1. Introduction

1.1. Problem statement

The main goal of this study is to obtain a universal law of the skin-friction coefficient in a steady and fully developed axisymmetric turbulent boundary layer (ATBL) flow with a zero pressure gradient. The surface drag experienced by an axisymmetric object, say a rocket engine nozzle or a submarine hull, is of considerable importance because of its tremendous impact on the overall system performance. Understanding the skin friction in an ATBL flow is therefore crucial for designing and optimising the flow past axisymmetric objects. By reducing the skin friction, the drag force can be minimised, resulting in an enhanced system performance.

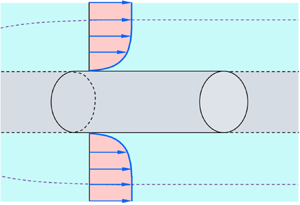

In an ATBL flow, the flow is rotationally symmetric around a central axis. The ATBL develops along an axisymmetric body, say flow past a cylinder with its axis aligned along the flow (figure 1). Let the cylinder radius be a, the boundary layer thickness be δ and the free stream velocity be U∞. For a fully developed flow (δ no longer depends on the longitudinal distance z) with a zero pressure gradient, the dimensional analysis allows us to express the skin-friction coefficient Cf as follows:

where ![]() $\tau_0$ is the wall shear stress, ρ is the mass density of fluid, f is the functional form, Rea = U∞a

$\tau_0$ is the wall shear stress, ρ is the mass density of fluid, f is the functional form, Rea = U∞a ![]() $/ \upsilon$ is the Reynolds number based on the cylinder radius and

$/ \upsilon$ is the Reynolds number based on the cylinder radius and ![]() $\upsilon$ is the coefficient of kinematic viscosity of fluid. The objective of this study is to find the functional form (1.1) by means of a theoretical approach. Since an analytical formula is simpler and computationally more efficient than the numerical techniques, the proposed formula would be easier to use and more accessible to researchers.

$\upsilon$ is the coefficient of kinematic viscosity of fluid. The objective of this study is to find the functional form (1.1) by means of a theoretical approach. Since an analytical formula is simpler and computationally more efficient than the numerical techniques, the proposed formula would be easier to use and more accessible to researchers.

Figure 1. Flow past an axisymmetric body, say a rigid cylinder with a radius a, described with respect to a cylindrical coordinate system (r, θ, z). Here, ūz is the time-averaged longitudinal velocity in the z direction, ![]() ${U_\infty } = {\bar{u}_z}{|_{r \,=\, a \,+\, \delta }}$ is the free stream velocity, δ is the boundary layer thickness, r = a defines the surface of the cylinder and r = a + δ defines the edge of the ATBL.

${U_\infty } = {\bar{u}_z}{|_{r \,=\, a \,+\, \delta }}$ is the free stream velocity, δ is the boundary layer thickness, r = a defines the surface of the cylinder and r = a + δ defines the edge of the ATBL.

1.2. The ATBL flow regimes

A plane turbulent boundary layer (TBL) flow is characterised by two length scales, namely, the boundary layer thickness δ and the viscous length scale ![]() $\upsilon / $u*, where

$\upsilon / $u*, where ![]() ${u_\ast } = {({\tau _0}/\rho )^{1/2}}$ is the friction velocity. However, an ATBL flow possesses an extra length scale, that is, the radius of transverse curvature a. The role of transverse curvature in an ATBL flow has long been studied experimentally (Richmond Reference Richmond1957; Yu Reference Yu1958; Rao Reference Rao1967; Chase Reference Chase1972; Rao & Keshavan Reference Rao and Keshavan1972; Patel, Nakayama & Damian Reference Patel, Nakayama and Damian1974; Willmarth et al. Reference Willmarth, Winkel, Sharma and Bogar1976; Luxton, Bull & Rajagopalan Reference Luxton, Bull and Rajagopalan1984; Lueptow, Leehey & Stellinger Reference Lueptow, Leehey and Stellinger1985; Cipolla & Keith Reference Cipolla and Keith2003; Krane, Grega & Wei Reference Krane, Grega and Wei2010). The additional length scale in an ATBL flow gives rise to three different flow regimes depending on two dimensionless parameters. They are the ratio of boundary layer thickness to radius of curvature, δ

${u_\ast } = {({\tau _0}/\rho )^{1/2}}$ is the friction velocity. However, an ATBL flow possesses an extra length scale, that is, the radius of transverse curvature a. The role of transverse curvature in an ATBL flow has long been studied experimentally (Richmond Reference Richmond1957; Yu Reference Yu1958; Rao Reference Rao1967; Chase Reference Chase1972; Rao & Keshavan Reference Rao and Keshavan1972; Patel, Nakayama & Damian Reference Patel, Nakayama and Damian1974; Willmarth et al. Reference Willmarth, Winkel, Sharma and Bogar1976; Luxton, Bull & Rajagopalan Reference Luxton, Bull and Rajagopalan1984; Lueptow, Leehey & Stellinger Reference Lueptow, Leehey and Stellinger1985; Cipolla & Keith Reference Cipolla and Keith2003; Krane, Grega & Wei Reference Krane, Grega and Wei2010). The additional length scale in an ATBL flow gives rise to three different flow regimes depending on two dimensionless parameters. They are the ratio of boundary layer thickness to radius of curvature, δ ![]() $/$a, and the dimensionless radius of curvature (in wall units),

$/$a, and the dimensionless radius of curvature (in wall units), ![]() ${a^ + } = a{u_\ast }/\upsilon$. The classification of flow regimes can be found in the work of Piquet & Patel (Reference Piquet and Patel1999), Woods (Reference Woods2006) and Kumar & Mahesh (Reference Kumar and Mahesh2018a). However, for the convenience of the readers, the flow regimes are briefly summarised below.

${a^ + } = a{u_\ast }/\upsilon$. The classification of flow regimes can be found in the work of Piquet & Patel (Reference Piquet and Patel1999), Woods (Reference Woods2006) and Kumar & Mahesh (Reference Kumar and Mahesh2018a). However, for the convenience of the readers, the flow regimes are briefly summarised below.

(i) Regime I (δ/a ≤ 1 and a + > 250): in this flow regime, the effect of the transverse curvature on the flow is negligible. The flow behaves as if it were a plane TBL flow. However, it offers an increased skin friction compared with a plane TBL flow having the same Reynolds number based on the boundary layer thickness,

$R{e_\delta } = {U_\infty }\delta /\upsilon$. Using the matched asymptotic expansion method, Afzal & Narasimha (Reference Afzal and Narasimha1976) showed that, for δ/a = O(1) and large a +, the longitudinal velocity distribution ūz(y) in the viscous sublayer is expressed as

(1.2)whereas that in the logarithmic layer follows the axisymmetric logarithmic law as

$R{e_\delta } = {U_\infty }\delta /\upsilon$. Using the matched asymptotic expansion method, Afzal & Narasimha (Reference Afzal and Narasimha1976) showed that, for δ/a = O(1) and large a +, the longitudinal velocity distribution ūz(y) in the viscous sublayer is expressed as

(1.2)whereas that in the logarithmic layer follows the axisymmetric logarithmic law as \begin{equation}u_z^ += {a^ + }\ln \left( {1 + \frac{y}{a}} \right),\end{equation}(1.3)

\begin{equation}u_z^ += {a^ + }\ln \left( {1 + \frac{y}{a}} \right),\end{equation}(1.3) \begin{equation}u_z^ += \frac{1}{\kappa }\ln \left[ {{a^ + }\ln \left( {1 + \frac{y}{a}} \right)} \right] + B.\end{equation}

\begin{equation}u_z^ += \frac{1}{\kappa }\ln \left[ {{a^ + }\ln \left( {1 + \frac{y}{a}} \right)} \right] + B.\end{equation}

In (1.2) and (1.3), ![]() $u_{z}^{+} = \bar{u}_{z}/u_{\ast}$, y is the wall-normal distance measured from the surface of the cylinder, κ is the von Kármán constant (that is, the slope of the axisymmetric logarithmic law) and B is the intercept. Afzal & Narasimha (Reference Afzal and Narasimha1976) found that B is a weak function of the transverse curvature as B = 5 + 236

$u_{z}^{+} = \bar{u}_{z}/u_{\ast}$, y is the wall-normal distance measured from the surface of the cylinder, κ is the von Kármán constant (that is, the slope of the axisymmetric logarithmic law) and B is the intercept. Afzal & Narasimha (Reference Afzal and Narasimha1976) found that B is a weak function of the transverse curvature as B = 5 + 236![]() $/$a +.

$/$a +.

(ii) Regime II (δ/a > 1 and a + > 250): in this flow regime, the effect of the curvature is sensed only in the outer flow layer. The velocity distribution preserves a logarithmic layer described by (1.3), having a decreasing slope (Lueptow et al. Reference Lueptow, Leehey and Stellinger1985).

(iii) Regime III (δ

$/$a > 1 and a + < 250): in this flow regime, the effect of the strong curvature influences both the inner and outer flow layers. The logarithmic layer decays and turns out to be negatively curved (Willmarth et al. Reference Willmarth, Winkel, Sharma and Bogar1976; Luxton et al. Reference Luxton, Bull and Rajagopalan1984).

$/$a > 1 and a + < 250): in this flow regime, the effect of the strong curvature influences both the inner and outer flow layers. The logarithmic layer decays and turns out to be negatively curved (Willmarth et al. Reference Willmarth, Winkel, Sharma and Bogar1976; Luxton et al. Reference Luxton, Bull and Rajagopalan1984).

Nearly all experimental studies paid attention to the last two flow regimes (regimes II and III). However, the availability of the experimental data for these flow regimes has been limited. This is because, to achieve a large δ ![]() $/$a, experiments were generally conducted using either a long tube or a wire having a small diameter. Therefore, the structural isolation of wires and the aeroelastic interaction between the wire and the flow had caused major issues. Moreover, in a typical experimental set-up, it was rather challenging to maintain the alignment of the cylinder with the flow and to prevent the sagging of the cylinder due to the elastic deformation (Piquet & Patel Reference Piquet and Patel1999). Furthermore, for a small a +, the measuring probe size with respect to the cylinder radius has been a serious concern in taking measurements close to the wall. To avoid such difficulties, researchers studied the problem extensively by means of numerical simulations (Neves, Moin & Moser Reference Neves, Moin and Moser1994; Tutty Reference Tutty2008; Jordan Reference Jordan2011, Reference Jordan2013, Reference Jordan2014a,Reference Jordanb; Monte, Sagaut & Gomez Reference Monte, Sagaut and Gomez2011). The results of the direct numerical simulation (DNS) (Neves et al. Reference Neves, Moin and Moser1994; Woods Reference Woods2006; Tutty Reference Tutty2008), large eddy simulation (LES) (Jordan Reference Jordan2011, Reference Jordan2013) and axisymmetric Reynolds-averaged Navier–Stokes (RANS) (Monte et al. Reference Monte, Sagaut and Gomez2011) provided deeper understanding of the skin-friction coefficient over a considerable range of the parameter space.

