1. Introduction

Flow-induced vibration of flexible structures has received much attention because of its applications in energy harvesting. The conversion of strain energy into electrical energy can be achieved via piezoelectric materials attached to a surface. Snap through, which is a rapid transition from one equilibrium state to another, is ubiquitous in nature and everyday life (e.g. rapid closure of a Venus flytrap (Forterre et al. Reference Forterre, Skotheim, Dumais and Mahadevan2005) or a sudden upward flip of an umbrella in wind (Gomez, Moulton & Vella Reference Gomez, Moulton and Vella2017a)). The flow-induced snap-through oscillation of a buckled elastic sheet is useful for energy harvesting (Kim et al. Reference Kim, Zhou, Kim and Oh2020, Reference Kim, Lahooti, Kim and Kim2021a). The buckled sheet exhibits large deflection with high strain energy during periodic oscillation. The energy harvesting performance is closely related to its snap-through dynamics in the surrounding flow.

Considerable research effort has been devoted to various flow-induced vibrations of a flag (or plate/filament), including self-excited vibration, forced vibration and vortex-induced vibration (Yu, Liu & Amandolese Reference Yu, Liu and Amandolese2019). The self-excited vibration of a conventional flag occurs depending on the flow velocity, flag's length, bending rigidity and flag-to-liquid mass ratio (Taneda Reference Taneda1968; Zhang et al. Reference Zhang, Childress, Libchaber and Shelley2000; Shelley, Vandenberghe & Zhang Reference Shelley, Vandenberghe and Zhang2005; Michelin, Smith & Glover Reference Michelin, Smith and Glover2008; Banerjee, Connell & Yue Reference Banerjee, Connell and Yue2015; Cisonni et al. Reference Cisonni, Lucey, Elliott and Heil2017). Instability of the flag is induced by a constructive interaction between the flag's movement and the aero/hydrodynamic load (i.e. a positive feedback among inertial force, elastic force and fluid force). Most energy harvesting devices have been developed on the basis of the self-excited vibration, even though the critical flow velocity activating the vibration is relatively high (Tang, Païdoussis & Jiang Reference Tang, Païdoussis and Jiang2009; Michelin & Doaré Reference Michelin and Doaré2013; Xia, Michelin & Doaré Reference Xia, Michelin and Doaré2015; Yu & Liu Reference Yu and Liu2016). Next, the critical flow velocity can be reduced by upstream installation of a bluff body, enhancing the instability in a wider range of flow velocity (Allen & Smits Reference Allen and Smits2001; Taylor et al. Reference Taylor, Burns, Kammann, Powers and Welsh2001; Manela & Howe Reference Manela and Howe2009; Gilmanov, Le & Sotiropoulos Reference Gilmanov, Le and Sotiropoulos2015; Hu et al. Reference Hu, Yang, Chen, Wang and Liu2018; Furquan & Mittal Reference Furquan and Mittal2021). Vortices shed from the bluff body give rise to a forced vibration with a higher vibration frequency and a lower vibration amplitude than those of the self-excited vibration. To avoid the additional bluff body, Kim et al. (Reference Kim, Cossé, Cerdeira and Gharib2013) proposed an inverted flag to reduce the critical flow velocity. The inverted flag is more unstable because of the leading- and trailing-edge vortices shed from the flag, which results in a vortex-induced vibration with high vibration amplitude and high mean strain energy. Some studies have also considered the flapping of heavy inverted flags as a form of self-excited vibration (Tavallaeinejad et al. Reference Tavallaeinejad, Païdoussis, Salinas, Legrand, Kheiri and Botez2020, Reference Tavallaeinejad, Salinas, Païdoussis, Legrand, Kheiri and Botez2021). Due to its strong vibration, the inverted flag has been found to be a promising candidate for energy harvesting applications but in a limited range (Gurugubelli & Jaiman Reference Gurugubelli and Jaiman2015; Ryu et al. Reference Ryu, Park, Kim and Sung2015; Tang, Liu & Lu Reference Tang, Liu and Lu2015; Sader et al. Reference Sader, Cossé, Kim, Fan and Gharib2016a,Reference Sader, Huertas-Cerdeira and Gharibb; Orrego et al. Reference Orrego, Shoele, Ruas, Doran, Caggiano, Mittal and Kang2017; Yu, Liu & Chen Reference Yu, Liu and Chen2017). On the other hand, the initial inclination angle (Shoele & Mittal Reference Shoele and Mittal2016; Lim & Park Reference Lim and Park2022) and oscillating incoming flow (Mazharmanesh et al. Reference Mazharmanesh, Young, Tian, Ravi and Lai2022) enhance the energy harvesting performance more effectively. Note that the strain energy of the inverted flag is very low when the flag returns to its initial state.

The snap-through oscillation of a buckled elastic sheet with two clamped edges provides a solution that increases the low strain energy. Considerable strain energy is stored in the sheet because of the large deflection of the initial shape. The buckled sheet has been used for energy harvesting, where it demonstrated a much higher output voltage than the unbuckled one (Jung & Yun Reference Jung and Yun2010; Cottone et al. Reference Cottone, Gammaitoni, Vocca, Ferrari and Ferrari2012; Boisseau et al. Reference Boisseau, Despesse, Monfray, Puscasu and Skotnicki2013; Zhu & Zu Reference Zhu and Zu2013; Bai et al. Reference Bai, Liao, Chen, Gan, Zou, Wei, Gu and Zheng2022). In these studies, an external input was required to activate the snap-through oscillation. Recently, Kim et al. (Reference Kim, Zhou, Kim and Oh2020) investigated an energy harvester based on flow-induced snap-through oscillation. They performed experiments to examine the critical conditions and snap-through dynamics (Kim et al. Reference Kim, Lahooti, Kim and Kim2021a; Kim, Kim & Kim Reference Kim, Kim and Kim2021b). According to these studies, the fluid force increases with increasing flow velocity, inducing the snap-through oscillation. The critical flow velocity is length dependent but insensitive to the mass ratio; a mode transition from equilibrium to snap-through oscillation is caused by the divergence instability. The vibration mode remains unchanged irrespective of the flow velocity. In addition, the snap-through oscillation of the sheet leads to flow separation and consequent vortex shedding. However, few numerical studies of the transition to snap-through oscillation of a buckled flexible filament have been reported. Numerical simulation is advantageous to parametric and quantitative analyses in fluid–flexible structure interaction. In particular, the immersed boundary (IB) method has been widely adopted to handle the interaction (Huang, Shin & Sung Reference Huang, Shin and Sung2007; Huang & Sung Reference Huang and Sung2010; Ryu et al. Reference Ryu, Park, Kim and Sung2015; Park, Ryu & Sung Reference Park, Ryu and Sung2019). More importantly, the influence of the bending rigidity and the relation between the mode transition and vortex shedding of a buckled filament have not yet been fully elucidated and warrant a more detailed investigation.

The objective of the present study is to explore the snap-through dynamics of a buckled flexible filament using the penalty IB method. The effects of the bending rigidity (![]() ${\gamma _{{L_0}}}$), length (

${\gamma _{{L_0}}}$), length (![]() $L$) and Reynolds number (

$L$) and Reynolds number (![]() $Re$) on the mode transition are examined. Three different modes are observed: an equilibrium mode, a streamwise oscillation mode and a snap-through oscillation mode. The transverse displacement of the intersection between the filament and the line

$Re$) on the mode transition are examined. Three different modes are observed: an equilibrium mode, a streamwise oscillation mode and a snap-through oscillation mode. The transverse displacement of the intersection between the filament and the line ![]() $x = 0$ (

$x = 0$ (![]() ${y_{x = 0}}$), oscillation amplitude (

${y_{x = 0}}$), oscillation amplitude (![]() $A$) and frequency (

$A$) and frequency ( ![]() ${f_{{y_\textrm{m}}}}$) are used to identify different oscillation modes. A scaling is performed on

${f_{{y_\textrm{m}}}}$) are used to identify different oscillation modes. A scaling is performed on ![]() ${y_{x = 0}}$, A,

${y_{x = 0}}$, A, ![]() ${f_{{y_\textrm{m}}}}$ and

${f_{{y_\textrm{m}}}}$ and ![]() ${\gamma _{{L_0}}}$. The instability mechanism is characterized in terms of the fluid force, elastic force and wake pattern. The relation between the filament's oscillation and vortex shedding is explored. A hysteresis near the critical Reynolds number is analysed. In addition, the energy harvesting performance is estimated via measurements of the deflection and strain energy of the filament.

${\gamma _{{L_0}}}$. The instability mechanism is characterized in terms of the fluid force, elastic force and wake pattern. The relation between the filament's oscillation and vortex shedding is explored. A hysteresis near the critical Reynolds number is analysed. In addition, the energy harvesting performance is estimated via measurements of the deflection and strain energy of the filament.

2. Computational model

2.1. Problem formulation

A schematic of the buckled flexible filament with two clamped edges in a uniform flow is shown in figure 1. The computational domain is ![]() $- 10{L_0} \le x \le 22{L_0}$ and

$- 10{L_0} \le x \le 22{L_0}$ and ![]() $- 8{L_0} \le y \le 8{L_0}$, where x and y represent the streamwise and transverse directions, respectively. The initial buckled shape is symmetric around

$- 8{L_0} \le y \le 8{L_0}$, where x and y represent the streamwise and transverse directions, respectively. The initial buckled shape is symmetric around ![]() $x = 0$. Here,

$x = 0$. Here, ![]() ${U_0}$ is the free-stream velocity,

${U_0}$ is the free-stream velocity, ![]() ${L_0}$ and L are the distance between two clamped edges and the length of the filament, respectively, where

${L_0}$ and L are the distance between two clamped edges and the length of the filament, respectively, where ![]() ${L_0}$ is set to be shorter than L to achieve an initial buckled shape and

${L_0}$ is set to be shorter than L to achieve an initial buckled shape and ![]() ${w_0}$ is the initial height of the filament without flow, which is close to one-half of the maximum transverse displacement of the filament during snap-through oscillation. The motion of the fluid is defined on a fixed Cartesian grid. Dirichlet boundary conditions (

${w_0}$ is the initial height of the filament without flow, which is close to one-half of the maximum transverse displacement of the filament during snap-through oscillation. The motion of the fluid is defined on a fixed Cartesian grid. Dirichlet boundary conditions (![]() $u = {U_0}$,

$u = {U_0}$, ![]() $v = 0$) are imposed at the inlet, top and bottom boundaries. A Neumann-type boundary condition (

$v = 0$) are imposed at the inlet, top and bottom boundaries. A Neumann-type boundary condition (![]() $\partial \boldsymbol{u}/\partial x = 0$) is specified at the outlet. The initial conditions are

$\partial \boldsymbol{u}/\partial x = 0$) is specified at the outlet. The initial conditions are ![]() $u = {U_0}$,

$u = {U_0}$, ![]() $v = 0$ and

$v = 0$ and ![]() $p = 0$. The motion of the filament is defined on a moving Lagrangian grid under a curvilinear coordinate system (

$p = 0$. The motion of the filament is defined on a moving Lagrangian grid under a curvilinear coordinate system (![]() $s$).

