1. Introduction

Over a wide range of melting phenomena, there is a special process called close-contact melting (CCM), where the unmelted solid surface and the heating surface are squeezed towards each other to maintain a close-contact status under the exertion of an external force. Unlike common convection melting in an expanding space involving Rayleigh–Bénard systems (Esfahani et al. Reference Esfahani, Hirata, Berti and Calzavarini2018), a sub-millimetre molten film remains between the unmelted solid and heating surfaces during CCM (Hu et al. Reference Hu, Zhang, Zhang, Liu and Fan2019), leading to a low-Reynolds-number film flow with solid–liquid phase change heat transfer. The CCM can be classified into two modes, i.e. heat source driven and unmelted solid driven, depending on the objective of the exerted force (Hu et al. Reference Hu, Li, Xu and Fan2022). The former mode usually represents the formation of a melting channel with a heating surface driven by a constant or an artificially set force through the solid to be melted, which occurs in magma migration (Marsh Reference Marsh1978), ‘self-burial’ (Chen, Hao & Chen Reference Chen, Hao and Chen2013) or ‘meltdown’ (Emerman & Turcotte Reference Emerman and Turcotte1983) in nuclear engineering, subtractive machining (Mayer & Moaveni Reference Mayer and Moaveni2008) and ice drilling (Schuller, Kowalski & Raback Reference Schuller, Kowalski and Raback2016). The latter mode, on the other hand, implies that the unmelted solid is extruded by its own weight onto the heating surface under gravity, which can be found in scenarios like the onset of glacier tables (Henot, Plihon & Taberlet Reference Henot, Plihon and Taberlet2021) and latent heat thermal energy storage (Kozak, Rozenfeld & Ziskind Reference Kozak, Rozenfeld and Ziskind2014) using solid–liquid phase change materials (PCMs), although the sinking process of the unmelted solid may be enhanced by an external force (Fu et al. Reference Fu, Yan, Gurumukhi, Garimella, King and Miljkovic2022).

The previous investigations on heat source-driven CCM have mainly been focused on prediction of the source migration rate. Moallemi and Viskanta measured experimentally the descending velocity of a heated tube at constant surface heat flux (Moallemi & Viskanta Reference Moallemi and Viskanta1985) and concluded that conduction is the dominant heat transfer mechanism during this process. A correlation of the dimensionless heat source velocity (![]() ${Pe}$, Pélect number) with the degree of superheat (

${Pe}$, Pélect number) with the degree of superheat (![]() ${Ste}$, Stefan number) and the imposed excess force (

${Ste}$, Stefan number) and the imposed excess force (![]() $\Delta P$) was given as

$\Delta P$) was given as ![]() ${Pe} \sim {Ste}^{3/4} \Delta P^{1/4}$ (Bejan Reference Bejan1992). Then various situations were considered for CCM, e.g. on a surface with arbitrary shape (Fomin, Wei & Chugunov Reference Fomin, Wei and Chugunov1995), through an unmelted solid with power-law viscosity at the liquid phase (Fomin, Saitoh & Chugunov Reference Fomin, Saitoh and Chugunov1997) and with spatially varying heat flux (Schueller & Kowalski Reference Schueller and Kowalski2017).

${Pe} \sim {Ste}^{3/4} \Delta P^{1/4}$ (Bejan Reference Bejan1992). Then various situations were considered for CCM, e.g. on a surface with arbitrary shape (Fomin, Wei & Chugunov Reference Fomin, Wei and Chugunov1995), through an unmelted solid with power-law viscosity at the liquid phase (Fomin, Saitoh & Chugunov Reference Fomin, Saitoh and Chugunov1997) and with spatially varying heat flux (Schueller & Kowalski Reference Schueller and Kowalski2017).

In contrast, unmelted solid-driven CCM is more complicated due to the coupling effect between the imposed force (i.e. weight of the unmelted solid) and melting rate that are both time dependent. Especially, when CCM occurs at the bottom of a container (except for ice melting where the unmelted solid will float on the top), it is usually accompanied by natural convection within the upper region of the container. Since it has been confirmed that convection melting cannot be neglected at large ![]() ${Ste}$, as compared with CCM, in spherical (Moore & Bayazitoglu Reference Moore and Bayazitoglu1982), rectangular (Dong et al. Reference Dong, Chen, Wang and Ebadian1991) or cylindrical (Sparrow & Geiger Reference Sparrow and Geiger1986) vessels, numerous efforts have been devoted to studying CCM on a horizontal plate to focus on the flow and heat transfer within the thin liquid film. Saito et al. studied CCM of ice and octadecane cylinders on an isothermal horizontal surface (Saito et al. Reference Saito, Utaka, Akiyoshi and Katayama1985a,Reference Saito, Utaka, Akiyoshi and Katayamab). Both experimental and numerical results indicated that non-dimensional mean heat flux is proportional to the 1/4 power of the non-dimensional contact pressure, and that the temperature distribution across the liquid film deviates gradually from a linear profile for

${Ste}$, as compared with CCM, in spherical (Moore & Bayazitoglu Reference Moore and Bayazitoglu1982), rectangular (Dong et al. Reference Dong, Chen, Wang and Ebadian1991) or cylindrical (Sparrow & Geiger Reference Sparrow and Geiger1986) vessels, numerous efforts have been devoted to studying CCM on a horizontal plate to focus on the flow and heat transfer within the thin liquid film. Saito et al. studied CCM of ice and octadecane cylinders on an isothermal horizontal surface (Saito et al. Reference Saito, Utaka, Akiyoshi and Katayama1985a,Reference Saito, Utaka, Akiyoshi and Katayamab). Both experimental and numerical results indicated that non-dimensional mean heat flux is proportional to the 1/4 power of the non-dimensional contact pressure, and that the temperature distribution across the liquid film deviates gradually from a linear profile for ![]() ${Ste} > 0.1$. Yoo et al. estimated this temperature profile deviation based on the non-dimensional interfacial temperature gradient predicted by magnitude analysis, showing discrepancies of less than 10 % at

${Ste} > 0.1$. Yoo et al. estimated this temperature profile deviation based on the non-dimensional interfacial temperature gradient predicted by magnitude analysis, showing discrepancies of less than 10 % at ![]() ${Ste} = 0.1$ and an exponential deviation when

${Ste} = 0.1$ and an exponential deviation when ![]() ${Ste} > 0.1$ (Yoo, Hong & Kim Reference Yoo, Hong and Kim1998). Moallemi et al. also carried out a similar study of this problem and gave a theoretical formula about the non-dimensional height of the unmelted solid by assuming a steady liquid film thickness and a quadratic polynomial temperature profile (Moallemi, Webb & Viskanta Reference Moallemi, Webb and Viskanta1986). Groulx & Lacroix established a three-dimensional transient model to predict the variation of liquid film thickness, and found that the effect of inertial force is negligible for high

${Ste} > 0.1$ (Yoo, Hong & Kim Reference Yoo, Hong and Kim1998). Moallemi et al. also carried out a similar study of this problem and gave a theoretical formula about the non-dimensional height of the unmelted solid by assuming a steady liquid film thickness and a quadratic polynomial temperature profile (Moallemi, Webb & Viskanta Reference Moallemi, Webb and Viskanta1986). Groulx & Lacroix established a three-dimensional transient model to predict the variation of liquid film thickness, and found that the effect of inertial force is negligible for high ![]() ${Pr}$ (Prandtl number) substances (Groulx & Lacroix Reference Groulx and Lacroix2007).

${Pr}$ (Prandtl number) substances (Groulx & Lacroix Reference Groulx and Lacroix2007).

Although these prior studies have led to a basic understanding of unmelted solid-driven CCM phenomena, there is still a need for deeper insights into this problem when complex fluid behaviours of the molten substances are involved, e.g. the use of different types of PCM for thermal energy storage applications. Recently, Kozak et al. considered the CCM process with a PCM having non-Newtonian behaviour in its liquid phase, and derived an extended analytical model to predict the melt fraction and liquid film thickness (Kozak et al. Reference Kozak, Zeng, Al Ghossein, Khodadadi and Ziskind2019). Despite a good extension into the non-Newtonian regime, this new model has limitations because it was developed under the assumptions of a Bingham fluid of the liquid PCM (which is still a ‘linear’ rheological model with yield stress) as well as a linear temperature profile within the liquid film.

However, numerous studies on the rheological properties of various emerging PCMs have shown shear-thinning behaviours in their liquid phase, e.g. organic PCMs having long-chain molecular structures or composite PCMs filled with particles at relatively high loadings. For instance, Motahar et al. reported that n-octadecane with mesoporous silica particles (3 % or 5 % mass fraction) exhibits a distinct shear-thinning feature at shear rates ![]() ${<}50\ {\rm s}^{-1}$ (Motahar et al. Reference Motahar, Nikkam, Alemrajabi, Khodabandeh, Toprak and Muhammed2014). Sugar alcohols, a family of polyols derived from sugars and having great potential for thermal energy storage in the low-to-medium-temperature range (

${<}50\ {\rm s}^{-1}$ (Motahar et al. Reference Motahar, Nikkam, Alemrajabi, Khodabandeh, Toprak and Muhammed2014). Sugar alcohols, a family of polyols derived from sugars and having great potential for thermal energy storage in the low-to-medium-temperature range (![]() $80\unicode{x2013}250\,^{\circ }{\rm C}$) (Shao et al. Reference Shao, Chen, Yang, Ku and Fan2019; Shao et al. Reference Shao, Yang, Chen, Fan and Yu2021), also exhibit complex shear-thinning behaviours over a wide span of shear rates from

$80\unicode{x2013}250\,^{\circ }{\rm C}$) (Shao et al. Reference Shao, Chen, Yang, Ku and Fan2019; Shao et al. Reference Shao, Yang, Chen, Fan and Yu2021), also exhibit complex shear-thinning behaviours over a wide span of shear rates from ![]() $0.001$ to

$0.001$ to ![]() $1000\ {\rm s}^{-1}$. As far as the authors are aware, the unmelted solid-driven CCM process with a shear-thinning fluid has not yet been studied, either theoretically or experimentally, in the available literature, although this case is deemed to be of potential interest for important applications like thermal energy storage towards a decarbonized energy future.