$/$a, experiments were generally conducted using either a long tube or a wire having a small diameter. Therefore, the structural isolation of wires and the aeroelastic interaction between the wire and the flow had caused major issues. Moreover, in a typical experimental set-up, it was rather challenging to maintain the alignment of the cylinder with the flow and to prevent the sagging of the cylinder due to the elastic deformation (Piquet & Patel Reference Piquet and Patel1999). Furthermore, for a small a +, the measuring probe size with respect to the cylinder radius has been a serious concern in taking measurements close to the wall. To avoid such difficulties, researchers studied the problem extensively by means of numerical simulations (Neves, Moin & Moser Reference Neves, Moin and Moser1994; Tutty Reference Tutty2008; Jordan Reference Jordan2011, Reference Jordan2013, Reference Jordan2014a,Reference Jordanb; Monte, Sagaut & Gomez Reference Monte, Sagaut and Gomez2011). The results of the direct numerical simulation (DNS) (Neves et al. Reference Neves, Moin and Moser1994; Woods Reference Woods2006; Tutty Reference Tutty2008), large eddy simulation (LES) (Jordan Reference Jordan2011, Reference Jordan2013) and axisymmetric Reynolds-averaged Navier–Stokes (RANS) (Monte et al. Reference Monte, Sagaut and Gomez2011) provided deeper understanding of the skin-friction coefficient over a considerable range of the parameter space.

1.3. Empirical formulae of skin-friction coefficient

The skin-friction coefficient can be obtained from (1.3) if the axisymmetric logarithmic law is preserved throughout the boundary layer. Although there have been efforts to identify the effect of the transverse curvature on the logarithmic law of the velocity distribution, a generic consensus is still lacking in this regard. The logarithmic law, involving the slope and intercept parameters κ and B, respectively, is expected to depend on the radius of curvature (Willmarth et al. Reference Willmarth, Winkel, Sharma and Bogar1976; Luxton et al. Reference Luxton, Bull and Rajagopalan1984). For example, Rao & Keshavan (Reference Rao and Keshavan1972) proposed that the slope parameter κ is a function of Rea only, whereas the intercept parameter B is a function of both Rea and a +.

Woods (Reference Woods2006) found that (1.3), with κ = 0.4 and B = 5.1, captures the velocity distribution in the ATBL flows. Using ![]() $U_{\infty}=\bar{u}_{z}\ (y=\delta)$, (1.3) gives

$U_{\infty}=\bar{u}_{z}\ (y=\delta)$, (1.3) gives

Using ![]() ${C_f} = 2u_\ast ^2/U_\infty ^2$ and

${C_f} = 2u_\ast ^2/U_\infty ^2$ and ![]() ${a^ + } = R{e_a}\sqrt {{C_f}/2} $, (1.4) is rearranged as

${a^ + } = R{e_a}\sqrt {{C_f}/2} $, (1.4) is rearranged as

\begin{equation}\sqrt {\frac{2}{{{C_f}}}} + 2.5\ln \sqrt {\frac{2}{{{C_f}}}} = 2.5\ln \left[ {R{e_a}\ln \left( {1 + \frac{\delta }{a}} \right)} \right] + 5.1,\end{equation}

\begin{equation}\sqrt {\frac{2}{{{C_f}}}} + 2.5\ln \sqrt {\frac{2}{{{C_f}}}} = 2.5\ln \left[ {R{e_a}\ln \left( {1 + \frac{\delta }{a}} \right)} \right] + 5.1,\end{equation}

which can be solved for the given Rea and δ ![]() $/$a. Figure 2 shows the numerical solution of (1.5), herein called the axisymmetric logarithmic solution, by plotting

$/$a. Figure 2 shows the numerical solution of (1.5), herein called the axisymmetric logarithmic solution, by plotting ![]() $\sqrt {2/{C_f}} $ as a function of

$\sqrt {2/{C_f}} $ as a function of ![]() $R{e_a}\ln (1 + \delta /a)$. As the analytical solution of (1.5) is not straightforward, Woods (Reference Woods2006) neglected the slowly evolving function

$R{e_a}\ln (1 + \delta /a)$. As the analytical solution of (1.5) is not straightforward, Woods (Reference Woods2006) neglected the slowly evolving function ![]() $\ln \sqrt {2/{C_f}} $ and proposed a reduced form of (1.5) as follows:

$\ln \sqrt {2/{C_f}} $ and proposed a reduced form of (1.5) as follows:

\begin{equation}\sqrt {\frac{2}{{{C_f}}}} = {A_0}\ln \left[ {R{e_a}\ln \left( {1 + \frac{\delta }{a}} \right)} \right] + {B_0},\end{equation}

\begin{equation}\sqrt {\frac{2}{{{C_f}}}} = {A_0}\ln \left[ {R{e_a}\ln \left( {1 + \frac{\delta }{a}} \right)} \right] + {B_0},\end{equation}where A 0 and B 0 are the fitting parameters. Using the available experimental data and the DNS data, Woods (Reference Woods2006) found A 0 = 2.97 and B 0 = −5.82. Woods’ (Reference Woods2006) empirical formula (1.6) is also plotted in figure 2. The axisymmetric logarithmic solution departs from Woods’ (Reference Woods2006) empirical formula. The reason is that, in (1.5), the slope and the intercept parameters of the axisymmetric logarithmic law are kept constant, although they are expected to vary with the curvature (Rao & Keshavan Reference Rao and Keshavan1972).

Figure 2. Comparison of the skin-friction coefficients obtained from the axisymmetric logarithmic solution and Woods’ (Reference Woods2006) empirical formula.

Monte et al. (Reference Monte, Sagaut and Gomez2011) used an axisymmetric RANS formulation and adjusted the fitting parameters of (1.6) as A 0 = 2.56 and B 0 = −2.53. They also performed the nonlinear fitting of their simulation data and proposed the following empirical form:

where G(β; γ) is a third-order polynomial function. It is given by ![]() $G(\beta ;\gamma ) = {a_0} + {a_1}\beta + {a_2}{\beta ^2} + {a_3}{\beta ^3} + {a_4}\beta \gamma + {a_5}\beta {\gamma ^2} + {a_6}{\beta ^2}\gamma + {a_7}{\gamma ^3} + {a_8}{\gamma ^2} + {a_9}\gamma$, where a 0 to a 9 are the coefficients.

$G(\beta ;\gamma ) = {a_0} + {a_1}\beta + {a_2}{\beta ^2} + {a_3}{\beta ^3} + {a_4}\beta \gamma + {a_5}\beta {\gamma ^2} + {a_6}{\beta ^2}\gamma + {a_7}{\gamma ^3} + {a_8}{\gamma ^2} + {a_9}\gamma$, where a 0 to a 9 are the coefficients.

Jordan (Reference Jordan2013, Reference Jordan2014b) proposed models for the skin-friction coefficient in an ATBL flow. The LES results of Jordan (Reference Jordan2011, Reference Jordan2013) offered an enhanced understanding of the ATBL flow properties over considerable ranges of Rea and δ ![]() $/$a.

$/$a.

Among recent studies, Kumar & Mahesh (Reference Kumar and Mahesh2018a) performed an insightful analysis of a developing ATBL flow using the momentum integral approach. The mathematical analysis could capture the effects of the pressure gradient and the transverse curvature on the skin-friction coefficient. The proposed analytical relations were in satisfactorily agreement with the experimental data of the skin-friction coefficient for a developing ATBL flow. Kumar & Mahesh (Reference Kumar and Mahesh2018b) and Morse & Mahesh (Reference Morse and Mahesh2021) presented the LES results of flow over an idealised submarine hull, providing enhanced understanding of the skin-friction coefficient along the axisymmetric body. Balantrapu et al. (Reference Balantrapu, Hickling, Alexander and Devenport2021) experimentally studied the highly decelerated ATBL flow over a body of revolution, focussing on the mean flow, turbulence statistics and the skin-friction coefficient.

Despite magnificent advances on the ATBL flow, a universal law of the skin-friction coefficient, even for a simplified flow configuration (steady and fully developed ATBL flow with a zero pressure gradient), has remained unexplored from a theoretical perspective. The empirical formulae of the skin-friction coefficient in an ATBL flow contain free parameters, which were obtained from the regression analyses of the available experimental and/or simulation data. The empirical formulae work satisfactorily over a wide range of the parameter space. However, as these formulae were developed on the empirical ground, they lack theoretical support. In this study, we seek a universal scaling law of the skin-friction coefficient in an ATBL flow. The governing equation for a steady and fully developed ATBL flow with a zero pressure gradient is derived systematically starting from the axisymmetric equations followed by Reynolds averaging and the boundary layer approximation. Then, the scaling law of the Reynolds shear stress caused by near-wall turbulent eddies is derived. This allows us to obtain the wall shear stress and subsequently provides an estimation of the skin-friction coefficient.

The rest of the paper is organised as follows. The theoretical analysis is described in § 2. In § 3, the theoretical results, including the compatibility of the proposed law with the classical law of the skin-friction coefficient in a plane TBL flow, comparison with previous work and some important scaling aspects, are thoroughly discussed. Finally, conclusions are drawn in § 4.

2. Theoretical analysis

2.1. Governing equations

In an axisymmetric flow (figure 1), the flow parameters with respect to a cylindrical coordinate system (r, θ, z) are invariant with the azimuthal angle θ, that is, ∂(⋅)/∂θ = 0. Therefore, on a given (r, θ) plane, any flow parameter remains unchanged along a circle of constant radius. For an incompressible ATBL flow, the continuity equation and the steady-state Navier–Stokes equations devoid of the body force terms are expressed as (see, for instance, Pope Reference Pope2000)

where ur, uθ and uz are the velocity components in the radial (r), azimuthal (θ) and longitudinal (z) directions, respectively, and p is the pressure. In (2.2) and (2.3), the operator ∇2 is given by

Under the assumption of a statistically stationary flow with no swirl motion, the instantaneous velocity components and pressure, according to the Reynolds decomposition, are expressed as ![]() $u_{r}=\bar{u}_{r}+ u_{r}^{\prime}, u_\theta = {u^{\prime}_\theta }, u_{z}=\bar{u}_{z}+u_{z}^{\prime}$ and

$u_{r}=\bar{u}_{r}+ u_{r}^{\prime}, u_\theta = {u^{\prime}_\theta }, u_{z}=\bar{u}_{z}+u_{z}^{\prime}$ and ![]() $p = \bar{p} + p^{\prime}$. Here, an overbar denotes a statistically time-averaged quantity and a prime denotes the fluctuation of an instantaneous quantity with respect to its time-averaged value. Performing the time averaging, the continuity and the momentum equations, (2.1)–(2.3), give the time-averaged continuity and the RANS equations for an ATBL flow as follows:

$p = \bar{p} + p^{\prime}$. Here, an overbar denotes a statistically time-averaged quantity and a prime denotes the fluctuation of an instantaneous quantity with respect to its time-averaged value. Performing the time averaging, the continuity and the momentum equations, (2.1)–(2.3), give the time-averaged continuity and the RANS equations for an ATBL flow as follows:

\begin{gather}{\bar{u}_r}\frac{{\partial {{\bar{u}}_r}}}{{\partial r}} + {\bar{u}_z}\frac{{\partial {{\bar{u}}_r}}}{{\partial z}} =- \frac{1}{\rho }\frac{{\partial \bar{p}}}{{\partial r}} + \upsilon \left[ {\frac{1}{r}\frac{\partial }{{\partial r}}\left( {r\frac{{\partial {{\bar{u}}_r}}}{{\partial r}}} \right) + \frac{{{\partial^2}{{\bar{u}}_r}}}{{\partial {z^2}}} - \frac{{{{\bar{u}}_r}}}{{{r^2}}}} \right] - \frac{1}{r}\frac{{\partial r\overline {{u^{\prime}_r}{u^{\prime}_r}} }}{{\partial r}}\notag\\ - \frac{{\partial \overline {{u^{\prime}_r}{u^{\prime}_z}} }}{{\partial z}} + \frac{{\overline {{u^{\prime}_\theta }{u^{\prime}_\theta }} }}{r}.\end{gather}

\begin{gather}{\bar{u}_r}\frac{{\partial {{\bar{u}}_r}}}{{\partial r}} + {\bar{u}_z}\frac{{\partial {{\bar{u}}_r}}}{{\partial z}} =- \frac{1}{\rho }\frac{{\partial \bar{p}}}{{\partial r}} + \upsilon \left[ {\frac{1}{r}\frac{\partial }{{\partial r}}\left( {r\frac{{\partial {{\bar{u}}_r}}}{{\partial r}}} \right) + \frac{{{\partial^2}{{\bar{u}}_r}}}{{\partial {z^2}}} - \frac{{{{\bar{u}}_r}}}{{{r^2}}}} \right] - \frac{1}{r}\frac{{\partial r\overline {{u^{\prime}_r}{u^{\prime}_r}} }}{{\partial r}}\notag\\ - \frac{{\partial \overline {{u^{\prime}_r}{u^{\prime}_z}} }}{{\partial z}} + \frac{{\overline {{u^{\prime}_\theta }{u^{\prime}_\theta }} }}{r}.\end{gather}

The expressions (2.6) and (2.7) show that, in a statistically stationary non-swirling axisymmetric flow, only the term ![]() $\overline {{u^{\prime}_r}{u^{\prime}_z}} $ contributes to the Reynolds shear stress. Among the Reynolds normal stresses, only the longitudinal Reynolds normal stress

$\overline {{u^{\prime}_r}{u^{\prime}_z}} $ contributes to the Reynolds shear stress. Among the Reynolds normal stresses, only the longitudinal Reynolds normal stress ![]() $\overline {{u^{\prime}_z}{u^{\prime}_z}} $ contributes to the longitudinal momentum balance, whereas the radial and azimuthal Reynolds normal stresses,

$\overline {{u^{\prime}_z}{u^{\prime}_z}} $ contributes to the longitudinal momentum balance, whereas the radial and azimuthal Reynolds normal stresses, ![]() $\overline {{u^{\prime}_r}{u^{\prime}_r}} $ and

$\overline {{u^{\prime}_r}{u^{\prime}_r}} $ and ![]() $\overline {{u^{\prime}_\theta }{u^{\prime}_\theta }} $, respectively, contribute to the radial momentum balance. The quantity

$\overline {{u^{\prime}_\theta }{u^{\prime}_\theta }} $, respectively, contribute to the radial momentum balance. The quantity ![]() $\overline {{u^{\prime}_\theta }{u^{\prime}_\theta }} $ in (2.7) remains finite because of the non-zero azimuthal velocity fluctuations, although the time-averaged azimuthal velocity is zero (ūθ = 0).

$\overline {{u^{\prime}_\theta }{u^{\prime}_\theta }} $ in (2.7) remains finite because of the non-zero azimuthal velocity fluctuations, although the time-averaged azimuthal velocity is zero (ūθ = 0).

2.2. The ATBL approximation

Applying the ATBL approximation (for detailed derivation, see Appendix A), (2.6) and (2.7) reduce to

The integration of (2.9) gives the pressure distribution as

\begin{equation}\bar{p} = {\bar{p}_\infty }(z) + \rho {\overline {{u^{\prime}_r}{u^{\prime}_r}} } |_r^\delta + \rho \int_r^\delta {\left( {\frac{{\overline {{u^{\prime}_r}{u^{\prime}_r}} - \overline {{u^{\prime}_\theta }{u^{\prime}_\theta }} }}{r}} \right)\,\textrm{d}r} ,\end{equation}

\begin{equation}\bar{p} = {\bar{p}_\infty }(z) + \rho {\overline {{u^{\prime}_r}{u^{\prime}_r}} } |_r^\delta + \rho \int_r^\delta {\left( {\frac{{\overline {{u^{\prime}_r}{u^{\prime}_r}} - \overline {{u^{\prime}_\theta }{u^{\prime}_\theta }} }}{r}} \right)\,\textrm{d}r} ,\end{equation}

where ![]() ${\bar{p}_\infty }$ is the time-averaged pressure at the edge of the boundary layer, that is, the free stream pressure. In (2.10), the difference between the radial and azimuthal Reynolds normal stresses,

${\bar{p}_\infty }$ is the time-averaged pressure at the edge of the boundary layer, that is, the free stream pressure. In (2.10), the difference between the radial and azimuthal Reynolds normal stresses, ![]() $\overline {{u^{\prime}_r}{u^{\prime}_r}} - \overline {{u^{\prime}_\theta }{u^{\prime}_\theta }} $, remains finite if the turbulence is statistically anisotropic

$\overline {{u^{\prime}_r}{u^{\prime}_r}} - \overline {{u^{\prime}_\theta }{u^{\prime}_\theta }} $, remains finite if the turbulence is statistically anisotropic ![]() $(\overline {{u^{\prime}_r}{u^{\prime}_r}} \ne \overline {{u^{\prime}_\theta }{u^{\prime}_\theta }} )$. Therefore, in an anisotropic turbulence, the quantity

$(\overline {{u^{\prime}_r}{u^{\prime}_r}} \ne \overline {{u^{\prime}_\theta }{u^{\prime}_\theta }} )$. Therefore, in an anisotropic turbulence, the quantity ![]() $\overline {{u^{\prime}_r}{u^{\prime}_r}} - \overline {{u^{\prime}_\theta }{u^{\prime}_\theta }} $ contributes to the pressure distribution. However, in an isotropic turbulence, the last term on the right-hand side of (2.10) vanishes.

$\overline {{u^{\prime}_r}{u^{\prime}_r}} - \overline {{u^{\prime}_\theta }{u^{\prime}_\theta }} $ contributes to the pressure distribution. However, in an isotropic turbulence, the last term on the right-hand side of (2.10) vanishes.

Substituting (2.10) into (2.8) gives

\begin{align}{\bar{u}_r}\frac{{\partial {{\bar{u}}_z}}}{{\partial r}} + {\bar{u}_z}\frac{{\partial {{\bar{u}}_z}}}{{\partial z}} =- \frac{1}{\rho }\frac{{\textrm{d}{{\bar{p}}_\infty }}}{{\textrm{d}z}} - \frac{{\partial {\overline {{u^{\prime}_r}{u^{\prime}_r}} } |_r^\delta }}{{\partial z}} - \frac{\partial }{{\partial z}}\int_r^\delta {\left( {\frac{{\overline {{u^{\prime}_r}{u^{\prime}_r}} - \overline {{u^{\prime}_\theta }{u^{\prime}_\theta }} }}{r}} \right)\,\textrm{d}r} + \frac{1}{{\rho r}}\frac{{\partial r\tau }}{{\partial r}},\end{align}

\begin{align}{\bar{u}_r}\frac{{\partial {{\bar{u}}_z}}}{{\partial r}} + {\bar{u}_z}\frac{{\partial {{\bar{u}}_z}}}{{\partial z}} =- \frac{1}{\rho }\frac{{\textrm{d}{{\bar{p}}_\infty }}}{{\textrm{d}z}} - \frac{{\partial {\overline {{u^{\prime}_r}{u^{\prime}_r}} } |_r^\delta }}{{\partial z}} - \frac{\partial }{{\partial z}}\int_r^\delta {\left( {\frac{{\overline {{u^{\prime}_r}{u^{\prime}_r}} - \overline {{u^{\prime}_\theta }{u^{\prime}_\theta }} }}{r}} \right)\,\textrm{d}r} + \frac{1}{{\rho r}}\frac{{\partial r\tau }}{{\partial r}},\end{align}

where τ is the total shear stress (= ![]() $\tau_v$ +

$\tau_v$ + ![]() $\tau_t$), that is, the sum of the viscous shear stress,

$\tau_t$), that is, the sum of the viscous shear stress, ![]() $\tau_{v}$ = ρ

$\tau_{v}$ = ρ ![]() $\upsilon$∂ūz/∂r and the Reynolds shear stress,

$\upsilon$∂ūz/∂r and the Reynolds shear stress, ![]() ${\tau _t} =- \rho \overline {{u^{\prime}_r}{u^{\prime}_z}} $.

${\tau _t} =- \rho \overline {{u^{\prime}_r}{u^{\prime}_z}} $.

2.3. Fully developed ATBL flow with a zero pressure gradient

In a fully developed ATBL flow, the flow parameters do not evolve in the longitudinal direction, that is, ∂(⋅)![]() $/$∂z = 0. Since ∂ūz

$/$∂z = 0. Since ∂ūz ![]() $/$∂z = 0 (that is, ūz is a function of r only) because of the fully developed flow, the continuity demands rūr = F(z) + c 1 (by virtue of (2.5)), where c 1 is a constant. However, the function F(z) must be a constant, because ūr should also remain invariant with z to satisfy the fully developed flow. This can also be concluded by setting ∂ūr

$/$∂z = 0 (that is, ūz is a function of r only) because of the fully developed flow, the continuity demands rūr = F(z) + c 1 (by virtue of (2.5)), where c 1 is a constant. However, the function F(z) must be a constant, because ūr should also remain invariant with z to satisfy the fully developed flow. This can also be concluded by setting ∂ūr ![]() $/$∂z = 0, which gives F′(z) = 0 (that is, F(z) is a constant). Letting F(z) = c 2 (c 2 is a constant), we obtain ūr = c 3/r with c 3 = c 1 + c 2. As the radial velocity vanishes at the wall due to the no-slip boundary condition, the condition ūr (r = a) = 0 predicts c 3 = 0, which eventually results in ūr = 0. Therefore, in a fully developed ATBL flow, the convective acceleration in the longitudinal momentum equation vanishes (left-hand side of (2.11)). In addition, the second and third terms on the right-hand side of (2.11) become zero. However, the longitudinal pressure gradient and the radial gradient of the total shear stress remain non-zero. This shows that the total shear stress varies radially to balance the longitudinal free stream pressure gradient. For the zero pressure gradient flow, it gives