$s$).

Figure 1. Schematic of the buckled flexible filament in a uniform flow.

The incompressible viscous fluid flow is governed by the Navier–Stokes (N–S) equations and the continuity equation, which are dimensionless:

where ![]() $\boldsymbol{u} = (u,v)$ is the velocity vector, p is the pressure and

$\boldsymbol{u} = (u,v)$ is the velocity vector, p is the pressure and ![]() $\boldsymbol{f} = (\,{f_x},{f_y})$ is the momentum forcing to enforce the no-slip condition along the IB. The value of

$\boldsymbol{f} = (\,{f_x},{f_y})$ is the momentum forcing to enforce the no-slip condition along the IB. The value of ![]() $Re$ is expressed as

$Re$ is expressed as ![]() $Re = {\rho _0}{U_0}{L_0}/\mu $, where

$Re = {\rho _0}{U_0}{L_0}/\mu $, where ![]() ${\rho _0}$ and

${\rho _0}$ and ![]() $\mu $ are the fluid density and the dynamic viscosity, respectively. Equations (2.1) and (2.2) are non-dimensionalized using the following characteristic scales:

$\mu $ are the fluid density and the dynamic viscosity, respectively. Equations (2.1) and (2.2) are non-dimensionalized using the following characteristic scales: ![]() ${L_0}$ for the length,

${L_0}$ for the length, ![]() ${U_0}$ for the velocity,

${U_0}$ for the velocity, ![]() ${L_0}/{U_0}$ for the time,

${L_0}/{U_0}$ for the time, ![]() ${\rho _0}U_0^2$ for the pressure and

${\rho _0}U_0^2$ for the pressure and ![]() ${\rho _0}U_0^2/{L_0}$ for the feedback momentum forcing

${\rho _0}U_0^2/{L_0}$ for the feedback momentum forcing ![]() $\boldsymbol{f}$. The dimensionless quantities are written in the same form as their dimensional counterparts for convenience.

$\boldsymbol{f}$. The dimensionless quantities are written in the same form as their dimensional counterparts for convenience.

The movement of the filament is governed by the motion equation and the inextensibility condition, which are dimensionless

where s ranges from 0 to L, ![]() $\boldsymbol{X} = (X(s,t),Y(s,t))$ is the displacement, T is the tension coefficient along the filament axis and

$\boldsymbol{X} = (X(s,t),Y(s,t))$ is the displacement, T is the tension coefficient along the filament axis and ![]() ${\gamma _{{L_0}}}$ is the bending rigidity. Here,

${\gamma _{{L_0}}}$ is the bending rigidity. Here, ![]() ${\boldsymbol{F}_s} = (\partial /\partial s)(T(\partial \boldsymbol{X}/\partial s)) - ({\partial ^2}/\partial {s^2})({\gamma _{{L_0}}}({\partial ^2}\boldsymbol{X}/\partial {s^2}))$ is the elastic force of the filament, and

${\boldsymbol{F}_s} = (\partial /\partial s)(T(\partial \boldsymbol{X}/\partial s)) - ({\partial ^2}/\partial {s^2})({\gamma _{{L_0}}}({\partial ^2}\boldsymbol{X}/\partial {s^2}))$ is the elastic force of the filament, and ![]() ${\boldsymbol{F}_f} = ({F_{fx}}(s),{F_{fy}}(s))$ denotes the Lagrangian forcing exerted on the filament by the surrounding fluid. Equations (2.3) and (2.4) were non-dimensionalized using the following characteristic scales:

${\boldsymbol{F}_f} = ({F_{fx}}(s),{F_{fy}}(s))$ denotes the Lagrangian forcing exerted on the filament by the surrounding fluid. Equations (2.3) and (2.4) were non-dimensionalized using the following characteristic scales: ![]() ${L_0}$ for the length,

${L_0}$ for the length, ![]() ${L_0}/{U_0}$ for the time,

${L_0}/{U_0}$ for the time, ![]() ${\rho _1}U_0^2/{L_0}$ for the Lagrangian forcing

${\rho _1}U_0^2/{L_0}$ for the Lagrangian forcing ![]() ${\boldsymbol{F}_f}$,

${\boldsymbol{F}_f}$, ![]() ${\rho _1}U_0^2$ for the tension coefficient

${\rho _1}U_0^2$ for the tension coefficient ![]() $T$ and

$T$ and ![]() ${\rho _1}U_0^2L_0^2$ for the bending rigidity

${\rho _1}U_0^2L_0^2$ for the bending rigidity ![]() ${\gamma _{{L_0}}}$. Parameter

${\gamma _{{L_0}}}$. Parameter ![]() ${\rho _1}$ denotes the density difference between the filament and the surrounding fluid. The actual filament line density is

${\rho _1}$ denotes the density difference between the filament and the surrounding fluid. The actual filament line density is ![]() ${\rho _s} = {\rho _1} + {\rho _0}A$, where

${\rho _s} = {\rho _1} + {\rho _0}A$, where ![]() ${\rho _0}$ is the density of fluid and A denotes the sectional area of the filament. The dimensionless quantities are written in the same form as their dimensional counterparts for convenience. In the present study, the bending rigidity

${\rho _0}$ is the density of fluid and A denotes the sectional area of the filament. The dimensionless quantities are written in the same form as their dimensional counterparts for convenience. In the present study, the bending rigidity ![]() ${\gamma _{{L_0}}}$ is assumed to be constant, whereas the tension coefficient T is determined by the constraint of inextensibility, is a function of s and

${\gamma _{{L_0}}}$ is assumed to be constant, whereas the tension coefficient T is determined by the constraint of inextensibility, is a function of s and ![]() $t$ and is solved by the Poisson equation for T (Huang et al. Reference Huang, Shin and Sung2007).

$t$ and is solved by the Poisson equation for T (Huang et al. Reference Huang, Shin and Sung2007).

At two fixed edges (![]() $\boldsymbol{X} = ( - {L_0}/2,0)$ and

$\boldsymbol{X} = ( - {L_0}/2,0)$ and ![]() $({L_0}/2,0)$ at

$({L_0}/2,0)$ at ![]() $s = 0$ and L, respectively), clamped boundary conditions are applied

$s = 0$ and L, respectively), clamped boundary conditions are applied

The boundary of the filament and the massless boundary (IB) are strongly connected by a virtual stiff spring. The Lagrangian forcing ![]() ${\boldsymbol{F}_\textrm{f}}$ can be calculated by the feedback law (Goldstein, Handler & Sirovich Reference Goldstein, Handler and Sirovich1993)

${\boldsymbol{F}_\textrm{f}}$ can be calculated by the feedback law (Goldstein, Handler & Sirovich Reference Goldstein, Handler and Sirovich1993)

where ![]() $\alpha $ and

$\alpha $ and ![]() $\beta $ are large negative free constants (Shin, Huang & Sung Reference Shin, Huang and Sung2008),

$\beta $ are large negative free constants (Shin, Huang & Sung Reference Shin, Huang and Sung2008), ![]() ${\boldsymbol{U}_{ib}}$ is the fluid velocity obtained by interpolation at the IB and

${\boldsymbol{U}_{ib}}$ is the fluid velocity obtained by interpolation at the IB and ![]() $\boldsymbol{U}$ is the velocity of the filament expressed by

$\boldsymbol{U}$ is the velocity of the filament expressed by ![]() $\boldsymbol{U} = \textrm{d}\kern0.7pt \boldsymbol{X}/\textrm{d}t$.

$\boldsymbol{U} = \textrm{d}\kern0.7pt \boldsymbol{X}/\textrm{d}t$.

The Dirac delta function is used to carry out the transformation between the Eulerian and Lagrangian variables (Peskin Reference Peskin2002). The velocity ![]() ${\boldsymbol{U}_{ib}}$ obtained by interpolation is expressed as

${\boldsymbol{U}_{ib}}$ obtained by interpolation is expressed as

The Eulerian momentum forcing ![]() $\boldsymbol{f}$ obtained by spreading the Lagrangian forcing

$\boldsymbol{f}$ obtained by spreading the Lagrangian forcing ![]() ${\boldsymbol{F}_f}$ to the nearby Eulerian grids is expressed as

${\boldsymbol{F}_f}$ to the nearby Eulerian grids is expressed as

where ![]() $\rho = {\rho _1}/({\rho _0}{L_0}) = 1$ arises from non-dimensionalization. The elastic strain energy

$\rho = {\rho _1}/({\rho _0}{L_0}) = 1$ arises from non-dimensionalization. The elastic strain energy ![]() ${E_s}(t)$ is defined by

${E_s}(t)$ is defined by

where ![]() $K(s,t) = {({\partial ^2}\boldsymbol{X}/\partial {s^2})^2}$ is the square of the curvature.

$K(s,t) = {({\partial ^2}\boldsymbol{X}/\partial {s^2})^2}$ is the square of the curvature.

The fractional step method on a staggered Cartesian grid is used to solve the N–S equations (Kim, Baek & Sung Reference Kim, Baek and Sung2002). A direct numerical method developed by Huang et al. (Reference Huang, Shin and Sung2007) is used to calculate the filament motion. Details regarding the discretization of the governing equations and numerical method can be found in the works of Kim et al. (Reference Kim, Baek and Sung2002) and Huang et al. (Reference Huang, Shin and Sung2007).