$1000\ {\rm s}^{-1}$. As far as the authors are aware, the unmelted solid-driven CCM process with a shear-thinning fluid has not yet been studied, either theoretically or experimentally, in the available literature, although this case is deemed to be of potential interest for important applications like thermal energy storage towards a decarbonized energy future.

Therefore, this work presents the derivation of a theoretical model for axisymmetric CCM on an isothermal horizontal surface, where the shear-thinning behaviour of the fluids (liquid PCMs) is described by two classical rheological models, i.e. power-law model and Carreau model, and the nonlinear temperature distribution within the liquid film is considered. Accurate numerical solutions and approximate analytical solutions are both obtained and validated by comparison with experimental results. The shear-thinning and convective effects on the dynamic process and heat transfer of CCM are investigated and discussed.

2. Physical model and theoretical framework

A typical axisymmetric CCM process is analysed as sketched in figure 1, where a cylindrical solid bulk PCM with radius ![]() $R$ and initial height

$R$ and initial height ![]() $H(t=0) = {H}_{0}$ is heated from below by an isothermal horizontal plate at temperature

$H(t=0) = {H}_{0}$ is heated from below by an isothermal horizontal plate at temperature ![]() ${T}_{w}$. The solid PCM maintains an initial temperature equal to its melting point

${T}_{w}$. The solid PCM maintains an initial temperature equal to its melting point ![]() ${T}_{m}$ (

${T}_{m}$ (![]() $< T_{w}$), so it will continuously melt from the bottom and squeeze the molten liquid consequently due to the weight of solid PCM, leading to a melt film with thickness

$< T_{w}$), so it will continuously melt from the bottom and squeeze the molten liquid consequently due to the weight of solid PCM, leading to a melt film with thickness ![]() ${\delta }$. It should be emphasized that the schematic diagram is not drawn to realistic scale (

${\delta }$. It should be emphasized that the schematic diagram is not drawn to realistic scale (![]() ${\delta } \ll R \sim {H}_{0}$) according to the thin film approximation validated in all previous studies. Here, and in what follows, the quantities with hat (

${\delta } \ll R \sim {H}_{0}$) according to the thin film approximation validated in all previous studies. Here, and in what follows, the quantities with hat (![]() $\bar {.}$) are non-dimensionalized.

$\bar {.}$) are non-dimensionalized.

Figure 1. Schematic illustration of the flow and heat transfer in the axisymmetric CCM region having radius ![]() $R$ and thickness

$R$ and thickness ![]() $\delta$, where

$\delta$, where ![]() $R \gg \delta$ and

$R \gg \delta$ and ![]() $H(0)/R$ is arbitrary.

$H(0)/R$ is arbitrary.

2.1. Rheological model

A number of empirical expressions have been used to describe variations in the apparent viscosity with the rate of strain. In a generalized incompressible Newtonian fluid the viscous stress is described by

where ![]() ${\boldsymbol {\varGamma }}$ is the rate of strain tensor and apparent viscosity

${\boldsymbol {\varGamma }}$ is the rate of strain tensor and apparent viscosity ![]() ${\mu }={\mu }{({\varGamma })}$;

${\mu }={\mu }{({\varGamma })}$; ![]() ${\varGamma }$ is the second invariant and equal to

${\varGamma }$ is the second invariant and equal to ![]() $\sqrt {\frac {1}{2} (\boldsymbol {\varGamma }\boldsymbol {:}\boldsymbol {\varGamma }})$. A well-known shear-thinning model is proposed as the Carreau–Yasuda model

$\sqrt {\frac {1}{2} (\boldsymbol {\varGamma }\boldsymbol {:}\boldsymbol {\varGamma }})$. A well-known shear-thinning model is proposed as the Carreau–Yasuda model

where ![]() ${\mu }_{\infty }$ is the viscosity at high shear rates

${\mu }_{\infty }$ is the viscosity at high shear rates ![]() $\dot {\gamma } = 2{\varGamma } \to \infty$,

$\dot {\gamma } = 2{\varGamma } \to \infty$, ![]() ${\mu }_{0}$ is the viscosity at low shear rates

${\mu }_{0}$ is the viscosity at low shear rates ![]() $2{\varGamma } \to 0$,

$2{\varGamma } \to 0$, ![]() ${\lambda }$ is a characteristic time of the fluid and

${\lambda }$ is a characteristic time of the fluid and ![]() $a$ and

$a$ and ![]() $b$ are characteristic parameters. It is worth noting that several widely used rheology constitutive models can be obtained by modifying conveniently the parameters in (2.2). When

$b$ are characteristic parameters. It is worth noting that several widely used rheology constitutive models can be obtained by modifying conveniently the parameters in (2.2). When ![]() $a = 2$ and

$a = 2$ and ![]() $b = (n-1)/{2}$, the Carreau model can be obtained as

$b = (n-1)/{2}$, the Carreau model can be obtained as ![]() $\mu =\mu _{\infty }+(\mu _{0}-\mu _{\infty })[1+(2{\lambda }{\varGamma })^{2}]^{(n-1)/{2}}$. If

$\mu =\mu _{\infty }+(\mu _{0}-\mu _{\infty })[1+(2{\lambda }{\varGamma })^{2}]^{(n-1)/{2}}$. If ![]() $a=1-n$ and

$a=1-n$ and ![]() $b=-1$ are satisfied, it leads to the Cross model:

$b=-1$ are satisfied, it leads to the Cross model: ![]() $\mu =\mu _{\infty }+(\mu _{0}-\mu _{\infty })[1+(2{\lambda }{\varGamma })^{1-n}]^{-1}$. The power-law model

$\mu =\mu _{\infty }+(\mu _{0}-\mu _{\infty })[1+(2{\lambda }{\varGamma })^{1-n}]^{-1}$. The power-law model ![]() $\mu \approx \mu _{0} (2 \lambda {\varGamma } )^{n-1}$ can be derived by setting

$\mu \approx \mu _{0} (2 \lambda {\varGamma } )^{n-1}$ can be derived by setting ![]() $a=1, b=n-1$ under the conditions of

$a=1, b=n-1$ under the conditions of ![]() $2{\lambda }{\varGamma } \gg 1$ and

$2{\lambda }{\varGamma } \gg 1$ and ![]() $\mu _{0} \gg \mu _{\infty }$. The Bingham model of

$\mu _{0} \gg \mu _{\infty }$. The Bingham model of ![]() $\mu = \mu _{0} + \tau _{0}/(2{\varGamma })$, which has been used and investigated in the CCM scenario by Kozak et al. (Reference Kozak, Zeng, Al Ghossein, Khodadadi and Ziskind2019), is established when

$\mu = \mu _{0} + \tau _{0}/(2{\varGamma })$, which has been used and investigated in the CCM scenario by Kozak et al. (Reference Kozak, Zeng, Al Ghossein, Khodadadi and Ziskind2019), is established when ![]() $a=b=-1$ and

$a=b=-1$ and ![]() $\lambda (\mu _{0}-\mu _{\infty })=\tau _{0}$.

$\lambda (\mu _{0}-\mu _{\infty })=\tau _{0}$.

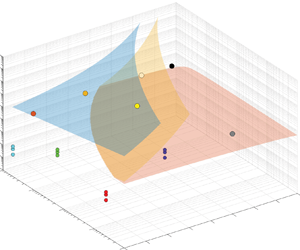

Among the above models, the Carreau model (drawn in figure 2a) is widely used to describe shear-thinning fluids because it can correctly predict the viscosity at both low and high shear rates (Nouar, Bottaro & Brancher Reference Nouar, Bottaro and Brancher2007; Chekila et al. Reference Chekila, Nouar, Plaut and Nemdili2011; Agbessi et al. Reference Agbessi, Alibenyahia, Nouar, Lemaitre and Choplin2015), and it is in better agreement with experimental results (Allouche et al. Reference Allouche, Botton, Millet, Henry, Dagois-Bohy, Guzel and Ben Hadid2017; Boyko & Stone Reference Boyko and Stone2021). Although the prediction of the power-law model significantly deviates at high and low shear rates (as shown in figure 2b), the simplicity of the model still makes it very attractive to describe shear-thinning fluids when the operating shear rates lie in the range of power-law region (Kumar et al. Reference Kumar, Zuri, Kogan, Gottlieb and Sayag2021). Here, figure 2(c) shows five PCMs with different shear-thinning rheological properties in their liquid phase. It can be found that the curves are more in line with the Carreau model, but there is a considerable range that can be well described by the power-law model. Consequently, both the Carreau model and power-law model are adopted in the following analysis.

Figure 2. Theoretical prediction of viscosity for (a) Carreau model and (b) power-law model, where the dashed line represents the baseline at ![]() $\mu _{0}=100\ {\rm Pa}\ {\rm s}$,

$\mu _{0}=100\ {\rm Pa}\ {\rm s}$, ![]() $n=0.2$,

$n=0.2$, ![]() $\lambda =100$ s and

$\lambda =100$ s and ![]() $\beta = 0.001$. (c) Measured viscosity of selected shear-thinning fluids of liquid PCMs including pure sugar alcohols (inostitol, dulcitol and xylitol (Shao et al. Reference Shao, Yang, Chen, Fan and Yu2021)) and eutectic sugar alcohols (erythritol

$\beta = 0.001$. (c) Measured viscosity of selected shear-thinning fluids of liquid PCMs including pure sugar alcohols (inostitol, dulcitol and xylitol (Shao et al. Reference Shao, Yang, Chen, Fan and Yu2021)) and eutectic sugar alcohols (erythritol ![]() $+$ d-mannitol and d-mannitol

$+$ d-mannitol and d-mannitol ![]() $+$ inositol (Shao et al. Reference Shao, Chen, Yang, Ku and Fan2019)).

$+$ inositol (Shao et al. Reference Shao, Chen, Yang, Ku and Fan2019)).

