is not met, pigs might not be able to make their way to a designated dunging area or to differentiate between spaces. However, excessive space allowance may result in pigs not being motivated to move away from the other pigs to perform their excretory behaviour. Thus, based on the above, an inappropriate climate or space allowance may result in fouling of the pen.

This review aims to summarise, based on the existing literature, which factors affect fouling in conventional slaughter pigs. Further, this review aims to summarise which actions that can help prevent fouling and to identify future perspectives for research within this area.

Methods

A literature search was performed on 26 February 2016 in the database Web of Science. The search strategy included three criteria: (1) the study should be of living weaner or slaughter pigs (from 7 kg to slaughter at around 110 kg), (2) the pigs included in the study should be housed under conventional production standards, (3) the study should focus on investigating lying or dunging behaviour of pigs, fouling or closely related terms. The search only included English-language articles but with no limitation on time span (all years included). The following search strategy was used on the subject fouling: Pen Fouling or ‘Dunging Pattern’ or ‘Dunging preferences’ or ‘Excretory behavio*’ or ‘excreting behavio*’ or ‘eliminative behavio*’ or ‘eliminatory behavio*’ or ‘Pen Hygiene’ or ‘Lying behavio*’ or ‘Thermoregulatory behavio*’, whereas the following search strategy was used on the object pig: Pig* or Swine or Porcine* or Growing-Finishing or ‘Slaughter Pig*’ or ‘Fattening pig*’ or ‘Finishing pig’ or Piggery NOT piglet* NOT sow* NOT cow* NOT goat*. The two search strategies were combined in the end.

Results and discussion

The literature search yielded 127 potential articles. Title and abstracts of the 127 articles were screened to identify those relevant, and articles were selected if they met the above mentioned criteria. This resulted in 28 articles for which full articles were retrieved for further assessment. After reading the full texts, further seven articles and proceedings were removed as they presented the same data as other studies. The end result was 21 articles of relevance.

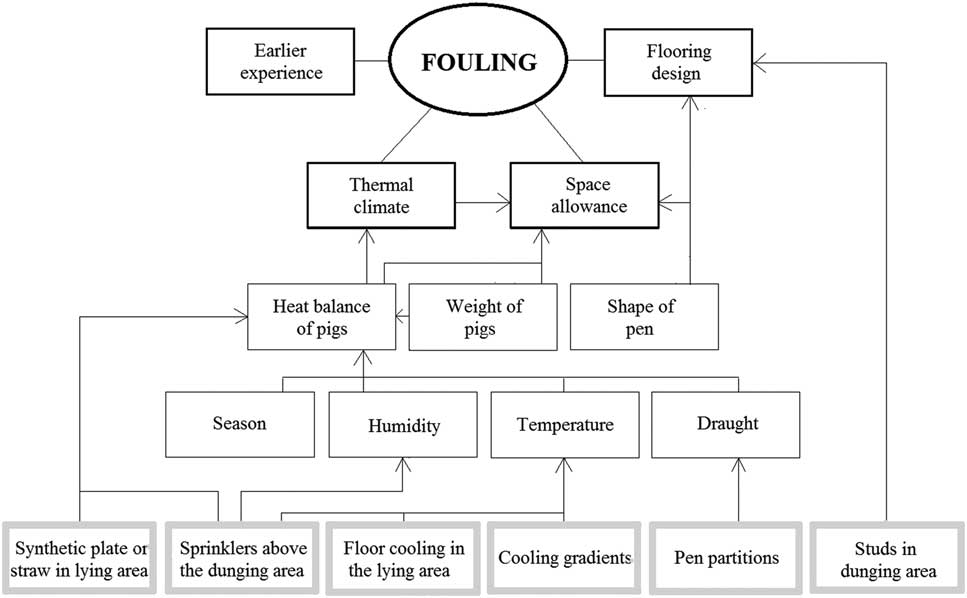

The results obtained from the current literature study is summarised in Figure 1. Figure 1 illustrates that four main factors affect fouling directly: space allowance, the flooring design of the pen, the thermal climate and pigs’ earlier experience. Other factors can be considered secondary, affecting one or more of the primary factors, or even tertiary only affecting the secondary factors directly. Figure 1 also illustrates described preventive actions against fouling and how these affect the risk factors of fouling. The discussion is build around Figure 1 with headings complying with the primary factors and followed by a description of the preventive actions.