2.2. Validation

Table 1 shows the results of the domain test for ![]() ${L_0}/L = 0.589$,

${L_0}/L = 0.589$, ![]() ${\gamma _{{L_0}}} = 0.005$ and

${\gamma _{{L_0}}} = 0.005$ and ![]() $Re = 200$ (snap-through oscillation mode), including the averaged drag coefficient

$Re = 200$ (snap-through oscillation mode), including the averaged drag coefficient ![]() ${\bar{C}_D}$, the root mean square of the lift coefficient

${\bar{C}_D}$, the root mean square of the lift coefficient ![]() ${C_{L\ rms}}$, the Strouhal number

${C_{L\ rms}}$, the Strouhal number ![]() $St$ (

$St$ ( ![]() ${f_{{y_m}}}{L_0}/{U_0}$) and the relative error

${f_{{y_m}}}{L_0}/{U_0}$) and the relative error ![]() $\varepsilon $;

$\varepsilon $; ![]() ${f_{{y_m}}}$ is the oscillation frequency of the filament undergoing snap-through oscillation, and

${f_{{y_m}}}$ is the oscillation frequency of the filament undergoing snap-through oscillation, and ![]() ${y_m}$ is the transverse displacement of the midpoint of the filament. The result for the

${y_m}$ is the transverse displacement of the midpoint of the filament. The result for the ![]() $32 \times 16$ domain agrees well with those for the

$32 \times 16$ domain agrees well with those for the ![]() $32 \times 24$ and

$32 \times 24$ and ![]() $64 \times 16$ domains. The domain size

$64 \times 16$ domains. The domain size ![]() $32 \times 16$ was selected to improve the accuracy of the present simulation. In addition, the sensitivity of the results to the grid resolution and time step is examined in figure 2. The results for

$32 \times 16$ was selected to improve the accuracy of the present simulation. In addition, the sensitivity of the results to the grid resolution and time step is examined in figure 2. The results for ![]() $\Delta x = 1/128$ and

$\Delta x = 1/128$ and ![]() $\Delta t = 2 \times {10^{ - 4}}$ agree well with those for

$\Delta t = 2 \times {10^{ - 4}}$ agree well with those for ![]() $\Delta x = 1/256$ and

$\Delta x = 1/256$ and ![]() $\Delta t = 0.5 \times {10^{ - 4}}$, respectively. The result does not converge for

$\Delta t = 0.5 \times {10^{ - 4}}$, respectively. The result does not converge for ![]() $\Delta t > 2 \times {10^{ - 4}}$. The grid resolution of 1/128 and a time step of

$\Delta t > 2 \times {10^{ - 4}}$. The grid resolution of 1/128 and a time step of ![]() $2 \times {10^{ - 4}}$ were chosen to ensure sufficiently high accuracy of the simulation. The maximum Courant number was ~0.04. The grid resolution of the filament was the same as that of the domain. The domain grid was uniformly distributed along the x-axis but was stretched along the y-axis. The grid size of the domain in

$2 \times {10^{ - 4}}$ were chosen to ensure sufficiently high accuracy of the simulation. The maximum Courant number was ~0.04. The grid resolution of the filament was the same as that of the domain. The domain grid was uniformly distributed along the x-axis but was stretched along the y-axis. The grid size of the domain in ![]() $- Y/4 \le y \le Y/4$ was

$- Y/4 \le y \le Y/4$ was ![]() $\Delta y = \Delta x$, where Y is the domain height.

$\Delta y = \Delta x$, where Y is the domain height.

Table 1. Domain test, including the averaged drag coefficient ![]() ${\bar{C}_D}$, the root mean square of the lift coefficient

${\bar{C}_D}$, the root mean square of the lift coefficient ![]() ${C_{L\ rms}}$, the Strouhal number

${C_{L\ rms}}$, the Strouhal number ![]() $St$ and the relative errors

$St$ and the relative errors ![]() $\varepsilon $ with respect to the domain

$\varepsilon $ with respect to the domain ![]() $32 \times 24$ in I and

$32 \times 24$ in I and ![]() $64 \times 16$ in II for

$64 \times 16$ in II for ![]() ${L_0}/L = 0.589$,

${L_0}/L = 0.589$, ![]() ${\gamma _{{L_0}}} = 0.005$ and

${\gamma _{{L_0}}} = 0.005$ and ![]() $Re = 200$.

$Re = 200$.

Figure 2. Time histories of the transverse displacement of the midpoint of the filament (![]() ${y_m}$) for different (a) grid resolutions and (b) time steps (

${y_m}$) for different (a) grid resolutions and (b) time steps (![]() ${L_0}/L = 0.589$,

${L_0}/L = 0.589$, ![]() ${\gamma _{{L_0}}} = 0.005$,

${\gamma _{{L_0}}} = 0.005$, ![]() $Re = 200$).

$Re = 200$).

3. Results and discussion

The buckled flexible filament initially exhibits fore–aft symmetry in the absence of fluid flow. Equation (2.3) was initially solved without the Lagrangian forcing. The initial shape is obtained from the average due to the small fluctuations of the filament. Figure 3 shows the initial height (![]() ${w_0}/L$) as

${w_0}/L$) as ![]() ${L_0}/L$ is varied and the initial shape for

${L_0}/L$ is varied and the initial shape for ![]() ${L_0}/L = 0.5$, 0.6 and 0.75 (

${L_0}/L = 0.5$, 0.6 and 0.75 (![]() ${\gamma _{{L_0}}} = 0.01$). The value of

${\gamma _{{L_0}}} = 0.01$). The value of ![]() ${w_0}/L$ decreases with increasing

${w_0}/L$ decreases with increasing ![]() ${L_0}/L$. The experimental data of Kim et al. (Reference Kim, Lahooti, Kim and Kim2021a) are included for comparison

${L_0}/L$. The experimental data of Kim et al. (Reference Kim, Lahooti, Kim and Kim2021a) are included for comparison ![]() $(0.0016 \le {\gamma _{{L_0}}} \le 0.0108)$. The present results show good agreement with the experimental data, validating the results of the present simulation.

$(0.0016 \le {\gamma _{{L_0}}} \le 0.0108)$. The present results show good agreement with the experimental data, validating the results of the present simulation.

Figure 3. (a) Initial height (![]() ${w_0}/L$) of the buckled flexible filament as a function of

${w_0}/L$) of the buckled flexible filament as a function of ![]() ${L_0}/L$. (b) Initial buckled shapes for different

${L_0}/L$. (b) Initial buckled shapes for different ![]() ${L_0}/L$; the red and grey lines represent the results of the present study and the experimental results of Kim et al. (Reference Kim, Lahooti, Kim and Kim2021a), respectively.

${L_0}/L$; the red and grey lines represent the results of the present study and the experimental results of Kim et al. (Reference Kim, Lahooti, Kim and Kim2021a), respectively.

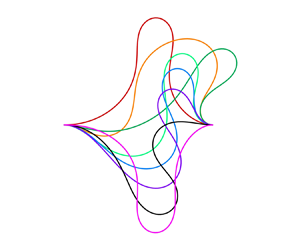

3.1. Effects of the length and bending rigidity

In the present study, three different modes are observed: an equilibrium (E) mode, a streamwise oscillation (SO) mode and a snap-through oscillation (STO) mode. The superposition of instantaneous shapes in these three modes is shown in figure 4 (![]() $Re = 100$). In figure 4(a), three short filaments (

$Re = 100$). In figure 4(a), three short filaments (![]() ${L_0}/L = 0.8$) with different bending rigidities (

${L_0}/L = 0.8$) with different bending rigidities (![]() ${\gamma _{{L_0}}}$) exhibit the E mode; the shape of the filaments is constant in time. The filament shape with relatively high bending rigidity (

${\gamma _{{L_0}}}$) exhibit the E mode; the shape of the filaments is constant in time. The filament shape with relatively high bending rigidity (![]() ${\gamma _{{L_0}}} = 0.03$) is similar to the filament's initial symmetric shape. The filament moves downstream as

${\gamma _{{L_0}}} = 0.03$) is similar to the filament's initial symmetric shape. The filament moves downstream as ![]() ${\gamma _{{L_0}}}$ decreases; the front part gradually approaches

${\gamma _{{L_0}}}$ decreases; the front part gradually approaches ![]() $y = 0$. In figure 4(b), a longer filament (

$y = 0$. In figure 4(b), a longer filament (![]() ${L_0}/L = 0.5$,

${L_0}/L = 0.5$, ![]() ${\gamma _{{L_0}}} = 0.02$) exhibits the SO mode, deviating from its initial shape and undergoing a periodic streamwise oscillation without crossing

${\gamma _{{L_0}}} = 0.02$) exhibits the SO mode, deviating from its initial shape and undergoing a periodic streamwise oscillation without crossing ![]() $y = 0$. Time histories of

$y = 0$. Time histories of ![]() ${x_m}$ and

${x_m}$ and ![]() ${y_m}$ for

${y_m}$ for ![]() ${\gamma _{{L_0}}} = 0.02$ are shown in figure 5(a). In figure 4(c), a soft filament (

${\gamma _{{L_0}}} = 0.02$ are shown in figure 5(a). In figure 4(c), a soft filament (![]() ${L_0}/L = 0.5$,

${L_0}/L = 0.5$, ![]() ${\gamma _{{L_0}}} = 0.01$) displays the STO mode, periodically crossing

${\gamma _{{L_0}}} = 0.01$) displays the STO mode, periodically crossing ![]() $y = 0$ with high oscillation amplitude. The STO mode encompasses both a snapping motion from upside/downside to downside/upside and a streamwise shift between two snapping motions, generated by decreasing

$y = 0$ with high oscillation amplitude. The STO mode encompasses both a snapping motion from upside/downside to downside/upside and a streamwise shift between two snapping motions, generated by decreasing ![]() ${\gamma _{{L_0}}}$ and

${\gamma _{{L_0}}}$ and ![]() ${L_0}/L$. Figure 5(b,c) shows the time histories of

${L_0}/L$. Figure 5(b,c) shows the time histories of ![]() ${x_m}$ and

${x_m}$ and ![]() ${y_m}$ and a sequential process of STO for

${y_m}$ and a sequential process of STO for ![]() ${L_0}/L = 0.5$ and

${L_0}/L = 0.5$ and ![]() ${\gamma _{{L_0}}} = 0.01$ (

${\gamma _{{L_0}}} = 0.01$ (![]() $\delta = 4000\Delta t$). The filament shifts downstream from moment A to moment B, with a decrease of

$\delta = 4000\Delta t$). The filament shifts downstream from moment A to moment B, with a decrease of ![]() ${y_m}$ and an increase of

${y_m}$ and an increase of ![]() ${x_m}$. A local minimum of

${x_m}$. A local minimum of ![]() ${y_m}$ is obtained at B. The front part gradually crosses

${y_m}$ is obtained at B. The front part gradually crosses ![]() $y = 0$, inducing a snapping motion from the upside to the downside from B to C (

$y = 0$, inducing a snapping motion from the upside to the downside from B to C (![]() ${y_m}$ first slowly increases and then rapidly decreases). A local maximum of

${y_m}$ first slowly increases and then rapidly decreases). A local maximum of ![]() ${y_m}$ is obtained between B and C. Accordingly, the streamwise shift produces two peaks of

${y_m}$ is obtained between B and C. Accordingly, the streamwise shift produces two peaks of ![]() ${y_m}$ in a half-period. Beyond C, the filament shifts downstream again. An ‘S’ shape with large deflection is shown in the snapping motion. The oscillation process is not changed irrespective of

${y_m}$ in a half-period. Beyond C, the filament shifts downstream again. An ‘S’ shape with large deflection is shown in the snapping motion. The oscillation process is not changed irrespective of ![]() ${\gamma _{{L_0}}}$,

${\gamma _{{L_0}}}$, ![]() ${L_0}/L$ and

${L_0}/L$ and ![]() $Re$.

$Re$.