2.2. Governing equations and dimensionless parameters

By distances scaled with ![]() $R$, pressure and stresses with

$R$, pressure and stresses with ![]() $\rho _{s} g H_{0}$ and time with

$\rho _{s} g H_{0}$ and time with ![]() $R/\sqrt {\rho _{s} g H_{0}/\rho _{l}}$, the incompressible flow governing equations in dimensionless form are given by

$R/\sqrt {\rho _{s} g H_{0}/\rho _{l}}$, the incompressible flow governing equations in dimensionless form are given by

where ![]() $\bar {\boldsymbol {u}}=\bar {u}_{r}\boldsymbol {{e}_{r}}+ \bar {u}_{z}\boldsymbol {{e}_{z}}$ denotes the fluid velocity,

$\bar {\boldsymbol {u}}=\bar {u}_{r}\boldsymbol {{e}_{r}}+ \bar {u}_{z}\boldsymbol {{e}_{z}}$ denotes the fluid velocity, ![]() $\bar {P}$ the pressure (including gravity effect) and

$\bar {P}$ the pressure (including gravity effect) and ![]() $\bar {\boldsymbol {\tau }}$ the viscous stress tensor. The melt film is supposed to be purely viscous as described by

$\bar {\boldsymbol {\tau }}$ the viscous stress tensor. The melt film is supposed to be purely viscous as described by

where ![]() ${Re}$ is the Reynolds number, defined as

${Re}$ is the Reynolds number, defined as

By introducing dimensionless temperature ![]() $\bar {T} = ( T- {T}_{m})/({T}_{w}-{T}_{m})$, the energy equation of flow considering viscous dissipation in dimensionless form is given by

$\bar {T} = ( T- {T}_{m})/({T}_{w}-{T}_{m})$, the energy equation of flow considering viscous dissipation in dimensionless form is given by

where ![]() ${Pe}$ is the Péclet number,

${Pe}$ is the Péclet number, ![]() ${Pr}$ the Prandtl number and

${Pr}$ the Prandtl number and ![]() ${Ec}$ the Eckert number, which are defined respectively as

${Ec}$ the Eckert number, which are defined respectively as

with ![]() $\alpha, g, {k}_{l},{\rho }_{l}$ and

$\alpha, g, {k}_{l},{\rho }_{l}$ and ![]() ${c}_{{p,l}}$ being the thermal diffusivity, gravitational acceleration, thermal conductivity, density and specific heat capacity of the fluids, respectively.

${c}_{{p,l}}$ being the thermal diffusivity, gravitational acceleration, thermal conductivity, density and specific heat capacity of the fluids, respectively.

As for the flow within the melt film, the following classical assumptions are adopted, consistent with previous works (Moallemi et al. Reference Moallemi, Webb and Viskanta1986; Kozak et al. Reference Kozak, Zeng, Al Ghossein, Khodadadi and Ziskind2019): (i) due to ![]() $R\gg \delta$, the lubrication approximation is valid for the melt film (i.e.

$R\gg \delta$, the lubrication approximation is valid for the melt film (i.e. ![]() $\partial / \partial z \gg \partial / \partial r$), (ii) the flow in the melt film is axisymmetric (i.e.

$\partial / \partial z \gg \partial / \partial r$), (ii) the flow in the melt film is axisymmetric (i.e. ![]() $\partial / {\partial \theta } = 0$), laminar and in quasi-steady state (i.e.

$\partial / {\partial \theta } = 0$), laminar and in quasi-steady state (i.e. ![]() $\partial / {\partial t} = 0$), (iii) thermophysical properties are temperature independent, (iv) the bottom surface of the solid is flat (i.e.

$\partial / {\partial t} = 0$), (iii) thermophysical properties are temperature independent, (iv) the bottom surface of the solid is flat (i.e. ![]() $\delta (t,r,\theta ) = \delta (t)$), (v) the temperature gradient in the

$\delta (t,r,\theta ) = \delta (t)$), (v) the temperature gradient in the ![]() $r$ direction is negligible, (vi) sensible heat of the melt liquid is neglected in heat transfer and (vii) viscous dissipation is negligible compared with the conductive term due to

$r$ direction is negligible, (vi) sensible heat of the melt liquid is neglected in heat transfer and (vii) viscous dissipation is negligible compared with the conductive term due to ![]() ${Pr}{Ec}\ll 1$ for most PCMs and thermal conditions. It is worth noting that the convective effect is here considered instead of the pure heat conduction simplification adopted by Kozak et al. (Reference Kozak, Zeng, Al Ghossein, Khodadadi and Ziskind2019).

${Pr}{Ec}\ll 1$ for most PCMs and thermal conditions. It is worth noting that the convective effect is here considered instead of the pure heat conduction simplification adopted by Kozak et al. (Reference Kozak, Zeng, Al Ghossein, Khodadadi and Ziskind2019).

Hence, the momentum equation (2.4) of fluid motion and the energy equation (2.7) can be described respectively by

Note that governing equations (2.9a–d) and (2.10) imply ![]() $\bar {u}_{r}=\bar {u}_{r}(\bar {z}, \partial \bar {P}/\partial \bar {r})$,

$\bar {u}_{r}=\bar {u}_{r}(\bar {z}, \partial \bar {P}/\partial \bar {r})$, ![]() $\bar {P} = \bar {P}(\bar {r})$ and

$\bar {P} = \bar {P}(\bar {r})$ and ![]() $\bar {T} = \bar {T}(\bar {z})$, respectively. Different from the pressure-driven flow (having a determinate pressure difference

$\bar {T} = \bar {T}(\bar {z})$, respectively. Different from the pressure-driven flow (having a determinate pressure difference ![]() $\Delta P$ along the channel), the pressure gradient

$\Delta P$ along the channel), the pressure gradient ![]() $\partial \bar {P}/\partial \bar {r}$ in the melt film stems from the extrusion of remaining solid bulk and is determined by force balance as

$\partial \bar {P}/\partial \bar {r}$ in the melt film stems from the extrusion of remaining solid bulk and is determined by force balance as

which can also be written in dimensionless form as

where the aspect ratio ![]() $A = H_{0}/R$.

$A = H_{0}/R$.

2.3. Force equilibrium relationship based on the power-law model

The constitutive expression of the power-law model for ![]() $\bar {\mu }$ is

$\bar {\mu }$ is

where ![]() $\varLambda$ is the ratio of the characteristic time of the fluid to the viscous diffusion time, which is fixed for a given fluid and flow length, as defined by

$\varLambda$ is the ratio of the characteristic time of the fluid to the viscous diffusion time, which is fixed for a given fluid and flow length, as defined by

By substituting (2.13) into (2.9a–d) and integrating twice in two parts, i.e. ![]() $0-0.5\bar {\delta }$ and

$0-0.5\bar {\delta }$ and ![]() $0.5\bar {\delta }-\bar {\delta }$, for opposite velocity gradients with the boundary conditions of

$0.5\bar {\delta }-\bar {\delta }$, for opposite velocity gradients with the boundary conditions of ![]() $\bar {u}_{r}|_{\bar {z}=0}=0$ and

$\bar {u}_{r}|_{\bar {z}=0}=0$ and ![]() ${\partial \bar {u}_{r}}/{\partial \bar {z}}|_{\bar {z}=\bar {\delta }/2} = 0$ as well as

${\partial \bar {u}_{r}}/{\partial \bar {z}}|_{\bar {z}=\bar {\delta }/2} = 0$ as well as ![]() $\bar {u}_{r}|_{\bar {z} =\bar {\delta }}= 0$ and

$\bar {u}_{r}|_{\bar {z} =\bar {\delta }}= 0$ and ![]() ${\partial \bar {u}_{r}}/{\partial \bar {z}}|_{\bar {z}=\bar {\delta }/2} = 0$, respectively, the velocity profile for

${\partial \bar {u}_{r}}/{\partial \bar {z}}|_{\bar {z}=\bar {\delta }/2} = 0$, respectively, the velocity profile for ![]() $\bar {z} = 0 -\bar {\delta }$ can be obtained as

$\bar {z} = 0 -\bar {\delta }$ can be obtained as

\begin{equation} \bar{u}_{r} =

\frac{n}{1+n}

\left(-\frac{\mathrm{d}\bar{P}}{\mathrm{d}\bar{r}}\right)^{1/n}

\varLambda^{(1-n)/n}{Re}^{(2-n)/n} \Biggl[\left(

\frac{\bar{\delta}}{2} \right)^{(1+n)/{n}} -\left |

\bar{z}-\frac{\bar{\delta}}{2} \right |^{(1+n)/n}\Biggr].

\end{equation}

\begin{equation} \bar{u}_{r} =

\frac{n}{1+n}

\left(-\frac{\mathrm{d}\bar{P}}{\mathrm{d}\bar{r}}\right)^{1/n}

\varLambda^{(1-n)/n}{Re}^{(2-n)/n} \Biggl[\left(

\frac{\bar{\delta}}{2} \right)^{(1+n)/{n}} -\left |

\bar{z}-\frac{\bar{\delta}}{2} \right |^{(1+n)/n}\Biggr].

