Article contents

Carcass gain per kg feed intake: developing a stakeholder-driven benchmark for comparing grow-finishing pig performance

Published online by Cambridge University Press: 13 July 2020

Abstract

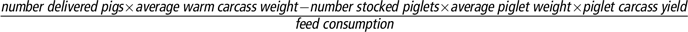

Feed conversion ratio (FCR) in grow-finishing pigs is one of the most important determinants of pig farm profitability and production efficiency. In its simplest form, FCR represents the amount of feed used per unit weight gain of the pig. Yet, this approach entails various limitations hampering its practical applicability such as availability of accurate data and large variation in ways to adapt FCR values for different starting and end weight as well as mortality rates. Various stakeholders are using their own formulas to determine FCR creating a ‘definition nonconformity’ when comparing FCRs among farms. This study aimed to optimize the calculation of FCR through the use of participatory qualitative research. A multidisciplinary research group of 9 persons (animal scientists, veterinarians and agricultural economists) and a consulting group of 31 stakeholders (representing the Flemish primary sector, feed industry, pharma, genetic companies, large retailers, academia and policy institutions) were involved. The decision problem analysis started with a literature review, followed by 25 in-depth interviews and their analyses (NVivo 11™). This led to an additional literature review and the formation of focus (expert) groups that helped to formulate preliminary FCR formulas. Revision rounds between the research team and the stakeholders further fine-tuned the formulas with the final result being two distinct complimentary formulas that are fit for purpose. Both refer to carcass gain per kg feed intake (plain (CGF) and standardized (CGFstandardized)). The first formula (CGF), namely  ${{{\it{number \, delivered \, pigs}} \times {\it{average \, warm \, carcass \, weight}} - {\it{number \, stocked \, piglets}} \times {\it{average \, piglet \, weight}} \times {\it{piglet \, carcass \, yield}}} \over {{\it{feed \, consumption}}}}$ is an objective representation of the animals’ performance. The second formula (CGFstandardized) was developed for farm benchmarking, incorporating a seven-step standardization process that corrects for mortality and ‘standardizes’ for a fixed (yet fictive) live weight trajectory of 25 to 115 kg. This second formula allows to compare farms (or batches of fattening pigs) with different weight trajectories and different mortality rates. A webtool was designed to ease this standardization process (https://varkensloket.be/tools/CGF).

${{{\it{number \, delivered \, pigs}} \times {\it{average \, warm \, carcass \, weight}} - {\it{number \, stocked \, piglets}} \times {\it{average \, piglet \, weight}} \times {\it{piglet \, carcass \, yield}}} \over {{\it{feed \, consumption}}}}$ is an objective representation of the animals’ performance. The second formula (CGFstandardized) was developed for farm benchmarking, incorporating a seven-step standardization process that corrects for mortality and ‘standardizes’ for a fixed (yet fictive) live weight trajectory of 25 to 115 kg. This second formula allows to compare farms (or batches of fattening pigs) with different weight trajectories and different mortality rates. A webtool was designed to ease this standardization process (https://varkensloket.be/tools/CGF).

- Type

- Research Article

- Information

- Copyright

- © The Author(s), 2020. Published by Cambridge University Press on behalf of The Animal Consortium

References

- 5

- Cited by