Figure 4. Superposition of the instantaneous shapes of the filament in (a) equilibrium mode (![]() ${L_0}/L = 0.8$,

${L_0}/L = 0.8$, ![]() ${\gamma _{{L_0}}} = 0.0058$, 0.008, 0.03), (b) streamwise oscillation mode (

${\gamma _{{L_0}}} = 0.0058$, 0.008, 0.03), (b) streamwise oscillation mode (![]() ${L_0}/L = 0.5$,

${L_0}/L = 0.5$, ![]() ${\gamma _{{L_0}}} = 0.02$) and (c) snap-through oscillation mode (

${\gamma _{{L_0}}} = 0.02$) and (c) snap-through oscillation mode (![]() ${L_0}/L = 0.5$,

${L_0}/L = 0.5$, ![]() ${\gamma _{{L_0}}} = 0.01$).

${\gamma _{{L_0}}} = 0.01$).

Figure 5. Time histories of ![]() ${x_m}$ and

${x_m}$ and ![]() ${y_m}$ in (a) streamwise oscillation mode (

${y_m}$ in (a) streamwise oscillation mode (![]() ${L_0}/L = 0.5$,

${L_0}/L = 0.5$, ![]() ${\gamma _{{L_0}}} = 0.02$) and (b) snap-through oscillation mode (

${\gamma _{{L_0}}} = 0.02$) and (b) snap-through oscillation mode (![]() ${L_0}/L = 0.5$,

${L_0}/L = 0.5$, ![]() ${\gamma _{{L_0}}} = 0.01$). (c) The sequential process of snap-through oscillation (

${\gamma _{{L_0}}} = 0.01$). (c) The sequential process of snap-through oscillation (![]() ${L_0}/L = 0.5$,

${L_0}/L = 0.5$, ![]() ${\gamma _{{L_0}}} = 0.01$).

${\gamma _{{L_0}}} = 0.01$).

We first examine the effects of the bending rigidity (![]() ${\gamma _{{L_0}}}$) and length (

${\gamma _{{L_0}}}$) and length (![]() ${L_0}/L$) on the mode transition. Figure 6 shows a mode diagram in the ranges

${L_0}/L$) on the mode transition. Figure 6 shows a mode diagram in the ranges ![]() $0.002 \le {\gamma _{{L_0}}} \le 0.04$ and

$0.002 \le {\gamma _{{L_0}}} \le 0.04$ and ![]() $0.5 \le {L_0}/L \le 0.8$. Regions I, II and III represent the regimes of the E, SO and STO modes, respectively. The SO mode is observed only in a relatively long filament (

$0.5 \le {L_0}/L \le 0.8$. Regions I, II and III represent the regimes of the E, SO and STO modes, respectively. The SO mode is observed only in a relatively long filament (![]() ${L_0}/L = 0.5$, 0.6). For

${L_0}/L = 0.5$, 0.6). For ![]() ${L_0}/L = 0.5$, the SO mode is distributed in a wide range of

${L_0}/L = 0.5$, the SO mode is distributed in a wide range of ![]() ${\gamma _{{L_0}}}$. The three modes appear in succession with decreasing

${\gamma _{{L_0}}}$. The three modes appear in succession with decreasing ![]() ${\gamma _{{L_0}}}$ for

${\gamma _{{L_0}}}$ for ![]() ${L_0}/L = 0.5$ and 0.6, whereas a direct transition from the E to the STO mode is observed for

${L_0}/L = 0.5$ and 0.6, whereas a direct transition from the E to the STO mode is observed for ![]() ${L_0}/L = 0.7$ and 0.8. The critical

${L_0}/L = 0.7$ and 0.8. The critical ![]() ${\gamma _{{L_0}}}$ for the transition to the SO or STO mode decreases with increasing

${\gamma _{{L_0}}}$ for the transition to the SO or STO mode decreases with increasing ![]() ${L_0}/L$. Cases with and without vortex shedding are highlighted by red and blue in figure 6. Details of the wake pattern are discussed later. Note that vortex shedding is absent only in the E mode for

${L_0}/L$. Cases with and without vortex shedding are highlighted by red and blue in figure 6. Details of the wake pattern are discussed later. Note that vortex shedding is absent only in the E mode for ![]() ${L_0}/L = 0.7$ and 0.8. For these two lengths, vortex shedding occurs in the STO mode, suggesting that vortex shedding is caused by the snapping motion. For

${L_0}/L = 0.7$ and 0.8. For these two lengths, vortex shedding occurs in the STO mode, suggesting that vortex shedding is caused by the snapping motion. For ![]() ${L_0}/L = 0.5$ and 0.6, vortex shedding precedes the onset of the SO mode. A transition from the STO to the E mode arises in a special case at

${L_0}/L = 0.5$ and 0.6, vortex shedding precedes the onset of the SO mode. A transition from the STO to the E mode arises in a special case at ![]() ${\gamma _{{L_0}}} = 0.0002$ for the longest filament (

${\gamma _{{L_0}}} = 0.0002$ for the longest filament (![]() ${L_0}/L = 0.5$). The long filament undergoing a high streamwise fluid force is too soft to complete the snapping motion from B to C (figure 5c). Kim et al. (Reference Kim, Lahooti, Kim and Kim2021a) also found that a long filament does not exhibit the STO mode. Note that the longest filament only exhibits the transition when the bending rigidity is extremely small (

${L_0}/L = 0.5$). The long filament undergoing a high streamwise fluid force is too soft to complete the snapping motion from B to C (figure 5c). Kim et al. (Reference Kim, Lahooti, Kim and Kim2021a) also found that a long filament does not exhibit the STO mode. Note that the longest filament only exhibits the transition when the bending rigidity is extremely small (![]() ${\gamma _{{L_0}}} = 0.0002$). The present STO mode is sustained in a wide range of

${\gamma _{{L_0}}} = 0.0002$). The present STO mode is sustained in a wide range of ![]() ${\gamma _{{L_0}}}$ beyond the critical value.

${\gamma _{{L_0}}}$ beyond the critical value.

Figure 6. Mode diagram depending on ![]() ${\gamma _{{L_0}}}$ and

${\gamma _{{L_0}}}$ and ![]() ${L_0}/L$; regions I, II and III correspond to the equilibrium mode, the streamwise oscillation mode and the snap-through oscillation mode, respectively. Blue and red markers represent the absence and the presence of vortex shedding in the wake, respectively.

${L_0}/L$; regions I, II and III correspond to the equilibrium mode, the streamwise oscillation mode and the snap-through oscillation mode, respectively. Blue and red markers represent the absence and the presence of vortex shedding in the wake, respectively.

The deflections in the E and SO modes (figures 4a,b) can be characterized by the transverse displacement of the intersection between the filament and the line ![]() $x = 0$ (

$x = 0$ (![]() ${y_{x = 0}}$). Note that

${y_{x = 0}}$). Note that ![]() ${y_{x = 0}}$ in the E mode is constant, whereas

${y_{x = 0}}$ in the E mode is constant, whereas ![]() ${y_{x = 0}}$ in the SO mode is obtained from the average. The decrease of

${y_{x = 0}}$ in the SO mode is obtained from the average. The decrease of ![]() ${y_{x = 0}}$ represents the streamwise and downward motions of the front part in figure 4(a). In figure 7(a),

${y_{x = 0}}$ represents the streamwise and downward motions of the front part in figure 4(a). In figure 7(a), ![]() ${y_{x = 0}}$ first slowly and then rapidly decreases with decreasing

${y_{x = 0}}$ first slowly and then rapidly decreases with decreasing ![]() ${\gamma _{{L_0}}}$ for each

${\gamma _{{L_0}}}$ for each ![]() ${L_0}/L$, showing a behaviour similar to that observed by Kim et al. (Reference Kim, Lahooti, Kim and Kim2021a) with increasing flow velocity. A non-dimensionalized bending rigidity

${L_0}/L$, showing a behaviour similar to that observed by Kim et al. (Reference Kim, Lahooti, Kim and Kim2021a) with increasing flow velocity. A non-dimensionalized bending rigidity ![]() ${\gamma _{{L_0}}} = \gamma /({\rho _1}U_0^2L_0^2)$ is defined by the ratio of the bending force to the fluid force. Either a decrease of

${\gamma _{{L_0}}} = \gamma /({\rho _1}U_0^2L_0^2)$ is defined by the ratio of the bending force to the fluid force. Either a decrease of ![]() $\gamma $ or an increase of

$\gamma $ or an increase of ![]() ${U_0}$ gives rise to a decrease of

${U_0}$ gives rise to a decrease of ![]() ${\gamma _{{L_0}}}$. The STO mode appears beyond the end of the curves in figure 7(a). The oscillation amplitude (

${\gamma _{{L_0}}}$. The STO mode appears beyond the end of the curves in figure 7(a). The oscillation amplitude (![]() $A$) defined by the maximum transverse displacement is another length parameter that can be used to identify the oscillation mode. As shown in figure 7(b), A is ignored when

$A$) defined by the maximum transverse displacement is another length parameter that can be used to identify the oscillation mode. As shown in figure 7(b), A is ignored when ![]() $A/{L_0} < 0.01$. In the E mode,

$A/{L_0} < 0.01$. In the E mode, ![]() $A = 0$. In the SO mode, A increases and then decreases with decreasing

$A = 0$. In the SO mode, A increases and then decreases with decreasing ![]() ${\gamma _{{L_0}}}$. A sudden increase in A is observed when the change to the STO mode occurs, at which A is close to

${\gamma _{{L_0}}}$. A sudden increase in A is observed when the change to the STO mode occurs, at which A is close to ![]() $2{w_0}$. Afterward, A slowly decreases with decreasing

$2{w_0}$. Afterward, A slowly decreases with decreasing ![]() ${\gamma _{{L_0}}}$.

${\gamma _{{L_0}}}$.

Figure 7. (a) The transverse displacement of the filament at ![]() $x = 0$ (

$x = 0$ (![]() ${y_{x = 0}}$) as a function of

${y_{x = 0}}$) as a function of ![]() ${\gamma _{{L_0}}}$ in the equilibrium mode and streamwise oscillation mode. (b) Oscillation amplitude (

${\gamma _{{L_0}}}$ in the equilibrium mode and streamwise oscillation mode. (b) Oscillation amplitude (![]() $A$) of the filament as a function of

$A$) of the filament as a function of ![]() ${\gamma _{{L_0}}}$.

${\gamma _{{L_0}}}$.