\end{equation}

Then, integrating (2.3) along ![]() $\bar {z}$ with the boundary conditions of

$\bar {z}$ with the boundary conditions of ![]() $\bar {u}_{z}|_{\bar {z}=0}=0$ and

$\bar {u}_{z}|_{\bar {z}=0}=0$ and ![]() $\bar {u}_{z}|_{\bar {z}=\bar {\delta }}= ({\mathrm {d}(\bar {H} -\bar {\delta })}/{\mathrm {d} \bar {t}})({\rho _{s}}/{\rho _{l}}) +{\mathrm {d}\bar {\delta }}/{\mathrm {d} \bar {t}}$ yields

$\bar {u}_{z}|_{\bar {z}=\bar {\delta }}= ({\mathrm {d}(\bar {H} -\bar {\delta })}/{\mathrm {d} \bar {t}})({\rho _{s}}/{\rho _{l}}) +{\mathrm {d}\bar {\delta }}/{\mathrm {d} \bar {t}}$ yields

\begin{align}

\frac{1}{\bar{r}} \frac{\partial

\Biggl[\left(-\dfrac{\mathrm{d}\bar{P}}{\mathrm{d}\bar{r}}\right)^{1/n}\bar{r}\Biggr]}{\partial

\bar{r}} \frac{n}{1+n} \varLambda^{(1-n)/n}{Re}^{(2-n)/n}

\int_{0}^{\bar{\delta}}\Biggl[ \left (

\frac{\bar{\delta}}{2} \right )^{({1+n})/{n}} -\left |

\bar{z}-\frac{\bar{\delta}}{2} \right|^{(1+n)/n} \Biggr]

-V^{{\ast} }=0, \end{align}

\begin{align}

\frac{1}{\bar{r}} \frac{\partial

\Biggl[\left(-\dfrac{\mathrm{d}\bar{P}}{\mathrm{d}\bar{r}}\right)^{1/n}\bar{r}\Biggr]}{\partial

\bar{r}} \frac{n}{1+n} \varLambda^{(1-n)/n}{Re}^{(2-n)/n}

\int_{0}^{\bar{\delta}}\Biggl[ \left (

\frac{\bar{\delta}}{2} \right )^{({1+n})/{n}} -\left |

\bar{z}-\frac{\bar{\delta}}{2} \right|^{(1+n)/n} \Biggr]

-V^{{\ast} }=0, \end{align}

where ![]() ${V^\ast }=-\bar {u}_{z}|_{\bar {z}=\bar {\delta }}>0$ is related to the descending velocity of the solid bulk and thickening velocity of the melt film. Integrating (2.16) with respect to

${V^\ast }=-\bar {u}_{z}|_{\bar {z}=\bar {\delta }}>0$ is related to the descending velocity of the solid bulk and thickening velocity of the melt film. Integrating (2.16) with respect to ![]() $r$ and applying the boundary conditions of

$r$ and applying the boundary conditions of ![]() $\mathrm {d}\bar {P}/\mathrm {d}\bar {r}|_{\bar {r}=0}=0$ and

$\mathrm {d}\bar {P}/\mathrm {d}\bar {r}|_{\bar {r}=0}=0$ and ![]() $\bar {P}|_{\bar {r}=1}=0$ yields

$\bar {P}|_{\bar {r}=1}=0$ yields

Here, we can substitute (2.17) into (2.15) to obtain

\begin{equation}

\bar{u}_r=\frac{V^{{\ast}}}{\bar{\delta}^2} \frac{(2

n+1)}{(n+1)}\Biggl[\left(\frac{\bar{\delta}}{2}\right)-\left|\bar{z}-\frac{\bar{\delta}}{2}\right|\left|\frac{2

\bar{z}}{\bar{\delta}}-1\right|^{{1}/{n}}\Biggr] \bar{r},

\end{equation}

\begin{equation}

\bar{u}_r=\frac{V^{{\ast}}}{\bar{\delta}^2} \frac{(2

n+1)}{(n+1)}\Biggl[\left(\frac{\bar{\delta}}{2}\right)-\left|\bar{z}-\frac{\bar{\delta}}{2}\right|\left|\frac{2

\bar{z}}{\bar{\delta}}-1\right|^{{1}/{n}}\Biggr] \bar{r},

\end{equation}

which indicates that ![]() $\bar {u}_r$ varies along both the

$\bar {u}_r$ varies along both the ![]() $z$ and

$z$ and ![]() $r$ directions. Finally, substituting (2.17) into (2.12) and integrating lead to

$r$ directions. Finally, substituting (2.17) into (2.12) and integrating lead to

2.4. Force equilibrium relationship based on the Carreau model

The constitutive description of the Carreau model for ![]() $\bar {\mu } ({\varGamma } )$ is given by

$\bar {\mu } ({\varGamma } )$ is given by

where ![]() $\beta = \mu _{\infty }/ \mu _{0}$.

$\beta = \mu _{\infty }/ \mu _{0}$.

Note that it is difficult to get explicit expressions for the velocity profile ![]() $\bar {u}_{r}(\bar {z})$ via substituting (2.20) into (2.9a–d), which implies that the pressure distribution

$\bar {u}_{r}(\bar {z})$ via substituting (2.20) into (2.9a–d), which implies that the pressure distribution ![]() $\bar {P}(\bar {r})$ cannot be obtained from integrating (2.3) without

$\bar {P}(\bar {r})$ cannot be obtained from integrating (2.3) without ![]() $\bar {u}_{r}(\bar {z})$. Thus, mass conservation in integral form, instead of differential form, should be used here to obtain the relationship between the flow rate

$\bar {u}_{r}(\bar {z})$. Thus, mass conservation in integral form, instead of differential form, should be used here to obtain the relationship between the flow rate ![]() $\bar {Q}$ and pressure gradient

$\bar {Q}$ and pressure gradient ![]() $\mathrm {d}\bar {P}/\mathrm {d}\bar {r}$. Although the solutions of governing equations (2.9a–d) combined with (2.20) under the no-slip boundary condition have been similarly investigated in plane Poiseuille flow (Chekila et al. Reference Chekila, Nouar, Plaut and Nemdili2011) or approximate slit flow (Sochi Reference Sochi2015; Boyko & Stone Reference Boyko and Stone2021) of Carreau fluids, only asymptotic solutions or numerically solvable hypergeometric functions are currently available for a

$\mathrm {d}\bar {P}/\mathrm {d}\bar {r}$. Although the solutions of governing equations (2.9a–d) combined with (2.20) under the no-slip boundary condition have been similarly investigated in plane Poiseuille flow (Chekila et al. Reference Chekila, Nouar, Plaut and Nemdili2011) or approximate slit flow (Sochi Reference Sochi2015; Boyko & Stone Reference Boyko and Stone2021) of Carreau fluids, only asymptotic solutions or numerically solvable hypergeometric functions are currently available for a ![]() $Q-\Delta P$ (flow rate

$Q-\Delta P$ (flow rate![]() $-$constant pressure drop) relation, which fails to meet the demand of this problem but is inspiring.

$-$constant pressure drop) relation, which fails to meet the demand of this problem but is inspiring.

We can refer to the transformation to avoid deriving the velocity profile by substituting (2.20) into (2.9a–d), which yields

According to the flow rate expression proposed by Sochi (Reference Sochi2015) and Wilkinson (Reference Wilkinson1972), the flow rate ![]() $\bar {Q}$ between two circular surfaces can be deduced from the shear stress

$\bar {Q}$ between two circular surfaces can be deduced from the shear stress ![]() $\bar {\tau }_{w}$, as given by

$\bar {\tau }_{w}$, as given by

After integrating (see Appendix A for details), (2.22) becomes

\begin{align}

\frac{\bar{Q}}{\bar{\delta}^{2}{\rm \pi} \bar{r}} &=

\frac{1}{3}\bar{\dot{\gamma}}_{w} \left\{\vphantom{\prod_{l=1}^{j}}1 -

\frac{\beta(1-\beta)(1+\varLambda^{2} {Re}^{2}

\bar{\dot{\gamma}}_{w}^{2})^{({n-1})/{2}}}{[\beta+(1-\beta)(1+\varLambda^{2}

{Re}^{2} \bar{\dot{\gamma}}_{w}^{2})^{({n-1})/{2}}]^2}\right.\nonumber\\ &\quad \left.\times

\sum_{j=1}^{\infty}\frac{(\varLambda^{2}

{Re}^{2}\bar{\dot{\gamma}}_{w}^{2})^{j}}{(1+\varLambda^{2}{Re}^{2}

\bar{\dot{\gamma}}_{w}^{2})^{j}}

\prod_{l=1}^{j}\frac{2l-n-1}{2l+3} \right.\nonumber\\ &\quad \left.

- \,\frac{\frac{1}{2}(1-\beta)^{2}(1+\varLambda^{2}

{Re}^{2}

\bar{\dot{\gamma}}_{w}^{2})^{n-1}}{[\beta+(1-\beta)(1+\varLambda^{2}

{Re}^{2} \bar{\dot{\gamma}}_{w}^{2})^{({n-1})/{2}} ]^2} \sum_{j=1}^{\infty}\frac{(\varLambda^{2}

{Re}^{2}\bar{\dot{\gamma}}_{w}^{2})^{j}}{(1+\varLambda^{2}{Re}^{2}

\bar{\dot{\gamma}}_{w}^{2})^{j}} \prod_{l=1}^{j}\frac{2l-2n}{2l+3} \right\}.

\end{align}

\begin{align}

\frac{\bar{Q}}{\bar{\delta}^{2}{\rm \pi} \bar{r}} &=

\frac{1}{3}\bar{\dot{\gamma}}_{w} \left\{\vphantom{\prod_{l=1}^{j}}1 -

\frac{\beta(1-\beta)(1+\varLambda^{2} {Re}^{2}

\bar{\dot{\gamma}}_{w}^{2})^{({n-1})/{2}}}{[\beta+(1-\beta)(1+\varLambda^{2}

{Re}^{2} \bar{\dot{\gamma}}_{w}^{2})^{({n-1})/{2}}]^2}\right.\nonumber\\ &\quad \left.\times

\sum_{j=1}^{\infty}\frac{(\varLambda^{2}

{Re}^{2}\bar{\dot{\gamma}}_{w}^{2})^{j}}{(1+\varLambda^{2}{Re}^{2}

\bar{\dot{\gamma}}_{w}^{2})^{j}}

\prod_{l=1}^{j}\frac{2l-n-1}{2l+3} \right.\nonumber\\ &\quad \left.

- \,\frac{\frac{1}{2}(1-\beta)^{2}(1+\varLambda^{2}

{Re}^{2}

\bar{\dot{\gamma}}_{w}^{2})^{n-1}}{[\beta+(1-\beta)(1+\varLambda^{2}

{Re}^{2} \bar{\dot{\gamma}}_{w}^{2})^{({n-1})/{2}} ]^2} \sum_{j=1}^{\infty}\frac{(\varLambda^{2}

{Re}^{2}\bar{\dot{\gamma}}_{w}^{2})^{j}}{(1+\varLambda^{2}{Re}^{2}

\bar{\dot{\gamma}}_{w}^{2})^{j}} \prod_{l=1}^{j}\frac{2l-2n}{2l+3} \right\}.