$/$∂z = 0, which gives F′(z) = 0 (that is, F(z) is a constant). Letting F(z) = c 2 (c 2 is a constant), we obtain ūr = c 3/r with c 3 = c 1 + c 2. As the radial velocity vanishes at the wall due to the no-slip boundary condition, the condition ūr (r = a) = 0 predicts c 3 = 0, which eventually results in ūr = 0. Therefore, in a fully developed ATBL flow, the convective acceleration in the longitudinal momentum equation vanishes (left-hand side of (2.11)). In addition, the second and third terms on the right-hand side of (2.11) become zero. However, the longitudinal pressure gradient and the radial gradient of the total shear stress remain non-zero. This shows that the total shear stress varies radially to balance the longitudinal free stream pressure gradient. For the zero pressure gradient flow, it gives ![]() $\textrm{d}{\bar{p}_\infty }/\textrm{d}z = 0$. Hence, in a fully developed ATBL flow with a zero pressure gradient, all barring the last term on the right-hand side of (2.11) are zero. As a result, (2.11) recovers the equilibrium model of, among others, Glauert & Lighthill (Reference Glauert and Lighthill1955) and Rao (Reference Rao1967). This indicates the moment of the total shear stress to be a constant (rτ = constant). The constant is obtained from the boundary condition τ(r = a) =

$\textrm{d}{\bar{p}_\infty }/\textrm{d}z = 0$. Hence, in a fully developed ATBL flow with a zero pressure gradient, all barring the last term on the right-hand side of (2.11) are zero. As a result, (2.11) recovers the equilibrium model of, among others, Glauert & Lighthill (Reference Glauert and Lighthill1955) and Rao (Reference Rao1967). This indicates the moment of the total shear stress to be a constant (rτ = constant). The constant is obtained from the boundary condition τ(r = a) = ![]() $\tau_0$. Thus, (2.11) reduces to

$\tau_0$. Thus, (2.11) reduces to

It is worth mentioning that the relationships (1.2) and (1.3) can be recovered from (2.12). In this regard, we set the outward wall-normal distance as y = r − a. In the near-wall flow region, ![]() $\tau_t$ vanishes within the thin viscous sublayer, resulting in τ =

$\tau_t$ vanishes within the thin viscous sublayer, resulting in τ = ![]() $\tau_v$. Substituting

$\tau_v$. Substituting ![]() $\tau_v$ = ρ

$\tau_v$ = ρ ![]() $\upsilon\,$dūz

$\upsilon\,$dūz ![]() $/$dy into (2.12) and integrating the resultant equation by applying the no-slip boundary condition ūz (r = a) = 0 yield (1.2). In fact, (1.2) resembles the linear law of the wall in a plane TBL flow given by

$/$dy into (2.12) and integrating the resultant equation by applying the no-slip boundary condition ūz (r = a) = 0 yield (1.2). In fact, (1.2) resembles the linear law of the wall in a plane TBL flow given by ![]() $u_z^ += {y^ + }$ (where

$u_z^ += {y^ + }$ (where ![]() ${y^ + } = y{u_\ast }/\upsilon$) (see, for instance, Ali & Dey Reference Ali and Dey2020), if the term a ln (1 + y/a) is replaced by y. In the logarithmic layer,

${y^ + } = y{u_\ast }/\upsilon$) (see, for instance, Ali & Dey Reference Ali and Dey2020), if the term a ln (1 + y/a) is replaced by y. In the logarithmic layer, ![]() $\tau_v$ becomes zero and τ =

$\tau_v$ becomes zero and τ = ![]() $\tau_t$. Therefore, (2.12) suggests an inverse scaling of

$\tau_t$. Therefore, (2.12) suggests an inverse scaling of ![]() $\tau_t$ with y, in conformity with the experimental measurements (Lueptow et al. Reference Lueptow, Leehey and Stellinger1985). Analogously to the mixing length hypothesis in a plane TBL flow,

$\tau_t$ with y, in conformity with the experimental measurements (Lueptow et al. Reference Lueptow, Leehey and Stellinger1985). Analogously to the mixing length hypothesis in a plane TBL flow, ![]() $\tau_t$ in an ATBL flow can be expressed as

$\tau_t$ in an ATBL flow can be expressed as ![]() $\tau_{t} = \rho l^{2}_{p} ({\rm d}\bar{u}_{z}/{\rm d}y)^{2}$, where lp is the mixing length. From (2.12), it follows that

$\tau_{t} = \rho l^{2}_{p} ({\rm d}\bar{u}_{z}/{\rm d}y)^{2}$, where lp is the mixing length. From (2.12), it follows that ![]() $\textrm{d}{\bar{u}_{z}}/\textrm{d}y = [a/(a + y)]^{1/2} u_{\ast} l^{-1}_{p}$, which, upon integration, in association with

$\textrm{d}{\bar{u}_{z}}/\textrm{d}y = [a/(a + y)]^{1/2} u_{\ast} l^{-1}_{p}$, which, upon integration, in association with ![]() ${l_p} = \kappa {[a(a + y)]^{1/2}}\ln (1 + y/a)$, produces (1.3). The present choice of lp in the limit of infinite radius (a → ∞) is consistent with the classical expression lp = κy in the logarithmic layer of a plane TBL flow (Schlichting Reference Schlichting1979). The relation (1.3) is analogous to the logarithmic law in a plane TBL flow, given the term a

${l_p} = \kappa {[a(a + y)]^{1/2}}\ln (1 + y/a)$, produces (1.3). The present choice of lp in the limit of infinite radius (a → ∞) is consistent with the classical expression lp = κy in the logarithmic layer of a plane TBL flow (Schlichting Reference Schlichting1979). The relation (1.3) is analogous to the logarithmic law in a plane TBL flow, given the term a ![]() $\ln$(1 + y

$\ln$(1 + y ![]() $/$a) is exchanged with y.

$/$a) is exchanged with y.

2.4. Scaling law of Reynolds shear stress

It is pertinent to mention that the present analysis aims at deriving the skin-friction coefficients for both the rough and smooth ATBL flows. However, due to the absence of experimental data on the skin-friction coefficient, specifically in a rough ATBL flow, the experimental verification of the proposed skin-friction coefficient is limited to the smooth ATBL flow data only (see § 3.2). The mathematical analysis starts with a rough wall configuration to establish a scaling law of the skin-friction coefficient. Subsequently, the skin-friction coefficient in a smooth ATBL flow is derived using this scaling law. We now intend to derive the scaling law of the Reynolds shear stress ![]() $\tau_t$ acting on the rough wall of the cylinder. The wall roughness is of k-type, where the surface of the cylinder is covered with a layer of closely packed identical particles of diameter ks, called the roughness height (see the enlarged view shown in figure 3). At a microscopic level, an undulating surface is formed above y = 0 (that is, r = a). The bulk flow Reynolds number is sufficiently large, so that the viscous shear stress is negligible, and the total shear stress includes only the Reynolds shear stress. The value of

$\tau_t$ acting on the rough wall of the cylinder. The wall roughness is of k-type, where the surface of the cylinder is covered with a layer of closely packed identical particles of diameter ks, called the roughness height (see the enlarged view shown in figure 3). At a microscopic level, an undulating surface is formed above y = 0 (that is, r = a). The bulk flow Reynolds number is sufficiently large, so that the viscous shear stress is negligible, and the total shear stress includes only the Reynolds shear stress. The value of ![]() $\tau_t$ is sought at the hypothetical surface S tangential to the roughness summits, given by y = ks

$\tau_t$ is sought at the hypothetical surface S tangential to the roughness summits, given by y = ks ![]() $/$2 (that is, r = a + ks

$/$2 (that is, r = a + ks ![]() $/$2). Consequently, the wall shear stress from (2.12) is obtained as

$/$2). Consequently, the wall shear stress from (2.12) is obtained as

Figure 3. The Reynolds shear stress ![]() $\tau_t$ developed at the surface S (tangential to the roughness summits) caused by a turbulent eddy of size ℓ straddling the surface and exchanging the momentum across S. The turbulent eddy carries high- and low-momentum fluid per unit volume inwards and outwards, respectively, across S. The value of

$\tau_t$ developed at the surface S (tangential to the roughness summits) caused by a turbulent eddy of size ℓ straddling the surface and exchanging the momentum across S. The turbulent eddy carries high- and low-momentum fluid per unit volume inwards and outwards, respectively, across S. The value of ![]() $\tau_t$ is obtained from the product of the momentum contrast per unit volume across S and the eddy turnover velocity uℓ as

$\tau_t$ is obtained from the product of the momentum contrast per unit volume across S and the eddy turnover velocity uℓ as ![]() ${\tau _t} = \rho ({\bar{u}_z}{|_{y \,=\, {k_s}/2 \,+\, \ell /2}} - {\bar{u}_z}{|_{y \,=\, {k_s}/2 \,-\, \ell /2}}){u_\ell }$.

${\tau _t} = \rho ({\bar{u}_z}{|_{y \,=\, {k_s}/2 \,+\, \ell /2}} - {\bar{u}_z}{|_{y \,=\, {k_s}/2 \,-\, \ell /2}}){u_\ell }$.

The Reynolds shear stress in a turbulent flow is caused by turbulent eddies of various length scales. The largest eddy size is comparable to the external length scale of the system. As discussed in the preceding section, the preservation of the law of the wall in an ATBL flow requires the wall-normal distance y in a plane TBL flow to be replaced by a ![]() $\ln$(1 + y

$\ln$(1 + y ![]() $/$a). For a given a, y is always larger than a

$/$a). For a given a, y is always larger than a ![]() $\ln$(1 + y

$\ln$(1 + y ![]() $/$a). This reveals that any wall-normal length scale in a plane TBL flow experiences a length contraction in an ATBL flow because of the transverse curvature. Let the boundary layer thickness be the same, say δ, for both the ATBL and plane TBL flows. The external length scale

$/$a). This reveals that any wall-normal length scale in a plane TBL flow experiences a length contraction in an ATBL flow because of the transverse curvature. Let the boundary layer thickness be the same, say δ, for both the ATBL and plane TBL flows. The external length scale ![]() $\mathscr{L}$ (that is, the largest eddy size) in a plane TBL flow is thus

$\mathscr{L}$ (that is, the largest eddy size) in a plane TBL flow is thus ![]() $\mathscr{L}$ ~ δ. However, due to the length contraction,

$\mathscr{L}$ ~ δ. However, due to the length contraction, ![]() $\mathscr{L}$ in an ATBL flow becomes smaller than that in a plane TBL flow. Following the length contraction in an ATBL flow,

$\mathscr{L}$ in an ATBL flow becomes smaller than that in a plane TBL flow. Following the length contraction in an ATBL flow, ![]() $\mathscr{L}$ takes the form of

$\mathscr{L}$ takes the form of

which, for a given δ, is consistent with the classical expression ![]() $\mathscr{L}$ ~ δ in a plane TBL flow in the limit of infinite radius (a → ∞).

$\mathscr{L}$ ~ δ in a plane TBL flow in the limit of infinite radius (a → ∞).