Figure 8(a) shows the power spectral density (PSD) of ![]() ${y_m}$ and

${y_m}$ and ![]() ${x_m}$ for

${x_m}$ for ![]() ${\gamma _{{L_0}}} = 0.02$ (SO,

${\gamma _{{L_0}}} = 0.02$ (SO, ![]() ${L_0}/L = 0.5$) and 0.01 (STO,

${L_0}/L = 0.5$) and 0.01 (STO, ![]() ${L_0}/L = 0.5$). For

${L_0}/L = 0.5$). For ![]() ${\gamma _{{L_0}}} = 0.02$, a peak is observed at

${\gamma _{{L_0}}} = 0.02$, a peak is observed at ![]() ${f_{{y_m}}} = {f_{{x_m}}} = 0.208$, representing the streamwise oscillation frequency. For

${f_{{y_m}}} = {f_{{x_m}}} = 0.208$, representing the streamwise oscillation frequency. For ![]() ${\gamma _{{L_0}}} = 0.01$, the PSD of

${\gamma _{{L_0}}} = 0.01$, the PSD of ![]() ${y_m}$ shows two peaks at

${y_m}$ shows two peaks at ![]() ${f_{{y_m}}} = 0.067$ and

${f_{{y_m}}} = 0.067$ and ![]() $3{f_{{y_m}}}$. Note that

$3{f_{{y_m}}}$. Note that ![]() ${f_{{y_m}}}$ is the snapping frequency. Recall in figure 5(b) that the streamwise shift produces two peaks of

${f_{{y_m}}}$ is the snapping frequency. Recall in figure 5(b) that the streamwise shift produces two peaks of ![]() ${y_m}$ in a half-period, even though the peaks are very small. The peak at

${y_m}$ in a half-period, even though the peaks are very small. The peak at ![]() $3{f_{{y_m}}}$ is caused by both the streamwise shift and the snapping motion. The PSD of

$3{f_{{y_m}}}$ is caused by both the streamwise shift and the snapping motion. The PSD of ![]() ${x_m}$ shows a peak at

${x_m}$ shows a peak at ![]() ${f_{{x_m}}} = 2{f_{{y_m}}}$ with two harmonic frequencies (

${f_{{x_m}}} = 2{f_{{y_m}}}$ with two harmonic frequencies (![]() $2{f_{{x_m}}}$ and

$2{f_{{x_m}}}$ and ![]() $3{f_{{x_m}}}$). The streamwise shift appears twice in one period of the snap-through oscillation (i.e.

$3{f_{{x_m}}}$). The streamwise shift appears twice in one period of the snap-through oscillation (i.e. ![]() ${f_{{x_m}}}$ is the streamwise shift frequency). The snapping motion produces a local maximum of

${f_{{x_m}}}$ is the streamwise shift frequency). The snapping motion produces a local maximum of ![]() ${x_m}$ in a half-period in figure 5(b) (i.e.

${x_m}$ in a half-period in figure 5(b) (i.e. ![]() $2{f_{{x_m}}}$ is caused by the combination of the streamwise shift and the snapping motion). The value of

$2{f_{{x_m}}}$ is caused by the combination of the streamwise shift and the snapping motion). The value of ![]() ${f_{{y_m}}}$ in the SO mode is much greater than that in the STO mode, which is attributable to the much smaller oscillation amplitude in the SO mode. Accordingly,

${f_{{y_m}}}$ in the SO mode is much greater than that in the STO mode, which is attributable to the much smaller oscillation amplitude in the SO mode. Accordingly, ![]() ${f_{{y_m}}}$ is a suitable parameter for mode identification. Figure 8(b) shows the variations of

${f_{{y_m}}}$ is a suitable parameter for mode identification. Figure 8(b) shows the variations of ![]() ${f_{{y_m}}}$ when

${f_{{y_m}}}$ when ![]() ${\gamma _{{L_0}}}$ is varied for different

${\gamma _{{L_0}}}$ is varied for different ![]() ${L_0}/L$ (the E mode is not included). A sudden decrease is observed when the STO mode appears. In the SO mode,

${L_0}/L$ (the E mode is not included). A sudden decrease is observed when the STO mode appears. In the SO mode, ![]() ${f_{{y_m}}}$ remains almost constant irrespective of

${f_{{y_m}}}$ remains almost constant irrespective of ![]() ${\gamma _{{L_0}}}$. In the STO mode,

${\gamma _{{L_0}}}$. In the STO mode, ![]() ${f_{{y_m}}}$ slowly increases and then decreases with decreasing

${f_{{y_m}}}$ slowly increases and then decreases with decreasing ![]() ${\gamma _{{L_0}}}$.

${\gamma _{{L_0}}}$.

Figure 8. (a) Power spectral density (PSD) of ![]() ${y_m}$ and

${y_m}$ and ![]() ${x_m}$ for

${x_m}$ for ![]() ${L_0}/L = 0.5$,

${L_0}/L = 0.5$, ![]() ${\gamma _{{L_0}}} = 0.02$ (streamwise oscillation mode) and 0.01 (snap-through oscillation mode). (b) Value of

${\gamma _{{L_0}}} = 0.02$ (streamwise oscillation mode) and 0.01 (snap-through oscillation mode). (b) Value of ![]() ${f_{{y_m}}}$ as a function of

${f_{{y_m}}}$ as a function of ![]() ${\gamma _{{L_0}}}$.

${\gamma _{{L_0}}}$.

A new bending rigidity ![]() ${\gamma _L}$ is defined by

${\gamma _L}$ is defined by ![]() $\gamma /{\rho _1}U_0^2{L^2}$ to incorporate the effects of

$\gamma /{\rho _1}U_0^2{L^2}$ to incorporate the effects of ![]() $\gamma $ and L. The filament is easier to deform in the surrounding flow when

$\gamma $ and L. The filament is easier to deform in the surrounding flow when ![]() $\gamma $ decreases and L increases. The value of

$\gamma $ decreases and L increases. The value of ![]() ${\rho _1}U_0^2{L^2}$ is more suitable to represent the fluid force acting on the filament than

${\rho _1}U_0^2{L^2}$ is more suitable to represent the fluid force acting on the filament than ![]() ${\rho _1}U_0^2L_0^2$. For a flexible flag, L is generally selected as a reference length (Yu et al. Reference Yu, Liu and Amandolese2019). Figure 9 shows the variations of

${\rho _1}U_0^2L_0^2$. For a flexible flag, L is generally selected as a reference length (Yu et al. Reference Yu, Liu and Amandolese2019). Figure 9 shows the variations of ![]() ${y_{x = 0}}/{w_0}$,

${y_{x = 0}}/{w_0}$, ![]() $A/(2{w_0})$, and

$A/(2{w_0})$, and ![]() ${f_{{y_m}}}A/{U_0}$ as functions of

${f_{{y_m}}}A/{U_0}$ as functions of ![]() ${\gamma _L}$. The E mode is not included in figure 9(c). The curves collapse onto a single curve as a whole. A critical bending rigidity for the transition to the STO mode is obtained near

${\gamma _L}$. The E mode is not included in figure 9(c). The curves collapse onto a single curve as a whole. A critical bending rigidity for the transition to the STO mode is obtained near ![]() ${\gamma _{{L_c}}} = 0.0037$ irrespective of L. The initial height

${\gamma _{{L_c}}} = 0.0037$ irrespective of L. The initial height ![]() ${w_0}$ is close to one-half of the maximum A in the STO mode, which is

${w_0}$ is close to one-half of the maximum A in the STO mode, which is ![]() ${y_{x = 0}}$ in the initial shape. In figure 9(a), most of the curves

${y_{x = 0}}$ in the initial shape. In figure 9(a), most of the curves ![]() ${y_{x = 0}}/{w_0}$ end at the vertical fold points; that is, the instability follows a saddle-node bifurcation (Gomez, Moulton & Vella Reference Gomez, Moulton and Vella2017b; Kim et al. Reference Kim, Lahooti, Kim and Kim2021a). Here,

${y_{x = 0}}/{w_0}$ end at the vertical fold points; that is, the instability follows a saddle-node bifurcation (Gomez, Moulton & Vella Reference Gomez, Moulton and Vella2017b; Kim et al. Reference Kim, Lahooti, Kim and Kim2021a). Here, ![]() ${L_0}/L = 0.5$ deviates substantially from the collapsed curve. This result is attributed to the large deformation of a long filament near the critical point, where the deformation is not linearly proportional to

${L_0}/L = 0.5$ deviates substantially from the collapsed curve. This result is attributed to the large deformation of a long filament near the critical point, where the deformation is not linearly proportional to ![]() ${w_0}$. Such a deviation is also observed in figure 9(b) for the STO mode. In figure 9(c),

${w_0}$. Such a deviation is also observed in figure 9(b) for the STO mode. In figure 9(c), ![]() ${L_0}/L = 0.8$ in the STO mode deviates from the collapsed curve. We found the snap-through oscillation near the critical point is relatively unstable in the shortest filament (

${L_0}/L = 0.8$ in the STO mode deviates from the collapsed curve. We found the snap-through oscillation near the critical point is relatively unstable in the shortest filament (![]() ${L_0}/L = 0.8$). This instability disappears with decreasing

${L_0}/L = 0.8$). This instability disappears with decreasing ![]() ${\gamma _L}$, accompanied by a small deviation from the collapse.

${\gamma _L}$, accompanied by a small deviation from the collapse.

Figure 9. (a) Value of ![]() ${y_{x = 0}}/{w_0}$ as a function of

${y_{x = 0}}/{w_0}$ as a function of ![]() ${\gamma _L}$ (bending rigidity non-dimensionalized by

${\gamma _L}$ (bending rigidity non-dimensionalized by ![]() $0.5{\rho _1}U_0^2{L^2}$) in the equilibrium state and streamwise oscillation mode. (b) Value of

$0.5{\rho _1}U_0^2{L^2}$) in the equilibrium state and streamwise oscillation mode. (b) Value of ![]() $A/(2{w_0})$ as a function of

$A/(2{w_0})$ as a function of ![]() ${\gamma _L}$. (c) Value of

${\gamma _L}$. (c) Value of ![]() ${f_{{y_m}}}A/{U_0}$ as a function of

${f_{{y_m}}}A/{U_0}$ as a function of ![]() ${\gamma _L}$.

${\gamma _L}$.

