Published online by Cambridge University Press: 27 November 2020

The ‘coffee stain ring’ is a particle deposit, that forms naturally, when the liquid of a suspension drop evaporates, leaving the particles at the edge of the deposit. Although observed in coffee cups in everyday life, such deposits appear in a wide range of liquid, particle and surface combinations and have attracted vivid research attention. Previous studies focused on the fluidics of evaporating suspension droplets on rigid materials, where the ring formation was shown to occur for pinned contact lines, and possible suppression of the coffee stain effect with surfactants, or other externally driven means, was investigated. Here, we show that, on soft materials, we can control the topography of the deposit on demand – promoting or suppressing the coffee ring effect – by simply changing the environmental humidity, regulating the evaporative flux. We perform particle tracking of droplets drying on soft substrates at varied environmental conditions and show with experimental observations and theoretical analysis that, at an expedited contact line velocity, particles are advected towards the receding contact line. We relate this advection to the viscous dissipation within the soft solid, retarding the contact line motion. The coffee ring formation in the presence of a receding contact line and its control by the environmental humidity, bring a new perspective to the conditions of the manifestation of this frequent deposit topography. We demonstrate the importance of our findings during the printing of a colloidal line, showing the ability to trigger line bifurcation on soft substrates by regulating the evaporative flux, introducing another degree of controllability for contact printing.

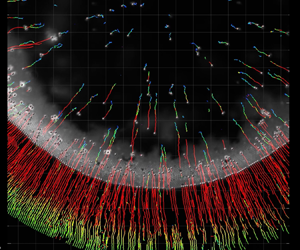

Movie showing the contact line motion during colloidal droplet drying on a compliant silicone substrate (E = 12.6 kPa), at T = 22°C and rh = 0%