Figure 1 Flowchart presenting factors affecting fouling, directly (bold lined boxes) and indirectly, and currently known actions against fouling (grey lined boxes).

Space allowance

The effect of insufficient space allowance on fouling of the pen is straightforward. If the pigs are housed at a too low space allowance they cannot move as easily between the different parts of the pen and might be forced to perform their excretory behaviour in the area where they are currently placed. The negative relationship between space allowance and fouling was indirectly confirmed by Hillmann et al. (Reference Hillmann, Mayer and Schrader2005). They saw a tendency for pigs spending more time lying in the dunging area in pens with a smaller space allowance per pig (0.7 m2/pig compared with 1.4 m2/pig) and they started doing so at lower temperatures. However, at temperatures above 25°C, pigs in the pens with larger space allowances would also start to lie in the dunging area. Another study found that a larger group size at similar space allowances (33 to 42 rather than 17 to 21 pigs/pen) resulted in pigs becoming more wet and dirty (Jensen, Reference Jensen2003, cited by Jensen et al., Reference Jensen, Nielsen, Vinther and D’Eath2012). Hacker et al. (Reference Hacker, Ogilvie, Morrison and Kains1994) found that lower space allowances (comparing 0.64 to 1.0 m2/pig) increased the effect of other factors such as open partitionings or inappropriate placement of the nipple drinker making the pen dirtier at high v. low space allowances. However, a small increase in available space was not found to reduce fouling in slaughter pigs in a study by Jensen et al. (Reference Jensen, Nielsen, Vinther and D’Eath2012) comparing 0.67 to 0.79 m2/pig, though the authors acknowledge that greater differences may have caused an effect on fouling. Hillmann et al. (Reference Hillmann, Mayer and Schrader2005) found a connection between the effect of space allowance and temperature which was confirmed by Spoolder et al. (Reference Spoolder, Aarnink, Vermeer, van Riel and Edwards2012). They found a significant relationship between the space requirements of a pig, its BW and increasing ambient temperatures with pigs taking up more space with increasing weight and temperatures. This relationship is probably due to the change in lying behaviour of pigs at higher temperatures and the fact that a heavier pig has a higher heat production. Spoolder et al. (Reference Spoolder, Aarnink, Vermeer, van Riel and Edwards2012) suggested that if the minimum legal space allowance is applied, then animals above 85 kg are all housed at too high stocking densities. Ekkel et al. (Reference Ekkel, Spoolder, Hulsegge and Hopster2003) also found, based on lying patterns of pigs from different weight classes, that a pig of 100 kg should have 0.76 m2 to lie on, which is more than the minimum requirement of 0.65 m2 for a pig of 85 to 110 kg (EU council Directive 2001/88/EC). Randall et al. (Reference Randall, Armsby and Sharp1983) found that a space allowance of neither less nor more than 120 kg/m2 resulted in the cleanest lying areas. However, the space allowance also depends on the shape of the pen and a narrow pen can result in pigs not being able to move between the designated lying and dunging areas (Randall et al., Reference Randall, Armsby and Sharp1983). An excessive space allowance in the resting area is not preferable either because too much space may prevent the pigs from being motivated to move outside the resting area to perform their excretory behaviour. With too abundant space in the resting area it has been observed that pigs often defecate in unoccupied corners or against walls (Aarnink et al., Reference Aarnink, Koetsier and Vandenberg1993).

The above studies indicate that space allowance may have a preventive effect on fouling if the space allowance is sufficient without being excessive. Also, the above studies indicate that the effect of and thereby choice of space allowance depends on the shape of the pen, the weight of the pigs and the environmental temperature. Future research should focus on the direct effect of space allowance on the incidence of fouling in conventional slaughter pigs at space allowances above the one chosen by Jensen et al. (Reference Jensen, Nielsen, Vinther and D’Eath2012). Further, it could be interesting to investigate whether a design without corners in the designated lying area could prevent pigs from performing their excretory behaviour in these areas.