We here further examine the wake pattern and pressure to characterize the instability mechanism. Figure 10 shows the instantaneous contours of vorticity (![]() ${\omega _z}$) and pressure (

${\omega _z}$) and pressure (![]() $p$) for

$p$) for ![]() ${L_0}/L = 0.8$ and

${L_0}/L = 0.8$ and ![]() ${\gamma _{{L_0}}} = 0.03$;

${\gamma _{{L_0}}} = 0.03$; ![]() ${L_0}/L = 0.8$ and

${L_0}/L = 0.8$ and ![]() ${\gamma _{{L_0}}} = 0.0058$; and

${\gamma _{{L_0}}} = 0.0058$; and ![]() ${L_0}/L = 0.6$ and

${L_0}/L = 0.6$ and ![]() ${\gamma _{{L_0}}} = 0.03$ in the E mode. For the short filament (

${\gamma _{{L_0}}} = 0.03$ in the E mode. For the short filament (![]() ${L_0}/L = 0.8$,

${L_0}/L = 0.8$, ![]() ${\gamma _{{L_0}}} = 0.03$ and 0.0058), no vortex shedding appears. The positive/negative pressure at the front/back of the filament are caused by the squeezing/flow separation, respectively. For

${\gamma _{{L_0}}} = 0.03$ and 0.0058), no vortex shedding appears. The positive/negative pressure at the front/back of the filament are caused by the squeezing/flow separation, respectively. For ![]() ${L_0}/L = 0.8$ and

${L_0}/L = 0.8$ and ![]() ${\gamma _{{L_0}}} = 0.03$, the averaged streamwise (

${\gamma _{{L_0}}} = 0.03$, the averaged streamwise (![]() ${\bar{F}_{ftx}} = 0.302$) and transverse (

${\bar{F}_{ftx}} = 0.302$) and transverse (![]() ${\bar{F}_{fty}} ={-} 0.182$) fluid forces induce the streamwise and downward motions, respectively. The averaged fluid force

${\bar{F}_{fty}} ={-} 0.182$) fluid forces induce the streamwise and downward motions, respectively. The averaged fluid force ![]() ${\bar{\boldsymbol{F}}_{ft}}$ is balanced by the averaged elastic force

${\bar{\boldsymbol{F}}_{ft}}$ is balanced by the averaged elastic force ![]() ${\bar{\boldsymbol{F}}_{st}}$ (

${\bar{\boldsymbol{F}}_{st}}$ (![]() ${\boldsymbol{F}_{ft}} = \sum\nolimits_{s = 0}^L {\boldsymbol{F}(s)}$ and

${\boldsymbol{F}_{ft}} = \sum\nolimits_{s = 0}^L {\boldsymbol{F}(s)}$ and ![]() ${\boldsymbol{F}_{st}} = \sum\nolimits_{s = 0}^L {{\boldsymbol{F}_s}(s)} $ are the instantaneous fluid force (Lagrangian forcing) and elastic force, respectively). For

${\boldsymbol{F}_{st}} = \sum\nolimits_{s = 0}^L {{\boldsymbol{F}_s}(s)} $ are the instantaneous fluid force (Lagrangian forcing) and elastic force, respectively). For ![]() ${L_0}/L = 0.8$ and

${L_0}/L = 0.8$ and ![]() ${\gamma _{{L_0}}} = 0.0058$, the larger deflection is observed because of the lower

${\gamma _{{L_0}}} = 0.0058$, the larger deflection is observed because of the lower ![]() ${\gamma _{{L_0}}}$, resulting in a lower

${\gamma _{{L_0}}}$, resulting in a lower ![]() ${\bar{F}_{fx}}$ and higher

${\bar{F}_{fx}}$ and higher ![]() $|{{{\bar{F}}_{fy}}} |$. The filament reaches a new equilibrium. Both

$|{{{\bar{F}}_{fy}}} |$. The filament reaches a new equilibrium. Both ![]() $|{{{\bar{F}}_{fy}}} |$ and

$|{{{\bar{F}}_{fy}}} |$ and ![]() ${\bar{F}_{sy}}$ increase with decreasing

${\bar{F}_{sy}}$ increase with decreasing ![]() ${\gamma _{{L_0}}}$ (table 2), showing a maximum at

${\gamma _{{L_0}}}$ (table 2), showing a maximum at ![]() ${\gamma _{{L_0}}} = 0.0058$. A further decrease of

${\gamma _{{L_0}}} = 0.0058$. A further decrease of ![]() ${\gamma _{{L_0}}}$ leads to a snapping motion due to the great deflection of the front part; no higher

${\gamma _{{L_0}}}$ leads to a snapping motion due to the great deflection of the front part; no higher ![]() ${\bar{F}_{sy}}$ is available to balance

${\bar{F}_{sy}}$ is available to balance ![]() ${\bar{F}_{fy}}$. For

${\bar{F}_{fy}}$. For ![]() ${L_0}/L = 0.6$ and

${L_0}/L = 0.6$ and ![]() ${\gamma _{{L_0}}} = 0.03$, a Kármán vortex configuration appears, producing an enhanced negative pressure behind the filament. The unsteady fluid force acting on the filament is also enhanced, whereas the stiff filament suppresses the oscillation. For the flow behind a bluff body, vortex shedding appears when the Reynolds number exceeds a critical value (Berger & Wille Reference Berger and Wille1972; Monkewitz, Williamson & Miller Reference Monkewitz, Williamson and Miller1996). The present filament also shows the vortex shedding because of its ‘bluff’ shape. A new Reynolds number can be defined as

${\gamma _{{L_0}}} = 0.03$, a Kármán vortex configuration appears, producing an enhanced negative pressure behind the filament. The unsteady fluid force acting on the filament is also enhanced, whereas the stiff filament suppresses the oscillation. For the flow behind a bluff body, vortex shedding appears when the Reynolds number exceeds a critical value (Berger & Wille Reference Berger and Wille1972; Monkewitz, Williamson & Miller Reference Monkewitz, Williamson and Miller1996). The present filament also shows the vortex shedding because of its ‘bluff’ shape. A new Reynolds number can be defined as ![]() $R{e_{{w_0}}} = {\rho _0}{U_0}{w_0}/\mu $ based on the filament's initial height (

$R{e_{{w_0}}} = {\rho _0}{U_0}{w_0}/\mu $ based on the filament's initial height (![]() ${w_0}$). The values of

${w_0}$). The values of ![]() $R{e_{{w_0}}}$ for

$R{e_{{w_0}}}$ for ![]() ${L_0}/L = 0.5$, 0.6, 0.7 and 0.8 are 72, 57, 44 and 33, respectively. A critical

${L_0}/L = 0.5$, 0.6, 0.7 and 0.8 are 72, 57, 44 and 33, respectively. A critical ![]() $R{e_{{w_0}}}$ for the appearance of vortex shedding before the onset of the STO mode lies between 57 and 44. The value of

$R{e_{{w_0}}}$ for the appearance of vortex shedding before the onset of the STO mode lies between 57 and 44. The value of ![]() $R{e_{{w_0}c}}$ is obtained in the next section.

$R{e_{{w_0}c}}$ is obtained in the next section.

Figure 10. Instantaneous contours of (a) vorticity (![]() ${\omega _z}$) and (b) pressure (

${\omega _z}$) and (b) pressure (![]() $p$) for

$p$) for ![]() ${L_0}/L = 0.8$ and

${L_0}/L = 0.8$ and ![]() ${\gamma _{{L_0}}} = 0.03$;

${\gamma _{{L_0}}} = 0.03$; ![]() ${L_0}/L = 0.8$ and

${L_0}/L = 0.8$ and ![]() ${\gamma _{{L_0}}} = 0.0058$; and

${\gamma _{{L_0}}} = 0.0058$; and ![]() ${L_0}/L = 0.6$ and

${L_0}/L = 0.6$ and ![]() ${\gamma _{{L_0}}} = 0.03$ in the equilibrium mode.

${\gamma _{{L_0}}} = 0.03$ in the equilibrium mode.

Table 2. Fluid force ![]() ${\bar{\boldsymbol{F}}_{ft}}$ and elastic force

${\bar{\boldsymbol{F}}_{ft}}$ and elastic force ![]() ${\bar{\boldsymbol{F}}_{st}}$ of the filament for different

${\bar{\boldsymbol{F}}_{st}}$ of the filament for different ![]() ${\gamma _{{L_0}}}$ (

${\gamma _{{L_0}}}$ (![]() ${L_0}/L = 0.8$).

${L_0}/L = 0.8$).

A relatively long filament with moderate ![]() ${\gamma _{{L_0}}}$ displays a streamwise oscillation because of the vortex shedding. Figure 11 shows the time histories of

${\gamma _{{L_0}}}$ displays a streamwise oscillation because of the vortex shedding. Figure 11 shows the time histories of ![]() ${x_m}$, streamwise fluid force

${x_m}$, streamwise fluid force ![]() ${F_{ftx}}$, streamwise elastic force

${F_{ftx}}$, streamwise elastic force ![]() ${F_{stx}}$, total streamwise force

${F_{stx}}$, total streamwise force ![]() ${F_{tx}}$ (

${F_{tx}}$ (![]() ${F_{ftx}} + {F_{stx}}$) and instantaneous contours of

${F_{ftx}} + {F_{stx}}$) and instantaneous contours of ![]() ${\omega _z}$ and p in the SO mode for

${\omega _z}$ and p in the SO mode for ![]() ${L_0}/L = 0.5$,

${L_0}/L = 0.5$, ![]() ${\gamma _{{L_0}}} = 0.02$. The SO mode is dominated by the combined

${\gamma _{{L_0}}} = 0.02$. The SO mode is dominated by the combined ![]() ${F_{ftx}}$ and

${F_{ftx}}$ and ![]() ${F_{stx}}$. At moment A,

${F_{stx}}$. At moment A, ![]() ${F_{stx}}$ dominates

${F_{stx}}$ dominates ![]() ${F_{ftx}}$ (

${F_{ftx}}$ (![]() ${F_{tx}} < 0$) because of the large deflection of the rear part, yielding an upstream motion;

${F_{tx}} < 0$) because of the large deflection of the rear part, yielding an upstream motion; ![]() ${F_{stx}}$ decreases during the upstream motion, whereas the formation of a negative vortex leads to an increase in

${F_{stx}}$ decreases during the upstream motion, whereas the formation of a negative vortex leads to an increase in ![]() ${F_{ftx}}$, resulting in an increase in

${F_{ftx}}$, resulting in an increase in ![]() ${F_{tx}}$. The filament undergoes acceleration and deceleration before reaching its upstream stroke extreme at B. Beyond B, the filament moves downstream because of the positive

${F_{tx}}$. The filament undergoes acceleration and deceleration before reaching its upstream stroke extreme at B. Beyond B, the filament moves downstream because of the positive ![]() ${F_{tx}}$. Recall that vortex shedding precedes the onset of the SO mode. The SO frequency (

${F_{tx}}$. Recall that vortex shedding precedes the onset of the SO mode. The SO frequency ( ![]() ${f_{{x_m}}}$ or

${f_{{x_m}}}$ or ![]() ${f_{{y_m}}}$) is the same as the vortex shedding frequency

${f_{{y_m}}}$) is the same as the vortex shedding frequency ![]() ${f_v}$ calculated from the transverse velocity v at (x, y) = (5, 0). The SO mode therefore represents a vortex-induced vibration.

${f_v}$ calculated from the transverse velocity v at (x, y) = (5, 0). The SO mode therefore represents a vortex-induced vibration.

Figure 11. (a) Time histories of ![]() ${x_m}$, streamwise fluid force

${x_m}$, streamwise fluid force ![]() ${F_{ftx}}$, streamwise elastic force

${F_{ftx}}$, streamwise elastic force ![]() ${F_{stx}}$ and total streamwise force

${F_{stx}}$ and total streamwise force ![]() ${F_{tx}}$ (

${F_{tx}}$ (![]() ${F_{ftx}} + {F_{stx}}$). Instantaneous contours of (b)

${F_{ftx}} + {F_{stx}}$). Instantaneous contours of (b) ![]() ${\omega _z}$ and (c) p at A and B for

${\omega _z}$ and (c) p at A and B for ![]() ${L_0}/L = 0.5$ and

${L_0}/L = 0.5$ and ![]() ${\gamma _{{L_0}}} = 0.02$ in the streamwise oscillation mode.