The Reynolds shear stress ![]() $\tau_t$ at S is developed by turbulent eddies that straddle the surface (eddies are bisected by the surface S) and exchange momentum across S. This mechanism was first applied by Gioia & Bombardelli (Reference Gioia and Bombardelli2002) to analyse the scaling and similarity in rough-channel flows (see, for instance, the review of Ali & Dey Reference Ali and Dey2018). Beneath S, the flow velocity is negligible, because of the protruding wall roughness (figure 3). The momentum that the flow transmits tangential to S is thus insignificant. By contrast, above S, the flow transmits a substantial momentum tangential to S. It follows that a turbulent eddy of size ℓ carries high-momentum fluid per unit volume inwards (towards the cylinder) across S and low-momentum fluid per unit volume outwards (away from the cylinder) across S. Therefore, across S, the momentum contrast per unit volume produced by the turbulent eddy is

$\tau_t$ at S is developed by turbulent eddies that straddle the surface (eddies are bisected by the surface S) and exchange momentum across S. This mechanism was first applied by Gioia & Bombardelli (Reference Gioia and Bombardelli2002) to analyse the scaling and similarity in rough-channel flows (see, for instance, the review of Ali & Dey Reference Ali and Dey2018). Beneath S, the flow velocity is negligible, because of the protruding wall roughness (figure 3). The momentum that the flow transmits tangential to S is thus insignificant. By contrast, above S, the flow transmits a substantial momentum tangential to S. It follows that a turbulent eddy of size ℓ carries high-momentum fluid per unit volume inwards (towards the cylinder) across S and low-momentum fluid per unit volume outwards (away from the cylinder) across S. Therefore, across S, the momentum contrast per unit volume produced by the turbulent eddy is ![]() $\rho(\bar{u}_{z}|_{y\,=\,k_{s}/2\,+\,\ell/2}- \bar{u}_{z}|_{y\,=\,k_{s}/2\,-\,\ell/2}) \approx \rho\ell(\textrm{d}\bar{u}_{z}/\textrm{d}y)|_{y\,=\,k_{s}/2}$. The rate of momentum exchange across S is caused by the eddy turnover velocity uℓ. The value of

$\rho(\bar{u}_{z}|_{y\,=\,k_{s}/2\,+\,\ell/2}- \bar{u}_{z}|_{y\,=\,k_{s}/2\,-\,\ell/2}) \approx \rho\ell(\textrm{d}\bar{u}_{z}/\textrm{d}y)|_{y\,=\,k_{s}/2}$. The rate of momentum exchange across S is caused by the eddy turnover velocity uℓ. The value of ![]() $\tau_t$ caused by a turbulent eddy of size ℓ is obtained as a product of the net momentum contrast per unit volume across S and uℓ. Therefore,

$\tau_t$ caused by a turbulent eddy of size ℓ is obtained as a product of the net momentum contrast per unit volume across S and uℓ. Therefore, ![]() $\tau_t$ is expressed as

$\tau_t$ is expressed as

\begin{equation}{\tau _t} = \rho {\left. {\frac{{\textrm{d}{{\bar{u}}_z}}}{{\textrm{d}y}}} \right|_{y \,=\, {k_s}/2}}\ell {u_{\ell}}.\end{equation}

\begin{equation}{\tau _t} = \rho {\left. {\frac{{\textrm{d}{{\bar{u}}_z}}}{{\textrm{d}y}}} \right|_{y \,=\, {k_s}/2}}\ell {u_{\ell}}.\end{equation}The velocity gradient in (2.15) is obtained from the differentiation of (1.3) as follows:

\begin{equation}{\left. {\frac{{\textrm{d}{{\bar{u}}_z}}}{{\textrm{d}y}}} \right|_{y \,=\, {k_s}/2}} = \frac{{{u_\ast }}}{{\kappa a\left( {1 + \dfrac{{{k_s}}}{{2a}}} \right)\ln \left( {1 + \dfrac{{{k_s}}}{{2a}}} \right)}}.\end{equation}

\begin{equation}{\left. {\frac{{\textrm{d}{{\bar{u}}_z}}}{{\textrm{d}y}}} \right|_{y \,=\, {k_s}/2}} = \frac{{{u_\ast }}}{{\kappa a\left( {1 + \dfrac{{{k_s}}}{{2a}}} \right)\ln \left( {1 + \dfrac{{{k_s}}}{{2a}}} \right)}}.\end{equation} The value of uℓ is obtained from the second-order transverse structure function as ![]() $u_\mathrm{\ell }^2 = S_2^ \bot (\mathrm{\ell })$, where

$u_\mathrm{\ell }^2 = S_2^ \bot (\mathrm{\ell })$, where ![]() $S_2^ \bot (\mathrm{\ell })$ is expressed as

$S_2^ \bot (\mathrm{\ell })$ is expressed as

It has been evidenced that, analogously to the second-order longitudinal structure function, given by

![]() $S_2^ \bot (\mathrm{\ell })$ obeys Kolmogorov's two-thirds law over a significant range (Frisch Reference Frisch1995). Dimensional argument produces

$S_2^ \bot (\mathrm{\ell })$ obeys Kolmogorov's two-thirds law over a significant range (Frisch Reference Frisch1995). Dimensional argument produces

where ε is the turbulent kinetic energy (TKE) dissipation rate, Re is the Reynolds number based on the external length scale and ℓ is considered to lie in the inertial range. For a complete similarity in the variables ℓ ![]() $/\mathscr{L}$ and Re, the function H becomes constant as ℓ

$/\mathscr{L}$ and Re, the function H becomes constant as ℓ ![]() $/\mathscr{L}$ → 0 and Re → ∞, recovering Kolmogorov's two-thirds law,

$/\mathscr{L}$ → 0 and Re → ∞, recovering Kolmogorov's two-thirds law, ![]() $u_\mathrm{\ell }^2\sim {(\varepsilon \ell )^{2/3}}$ for the limiting state of fully developed turbulence. However, as ℓ

$u_\mathrm{\ell }^2\sim {(\varepsilon \ell )^{2/3}}$ for the limiting state of fully developed turbulence. However, as ℓ ![]() $/ \mathscr{L}$ → 0, the complete similarity breaks down because of the TKE dissipation rate fluctuations. Therefore, for an incomplete similarity, H does not approach a finite limit as ℓ

$/ \mathscr{L}$ → 0, the complete similarity breaks down because of the TKE dissipation rate fluctuations. Therefore, for an incomplete similarity, H does not approach a finite limit as ℓ ![]() $/ \mathscr{L}$ → 0. Under such circumstance, (2.19) takes the form of

$/ \mathscr{L}$ → 0. Under such circumstance, (2.19) takes the form of

which is valid not only for a large Re but also for a large ln Re (Barenblatt & Goldenfeld Reference Barenblatt and Goldenfeld1995). For an incomplete similarity, as ℓ ![]() $/ \mathscr{L}$ → 0, (2.20) is expanded as

$/ \mathscr{L}$ → 0, (2.20) is expanded as

\begin{equation}\left. \begin{array}{c@{}} u_\mathrm{\ell }^2 = {(\varepsilon \mathrm{\ell })^{2/3}}C(\ln Re){\left( {\dfrac{\mathrm{\ell}}{\mathscr{L}}} \right)^\alpha },\\ C(\ln Re) = {C_0} + \dfrac{{{C_1}}}{{\ln Re}} + O\left( {\dfrac{1}{{{{\ln}^2}\,Re}}} \right),\textrm{ }\\ \alpha = {\alpha_0} + \dfrac{{{\alpha_1}}}{{\ln Re}} + O\left( {\dfrac{1}{{{{\ln }^2}\,Re}}} \right), \end{array}\!\!\!\right\}\end{equation}

\begin{equation}\left. \begin{array}{c@{}} u_\mathrm{\ell }^2 = {(\varepsilon \mathrm{\ell })^{2/3}}C(\ln Re){\left( {\dfrac{\mathrm{\ell}}{\mathscr{L}}} \right)^\alpha },\\ C(\ln Re) = {C_0} + \dfrac{{{C_1}}}{{\ln Re}} + O\left( {\dfrac{1}{{{{\ln}^2}\,Re}}} \right),\textrm{ }\\ \alpha = {\alpha_0} + \dfrac{{{\alpha_1}}}{{\ln Re}} + O\left( {\dfrac{1}{{{{\ln }^2}\,Re}}} \right), \end{array}\!\!\!\right\}\end{equation}where C 0 and C 1 are the coefficients, and α 0 and α 1 are the exponents.

The expression (2.21) shows that, as the eddy size ℓ increases, its turnover velocity uℓ also increases and, subsequently, ℓuℓ increases. Therefore, ![]() $\tau_t$ at S enhances with an increase in ℓ, in accord with (2.15). The gathering of near-wall eddies that exchange momentum through S can be visualised as a set of circular fluid cells in two dimensions (or spheroidal fluid cells in three dimensions) between two successive roughness summits (figure 4a). The length scale ℓ of such eddies can be divided into two groups, such as ℓ ≤ ℓm and ℓ > ℓm (ℓ still lies in the inertial range), where ℓm is the maximum size of an eddy (that is, the presiding eddy) being bisected by the surface S. For ℓ < ℓm, the eddies are perfectly bisected by the surface S and, thereby,

$\tau_t$ at S enhances with an increase in ℓ, in accord with (2.15). The gathering of near-wall eddies that exchange momentum through S can be visualised as a set of circular fluid cells in two dimensions (or spheroidal fluid cells in three dimensions) between two successive roughness summits (figure 4a). The length scale ℓ of such eddies can be divided into two groups, such as ℓ ≤ ℓm and ℓ > ℓm (ℓ still lies in the inertial range), where ℓm is the maximum size of an eddy (that is, the presiding eddy) being bisected by the surface S. For ℓ < ℓm, the eddies are perfectly bisected by the surface S and, thereby, ![]() $\tau_t$ at S increases with ℓ (figure 4b). However,

$\tau_t$ at S increases with ℓ (figure 4b). However, ![]() $\tau_t$ at S does not continue to increase persistently as ℓ increases. There remains an upper limit of ℓ (= ℓm) for which the presiding eddy maximises

$\tau_t$ at S does not continue to increase persistently as ℓ increases. There remains an upper limit of ℓ (= ℓm) for which the presiding eddy maximises ![]() $\tau_t$ at S. For ℓ > ℓm, the eddies are not bisected by the surface S, because of the geometrical constraint produced by the wall roughness. These eddies contribute minimally to the shear stress generation due to their insignificant momentum exchanges across S. This suggests that the maximum

$\tau_t$ at S. For ℓ > ℓm, the eddies are not bisected by the surface S, because of the geometrical constraint produced by the wall roughness. These eddies contribute minimally to the shear stress generation due to their insignificant momentum exchanges across S. This suggests that the maximum ![]() $\tau_t$ at S is caused by the presiding eddy of size ℓ = ℓm. From the two-dimensional geometry (figure 4a), ℓm turns out to be

$\tau_t$ at S is caused by the presiding eddy of size ℓ = ℓm. From the two-dimensional geometry (figure 4a), ℓm turns out to be ![]() ${\ell _m}\, = (\sqrt 2 - 1){k_s} \approx 0.414{k_s}$ (that is, ℓm is of the order of the roughness height). The maximum