Flooring design

The importance of a sufficiently large slatted floor area to keep the pen clean was confirmed by Rantzer and Svendsen (Reference Rantzer and Svendsen2001). They found that weaners in pens with around 36% slatted floor had a better hygiene than weaners in pens with solid floors and only 20 cm urine drainage. However, pigs prefer to lie on the solid floor when not in heat stress (Aarnink et al., Reference Aarnink, Wagemans and vandenBerg1996) and thus to improve animal welfare the floor should not only consist of slatted floor. The pen design should, however, allow pigs to be able to distinguish the lying area from the dunging area. This appear to be easier if the dunging area and thereby the slatted floor is placed at the bottom compared with at the long side of a narrow pen (Randall et al., Reference Randall, Armsby and Sharp1983). Also, there is an interest in reducing the slatted area to reduce ammonia emission. A decrease in the proportion of slatted floor from 50% to 25% was found to increase the amount of fouling and thereby ammonia emission (Aarnink et al., Reference Aarnink, Wagemans and vandenBerg1996). However, in the 50% slatted pens, the slatted area was divided between the two ends of the pen with 25% in each end. If the slatted floor had been only in the backend of the pen (where most of the defaecations and urinations occurred independent of proportion of slats) the results might have been different. Contradictory to these results, Huynh et al. (Reference Huynh, Aarnink, Spoolder, Verstegen and Kemp2004) found that pens with 15% slatted floor in the front and 40% slatted floor in the back were cleaner than pens with only 40% slatted floor in the back. The authors suggest themselves that this could partly be explained by the convex shape of the 40% floors in the first mentioned pens. When considering the increased attention on ammonia emission, it is surprising that we did not locate published studies comparing different proportions of slatted floors on the incidence of fouling without confounding effects of the placement of the slats. This is definitely a gap in our knowledge towards both preventing fouling and reducing the ammonia emission. Aarnink et al. (Reference Aarnink, Schrama, Heetkamp, Stefanowska and Huynh1997a) investigated the effect of different types of slatted floor on fouling and ammonia emission comparing concrete, metal and cast iron slats. Metal slats led to the lowest level of ammonia emission, but did not differ from concrete slats when considering fouling. However, cast iron slats resulted in the dirtiest pens and it was suggested that the pigs walked less steadily on these slats which could discourage them from using the dunging area. All in all, not many studies have looked into the effect of either type of slats or proportion of slatted area in the pen. The above studies suggest that both factors could be important for the prevention of fouling, but more research is needed to implement this knowledge in practice. For example, some pens also include drained flooring consisting of slats with a higher width than normal slatted flooring. No studies with drained flooring could be located even though this could be a compromise to decrease ammonia emission from the slatted floor and fouling on the solid floor.

Thermal climate

If pigs choose to lie in the designated dunging area, they no longer perform their excretory behaviour there and will choose to do so in the designated lying area instead, resulting in fouling of the pen. As discussed above, pigs may be forced to lie in the dunging area due to insufficient space allowance. However, the lying behaviour of pigs is also affected by the climate of the pen including temperature, humidity and draught, as already described in the introduction.