\end{align}

The results of ![]() $\bar {Q}/(\delta ^{2}{\rm \pi} \bar {r})$ along

$\bar {Q}/(\delta ^{2}{\rm \pi} \bar {r})$ along ![]() ${\bar {\dot {\gamma }}}_{w}$ under various

${\bar {\dot {\gamma }}}_{w}$ under various ![]() $n$ and number of terms

$n$ and number of terms ![]() $j$ are depicted in figure 9 by numerically computing the series in (2.23). When

$j$ are depicted in figure 9 by numerically computing the series in (2.23). When ![]() ${\varLambda } {Re}{\bar {\dot {\gamma }}}_{w} \ll 1$, (2.23) can be simplified to

${\varLambda } {Re}{\bar {\dot {\gamma }}}_{w} \ll 1$, (2.23) can be simplified to

Furthermore, when ![]() $1 \ll {\varLambda } {Re}{\bar {\dot {\gamma }}}_{w} \ll \sqrt [1-n]{(1-\beta )/\beta }$, (2.23) can be written as

$1 \ll {\varLambda } {Re}{\bar {\dot {\gamma }}}_{w} \ll \sqrt [1-n]{(1-\beta )/\beta }$, (2.23) can be written as

\begin{align} \frac{\bar{Q}}{{\bar{\delta}}^{2}{\rm \pi} \bar{r}} &= \frac{1}{3}{\bar{\dot{\gamma}}}_{w} \left[1 - \frac{\beta(\varLambda {Re}{\bar{\dot{\gamma}}}_{w})^{1-n} }{1-\beta}\sum_{j=1}^{\infty } \prod_{l=1}^{j}\frac{2l-n-1}{2l+3}-\frac{1}{2}\sum_{j=1}^{\infty } \prod_{l=1}^{j}\frac{2l-2n}{2l+3} \right]\nonumber\\ & = \frac{1}{3}{\bar{\dot{\gamma}}}_{w} \left(1 -\frac{1}{2}\sum_{j=1}^{\infty } \prod_{l=1}^{j}\frac{2l-2n}{2l+3} \right) = \frac{1}{3}{\bar{\dot{\gamma}}}_{w} \mathcal{H}(n), \end{align}

\begin{align} \frac{\bar{Q}}{{\bar{\delta}}^{2}{\rm \pi} \bar{r}} &= \frac{1}{3}{\bar{\dot{\gamma}}}_{w} \left[1 - \frac{\beta(\varLambda {Re}{\bar{\dot{\gamma}}}_{w})^{1-n} }{1-\beta}\sum_{j=1}^{\infty } \prod_{l=1}^{j}\frac{2l-n-1}{2l+3}-\frac{1}{2}\sum_{j=1}^{\infty } \prod_{l=1}^{j}\frac{2l-2n}{2l+3} \right]\nonumber\\ & = \frac{1}{3}{\bar{\dot{\gamma}}}_{w} \left(1 -\frac{1}{2}\sum_{j=1}^{\infty } \prod_{l=1}^{j}\frac{2l-2n}{2l+3} \right) = \frac{1}{3}{\bar{\dot{\gamma}}}_{w} \mathcal{H}(n), \end{align}

where ![]() $\mathcal {H}(n) = 1 -\frac {1}{2}\sum _{j=1}^{\infty } \prod _{l=1}^{j}({2l-2n})/({2l+3})$.

$\mathcal {H}(n) = 1 -\frac {1}{2}\sum _{j=1}^{\infty } \prod _{l=1}^{j}({2l-2n})/({2l+3})$.

As for ![]() ${\varLambda } {Re}{\bar {\dot {\gamma }}}_{w}\gg \sqrt [1-n]{(1-\beta )/\beta }$, (2.23) can be rewritten as

${\varLambda } {Re}{\bar {\dot {\gamma }}}_{w}\gg \sqrt [1-n]{(1-\beta )/\beta }$, (2.23) can be rewritten as

\begin{align} \frac{\bar{Q}}{{\bar{\delta}}^{2}{\rm \pi} \bar{r}} &= \frac{1}{3}{\bar{\dot{\gamma}}}_{w} \left[1 - \frac{(1-\beta) }{\beta(\varLambda {Re}{\bar{\dot{\gamma}}}_{w})^{1-n} }\sum_{j=1}^{\infty } \prod_{l=1}^{j}\frac{2l-n-1}{2l+3}\right.\nonumber\\ &\quad \left.-\frac{1}{2}\frac{(1-\beta)^{2}}{\beta^2( \varLambda {Re}{\bar{\dot{\gamma}}}_{w})^{2-2n} }\sum_{j=1}^{\infty } \prod_{l=1}^{j}\frac{2l-2n}{2l+3} \right]. \end{align}

\begin{align} \frac{\bar{Q}}{{\bar{\delta}}^{2}{\rm \pi} \bar{r}} &= \frac{1}{3}{\bar{\dot{\gamma}}}_{w} \left[1 - \frac{(1-\beta) }{\beta(\varLambda {Re}{\bar{\dot{\gamma}}}_{w})^{1-n} }\sum_{j=1}^{\infty } \prod_{l=1}^{j}\frac{2l-n-1}{2l+3}\right.\nonumber\\ &\quad \left.-\frac{1}{2}\frac{(1-\beta)^{2}}{\beta^2( \varLambda {Re}{\bar{\dot{\gamma}}}_{w})^{2-2n} }\sum_{j=1}^{\infty } \prod_{l=1}^{j}\frac{2l-2n}{2l+3} \right]. \end{align}Notice that the last two terms in brackets of (2.26) are far less than 1. Hence, (2.26) can be simplified to

On the other hand, the unknown ![]() $\bar {\dot {\gamma }}_{w}$ is related to the pressure gradient

$\bar {\dot {\gamma }}_{w}$ is related to the pressure gradient ![]() $\mathrm {d}\bar {P}/\mathrm {d}\bar {r}$ as given by

$\mathrm {d}\bar {P}/\mathrm {d}\bar {r}$ as given by

Hence, the pressure gradient in asymptotic form can also be obtained after substituting ![]() $\bar {Q} =V^{\ast } {\rm \pi}{\bar {r}}^2$ into the expressions (2.24), (2.25) and (2.27), as given by

$\bar {Q} =V^{\ast } {\rm \pi}{\bar {r}}^2$ into the expressions (2.24), (2.25) and (2.27), as given by

\begin{align}

-\frac{\mathrm{d}\bar{P}}{\mathrm{d}\bar{r}}\frac{\bar{\delta}}{2}

= \begin{cases}

\displaystyle\frac{1}{Re}\frac{3~V^{{\ast}}\bar{r}}{{\bar{\delta}}^2}

& \text{if } 0<\bar{r}\ll

\dfrac{{\bar{\delta}}^2}{3V^{{\ast}} \varLambda {Re}},

\\[12pt] \displaystyle\frac{1-\beta}{{Re}\left(\varLambda

{Re}\right)^{1-n}}\Biggl(\dfrac{3~V^{{\ast}}\bar{r}}{{\bar{\delta}}^2

\mathcal{H}(n)}\Biggr)^{n} & \text{if }

\dfrac{{\bar{\delta}}^2\mathcal{H}(n)}{3V^{{\ast}}

\varLambda {Re}} \ll \bar{r}\ll

\dfrac{{\bar{\delta}}^2\mathcal{H}(n)}{3~V^{{\ast}}

\varLambda {Re}}

\left(\dfrac{1-\beta}{\beta}\right)^{{1}/({1-n})},\\[12pt]

\displaystyle\frac{\beta}{Re}\frac{3V^{{\ast}}\bar{r}}{{\bar{\delta}}^2}

& \text{if } \bar{r}\gg \frac{{\bar{\delta}}^2}{3V^{{\ast}}

\varLambda {Re}}

\left(\dfrac{1-\beta}{\beta}\right)^{{1}/({1-n})}.

\end{cases} \end{align}

\begin{align}

-\frac{\mathrm{d}\bar{P}}{\mathrm{d}\bar{r}}\frac{\bar{\delta}}{2}

= \begin{cases}

\displaystyle\frac{1}{Re}\frac{3~V^{{\ast}}\bar{r}}{{\bar{\delta}}^2}

& \text{if } 0<\bar{r}\ll

\dfrac{{\bar{\delta}}^2}{3V^{{\ast}} \varLambda {Re}},

\\[12pt] \displaystyle\frac{1-\beta}{{Re}\left(\varLambda

{Re}\right)^{1-n}}\Biggl(\dfrac{3~V^{{\ast}}\bar{r}}{{\bar{\delta}}^2

\mathcal{H}(n)}\Biggr)^{n} & \text{if }

\dfrac{{\bar{\delta}}^2\mathcal{H}(n)}{3V^{{\ast}}

\varLambda {Re}} \ll \bar{r}\ll

\dfrac{{\bar{\delta}}^2\mathcal{H}(n)}{3~V^{{\ast}}

\varLambda {Re}}

\left(\dfrac{1-\beta}{\beta}\right)^{{1}/({1-n})},\\[12pt]

\displaystyle\frac{\beta}{Re}\frac{3V^{{\ast}}\bar{r}}{{\bar{\delta}}^2}

& \text{if } \bar{r}\gg \frac{{\bar{\delta}}^2}{3V^{{\ast}}

\varLambda {Re}}

\left(\dfrac{1-\beta}{\beta}\right)^{{1}/({1-n})}.