${\gamma _{{L_0}}} = 0.02$ in the streamwise oscillation mode.

A further decrease in ![]() ${\gamma _{{L_0}}}$ causes a greater deflection of the front part, inducing the STO mode. Figure 12 shows the instantaneous contours of

${\gamma _{{L_0}}}$ causes a greater deflection of the front part, inducing the STO mode. Figure 12 shows the instantaneous contours of ![]() ${\omega _z}$ and the PSD of v for

${\omega _z}$ and the PSD of v for ![]() ${L_0}/L = 0.7$ and

${L_0}/L = 0.7$ and ![]() ${\gamma _{{L_0}}} = 0.004$;

${\gamma _{{L_0}}} = 0.004$; ![]() ${L_0}/L = 0.6$ and

${L_0}/L = 0.6$ and ![]() ${\gamma _{{L_0}}} = 0.01$; and

${\gamma _{{L_0}}} = 0.01$; and ![]() ${L_0}/L = 0.5$ and

${L_0}/L = 0.5$ and ![]() ${\gamma _{{L_0}}} = 0.01$. For

${\gamma _{{L_0}}} = 0.01$. For ![]() ${L_0}/L = 0.7$ and

${L_0}/L = 0.7$ and ![]() ${\gamma _{{L_0}}} = 0.004$ in figure 12(a), a single vortex induced by the snapping motion (

${\gamma _{{L_0}}} = 0.004$ in figure 12(a), a single vortex induced by the snapping motion (![]() ${V_{snap}}$) and the consequent pair of vortices (

${V_{snap}}$) and the consequent pair of vortices (![]() ${V_P}$) appear in a half-period of the oscillation. This pattern is termed the ‘2S + 2P’ mode in the present study. The

${V_P}$) appear in a half-period of the oscillation. This pattern is termed the ‘2S + 2P’ mode in the present study. The ![]() ${V_P}$ are caused by the interaction between two shear layers, where the interaction is induced by

${V_P}$ are caused by the interaction between two shear layers, where the interaction is induced by ![]() ${V_{snap}}$. A similar wake pattern is observed in three cases even though

${V_{snap}}$. A similar wake pattern is observed in three cases even though ![]() ${V_{snap}}$ is divided into two parts with increasing

${V_{snap}}$ is divided into two parts with increasing ![]() ${L_0}/L$, which might be caused by the increase of

${L_0}/L$, which might be caused by the increase of ![]() $R{e_{{w_0}}}$. In figure 12(b), the vortex shedding frequency (

$R{e_{{w_0}}}$. In figure 12(b), the vortex shedding frequency ( ![]() ${f_v}$) for the 2S + 2P mode locks in with the STO frequency (

${f_v}$) for the 2S + 2P mode locks in with the STO frequency ( ![]() ${f_{{y_m}}}$). The harmonic frequency (

${f_{{y_m}}}$). The harmonic frequency (![]() $3{f_v}$) is formed by six vortices shed in one oscillation period, which is equal to the STO harmonic frequency (

$3{f_v}$) is formed by six vortices shed in one oscillation period, which is equal to the STO harmonic frequency (![]() $3{f_{{y_m}}}$) in figure 8(a). The values of

$3{f_{{y_m}}}$) in figure 8(a). The values of ![]() ${f_v}$ and

${f_v}$ and ![]() ${f_{{y_m}}}$ decrease with increasing

${f_{{y_m}}}$ decrease with increasing ![]() ${L_0}/L$ because of the higher oscillation amplitude.

${L_0}/L$ because of the higher oscillation amplitude.

Figure 12. (a) Instantaneous contours of ![]() ${\omega _z}$ when

${\omega _z}$ when ![]() ${y_m} = 0$. (b) The PSD of v (

${y_m} = 0$. (b) The PSD of v (![]() $x = 5$,

$x = 5$, ![]() $y = 0$) for

$y = 0$) for ![]() ${L_0}/L = 0.7$ and

${L_0}/L = 0.7$ and ![]() ${\gamma _{{L_0}}} = 0.004$;

${\gamma _{{L_0}}} = 0.004$; ![]() ${L_0}/L = 0.6$ and

${L_0}/L = 0.6$ and ![]() ${\gamma _{{L_0}}} = 0.01$ and

${\gamma _{{L_0}}} = 0.01$ and ![]() ${L_0}/L = 0.5$ and

${L_0}/L = 0.5$ and ![]() ${\gamma _{{L_0}}} = 0.01$ in the STO mode.

${\gamma _{{L_0}}} = 0.01$ in the STO mode.

To explore the snap-through dynamics and vortex dynamics in the STO mode, we further examine the time histories of ![]() ${x_m}$,

${x_m}$, ![]() ${y_m}$,

${y_m}$, ![]() $\boldsymbol{F}$ and

$\boldsymbol{F}$ and ![]() ${E_s}$ in concert with the contours of

${E_s}$ in concert with the contours of ![]() ${\omega _z}$ and p for

${\omega _z}$ and p for ![]() ${L_0}/L = 0.6$ and

${L_0}/L = 0.6$ and ![]() ${\gamma _{{L_0}}} = 0.01$. In figure 13(a), local maxima and minima of

${\gamma _{{L_0}}} = 0.01$. In figure 13(a), local maxima and minima of ![]() ${x_m}$ are obtained at moments A and D and at moments B and C, respectively. At moment A, the filament is close to its initial shape after completing a snapping motion, showing a local minimum of

${x_m}$ are obtained at moments A and D and at moments B and C, respectively. At moment A, the filament is close to its initial shape after completing a snapping motion, showing a local minimum of ![]() ${E_s}$ (

${E_s}$ (![]() ${E_{s\ min}}$). The

${E_{s\ min}}$). The ![]() ${E_{s\ min}}$ value is substantially greater than that of an inverted flag. A negative

${E_{s\ min}}$ value is substantially greater than that of an inverted flag. A negative ![]() ${V_{snap}}$ shed from the filament leads to an increase in pressure near the rear part, resulting in a local minimum of

${V_{snap}}$ shed from the filament leads to an increase in pressure near the rear part, resulting in a local minimum of ![]() ${F_{ftx}}$. Notably,

${F_{ftx}}$. Notably, ![]() ${F_{ftx}}$ is always greater than zero. The front part is deflected from its initial shape, yielding a positive

${F_{ftx}}$ is always greater than zero. The front part is deflected from its initial shape, yielding a positive ![]() ${F_{stx}}$. Both

${F_{stx}}$. Both ![]() ${F_{ftx}}$ and

${F_{ftx}}$ and ![]() ${F_{stx}}$ drive a streamwise shift from A to B. Here,

${F_{stx}}$ drive a streamwise shift from A to B. Here, ![]() ${E_s}$ increases because of the deflection of the rear part. At moment B,

${E_s}$ increases because of the deflection of the rear part. At moment B, ![]() ${E_s}$ and negative

${E_s}$ and negative ![]() ${F_{stx}}$ reach their local maximum and minimum, respectively. A positive vortex is formed behind the filament, leading to a local maximum of

${F_{stx}}$ reach their local maximum and minimum, respectively. A positive vortex is formed behind the filament, leading to a local maximum of ![]() ${F_{ftx}}$ at

${F_{ftx}}$ at ![]() $B$;

$B$; ![]() ${F_{stx}}$ dominates

${F_{stx}}$ dominates ![]() ${F_{ftx}}$, resulting in an upstream motion and an increase of the positive pressure at the front of the filament. This increased pressure leads to a downward motion of the front part, inducing a snapping motion from the upside to the downside. At moment C, the ‘S’ shape is observed, having a local maximum of

${F_{ftx}}$, resulting in an upstream motion and an increase of the positive pressure at the front of the filament. This increased pressure leads to a downward motion of the front part, inducing a snapping motion from the upside to the downside. At moment C, the ‘S’ shape is observed, having a local maximum of ![]() ${E_s}$. A positive

${E_s}$. A positive ![]() ${V_{snap}}$ is formed at the downside of the filament, following the

${V_{snap}}$ is formed at the downside of the filament, following the ![]() ${V_P}$ shed from the filament. The positive

${V_P}$ shed from the filament. The positive ![]() ${V_{snap}}$ with a negative

${V_{snap}}$ with a negative ![]() ${F_{fty}}$ is beneficial to the snapping motion. At moment D, the snapping motion is completed, resulting in a shape symmetric to that at A. The streamwise shift and ‘S’ shape play important roles in increasing the strain energy. Note that if the filament snaps and experiences a large deflection, it can lead to a shortened lifespan of the device.

${F_{fty}}$ is beneficial to the snapping motion. At moment D, the snapping motion is completed, resulting in a shape symmetric to that at A. The streamwise shift and ‘S’ shape play important roles in increasing the strain energy. Note that if the filament snaps and experiences a large deflection, it can lead to a shortened lifespan of the device.

Figure 13. (a) Time histories of ![]() ${x_m}$,

${x_m}$, ![]() ${y_m}$,

${y_m}$, ![]() $F$ and

$F$ and ![]() ${E_s}$. Instantaneous contours of (b)

${E_s}$. Instantaneous contours of (b) ![]() ${\omega _z}$ and (c) p at A, B,

${\omega _z}$ and (c) p at A, B, ![]() $C$ and D for

$C$ and D for ![]() ${L_0}/L = 0.6$ and

${L_0}/L = 0.6$ and ![]() ${\gamma _{{L_0}}} = 0.01$ in the STO mode.

${\gamma _{{L_0}}} = 0.01$ in the STO mode.

Recall that no vortex shedding appears before the onset of the STO mode for ![]() ${L_0}/L = 0.7$ and 0.8. A one-off snap through can be realized at

${L_0}/L = 0.7$ and 0.8. A one-off snap through can be realized at ![]() $Re = O({10^{ - 2}})$ in a small flow channel without vortex shedding (Gomez et al. Reference Gomez, Moulton and Vella2017b). Thus, the initial snapping motion is obtained without unsteady fluid force;

$Re = O({10^{ - 2}})$ in a small flow channel without vortex shedding (Gomez et al. Reference Gomez, Moulton and Vella2017b). Thus, the initial snapping motion is obtained without unsteady fluid force; ![]() ${\boldsymbol{F}_{st}}$ cannot balance

${\boldsymbol{F}_{st}}$ cannot balance ![]() ${\boldsymbol{F}_{ft}}$ under the critical conditions, yielding a snapping motion. The STO is a self-excited vibration caused by a fluid-elastic instability. The snapping motion supports the formation of

${\boldsymbol{F}_{ft}}$ under the critical conditions, yielding a snapping motion. The STO is a self-excited vibration caused by a fluid-elastic instability. The snapping motion supports the formation of ![]() ${V_{snap}}$ by the interaction with shear layers, thereby inducing the formation of

${V_{snap}}$ by the interaction with shear layers, thereby inducing the formation of ![]() ${V_P}$ in figures 12 and 13. On the other hand,

${V_P}$ in figures 12 and 13. On the other hand, ![]() ${f_v}$ (

${f_v}$ ( ![]() ${f_{{y_m}}}$) in the STO mode obviously differs from that in the SO mode for

${f_{{y_m}}}$) in the STO mode obviously differs from that in the SO mode for ![]() ${L_0}/L = 0.5$ and 0.6. This difference suggests that vortex shedding is caused by the STO, not vice versa. The unsteady fluid force caused by vortex shedding supports the snapping motion, but it is not an excitation source of the STO mode.