Multiple studies have shown that the degree of fouling increases at high ambient temperatures (Huynh et al., Reference Huynh, Aarnink and Verstegen2005a; Aarnink et al., Reference Aarnink, vandenBerg, Keen, Hoeksma and Verstegen2006; Savary et al., Reference Savary, Gygax, Wechsler and Hauser2009; Spoolder et al., Reference Spoolder, Aarnink, Vermeer, van Riel and Edwards2012). This is thought to be caused by the pigs’ desire to cool themselves by lying on the slatted floors measured to be 3°C to 5°C cooler than the solid floor (Randall et al., Reference Randall, Armsby and Sharp1983). Further, pigs react faster to an increase in temperature at higher humidities (Huynh et al., Reference Huynh, Aarnink and Verstegen2005a), and Aarnink et al. (Reference Aarnink, Swierstra, vandenBerg and Speelman1997b) found that more pigs lay in the dunging area during summer than during winter. Draughty or cold lying areas will also discourage the pigs from choosing this site for resting (Randall et al., Reference Randall, Armsby and Sharp1983). However, this knowledge is only interesting in practice if the optimal and inflection temperatures are known. Hillmann et al. (Reference Hillmann, Mayer, Gygax and Schrader2004) found that pigs weighing >85 kg were comfortable at a temperature range of 5°C to 17°C. Pigs weighing 50 to 70 kg were comfortable at 10°C to 17°C and smaller pigs of 25 to 35 kg at 19°C to 21°C. Lower and upper optimal temperature thresholds were indicated by 20% of the pigs huddling and by 20% of the pigs lying without contact, respectively. This illustrates that older, heavier pigs can tolerate quite a large span of temperatures as long as they do not get too hot, whereas smaller pigs need more heat and have a very narrow interval of optimal temperatures. This effect of weight on the effect of temperature was also found by Spoolder et al. (Reference Spoolder, Aarnink, Vermeer, van Riel and Edwards2012) and by the finding that most fouling happens in the end of the finishing period (e.g. Savary et al., Reference Savary, Gygax, Wechsler and Hauser2009; Jensen et al., Reference Jensen, Nielsen, Vinther and D’Eath2012; Spoolder et al., Reference Spoolder, Aarnink, Vermeer, van Riel and Edwards2012), and is probably mainly due to the higher heat production of heavier pigs. When designing the airflow and temperature regulation of pig housing, these optimal temperature ranges should be taken into account. Knowing at which temperature fouling actually occurs could be very helpful when deciding on which actions to use against fouling at different temperatures. The ambient temperature has two inflection points: (1) the temperature at which pigs start to defecate in the lying area with solid floors and (2) the temperature at which pigs start to lie more in the slatted dunging area. Aarnink et al. (Reference Aarnink, vandenBerg, Keen, Hoeksma and Verstegen2006) found a linear increase in excretions on the solid floor above 19.5°C for pigs weighing 65 kg and housed at 1.02 m2/pig, whereas the inflection temperature for lying in the dunging area was 25.4°C. Huynh et al. (Reference Huynh, Aarnink and Verstegen2005a) found a linear relationship between temperature and excretions on the solid floor with an average inflection temperature of 20°C across relative humidities of 50%, 65% and 80% at 61 kg and 1.0 m2/pig, whereas this was 18.8°C for dunging on the slatted floor. Further, both inflection temperatures become lower as the pigs grow. Excreting on the solid floor has been found to start on average at 25°C for pigs of 25 kg and change to ~20°C for pigs of 100 kg (Aarnink et al., Reference Aarnink, vandenBerg, Keen, Hoeksma and Verstegen2006), whereas pigs started to lie in the dunging area during the hot summer period at ambient temperatures of 27°C, 23°C and 22°C for the 25 to 35, 50 to 70 and >85 kg groups, respectively (Hillmann et al., Reference Hillmann, Mayer, Gygax and Schrader2004).

From the results of Huynh et al. (Reference Huynh, Aarnink and Verstegen2005a), the pigs seems first to change their lying behaviour and next their dunging behaviour which fits with the theory that pigs change their lying area to be able to thermoregulate and then keep this new lying area clean. However, the results of Aarnink et al. (Reference Aarnink, vandenBerg, Keen, Hoeksma and Verstegen2006) show the opposite order of behavioural change when only looking at the inflection temperature. When looking more closely, they also found that when more than 28% of the dunging area was occupied by pigs, it resulted in an increased number of excretions in the lying area. This means that excretion in the lying area had already increased before the maximum occupation of the slatted floors in the dunging area had been reached, but pigs did change their lying behaviour before fouling occurred. One explanation could be that a few pigs start out by changing their lying behaviour to lying in the dunging area, which in the beginning might be sparsely occupied and thus does not motivate the pigs to move further away than the other end of the dunging area to defecate. As more pigs start to change their lying behaviour, the dunging area becomes more occupied and pigs now get up to defecate further away; that is in the lying area. Huynh et al. (Reference Huynh, Aarnink, Spoolder, Verstegen and Kemp2004) also reported that only a maximum of 30% to 35% of pigs lay in the dunging area at temperatures above 30°C and Hillmann et al. (Reference Hillmann, Mayer, Gygax and Schrader2004) reported 40%. This may be explained by the finding that pigs do not want to lie too close to each other when it is hot, even when they lie on the cooler slats. Besides, if the lying area is wet due to fouling, it would fulfil the pigs’ need for cooling as it can be used for wallowing. Further, at these high ambient temperatures, almost all the pigs will be lying (Huynh et al., Reference Huynh, Aarnink and Verstegen2005a). Therefore, it is harder for a pig to move from one end of the pen to the other to defecate, resulting in pigs defecating in the lying area even though there might still be space in the dunging area.