\end{cases} \end{align}

Then, integrating (2.29) twice under asymptotic assumptions and substituting into (2.12) leads to two control equations (details are given in Appendix B), depending on whether the magnitude of the maximum shear rate at the radius edge reaches the high shear rate in the Carreau model . The two equations are defined as ![]() $\mathcal {MN}$ and

$\mathcal {MN}$ and ![]() $\mathcal {PQ}$ equation as follows. For the

$\mathcal {PQ}$ equation as follows. For the ![]() $\mathcal {MN}$ equation

$\mathcal {MN}$ equation

\begin{equation} \mathcal{M} \frac{{\bar{\delta}}^5}{\left(V^{{\ast}}\right)^3}+ \mathcal{N} \frac{\left(V^{{\ast}}\right)^n}{{\bar{\delta}}^{2n+1}}= \bar{ H} -\bar{\delta} \quad \text{for} \left(\frac{\beta}{1-\beta}\right)^{{1}/({1-n})} \leqslant \frac{{\bar{\delta}}^2}{3V^{{\ast}}\varLambda {Re} } \leqslant 1 , \end{equation}

\begin{equation} \mathcal{M} \frac{{\bar{\delta}}^5}{\left(V^{{\ast}}\right)^3}+ \mathcal{N} \frac{\left(V^{{\ast}}\right)^n}{{\bar{\delta}}^{2n+1}}= \bar{ H} -\bar{\delta} \quad \text{for} \left(\frac{\beta}{1-\beta}\right)^{{1}/({1-n})} \leqslant \frac{{\bar{\delta}}^2}{3V^{{\ast}}\varLambda {Re} } \leqslant 1 , \end{equation}where

and

For the ![]() $\mathcal {PQ}$ equation

$\mathcal {PQ}$ equation

\begin{equation} \mathcal{P} \frac{{\bar{\delta}}^5}{\left(V^{{\ast}}\right)^3} + \mathcal{Q} \frac{V^{{\ast}}}{{\bar{\delta}}^{3}} = \bar{ H} -\bar{\delta} \quad \text{for} \left(\frac{\beta}{1-\beta}\right)^{{1}/({1-n})} \geqslant \frac{{\bar{\delta}}^2}{3V^{{\ast}}\varLambda {Re} } , \end{equation}

\begin{equation} \mathcal{P} \frac{{\bar{\delta}}^5}{\left(V^{{\ast}}\right)^3} + \mathcal{Q} \frac{V^{{\ast}}}{{\bar{\delta}}^{3}} = \bar{ H} -\bar{\delta} \quad \text{for} \left(\frac{\beta}{1-\beta}\right)^{{1}/({1-n})} \geqslant \frac{{\bar{\delta}}^2}{3V^{{\ast}}\varLambda {Re} } , \end{equation}where

\begin{align} \mathcal{P} &= \frac{A}{27{Re}}\frac{1}{\left(\varLambda {Re}\right)^4} \left[ \frac{1}{2}+\frac{-2}{n+3}\frac{(1- \beta)}{\left(\mathcal{H}(n)\right)^n} +\frac{2}{n+3}\frac{1-\beta}{\left(\mathcal{H}(n)\right)^n}\left(\frac{1-\beta}{\beta}\right)^{({3+n})/({1-n})} \right.\nonumber\\ &\quad \left. +\frac{-\beta}{2}\left(\frac{1-\beta}{\beta}\right)^{{4}/({1-n})}\right], \end{align}

\begin{align} \mathcal{P} &= \frac{A}{27{Re}}\frac{1}{\left(\varLambda {Re}\right)^4} \left[ \frac{1}{2}+\frac{-2}{n+3}\frac{(1- \beta)}{\left(\mathcal{H}(n)\right)^n} +\frac{2}{n+3}\frac{1-\beta}{\left(\mathcal{H}(n)\right)^n}\left(\frac{1-\beta}{\beta}\right)^{({3+n})/({1-n})} \right.\nonumber\\ &\quad \left. +\frac{-\beta}{2}\left(\frac{1-\beta}{\beta}\right)^{{4}/({1-n})}\right], \end{align}and

Here, we denote

\begin{align} \mathcal{B} &=

\frac{1}{2}+\frac{-2}{n+3}\frac{(1-

\beta)}{(\mathcal{H}(n))^n}

+\frac{2}{n+3}\frac{1-\beta}{(\mathcal{H}(n))^n}\left(\frac{1-\beta}{\beta}\right)^{({3+n})/({1-n})}\nonumber\\

&\quad +

\frac{-\beta}{2}\left(\frac{1-\beta}{\beta}\right)^{{4}/({1-n})}

, \end{align}

\begin{align} \mathcal{B} &=

\frac{1}{2}+\frac{-2}{n+3}\frac{(1-

\beta)}{(\mathcal{H}(n))^n}

+\frac{2}{n+3}\frac{1-\beta}{(\mathcal{H}(n))^n}\left(\frac{1-\beta}{\beta}\right)^{({3+n})/({1-n})}\nonumber\\

&\quad +

\frac{-\beta}{2}\left(\frac{1-\beta}{\beta}\right)^{{4}/({1-n})}

, \end{align}

and ![]() $\mathcal {P} = ({A}/{27{Re}})({\mathcal {B}}/{(\varLambda {Re})^4)}$ for ease of writing in the subsequent sections.

$\mathcal {P} = ({A}/{27{Re}})({\mathcal {B}}/{(\varLambda {Re})^4)}$ for ease of writing in the subsequent sections.

Furthermore, it is of interest to analyse expressions (2.30) and (2.33) in the limit of ![]() $2\lambda \varGamma \ll 1$ and

$2\lambda \varGamma \ll 1$ and ![]() $\beta = 0$ to compare with the power-law model in § 2.3. It can be easily known that the dimensionless form of limit

$\beta = 0$ to compare with the power-law model in § 2.3. It can be easily known that the dimensionless form of limit ![]() $2\lambda \varGamma \ll 1$ is

$2\lambda \varGamma \ll 1$ is ![]() ${\varLambda }{Re}\bar {\dot {\gamma }}_w\gg 1$. With the limit of

${\varLambda }{Re}\bar {\dot {\gamma }}_w\gg 1$. With the limit of ![]() $\beta = 0$ and

$\beta = 0$ and ![]() $\varLambda Re{\bar {\dot {\gamma }}_w}\gg 1$, (2.27) and (2.24) will become absent, which consequently leads to a transformation of (2.29) as

$\varLambda Re{\bar {\dot {\gamma }}_w}\gg 1$, (2.27) and (2.24) will become absent, which consequently leads to a transformation of (2.29) as

Then, it can be found that the pressure distribution of the Carreau model in the limits of ![]() $\beta = 0$ and

$\beta = 0$ and ![]() ${\varLambda }{Re}{\bar {\dot {\gamma }}_w}\gg 1$ is

${\varLambda }{Re}{\bar {\dot {\gamma }}_w}\gg 1$ is

which is equivalent to the pressure distribution (2.17) in the power-law model because ![]() $\mathcal {H}(n)={3n}/{(2n+1)}$ can be verified by numerical calculation.

$\mathcal {H}(n)={3n}/{(2n+1)}$ can be verified by numerical calculation.

Consequently, (2.30) is also equivalent to (2.19) because the term of ![]() $\mathcal {M}$ disappears when integrating (2.38). In summary, it is clear, as expected, that the Carreau model will be converged to the power-law model in the limit of

$\mathcal {M}$ disappears when integrating (2.38). In summary, it is clear, as expected, that the Carreau model will be converged to the power-law model in the limit of ![]() $2\lambda \varGamma \ll 1$ and

$2\lambda \varGamma \ll 1$ and ![]() $\beta = 0$.

$\beta = 0$.

2.5. Temperature profile and energy equation at interface

Recall the energy equation (2.10) considering the convective effect, where ![]() ${\bar {u}}_{z}$ should be found to solve the temperature profile

${\bar {u}}_{z}$ should be found to solve the temperature profile ![]() $\bar {T}(\bar {z})$ and temperature gradient

$\bar {T}(\bar {z})$ and temperature gradient ![]() $\mathrm {d} \bar T/\mathrm {d}\bar {z}$ at

$\mathrm {d} \bar T/\mathrm {d}\bar {z}$ at ![]() $\bar {z} =\bar {\delta }$. For a given

$\bar {z} =\bar {\delta }$. For a given ![]() ${\bar {u}}_r$, e.g. (2.15) for power-law fluids,

${\bar {u}}_r$, e.g. (2.15) for power-law fluids, ![]() ${\bar {u}}_z$ can be solved by integrating the continuity equation along the z direction, while it fails for Carreau fluids due to the absence of an explicit expression for

${\bar {u}}_z$ can be solved by integrating the continuity equation along the z direction, while it fails for Carreau fluids due to the absence of an explicit expression for ![]() ${\bar {u}}_r$. After evaluating different assumptions for

${\bar {u}}_r$. After evaluating different assumptions for ![]() ${\bar {u}}_z$ (see details in Appendix C), we can adopt the approximation

${\bar {u}}_z$ (see details in Appendix C), we can adopt the approximation ![]() $\bar {u}_{z}\sim \bar {u}_{z}|_{\bar {z}=\bar {\delta }}$ in (2.10), leading to

$\bar {u}_{z}\sim \bar {u}_{z}|_{\bar {z}=\bar {\delta }}$ in (2.10), leading to

Then (2.39) can be theoretically solved with the boundary conditions

The solution of the temperature profile over the melt film is given by

which implies that the temperature ![]() $\bar {T}(\bar {z})$ will gradually deviate from a linear distribution with increasing

$\bar {T}(\bar {z})$ will gradually deviate from a linear distribution with increasing ![]() $V^{\ast }{Pe}$ that is related to the convection intensity.

$V^{\ast }{Pe}$ that is related to the convection intensity.