${\ell _m}\, = (\sqrt 2 - 1){k_s} \approx 0.414{k_s}$ (that is, ℓm is of the order of the roughness height). The maximum ![]() $\tau_t$ at S is obtained from (2.15) by setting ℓ = 0.414ks. After some algebra,

$\tau_t$ at S is obtained from (2.15) by setting ℓ = 0.414ks. After some algebra, ![]() $\tau_t$ is expressed as follows:

$\tau_t$ is expressed as follows:

\begin{align}{\tau _t}&\sim \rho \frac{{{u_\ast }}}{{a\left( {1 + \dfrac{{{k_s}}}{{2a}}} \right)\ln \left( {1 + \dfrac{{{k_s}}}{{2a}}} \right)}}{k_s}{(\varepsilon {k_s})^{1/3}}{\left( {{C_0} + \frac{{{C_1}}}{{\ln Re}}} \right)^{1/2}}\nonumber\\&\quad \times \begin{bmatrix}\displaystyle\frac{{{k_s}}}{{a\ln \left( {1 + \dfrac{\delta }{a}} \right)}}\end{bmatrix}^{(\alpha _0 \,+\, \alpha _1/\ln Re)/2}. \end{align}

\begin{align}{\tau _t}&\sim \rho \frac{{{u_\ast }}}{{a\left( {1 + \dfrac{{{k_s}}}{{2a}}} \right)\ln \left( {1 + \dfrac{{{k_s}}}{{2a}}} \right)}}{k_s}{(\varepsilon {k_s})^{1/3}}{\left( {{C_0} + \frac{{{C_1}}}{{\ln Re}}} \right)^{1/2}}\nonumber\\&\quad \times \begin{bmatrix}\displaystyle\frac{{{k_s}}}{{a\ln \left( {1 + \dfrac{\delta }{a}} \right)}}\end{bmatrix}^{(\alpha _0 \,+\, \alpha _1/\ln Re)/2}. \end{align}

Figure 4. (a) Near-wall eddies having length scales ℓ < ℓm (green), ℓ = ℓm (blue) and ℓ > ℓm (red) exchanging momentum across the surface S. Here, ℓm is the maximum size of an eddy, called the presiding eddy (in blue), which is bisected by surface S. (b) Conceptual variation of ![]() $\tau_t$ with ℓ. The value of

$\tau_t$ with ℓ. The value of ![]() $\tau_t$ at S enhances with an increase in ℓ attaining a maximum at ℓ = ℓm and then decreases with a further increase in ℓ.

$\tau_t$ at S enhances with an increase in ℓ attaining a maximum at ℓ = ℓm and then decreases with a further increase in ℓ.

The value of ε in (2.22) can be inferred from the TKE budget equation, which defines the rate of conservation of the TKE through the mechanisms of advection, diffusion, dissipation and production. The diffusion rate comprises the TKE, pressure energy and viscous diffusion rates. In the near-wall flow region, say, in the logarithmic layer, the numerical simulations have evidenced that the key contributors to the TKE budget equation are the TKE production and dissipation rates (Woods Reference Woods2006). Considering various ranges of a + (= 21 to 1124.9) and δ ![]() $/$a (= 0.16 to 27.6), Woods (Reference Woods2006) found the following ranges of the dimensionless TKE budget components (scaled by

$/$a (= 0.16 to 27.6), Woods (Reference Woods2006) found the following ranges of the dimensionless TKE budget components (scaled by ![]() $u_\ast ^4/\upsilon $) at y + = 30: TKE production rate (0.03 to 0.08), TKE dissipation rate (0.02 to 0.08), TKE diffusion rate (0.012 to 0.016), pressure energy diffusion rate (0 to −1.3 × 10−3) and viscous diffusion rate (≈0). Therefore, in the absence of the TKE advection rate, the TKE production rate is balanced by the TKE dissipation rate. It follows that ε at S is obtained from the energy balance,

$u_\ast ^4/\upsilon $) at y + = 30: TKE production rate (0.03 to 0.08), TKE dissipation rate (0.02 to 0.08), TKE diffusion rate (0.012 to 0.016), pressure energy diffusion rate (0 to −1.3 × 10−3) and viscous diffusion rate (≈0). Therefore, in the absence of the TKE advection rate, the TKE production rate is balanced by the TKE dissipation rate. It follows that ε at S is obtained from the energy balance, ![]() $\varepsilon= P=(\tau_{t}/\rho)(\textrm{d}\bar{u}_{z}/\textrm{d}y)|_{y\,=\,k_{s}/2}$, where P is the TKE production rate. Using (2.13) and (2.16), ε is expressed as

$\varepsilon= P=(\tau_{t}/\rho)(\textrm{d}\bar{u}_{z}/\textrm{d}y)|_{y\,=\,k_{s}/2}$, where P is the TKE production rate. Using (2.13) and (2.16), ε is expressed as

\begin{equation}\varepsilon = \frac{{u_\ast ^3}}{{\kappa a{{\left( {1 + \dfrac{{{k_s}}}{{2a}}} \right)}^2}\ln \left( {1 + \dfrac{{{k_s}}}{{2a}}} \right)}}.\end{equation}

\begin{equation}\varepsilon = \frac{{u_\ast ^3}}{{\kappa a{{\left( {1 + \dfrac{{{k_s}}}{{2a}}} \right)}^2}\ln \left( {1 + \dfrac{{{k_s}}}{{2a}}} \right)}}.\end{equation} To relate the velocity and the TKE dissipation rate at the local scale with those at the global scale, we introduce ![]() ${u_\ast } = {C_u}{U_\infty }$ and

${u_\ast } = {C_u}{U_\infty }$ and ![]() $\varepsilon = {C_\varepsilon }\varepsilon_b$, where

$\varepsilon = {C_\varepsilon }\varepsilon_b$, where ![]() $\varepsilon_b$ is the global TKE dissipation rate, and Cu and Cε are the coefficients. The value of

$\varepsilon_b$ is the global TKE dissipation rate, and Cu and Cε are the coefficients. The value of ![]() $\varepsilon_b$ associated with the scale

$\varepsilon_b$ associated with the scale ![]() $\mathscr{L}$ is defined as the bulk energy

$\mathscr{L}$ is defined as the bulk energy ![]() $({\sim} U_\infty ^2)$ per unit turnover time (~

$({\sim} U_\infty ^2)$ per unit turnover time (~![]() $\mathscr{L} / $U∞). Thus,

$\mathscr{L} / $U∞). Thus, ![]() $\varepsilon_b\sim U_\infty ^3/\mathscr{L}\sim U_\infty ^3/[a\ln (1 + \delta /a)]$. Therefore, (2.22) takes the form of

$\varepsilon_b\sim U_\infty ^3/\mathscr{L}\sim U_\infty ^3/[a\ln (1 + \delta /a)]$. Therefore, (2.22) takes the form of

\begin{align}\frac{{{\tau _t}}}{{\rho U_\infty ^2}} &\sim {C_u}C_\varepsilon^{1/3}\frac{{k_s^{4/3}}}{{{a^{4/3}}\left( {1 + \dfrac{{{k_s}}}{{2a}}} \right)\ln \left( {1 + \dfrac{{{k_s}}}{{2a}}} \right){{\ln }^{1/3}}\left( {1 + \dfrac{\delta }{a}} \right)}}{\left( {{C_0} + \frac{{{C_1}}}{{\ln Re}}} \right)^{1/2}}\notag\\ &\quad \times \begin{bmatrix} \displaystyle\frac{{{k_s}}}{{a\ln \left( {1 + \dfrac{\delta }{a}} \right)}}\end{bmatrix}^{({\alpha _0} \,+\, {\alpha _1}/\ln Re)/2}.\end{align}

\begin{align}\frac{{{\tau _t}}}{{\rho U_\infty ^2}} &\sim {C_u}C_\varepsilon^{1/3}\frac{{k_s^{4/3}}}{{{a^{4/3}}\left( {1 + \dfrac{{{k_s}}}{{2a}}} \right)\ln \left( {1 + \dfrac{{{k_s}}}{{2a}}} \right){{\ln }^{1/3}}\left( {1 + \dfrac{\delta }{a}} \right)}}{\left( {{C_0} + \frac{{{C_1}}}{{\ln Re}}} \right)^{1/2}}\notag\\ &\quad \times \begin{bmatrix} \displaystyle\frac{{{k_s}}}{{a\ln \left( {1 + \dfrac{\delta }{a}} \right)}}\end{bmatrix}^{({\alpha _0} \,+\, {\alpha _1}/\ln Re)/2}.\end{align}2.5. Scaling law of skin-friction coefficient

Substituting (2.24) into (2.13), the scaling law of ![]() $\tau_0$ is obtained. As

$\tau_0$ is obtained. As ![]() ${C_f} = 2{\tau _0}/(\rho U_\infty ^2)$, it follows

${C_f} = 2{\tau _0}/(\rho U_\infty ^2)$, it follows

\begin{align}{C_f}&\sim {C_u}C_\varepsilon ^{1/3}\frac{{k_s^{4/3}}}{{{a^{4/3}}\ln \left( {1 + \dfrac{{{k_s}}}{{2a}}} \right){{\ln }^{1/3}}\left( {1 + \dfrac{\delta }{a}} \right)}}{\left({{C_0} + \frac{{{C_1}}}{{\ln Re}}} \right)^{1/2}}\nonumber\\&\quad \times \begin{bmatrix} \displaystyle\frac{{{k_s}}}{{a\ln \left( {1 + \dfrac{\delta }{a}} \right)}} \end{bmatrix}^{({\alpha _0} \,+\, {\alpha _1}/\ln Re)/2}.\end{align}

\begin{align}{C_f}&\sim {C_u}C_\varepsilon ^{1/3}\frac{{k_s^{4/3}}}{{{a^{4/3}}\ln \left( {1 + \dfrac{{{k_s}}}{{2a}}} \right){{\ln }^{1/3}}\left( {1 + \dfrac{\delta }{a}} \right)}}{\left({{C_0} + \frac{{{C_1}}}{{\ln Re}}} \right)^{1/2}}\nonumber\\&\quad \times \begin{bmatrix} \displaystyle\frac{{{k_s}}}{{a\ln \left( {1 + \dfrac{\delta }{a}} \right)}} \end{bmatrix}^{({\alpha _0} \,+\, {\alpha _1}/\ln Re)/2}.\end{align} The term ![]() ${C_u}C_\varepsilon ^{1/3}$ in (2.25) can be expressed, using (2.23), as