From the above discussion, it is evident that the climate of the pen, and especially the temperature, affects fouling and that it occurs through a change in lying behaviour induced by a need to thermoregulate. The effect of temperature may also overrule the effect of space allowance at high enough temperatures (Hillmann et al., Reference Hillmann, Mayer and Schrader2005). Thus, to prevent fouling in conventional slaughter pigs with partly slatted floor, it is essential to control the temperature in a pig house or at least to ensure that the designated lying area has the most comfortable climate for lying. Studies conducted so far on fouling in pigs have focused on the risk factors for fouling and ways to lower these risks and thereby prevent fouling. However, use of precision livestock farming may also be a strategy to prevent fouling by developing algorithms that can predict whether a fouling event will happen at pen level. This could, for example, be through surveillance of the lying pattern of the pigs or the ambient temperature of the pen.

Previous experience

It has been suggested that different forms of training or previous experience could affect fouling of pens. It seems that pigs choose their lying area very soon after being transferred to a new pen. Blackshaw (Reference Blackshaw1981) saw that weaners, being transferred to their slaughter pig pens, decided on their lying area 25 to 60 min after being mixed and introduced to the pen. Hacker et al. (Reference Hacker, Ogilvie, Morrison and Kains1994) trained the pigs included in their study. Training consisted of locking the pigs over the dunging area when moving them to the pens, for 2 h, before releasing them into the rest of the clean pen. They found a tendency towards trained pigs fouling more than untrained pigs. The training might have given the pigs an unpleasant experience, thus avoiding the dunging area to some degree afterwards, or the pigs might have chosen the dunging area as their lying area. Rantzer and Svendsen (Reference Rantzer and Svendsen2001) found that weaners moved from slatted farrowing facilities to a slatted weaner pen had better pen hygiene than weaners staying in the slatted farrowing facilities. This could be explained by a break in the infection chain leading to less diarrhoea. Fouling and diarrhoea have been linked because pigs might not make it to the dunging area in time or they might feel too ill to perform their natural behaviour (Rantzer et al., Reference Rantzer, Westroem and Svendsen1999). Randall et al. (Reference Randall, Armsby and Sharp1983) argue that pigs transferred from totally slatted floors are more likely to defecate in the entire area of a partly slatted floor than pigs moved from a completely solid or partially slatted floor. However, they do not present any results or studies to back this up. Not many studies have looked at the connection between fouling and previous experience, thus this field of research still have great potential. For example, it could be interesting to investigate whether fewer pens are fouled if the slaughter pigs experience the same type of flooring through their entire life because they then might find it easier to differentiate between lying and dunging areas of the pen.