The energy conservation equation at the solid–liquid interface is given by

where ![]() $L$ is the latent heat of fusion. The dimensionless form of (2.42) is

$L$ is the latent heat of fusion. The dimensionless form of (2.42) is

where ![]() $\bar {\rho } = \rho _{s}/\rho _{l}$ is the solid–liquid density ratio and the Stefan number

$\bar {\rho } = \rho _{s}/\rho _{l}$ is the solid–liquid density ratio and the Stefan number ![]() ${Ste}$ is defined as

${Ste}$ is defined as

Substitution of (2.41) into (2.43) yields the comprehensive expression for the transient velocity relationship with ![]() $\bar {\delta }^{\prime }(\bar {t})$ and

$\bar {\delta }^{\prime }(\bar {t})$ and ![]() $\bar {H}^{\prime }(\bar {t})$

$\bar {H}^{\prime }(\bar {t})$

Considering the scaling of ![]() $({\mathrm {d} \bar {\delta } }/{\mathrm {d} \bar {t}}) ({\rho _{s}-\rho _{l}}/{\rho _{l}}) \ll - ({\mathrm {d}\bar {H} }/{\mathrm {d} \bar {t}} )({\rho _{s}}/{\rho _{l}})$, leads to

$({\mathrm {d} \bar {\delta } }/{\mathrm {d} \bar {t}}) ({\rho _{s}-\rho _{l}}/{\rho _{l}}) \ll - ({\mathrm {d}\bar {H} }/{\mathrm {d} \bar {t}} )({\rho _{s}}/{\rho _{l}})$, leads to

Then, with the scaling of ![]() ${\mathrm {d} \bar {\delta } }/{\mathrm {d} \bar {t}} \ll - {\mathrm {d}\bar { H} }/{\mathrm {d} \bar {t}}$, (2.45) and (2.46) can be simplified respectively as

${\mathrm {d} \bar {\delta } }/{\mathrm {d} \bar {t}} \ll - {\mathrm {d}\bar { H} }/{\mathrm {d} \bar {t}}$, (2.45) and (2.46) can be simplified respectively as

and

Note that (2.47) can be written in the following Taylor expansion form:

\begin{equation} {-} \frac{\mathrm{d}\bar{ H} }{\mathrm{d} \bar{t}} = \frac{\ln({Ste}+1)}{\bar{\rho}{Pe} \bar{\delta}} = \frac{1}{\bar{\rho}{Pe} \bar{\delta}}\sum_{i=0}^{\infty} \frac{({-}1)^i}{i+1} {Ste}^{i+1}. \end{equation}

\begin{equation} {-} \frac{\mathrm{d}\bar{ H} }{\mathrm{d} \bar{t}} = \frac{\ln({Ste}+1)}{\bar{\rho}{Pe} \bar{\delta}} = \frac{1}{\bar{\rho}{Pe} \bar{\delta}}\sum_{i=0}^{\infty} \frac{({-}1)^i}{i+1} {Ste}^{i+1}. \end{equation}This implies that (2.47) can be approximated to

which is the pure conductive form consistent with previous studies (Kozak et al. Reference Kozak, Zeng, Al Ghossein, Khodadadi and Ziskind2019; Kozak Reference Kozak2022).

The relative deviation between (2.47) and (2.50) can be estimated by ![]() ${Ste}/\ln ({Ste}+1)-1$, resulting in an approximate deviation of

${Ste}/\ln ({Ste}+1)-1$, resulting in an approximate deviation of ![]() $4.9\,\%$ for

$4.9\,\%$ for ![]() $Ste = 0.1$,

$Ste = 0.1$, ![]() $9.7\,\%$ for

$9.7\,\%$ for ![]() $Ste = 0.2$ and

$Ste = 0.2$ and ![]() $23.3\,\%$ for

$23.3\,\%$ for ![]() $Ste = 0.5$. This estimation indicates that the assumption of pure heat conduction in the melt film will lead to an overestimated melting rate, especially at higher values of

$Ste = 0.5$. This estimation indicates that the assumption of pure heat conduction in the melt film will lead to an overestimated melting rate, especially at higher values of ![]() ${Ste}$.

${Ste}$.

3. Approaches to numerical solution

3.1. Numerical solution for the power-law model

By substituting (2.48) into (2.19), the following relation can be derived:

Equations (2.47) and (3.1) comprise a set of first-order ordinary differential equations and nonlinear algebraic equations, respectively, that can be solved numerically. Equation (2.47) can be discretized using a forward Euler scheme as

where ![]() $i$ and

$i$ and ![]() $i+1$ denote the current and next time steps, respectively, and

$i+1$ denote the current and next time steps, respectively, and ![]() $\Delta \bar {t}$ is the discrete time step size.

$\Delta \bar {t}$ is the discrete time step size.

The current film thickness ![]() $\bar {\delta }^{i}$ can be obtained via solving the following equation:

$\bar {\delta }^{i}$ can be obtained via solving the following equation:

\begin{equation} \frac{2(2n+1)^{n}}{(n+3)n^{n}} \frac{A}{ (\varLambda {Re})^{1-n} {Re}} \left[\frac{\ln({Ste}+1)}{Pe}\right]^n \frac{1}{ {(\bar{\delta} ^i)}^{1+3n}} +\bar{\delta} ^{i} = \bar{ H}^{i}. \end{equation}

\begin{equation} \frac{2(2n+1)^{n}}{(n+3)n^{n}} \frac{A}{ (\varLambda {Re})^{1-n} {Re}} \left[\frac{\ln({Ste}+1)}{Pe}\right]^n \frac{1}{ {(\bar{\delta} ^i)}^{1+3n}} +\bar{\delta} ^{i} = \bar{ H}^{i}. \end{equation}

The initial condition of ![]() $\bar { H}(\bar {t} = 0)$ is applied

$\bar { H}(\bar {t} = 0)$ is applied

At each time step, (3.3) is solved for ![]() $\bar {\delta }^{i}$ and then the new remaining height

$\bar {\delta }^{i}$ and then the new remaining height ![]() $\bar { H}^{i+1}$ is calculated via (3.2). Especially, for the first time step,

$\bar { H}^{i+1}$ is calculated via (3.2). Especially, for the first time step, ![]() $\bar {H}^{i} = A$ is set according to (3.4). The dimensional time step

$\bar {H}^{i} = A$ is set according to (3.4). The dimensional time step ![]() $\Delta t = 0.1$ s is adopted due to proper convergence and computational cost after performing an independence test of the time step size.

$\Delta t = 0.1$ s is adopted due to proper convergence and computational cost after performing an independence test of the time step size.

3.2. Numerical method for the Carreau model

First, we can find a turning condition from (2.30) to (2.33) as

\begin{equation} \frac{\bar{\delta}^2}{3 V^* \varLambda {Re}}\left(\frac{1-\beta}{\beta}\right)^{{1}/({1-n})} = 1. \end{equation}

\begin{equation} \frac{\bar{\delta}^2}{3 V^* \varLambda {Re}}\left(\frac{1-\beta}{\beta}\right)^{{1}/({1-n})} = 1. \end{equation}

By substituting (2.48) into (3.5), a critical film thickness ![]() $\bar {\delta }_{cr}$ can be identified, as given by

$\bar {\delta }_{cr}$ can be identified, as given by

\begin{equation} \bar{\delta}_{cr} =

\Biggl[ \frac{3\varLambda {Re} \ln({Ste}+1)}{Pe}

\left(\frac{\beta}{1-\beta}\right)^{{1}/({1-n})}\Biggr]^{{1}/{3}}.

\end{equation}

\begin{equation} \bar{\delta}_{cr} =

\Biggl[ \frac{3\varLambda {Re} \ln({Ste}+1)}{Pe}

\left(\frac{\beta}{1-\beta}\right)^{{1}/({1-n})}\Biggr]^{{1}/{3}}.

\end{equation}

Essentially the critical liquid film thickness ![]() $\bar {\delta }_{cr}$ implies whether the wall shear rates

$\bar {\delta }_{cr}$ implies whether the wall shear rates ![]() $\bar {\gamma }_{w}$ at the outlet (

$\bar {\gamma }_{w}$ at the outlet (![]() $\bar {r} = 1$) reaches the plateau region for high shear rate in the Carreau model during the CCM process, which leads to the transition of the pressure distribution (i.e. transition from (B3) to (B9) as derived in Appendix B) and consequently determines the choice of

$\bar {r} = 1$) reaches the plateau region for high shear rate in the Carreau model during the CCM process, which leads to the transition of the pressure distribution (i.e. transition from (B3) to (B9) as derived in Appendix B) and consequently determines the choice of ![]() $\mathcal {PQ}$ or

$\mathcal {PQ}$ or ![]() $\mathcal {MN}$ equation.

$\mathcal {MN}$ equation.

Similarly, the following nonlinear relations can be obtained, respectively, via substituting (2.48) into (2.30) and (2.33):

and

Equation (3.2) is still utilized to calculate the height of solid PCM while the current thickness ![]() $\bar {\delta }^{i}$ is obtained via

$\bar {\delta }^{i}$ is obtained via

\begin{equation} \mathcal{M} \left[ \frac{Pe}{\ln({Ste}+1)}\right]^3({\bar{\delta}^i})^8 + \mathcal{N}\left[\frac{\ln({Ste}+1)}{Pe}\right]^n \frac{1}{({\bar{\delta}^i})^{2n+1}} +{\bar{\delta}^i} = \bar{ H} ^{i}, \end{equation}

\begin{equation} \mathcal{M} \left[ \frac{Pe}{\ln({Ste}+1)}\right]^3({\bar{\delta}^i})^8 + \mathcal{N}\left[\frac{\ln({Ste}+1)}{Pe}\right]^n \frac{1}{({\bar{\delta}^i})^{2n+1}} +{\bar{\delta}^i} = \bar{ H} ^{i}, \end{equation}or

\begin{equation} \mathcal{P} \left[ \frac{Pe}{\ln({Ste}+1)}\right]^3{({\bar{\delta}^i})}^8 + \mathcal{Q} \frac{\ln({Ste}+1)}{Pe} \frac{1}{{({\bar{\delta}^i})}^{3}} +{\bar{\delta}^i} = \bar{ H} ^{i}. \end{equation}

\begin{equation} \mathcal{P} \left[ \frac{Pe}{\ln({Ste}+1)}\right]^3{({\bar{\delta}^i})}^8 + \mathcal{Q} \frac{\ln({Ste}+1)}{Pe} \frac{1}{{({\bar{\delta}^i})}^{3}} +{\bar{\delta}^i} = \bar{ H} ^{i}. \end{equation}

Note that both (3.9) and (3.10) are solved for each time step to obtain ![]() $\bar {\delta }^{i}$ to compare with the critical value

$\bar {\delta }^{i}$ to compare with the critical value ![]() $\bar {\delta }_{cr}$. Subsequently, the

$\bar {\delta }_{cr}$. Subsequently, the ![]() $\bar {\delta }^{i}$ that meets the inequality requirement is adopted for consequent calculations. Also, the same initial condition (3.4) and time step

$\bar {\delta }^{i}$ that meets the inequality requirement is adopted for consequent calculations. Also, the same initial condition (3.4) and time step ![]() $\Delta t = 0.1$ s are adopted for all cases.

$\Delta t = 0.1$ s are adopted for all cases.