${C_u}C_\varepsilon ^{1/3}$ in (2.25) can be expressed, using (2.23), as

\begin{equation}{C_u}C_\varepsilon^{1/3} = \frac{{{u_\ast }}}{{{U_\infty }}}{\left( {\frac{\varepsilon }{\varepsilon_b}} \right)^{1/3}} \Rightarrow {C_u}C_\varepsilon ^{1/3}\sim {C_f}\frac{{{{\ln}^{1/3}}\left( {1 + \dfrac{\delta }{a}} \right)}}{{{{\left({1 + \dfrac{{{k_s}}}{{2a}}} \right)}^{2/3}}{{\ln }^{1/3}}\left( {1 + \dfrac{{{k_s}}}{{2a}}} \right)}}.\end{equation}

\begin{equation}{C_u}C_\varepsilon^{1/3} = \frac{{{u_\ast }}}{{{U_\infty }}}{\left( {\frac{\varepsilon }{\varepsilon_b}} \right)^{1/3}} \Rightarrow {C_u}C_\varepsilon ^{1/3}\sim {C_f}\frac{{{{\ln}^{1/3}}\left( {1 + \dfrac{\delta }{a}} \right)}}{{{{\left({1 + \dfrac{{{k_s}}}{{2a}}} \right)}^{2/3}}{{\ln }^{1/3}}\left( {1 + \dfrac{{{k_s}}}{{2a}}} \right)}}.\end{equation}

As (2.26) is applied to a plane TBL flow (a → ∞), we find ![]() ${C_u}C_\varepsilon ^{1/3}\sim {C_{f0}}{(\delta /{k_s})^{1/3}}$, where Cf 0 = Cf(a → ∞). However, in a rough plane TBL flow, Cf 0 satisfies Strickler's scaling law as

${C_u}C_\varepsilon ^{1/3}\sim {C_{f0}}{(\delta /{k_s})^{1/3}}$, where Cf 0 = Cf(a → ∞). However, in a rough plane TBL flow, Cf 0 satisfies Strickler's scaling law as ![]() ${C_{f0}}\sim {({k_s}/\delta )^{1/3}}$ (Strickler Reference Strickler1981). This concludes that

${C_{f0}}\sim {({k_s}/\delta )^{1/3}}$ (Strickler Reference Strickler1981). This concludes that ![]() ${C_u}C_\varepsilon ^{1/3}$ must be a constant. Further, as the roughness height is much smaller than the cylinder diameter

${C_u}C_\varepsilon ^{1/3}$ must be a constant. Further, as the roughness height is much smaller than the cylinder diameter ![]() $[{k_s}/(2a) \ll 1]$, it follows that

$[{k_s}/(2a) \ll 1]$, it follows that ![]() $\ln [1 + {k_s}/(2a)] \approx {k_s}/(2a)$. Therefore, (2.25) takes the form of

$\ln [1 + {k_s}/(2a)] \approx {k_s}/(2a)$. Therefore, (2.25) takes the form of

\begin{equation}{C_f}\sim {\left( {{C_0} + \frac{{{C_1}}}{{\ln Re}}} \right)^{1/2}}{\begin{bmatrix} \displaystyle\frac{{{k_s}}}{{a\ln \left( {1 + \dfrac{\delta }{a}} \right)}}\end{bmatrix}^{1/3 \,+\, ({\alpha _0} \,+\, {\alpha_1}/\ln Re)/2}}.\end{equation}

\begin{equation}{C_f}\sim {\left( {{C_0} + \frac{{{C_1}}}{{\ln Re}}} \right)^{1/2}}{\begin{bmatrix} \displaystyle\frac{{{k_s}}}{{a\ln \left( {1 + \dfrac{\delta }{a}} \right)}}\end{bmatrix}^{1/3 \,+\, ({\alpha _0} \,+\, {\alpha_1}/\ln Re)/2}}.\end{equation}Now we shall prove that, for (2.27) to hold, C 0 must be a non-zero and positive quantity. For the given ks, a and δ, if C 0 = 0, then the leading term of (2.27) is a function of Re. This gives

\begin{equation}{C_f}\sim {\left({\frac{{{C_1}}}{{\ln Re}}} \right)^{1/2}}{\begin{bmatrix} \displaystyle\frac{{{k_s}}}{{a\ln \left( {1 + \dfrac{\delta }{a}} \right)}} \end{bmatrix}^{1/3 \,+\, ({\alpha _0} \,+\, {\alpha_1}/\ln Re)/2}}.\end{equation}

\begin{equation}{C_f}\sim {\left({\frac{{{C_1}}}{{\ln Re}}} \right)^{1/2}}{\begin{bmatrix} \displaystyle\frac{{{k_s}}}{{a\ln \left( {1 + \dfrac{\delta }{a}} \right)}} \end{bmatrix}^{1/3 \,+\, ({\alpha _0} \,+\, {\alpha_1}/\ln Re)/2}}.\end{equation}Thus, for C 0 = 0, (2.28) shows that Cf vanishes for a large Re (also for a large ln Re), which is not a rational conclusion. On the other hand, if C 0 > 0, then (2.27) for a large Re produces

\begin{equation}{C_f}\sim \sqrt {{C_0}} {\begin{bmatrix}\displaystyle\frac{{{k_s}}}{{a\ln \left( {1 + \dfrac{\delta}{a}} \right)}}\end{bmatrix}^{1/3 \,+\, {\alpha_0}/2}},\end{equation}

\begin{equation}{C_f}\sim \sqrt {{C_0}} {\begin{bmatrix}\displaystyle\frac{{{k_s}}}{{a\ln \left( {1 + \dfrac{\delta}{a}} \right)}}\end{bmatrix}^{1/3 \,+\, {\alpha_0}/2}},\end{equation}which is an acceptable result. Thus, we conclude that C 0 in (2.27) is a positive constant. The relation (2.29) represents the scaling law of the skin-friction coefficient in a rough ATBL flow.

Let us now consider the situation when the roughness height approaches zero. We recall that (2.27) is valid for a rough flow, where ks is quantitatively larger than the viscous length scale η. The value of η as a function of the global TKE dissipation rate is defined as

\begin{equation}\left. \begin{array}{l@{}} \eta \sim {\left({\dfrac{{{\upsilon^3}}}{\varepsilon_b}} \right)^{1/4}}\sim {\left({\dfrac{{{\upsilon^3}\mathscr{L}}}{{U_\infty^3}}}\right)^{1/4}}\\ \Rightarrow \textrm{}\dfrac{\eta }{\mathscr{L}}\sim R{e^{ -3/4}}\\ \Rightarrow \textrm{}\dfrac{\eta }{a}\sim Re_a^{ - 3/4}\,{\ln^{1/4}}\left( {1 +\dfrac{\delta }{a}} \right). \end{array}\right\}\end{equation}

\begin{equation}\left. \begin{array}{l@{}} \eta \sim {\left({\dfrac{{{\upsilon^3}}}{\varepsilon_b}} \right)^{1/4}}\sim {\left({\dfrac{{{\upsilon^3}\mathscr{L}}}{{U_\infty^3}}}\right)^{1/4}}\\ \Rightarrow \textrm{}\dfrac{\eta }{\mathscr{L}}\sim R{e^{ -3/4}}\\ \Rightarrow \textrm{}\dfrac{\eta }{a}\sim Re_a^{ - 3/4}\,{\ln^{1/4}}\left( {1 +\dfrac{\delta }{a}} \right). \end{array}\right\}\end{equation}

For the given ks and large Re, as long as the condition ![]() ${k_s} \gg \eta $ holds, (2.27) remains valid. As Re keeps on increasing for a given

${k_s} \gg \eta $ holds, (2.27) remains valid. As Re keeps on increasing for a given ![]() $\mathscr{L}$, η becomes smaller and smaller (see (2.30)). Therefore, the smaller eddies crowd the flow. Nevertheless, the momentum exchange mechanism continues to be governed by the eddy size of the order of ks, regardless of the smallness of the roughness height. The scenario changes completely for ks = 0. In this case, the applicability of (2.27) becomes questionable because, for ks = 0, the condition

$\mathscr{L}$, η becomes smaller and smaller (see (2.30)). Therefore, the smaller eddies crowd the flow. Nevertheless, the momentum exchange mechanism continues to be governed by the eddy size of the order of ks, regardless of the smallness of the roughness height. The scenario changes completely for ks = 0. In this case, the applicability of (2.27) becomes questionable because, for ks = 0, the condition ![]() ${k_s} \gg \eta $ can never be achieved even for tremendously large Re. In a smooth flow, the wall roughness is completely protected by the viscous sublayer thickness. The momentum exchange mechanism switches from turbulent to viscous and is governed by the smallest possible eddies (in the inertial range), whose size scales with η. Replacing ks in (2.27) with η and using (2.30), the skin-friction coefficient becomes

${k_s} \gg \eta $ can never be achieved even for tremendously large Re. In a smooth flow, the wall roughness is completely protected by the viscous sublayer thickness. The momentum exchange mechanism switches from turbulent to viscous and is governed by the smallest possible eddies (in the inertial range), whose size scales with η. Replacing ks in (2.27) with η and using (2.30), the skin-friction coefficient becomes

\begin{equation}{C_f}\sim {\left( {{C_0} + \frac{{{C_1}}}{{\ln Re}}} \right)^{1/2}}{\left[ {R{e_a}\ln \left( {1 + \frac{\delta }{a}} \right)} \right]^{ - [1/4 \,+\, 3({\alpha _0} \,+\, {\alpha _1}/\ln Re)/8]}}.\end{equation}

\begin{equation}{C_f}\sim {\left( {{C_0} + \frac{{{C_1}}}{{\ln Re}}} \right)^{1/2}}{\left[ {R{e_a}\ln \left( {1 + \frac{\delta }{a}} \right)} \right]^{ - [1/4 \,+\, 3({\alpha _0} \,+\, {\alpha _1}/\ln Re)/8]}}.\end{equation}Noting that C 0 is a positive constant (as concluded previously) and ln−1/2 Re is a slowly varying function for large Re, the scaling law (2.31) for large Re gives

\begin{align}\left.\begin{aligned}&{C_f}\sim \sqrt {{C_0}}{\left[ {R{e_a}\ln \left( {1 + \frac{\delta }{a}} \right)}\right]^{ - (1/4 \,+\, 3{\alpha _0}/8)}}\nonumber\\& \Rightarrow {C_f} ={C_s}\sqrt {{C_0}} {\left[ {R{e_a}\ln \left( {1 +\frac{\delta }{a}} \right)} \right]^{ - (1/4 \,+\, 3{\alpha_0}/8)}},\end{aligned}\right\}\end{align}

\begin{align}\left.\begin{aligned}&{C_f}\sim \sqrt {{C_0}}{\left[ {R{e_a}\ln \left( {1 + \frac{\delta }{a}} \right)}\right]^{ - (1/4 \,+\, 3{\alpha _0}/8)}}\nonumber\\& \Rightarrow {C_f} ={C_s}\sqrt {{C_0}} {\left[ {R{e_a}\ln \left( {1 +\frac{\delta }{a}} \right)} \right]^{ - (1/4 \,+\, 3{\alpha_0}/8)}},\end{aligned}\right\}\end{align}where Cs is a proportionality constant. The relation (2.32) represents the scaling law of the skin-friction coefficient in a smooth ATBL flow.