Actions to prevent fouling

Most studies so far on actions to prevent fouling have focused on controlling the climate of the pen either through sprinklers, floor cooling or cooling gradients. Sprinklers can be used to cool pigs when temperatures are high. Huynh et al. (Reference Huynh, Aarnink, Gerrits, Heetkamp, Canh, Spoolder, Kemp and Verstegen2005b) found that pens with sprinklers had a better production with a higher feed intake and daily gain and a lower skin temperature resulting in fewer pigs lying laterally. Spoolder et al. (Reference Spoolder, Aarnink, Vermeer, van Riel and Edwards2012) found that the amount of space that pigs use is affected by the presence of a showering system activated at temperatures above 25°C. This meant that pigs lying in the dunging area did not need to change to lateral lying (and thereby taking up more space) because they were cooled by the water. Jensen and Kristensen (Reference Jensen and Kristensen2016) saw that when temperatures fell quickly in the dunging area, as a result of sprinklers being turned on, the risk of undesired events such as fouling was reduced. Thus, use of sprinklers when temperatures are high helps to reduce fouling through cooling of the pigs, but it will also make the dunging area wet and undesirable for the pigs to lie in. Instead of making the dunging area undesirable, it would be better to increase the desirability of the lying area, for example, through floor cooling in the solid floors. Geers et al. (Reference Geers, Goedseels, Parduyns, Nijns and Wouters1990) used water tubes in the floors to control the temperature, thereby achieving a microclimate that encouraged weaned pigs from 10 to 30 kg to lie in the designated lying area. Similar results were found by Huynh et al. (Reference Huynh, Aarnink, Spoolder, Verstegen and Kemp2004) who found less fouling and fewer pigs lying in the dunging area in pens with cooled floors. Randall et al. (Reference Randall, Armsby and Sharp1983) did an experiment with cooling gradients in pens for slaughter pigs. They found that pens were cleaner with an air inflow that ensured that the lying area was warmer and with lower air speed than the dunging area. However, this would probably have the opposite effect if the temperature in the room is not kept optimally low. The best temperature gradient tested in the experiment was with the lying end being 2.6°C higher than the lower critical temperature and the dunging end being 3.7°C lower than the lower critical temperature, with a total cooling gradient of 6.3°C. The lower critical temperature was not defined in the study but, as mentioned earlier, Hillmann et al. (Reference Hillmann, Mayer, Gygax and Schrader2004) defined these as ranging from 19°C for pigs of 25 to 35 kg to 5°C for pigs of >85 kg. Pens in which the airflow was directed first to the lying area and then towards the dunging area were significantly dirtier. This could be explained by pigs avoiding lying in the draughty cooler lying area and thus initiating fouling. Another aspect of controlling the climate is to decrease draught in the lying area. Hacker et al. (Reference Hacker, Ogilvie, Morrison and Kains1994) found pens with open partitions in the entire pen to be dirtier than closed pens even though both pen types had open partitions in the dunging area. The closed pen partitions may result in reduced draught and maintain a temperature gradient with a warmer lying area compared with the dunging area. However, another theory is that the open partitions in the entire pen could provoke a need to mark not just the dunging area but the whole length of the pen with dung as a territorial behaviour (Hacker et al., Reference Hacker, Ogilvie, Morrison and Kains1994). An alternative to control the climate of the pen and especially the designated lying area to prevent fouling may be to increase the comfort of the surface in the lying area. Savary et al. (Reference Savary, Gygax, Wechsler and Hauser2009) investigated the effect of a synthetic plate in the lying area, compared with concrete or a slight straw layer, on fouling. Lying area was 75% of the pen and the synthetic plate covered this area entirely. They found that the proportion of pigs lying in the dunging area was higher in pens with a synthetic plate or straw compared with pens with concrete flooring. Again, fouling increased as temperature increased ranging from 4°C to 28°C and this increase was steeper in pens with a synthetic plate or straw. They concluded that the synthetic plate and straw may cause heat loss problems and more fouling because the pigs instead choose to lie in the dunging area. Thus, increasing the comfort of the surface in the lying area did not reduce fouling but had the opposite effect. However, Vermeer et al. (Reference Vermeer, Altena, Vereijken and Bracke2015) found that adding a rooting area to outdoor runs of organic pigs improved the cleanliness of the outdoor area. Thus, materials such as hay or straw may help pigs differentiate areas of the pen as long as it does not limit their thermoregulatory behaviour. Aarnink et al. (Reference Aarnink, Swierstra, vandenBerg and Speelman1997b) instead reduced the comfort of the dunging area through 5 cm high studs on the slatted area which did result in cleaner pens. This solution does not, however, reduce heat stress at high temperatures and might increase the risk of lameness and thus, does not improve the welfare of the pigs. An alternative action against fouling found in the literature investigated here was to design the pen with a step down between the designated lying and dunging area. The half of the lying area closest to the step down, was found to have significantly less excreta when the step down was installed than when it was not (Randall et al., Reference Randall, Armsby and Sharp1983). All in all, controlling the climate through sprinklers, floor cooling, cooling gradients or closed pen partitions seems effective in reducing fouling, whereas the same applies for installing a step down between the designated lying and dunging area and decreasing the comfort of the dunging area surface. Increasing the comfort of the lying area surface will probably also help prevent fouling, but it is important always to have in mind whether the surface will also change pigs’ ability to thermoregulate.

Conclusion and future perspectives

From the studies included in this review on factors affecting fouling, it is evident that multiple factors affect fouling, but ensuring the right climate while considering the weight of the pigs seems the most effective way to control fouling. Other aspects important to consider is that the space allowance is neither too low nor too high and that the slatted floor should be comfortable for the pigs to walk on. However, if the climate is not appropriate, most other factors will not matter. If the ambient temperature cannot be kept in the optimal range, sprinklers or floor cooling are effective in cooling the pigs. Suggestions for future studies have been made throughout the review, but most importantly, they should focus on optimising the lying area instead of making the dunging area less desirable. Further, a new approach may be to predict fouling events at pen level through changes in lying pattern and temperature, thereby preventing it from happening.

Acknowledgments

The study was granted by the Green Development and Demonstration Programme under the Ministry of Food, Agriculture and Fisheries, Denmark (project StrawWell j.nr.: 34009-13-0736) and by the Danish Council for Strategic Research (The PigIT project, Grant no. 11-116191).