${L_0}/L = 0.5$ and 0.6. This difference suggests that vortex shedding is caused by the STO, not vice versa. The unsteady fluid force caused by vortex shedding supports the snapping motion, but it is not an excitation source of the STO mode.

3.2. The Reynolds number effect and hysteresis characteristics

We here further examine the effect of ![]() $Re$ on the mode transition. In this section, the length is fixed at

$Re$ on the mode transition. In this section, the length is fixed at ![]() ${L_0}/L = 0.6$. Figure 14 shows a mode diagram in the range

${L_0}/L = 0.6$. Figure 14 shows a mode diagram in the range ![]() $20 \le Re \le 220$ and

$20 \le Re \le 220$ and ![]() $0.009 \le {\gamma _{{L_0}}} \le 0.012$. A transition to the STO mode is observed with increasing

$0.009 \le {\gamma _{{L_0}}} \le 0.012$. A transition to the STO mode is observed with increasing ![]() $Re$ for each

$Re$ for each ![]() ${\gamma _{{L_0}}}$ because of the increase in the fluid force. The SO mode is observed only in a relatively stiff filament (

${\gamma _{{L_0}}}$ because of the increase in the fluid force. The SO mode is observed only in a relatively stiff filament (![]() ${\gamma _{{L_0}}} = 0.011$ and 0.012). A critical

${\gamma _{{L_0}}} = 0.011$ and 0.012). A critical ![]() $Re$ is obtained at

$Re$ is obtained at ![]() $R{e_c} = 85$ for the transition from the E mode to the SO mode, thereby

$R{e_c} = 85$ for the transition from the E mode to the SO mode, thereby ![]() $R{e_{{w_0}c}} = 49$. This result is consistent with the finding in figure 10; the appearance of vortex shedding in the E and SO modes is caused by the increase of

$R{e_{{w_0}c}} = 49$. This result is consistent with the finding in figure 10; the appearance of vortex shedding in the E and SO modes is caused by the increase of ![]() $R{e_{{w_0}}}$. Note that

$R{e_{{w_0}}}$. Note that ![]() $R{e_{{w_0}}}$ for

$R{e_{{w_0}}}$ for ![]() ${L_0}/L = 0.5$, 0.6, 0.7 and 0.8 is 72, 57, 44 and 33, respectively. With increasing

${L_0}/L = 0.5$, 0.6, 0.7 and 0.8 is 72, 57, 44 and 33, respectively. With increasing ![]() ${\gamma _{{L_0}}}$, the SO mode is distributed in a wide range of

${\gamma _{{L_0}}}$, the SO mode is distributed in a wide range of ![]() $Re$. The critical

$Re$. The critical ![]() $Re$ for the transition to the STO mode increases with increasing

$Re$ for the transition to the STO mode increases with increasing ![]() ${\gamma _{{L_0}}}$; a stiffer filament suppresses the snapping motion. Both the increase of

${\gamma _{{L_0}}}$; a stiffer filament suppresses the snapping motion. Both the increase of ![]() $Re$ (or

$Re$ (or ![]() $R{e_{{w_0}}}$) and the decrease of

$R{e_{{w_0}}}$) and the decrease of ![]() ${\gamma _{{L_0}}}$ (or

${\gamma _{{L_0}}}$ (or ![]() ${\gamma _L}$) enhance the fluid force, inducing instability of the filament. A similar wake pattern (2S + 2P) is observed in the STO mode for different

${\gamma _L}$) enhance the fluid force, inducing instability of the filament. A similar wake pattern (2S + 2P) is observed in the STO mode for different ![]() $R{e_{{w_0}}}$. Here,

$R{e_{{w_0}}}$. Here, ![]() ${V_{snap}}$ is divided into two parts with increasing

${V_{snap}}$ is divided into two parts with increasing ![]() $R{e_{{w_0}}}$, consistent with the finding in figure 12. The increase of

$R{e_{{w_0}}}$, consistent with the finding in figure 12. The increase of ![]() $R{e_{{w_0}}}$ leads to stronger vortices; increasing viscosity disfavours vortex formation because of the thick boundary layer along the filament at low Reynolds numbers (Mackowski & Williamson Reference Mackowski and Williamson2015). The division of

$R{e_{{w_0}}}$ leads to stronger vortices; increasing viscosity disfavours vortex formation because of the thick boundary layer along the filament at low Reynolds numbers (Mackowski & Williamson Reference Mackowski and Williamson2015). The division of ![]() ${V_{snap}}$ results from its interaction with strong

${V_{snap}}$ results from its interaction with strong ![]() ${V_P}$.

${V_P}$.

Figure 14. Mode diagram depending on ![]() ${\gamma _{{L_0}}}$ and

${\gamma _{{L_0}}}$ and ![]() $Re$; regions I, II and III correspond to the E mode, the SO mode and the STO mode, respectively. The blue and red markers represent the absence and presence of vortex shedding in the wake, respectively (

$Re$; regions I, II and III correspond to the E mode, the SO mode and the STO mode, respectively. The blue and red markers represent the absence and presence of vortex shedding in the wake, respectively (![]() ${L_0}/L = 0.6$).

${L_0}/L = 0.6$).

Figure 15 shows the variations of ![]() $A/(2{w_0})$ and

$A/(2{w_0})$ and ![]() ${f_{{y_\textrm{m}}}}A/{U_0}$ with increasing

${f_{{y_\textrm{m}}}}A/{U_0}$ with increasing ![]() $Re$, where the tendency is similar to that observed for decreasing

$Re$, where the tendency is similar to that observed for decreasing ![]() ${\gamma _L}$ in figure 9. The E mode is not included in figure 15(b). In the E and SO modes,

${\gamma _L}$ in figure 9. The E mode is not included in figure 15(b). In the E and SO modes, ![]() $A/(2{w_0})$ and

$A/(2{w_0})$ and ![]() ${f_{{y_m}}}A/{U_0}$ are almost zero. In figure 15(a),

${f_{{y_m}}}A/{U_0}$ are almost zero. In figure 15(a), ![]() $A/2{w_0}$ is close to one in the STO mode; the oscillation amplitude is insensitive to

$A/2{w_0}$ is close to one in the STO mode; the oscillation amplitude is insensitive to ![]() $Re$ in the range of parameters studied. In figure 15(b), the points within the STO mode converge to a straight line. The STO frequency increases with increasing

$Re$ in the range of parameters studied. In figure 15(b), the points within the STO mode converge to a straight line. The STO frequency increases with increasing ![]() $Re$.

$Re$.

Figure 15. (a) Values of ![]() $A/(2{w_0})$ and (b)

$A/(2{w_0})$ and (b) ![]() ${f_{{y_\textrm{m}}}}A/{U_0}$ as functions of

${f_{{y_\textrm{m}}}}A/{U_0}$ as functions of ![]() $Re$ (

$Re$ (![]() ${L_0}/L = 0.6$).

${L_0}/L = 0.6$).

A hysteresis is observed when ![]() $Re$ and

$Re$ and ![]() ${\gamma _{{L_0}}}$ are varied near the critical

${\gamma _{{L_0}}}$ are varied near the critical ![]() $Re$. Figure 16(a) shows the variation of

$Re$. Figure 16(a) shows the variation of ![]() $A/(2{w_0})$ as a function of

$A/(2{w_0})$ as a function of ![]() $Re$ for

$Re$ for ![]() ${\gamma _{{L_0}}} = 0.009$. Simulations with increasing and decreasing

${\gamma _{{L_0}}} = 0.009$. Simulations with increasing and decreasing ![]() $Re$ lead to different responses. For increasing

$Re$ lead to different responses. For increasing ![]() $Re$, simulations are first carried out for

$Re$, simulations are first carried out for ![]() $Re = 45$. The fully developed flow for

$Re = 45$. The fully developed flow for ![]() $Re = 45$ is used as an initial condition for the case with an incremented

$Re = 45$ is used as an initial condition for the case with an incremented ![]() $Re$. The fully developed solution for this

$Re$. The fully developed solution for this ![]() $Re$ is used as an initial condition for the next case with an incremented

$Re$ is used as an initial condition for the next case with an incremented ![]() $Re$ and so on. Similarly, for decreasing

$Re$ and so on. Similarly, for decreasing ![]() $Re$, the simulations begin with the fully developed solution for

$Re$, the simulations begin with the fully developed solution for ![]() $Re = 65$ as an initial condition for the case with a decremented

$Re = 65$ as an initial condition for the case with a decremented ![]() $Re$ (Sahu, Furquan & Mittal Reference Sahu, Furquan and Mittal2019). For increasing

$Re$ (Sahu, Furquan & Mittal Reference Sahu, Furquan and Mittal2019). For increasing ![]() $Re$, the critical

$Re$, the critical ![]() $Re$ for the transition to the STO mode is

$Re$ for the transition to the STO mode is ![]() $R{e_{c2}}$. For decreasing

$R{e_{c2}}$. For decreasing ![]() $Re$, the critical

$Re$, the critical ![]() $Re$ for the transition to the E/SO mode (

$Re$ for the transition to the E/SO mode (![]() $R{e_{c1}}$) is smaller than

$R{e_{c1}}$) is smaller than ![]() $R{e_{c2}}$. This result might be attributable to the unsteady fluid force in the STO mode, which maintains a periodic oscillation at lower

$R{e_{c2}}$. This result might be attributable to the unsteady fluid force in the STO mode, which maintains a periodic oscillation at lower ![]() $Re$. A hysteresis loop defined by

$Re$. A hysteresis loop defined by ![]() $\Delta R{e_c}/R{e_{c2}} = (R{e_{c2}} - R{e_{c1}})/R{e_{c2}}$ can be used to quantify the importance of hysteresis (Eloy, Kofman & Schouveiler Reference Eloy, Kofman and Schouveiler2012). The variation of

$\Delta R{e_c}/R{e_{c2}} = (R{e_{c2}} - R{e_{c1}})/R{e_{c2}}$ can be used to quantify the importance of hysteresis (Eloy, Kofman & Schouveiler Reference Eloy, Kofman and Schouveiler2012). The variation of ![]() $\Delta R{e_c}/R{e_{c2}}$ as a function of

$\Delta R{e_c}/R{e_{c2}}$ as a function of ![]() ${\gamma _{{L_0}}}$ is shown in figure 16(b).

${\gamma _{{L_0}}}$ is shown in figure 16(b). ![]() $\Delta R{e_c}/R{e_{c2}}$ increases with increasing