3. Discussion of results

3.1. Compatibility of the scaling law in the limit a → ∞

It is readily confirmed that, for a rough flow, if we let a → ∞ with α 0 = 0 (no intermittency correction) in (2.29), we find that it recovers Strickler's scaling law in a plane TBL flow as ![]() ${C_{f0}} = {C_f}(a \to \infty )\sim {({k_s}/\delta )^{1/3}}$ (see, for instance, Ali & Dey Reference Ali and Dey2022). Further, in a smooth flow, if we let a → ∞ with α 0 = 0 in (2.32), it recovers Blasius’ scaling law in a plane TBL flow as

${C_{f0}} = {C_f}(a \to \infty )\sim {({k_s}/\delta )^{1/3}}$ (see, for instance, Ali & Dey Reference Ali and Dey2022). Further, in a smooth flow, if we let a → ∞ with α 0 = 0 in (2.32), it recovers Blasius’ scaling law in a plane TBL flow as ![]() ${C_{f0}}\sim Re_\delta ^{ - 1/4}$ (Ali & Dey Reference Ali and Dey2022). We recall Blasius’ empirical formula for a smooth plane TBL flow as

${C_{f0}}\sim Re_\delta ^{ - 1/4}$ (Ali & Dey Reference Ali and Dey2022). We recall Blasius’ empirical formula for a smooth plane TBL flow as

Comparing (2.32) (in the limit a → ∞ with α 0 = 0) and (3.1), we obtain ![]() ${C_s}\sqrt {{C_0}} = 4.56 \times {10^{ - 2}}$. In the subsequent section, it is shown that (2.32) without having an intermittency correction satisfactorily complies with the experimental data and numerical simulations. Therefore, the skin-friction coefficient in a smooth ATBL flow is given by

${C_s}\sqrt {{C_0}} = 4.56 \times {10^{ - 2}}$. In the subsequent section, it is shown that (2.32) without having an intermittency correction satisfactorily complies with the experimental data and numerical simulations. Therefore, the skin-friction coefficient in a smooth ATBL flow is given by

\begin{equation}{C_f} = 4.56 \times {10^{ - 2}}{\left[ {R{e_a}\ln \left( {1 + \frac{\delta }{a}} \right)} \right]^{ - 1/4}}.\end{equation}

\begin{equation}{C_f} = 4.56 \times {10^{ - 2}}{\left[ {R{e_a}\ln \left( {1 + \frac{\delta }{a}} \right)} \right]^{ - 1/4}}.\end{equation} The relation (3.2) unveils the functional form given in (1.1). Although (1.1) shows that Cf is a function of both Rea and δ ![]() $/$a, these parameters can be combined into a single parameter as Rea

$/$a, these parameters can be combined into a single parameter as Rea ![]() $\ln$(1 + δ

$\ln$(1 + δ ![]() $/$a) (see (3.2)). The above form shows that Cf follows the ‘−1

$/$a) (see (3.2)). The above form shows that Cf follows the ‘−1![]() $/$4’ power law scaling with Rea

$/$4’ power law scaling with Rea ![]() $\ln$(1 + δ

$\ln$(1 + δ ![]() $/$a). In the subsequent section, the comparison of (3.2) with the experimental data and numerical simulations is discussed.

$/$a). In the subsequent section, the comparison of (3.2) with the experimental data and numerical simulations is discussed.

We observe that (3.2) can be derived from (3.1) by substituting δ with a ![]() $\ln$(1 + δ

$\ln$(1 + δ ![]() $/$a). Consequently, one might assume that (3.2) could have been obtained easily, without requiring an extensive mathematical analysis, by utilising the relationship Reδ = Rea(δ

$/$a). Consequently, one might assume that (3.2) could have been obtained easily, without requiring an extensive mathematical analysis, by utilising the relationship Reδ = Rea(δ ![]() $/$a) and then replacing δ with a

$/$a) and then replacing δ with a ![]() $\ln$(1 + δ

$\ln$(1 + δ ![]() $/$a), following the reasoning presented in (1.2) and (1.3). However, this assumption may be misleading due to the following reasons:

$/$a), following the reasoning presented in (1.2) and (1.3). However, this assumption may be misleading due to the following reasons:

(i) First and foremost, (3.2) is derived entirely through a theoretical analysis based on the momentum balance. Blasius’ scaling law is not employed in the derivation process. However, it is revealed that the proposed scaling law derived from the theoretical analysis corroborates Blasius’ scaling law in the limit a → ∞. As a result, Blasius’ scaling law serves as a boundary condition for obtaining the proportionality constant in the limit a → ∞.

(ii) Additionally, this study does not consider Blasius’ scaling law as a benchmark and subsequently modifies it for an ATBL flow by merely replacing δ with a

$\ln$(1 + δ

$\ln$(1 + δ  $/$a). Blasius’ scaling law was not the starting point for the derivation process in any way.

$/$a). Blasius’ scaling law was not the starting point for the derivation process in any way.(iii) Moreover, it may be emphasised that the proposed scaling law (3.2) of this study presents a precise functional form of (1.1). Afzal & Narasimha (Reference Afzal and Narasimha1976) did not provide an exact power law scaling behaviour similar to (3.2). Therefore, the scaling law (3.2) has not been formerly known. While it was acknowledged that the axisymmetric logarithmic law holds when y is replaced by a

$\ln$(1 + y

$\ln$(1 + y  $/$a), this replacement was not specifically extended to the entire ATBL in the work of Afzal & Narasimha (Reference Afzal and Narasimha1976).

$/$a), this replacement was not specifically extended to the entire ATBL in the work of Afzal & Narasimha (Reference Afzal and Narasimha1976).(iv) Furthermore, even if one were to modify Blasius’ scaling law by replacing δ with a

$\ln$(1 + δ

$\ln$(1 + δ  $/$a), such a modification, while producing the correct result, would lack scientific relevance. This replacement would give the impression that the ATBL thickness becomes smaller than the plane TBL thickness. However, this is inappropriate when the boundary layer thickness remains identical for both the ATBL and plane TBL flows. The notable change occurs in the contraction of the external length scale rather than a reduction in the boundary layer thickness.

$/$a), such a modification, while producing the correct result, would lack scientific relevance. This replacement would give the impression that the ATBL thickness becomes smaller than the plane TBL thickness. However, this is inappropriate when the boundary layer thickness remains identical for both the ATBL and plane TBL flows. The notable change occurs in the contraction of the external length scale rather than a reduction in the boundary layer thickness.(v) Finally, it is worth highlighting that the substitution of δ with a

$\ln$(1 + δ

$\ln$(1 + δ  $/$a) in Blasius’ scaling law would not offer any information regarding the intermittency correction, as described in (2.32). Therefore, the proposed replacement cannot anticipate the general scaling behaviour including the intermittency correction.

$/$a) in Blasius’ scaling law would not offer any information regarding the intermittency correction, as described in (2.32). Therefore, the proposed replacement cannot anticipate the general scaling behaviour including the intermittency correction.

3.2. Comparison with experimental data and numerical simulations

To compare the proposed skin-friction coefficient (see (3.2)) with the experimental data and numerical simulations, we consider the available experimental and numerical database reported in the literature. The experimental data of Willmarth et al. (Reference Willmarth, Winkel, Sharma and Bogar1976), Luxton et al. (Reference Luxton, Bull and Rajagopalan1984), Snarski & Lueptow (Reference Snarski and Lueptow1995) and Berera (Reference Berera2004), and the numerical simulations of Neves et al. (Reference Neves, Moin and Moser1994), Woods (Reference Woods2006), Tutty (Reference Tutty2008), Jordan (Reference Jordan2011, Reference Jordan2013) and Monte et al. (Reference Monte, Sagaut and Gomez2011) are used for this purpose. Table 1 shows the typical ranges of parameters Rea, δ ![]() $/$a, Reδ, and a + used in previous studies. The considered ranges of Rea, δ

$/$a, Reδ, and a + used in previous studies. The considered ranges of Rea, δ ![]() $/$a, Reδ and a + can capture all the axisymmetric flow regimes (regimes I, II and III). Figure 5 shows the experimental and numerical data points of the skin-friction coefficient, corresponding to each author given in table 1, on an (Rea, δ/a) plane. The data points cover wide ranges of Rea and δ

$/$a, Reδ and a + can capture all the axisymmetric flow regimes (regimes I, II and III). Figure 5 shows the experimental and numerical data points of the skin-friction coefficient, corresponding to each author given in table 1, on an (Rea, δ/a) plane. The data points cover wide ranges of Rea and δ ![]() $/$a of 140 ≤ Rea ≤ 92 310 and 0.16 ≤ δ/a ≤ 300.

$/$a of 140 ≤ Rea ≤ 92 310 and 0.16 ≤ δ/a ≤ 300.

Table 1. Typical ranges of parameters in experimental measurements and numerical simulations.

Figure 5. Experimental and numerical database of Cf on a (Rea, δ/a) plane.

Figure 6(a) shows the comparison of the skin-friction coefficient obtained from (3.2) with the experimental data and numerical simulations. To make the comparison, the experimental and numerical data are presented plotting Cf as a function of Rea ln(1 + δ/a) on logarithmic scales. The ±20 % error band is also shown to understand the quantitative departure of the data from the proposed law (3.2). Overall, the theoretical prediction matches satisfactorily with the data without invoking any intermittency correction α 0. The value of α 0 is usually small for a large Re. This suggests that ![]() $|3{\alpha_0}/8|\ll 1/4$ (see (2.32)), and therefore,

$|3{\alpha_0}/8|\ll 1/4$ (see (2.32)), and therefore, ![]() $|{\alpha_0}|\ll 2/3$, in conformity with the usual estimates of α 0 (Frisch Reference Frisch1995). The data plots on logarithmic scales respect the ‘−1

$|{\alpha_0}|\ll 2/3$, in conformity with the usual estimates of α 0 (Frisch Reference Frisch1995). The data plots on logarithmic scales respect the ‘−1![]() $/$4’ slope as predicted by (3.2) (figure 6a). For a given Rea

$/$4’ slope as predicted by (3.2) (figure 6a). For a given Rea ![]() $\ln$(1 + δ/a), the relative error in Cf is calculated as

$\ln$(1 + δ/a), the relative error in Cf is calculated as ![]() $[{C_f}(\,predicted) - {C_f}(observed)]/{C_f}(observed)$. Figure 6(b) shows the relative error (in percentage) as a function of Rea

$[{C_f}(\,predicted) - {C_f}(observed)]/{C_f}(observed)$. Figure 6(b) shows the relative error (in percentage) as a function of Rea ![]() $\ln$(1 + δ

$\ln$(1 + δ ![]() $/$a) on a semi-logarithmic plot. The absolute relative errors for most of the data plots lie within 20 %. However, for a very few data, the absolute relative errors range from 25 % to 45 %.

$/$a) on a semi-logarithmic plot. The absolute relative errors for most of the data plots lie within 20 %. However, for a very few data, the absolute relative errors range from 25 % to 45 %.

Figure 6. (a) Comparison of the theoretical prediction of Cf (subject to ±20 % error band) with the experimental data and numerical simulations. Woods’ (Reference Woods2006) empirical formula is also shown for the comparison. (b) Relative error in Cf versus Rea ![]() $\ln$(1 + δ/a).

$\ln$(1 + δ/a).