As for determining the initial film thickness ![]() $\bar {\delta }(0)$, we first assume that the

$\bar {\delta }(0)$, we first assume that the ![]() $\mathcal {PQ}$ equation is satisfied by substituting

$\mathcal {PQ}$ equation is satisfied by substituting ![]() $\bar { H}(0) = A$ to solve (3.10). If the condition of

$\bar { H}(0) = A$ to solve (3.10). If the condition of ![]() $\bar {\delta }(0) \leqslant \bar {\delta }_{cr}$ is satisfied, it can be verified that the presumption is correct. If

$\bar {\delta }(0) \leqslant \bar {\delta }_{cr}$ is satisfied, it can be verified that the presumption is correct. If ![]() $\bar {\delta }(0) > \bar {\delta }_{cr}$, it means that the

$\bar {\delta }(0) > \bar {\delta }_{cr}$, it means that the ![]() $\mathcal {PQ}$ equation is not satisfied and the initial value needs to be solved by the

$\mathcal {PQ}$ equation is not satisfied and the initial value needs to be solved by the ![]() $\mathcal {MN}$ equation. Since the

$\mathcal {MN}$ equation. Since the ![]() $\mathcal {PQ}$ and

$\mathcal {PQ}$ and ![]() $\mathcal {MN}$ equations are equivalent when the liquid film thickness is exactly equal to the critical value, this a posteriori solution method to determine the initial film thickness will not cause errors.

$\mathcal {MN}$ equations are equivalent when the liquid film thickness is exactly equal to the critical value, this a posteriori solution method to determine the initial film thickness will not cause errors.

4. Numerical results and experimental validation

4.1. Experimental set-up and procedure

4.1.1. Experimental apparatus

As shown in figure 3(a), a heated-from-below configuration was arranged by placing vertically a cylindrically shaped PCM sample on a heating plate. Two experimental devices were established to separately measure the instantaneous top surface height ![]() $H(t)$ of solid PCM and thickness

$H(t)$ of solid PCM and thickness ![]() $\delta (t)$ of melt film during CCM. The height

$\delta (t)$ of melt film during CCM. The height ![]() $H(t)$ was recorded by a digital camera, whereas thickness

$H(t)$ was recorded by a digital camera, whereas thickness ![]() $\delta (t)$ was obtained based on laser interference method similar to the measurement of the microlayer under vapour bubbles during boiling (Chen et al. Reference Chen, Hu, Hu, Utaka and Mori2020; Sinha, Narayan & Srivastava Reference Sinha, Narayan and Srivastava2021). Details of the experimental set-up and procedure for measuring height

$\delta (t)$ was obtained based on laser interference method similar to the measurement of the microlayer under vapour bubbles during boiling (Chen et al. Reference Chen, Hu, Hu, Utaka and Mori2020; Sinha, Narayan & Srivastava Reference Sinha, Narayan and Srivastava2021). Details of the experimental set-up and procedure for measuring height ![]() $H(t)$ and thickness

$H(t)$ and thickness ![]() $\delta (t)$ can be found in our previous work (Hu et al. Reference Hu, Zhu, Li, Tu and Fan2018, Reference Hu, Zhang, Zhang, Liu and Fan2019). Two heating boundary temperatures were used for each PCM corresponding to wall superheats

$\delta (t)$ can be found in our previous work (Hu et al. Reference Hu, Zhu, Li, Tu and Fan2018, Reference Hu, Zhang, Zhang, Liu and Fan2019). Two heating boundary temperatures were used for each PCM corresponding to wall superheats ![]() $\Delta T$ of

$\Delta T$ of ![]() $10\,^{\circ }{\rm C}$ and

$10\,^{\circ }{\rm C}$ and ![]() $30\,^{\circ }{\rm C}$, respectively, in all cases. Given the slim shape of the PCM sample, it tended to tilt upon melting from the bottom. Hence, a glass tube having an inner diameter that is slightly greater than the outer diameter of the PCM column was suspended vertically to hold it as a guide, so as to prevent it from titling during each CCM run.

$30\,^{\circ }{\rm C}$, respectively, in all cases. Given the slim shape of the PCM sample, it tended to tilt upon melting from the bottom. Hence, a glass tube having an inner diameter that is slightly greater than the outer diameter of the PCM column was suspended vertically to hold it as a guide, so as to prevent it from titling during each CCM run.

Figure 3. (a) Sketch of the experimental apparatus measuring the melt film thickness ![]() $\delta (t)$ and recording the height of the solid

$\delta (t)$ and recording the height of the solid ![]() $H(t)$. (b) In-house measurements of viscosity as a function of strain rate of 1,6H/G-X1 % and T-X1 %, also included are data points for inositol and dulcitol (Shao et al. Reference Shao, Yang, Chen, Fan and Yu2021), where the shaded patches represent the scatter range of the measured viscosity. The regression to Carreau (blue lines) functions and fitting parameters are listed in table 1, and the power-law (red lines) functions are determined by using the same fitting parameters from the Carreau model.

$H(t)$. (b) In-house measurements of viscosity as a function of strain rate of 1,6H/G-X1 % and T-X1 %, also included are data points for inositol and dulcitol (Shao et al. Reference Shao, Yang, Chen, Fan and Yu2021), where the shaded patches represent the scatter range of the measured viscosity. The regression to Carreau (blue lines) functions and fitting parameters are listed in table 1, and the power-law (red lines) functions are determined by using the same fitting parameters from the Carreau model.

During the measurement of ![]() $H(t)$, a three-way valve was used to trigger melting from the low-temperature loop to the high-temperature loop. The analysis ignored the little delay in the copper base's temperature response after switching the valve. To prevent heat losses to the environment, the entire arrangement was enclosed in a thermostat that was kept at the initial temperature of the PCM. During the melting process, the decreasing height of the PCM sample was captured by a digital camera every 5 s. The photos were then loaded into an image processing program to precisely calculate the height. A circumferentially grooved shape on the base allowed drainage of the liquid melt squeezed from the thin film.

$H(t)$, a three-way valve was used to trigger melting from the low-temperature loop to the high-temperature loop. The analysis ignored the little delay in the copper base's temperature response after switching the valve. To prevent heat losses to the environment, the entire arrangement was enclosed in a thermostat that was kept at the initial temperature of the PCM. During the melting process, the decreasing height of the PCM sample was captured by a digital camera every 5 s. The photos were then loaded into an image processing program to precisely calculate the height. A circumferentially grooved shape on the base allowed drainage of the liquid melt squeezed from the thin film.

As for measuring ![]() $\delta (t)$, experiments were carried out inside an acrylic reservoir that was utilized to collect molten PCM and serve as a confined environment under atmospheric pressure. The PCM sample was kept in the thermostat at a starting temperature of

$\delta (t)$, experiments were carried out inside an acrylic reservoir that was utilized to collect molten PCM and serve as a confined environment under atmospheric pressure. The PCM sample was kept in the thermostat at a starting temperature of ![]() $T_{m}-0.5\,^{\circ }{\rm C}$ before each run, and the heating plate was verified to be in steady state at the predetermined temperature

$T_{m}-0.5\,^{\circ }{\rm C}$ before each run, and the heating plate was verified to be in steady state at the predetermined temperature ![]() $T_{w}$. A typical run was triggered by moving the PCM quickly from the thermostat onto the transparent isothermal heating plate, while the high-speed camera started recording the interference patterns synchronously.

$T_{w}$. A typical run was triggered by moving the PCM quickly from the thermostat onto the transparent isothermal heating plate, while the high-speed camera started recording the interference patterns synchronously.

As introduced in our previous work (Hu et al. Reference Hu, Zhang, Zhang, Liu and Fan2019), a high-speed camera at 1000 fps was used to capture the interferometric fringes, in order to ensure fringes within the field view shifted monotonically (only expanded) without any oscillating effects, thus verifying the increasing trend of the melt film thickness during melting. Due to memory limitations and the inability to switch cameras during the experiment, we were only able to measure the early liquid film thickness changes. However, given the slow change in film thickness after melting stabilization, we can still find its quasi-steady-state value from early measurements and compare it with the analytical/numerical prediction.

4.1.2. Preparation of the experimental PCM

Due to the relatively high melting points of sugar alcohol-based PCMs (![]() $T_{m} > 100\,^{\circ }{\rm C}$ for most), two home-made PCMs based on 1,6-hexanediol/glycerol mixture (

$T_{m} > 100\,^{\circ }{\rm C}$ for most), two home-made PCMs based on 1,6-hexanediol/glycerol mixture (![]() $T_{m} = 29\,^{\circ }{\rm C}$) and tetradecanol (

$T_{m} = 29\,^{\circ }{\rm C}$) and tetradecanol (![]() $T_{m} = 37\,^{\circ }{\rm C}$) having lower melting points were prepared for experimental studies. One PCM, denoted as T-X1 %, was obtained by thorough mixing of 1 wt.% polymer thickener (Carbopol 940) in molten tetradecanol. Another PCM named 1,6H/GX1 % was obtained by adding 1 wt.% Carbopol 940 to a molten 1,6-hexanediol/glycerol (9 : 1 mass ratio) mixture. To prepare uniformly dissolved and air-bubble-free solutions, the process of adding thickener to both PCMs was done by ultrasonic oscillation for 30 min, followed by degassing in a vacuum chamber during solidification. No phase separation was found after resting on the shelf and several cycles of solid–liquid phase change.

$T_{m} = 37\,^{\circ }{\rm C}$) having lower melting points were prepared for experimental studies. One PCM, denoted as T-X1 %, was obtained by thorough mixing of 1 wt.% polymer thickener (Carbopol 940) in molten tetradecanol. Another PCM named 1,6H/GX1 % was obtained by adding 1 wt.% Carbopol 940 to a molten 1,6-hexanediol/glycerol (9 : 1 mass ratio) mixture. To prepare uniformly dissolved and air-bubble-free solutions, the process of adding thickener to both PCMs was done by ultrasonic oscillation for 30 min, followed by degassing in a vacuum chamber during solidification. No phase separation was found after resting on the shelf and several cycles of solid–liquid phase change.

The solid PCM fabrication procedure prior to the melting experiments was as follows. A glass test tube with an inner diameter of 12 mm was used to serve as the solidification mould, which was submerged in water bath maintained at ![]() $T = T_{m} - 5\,^{\circ }{\rm C}$. To minimize void formation during solidification, a layer-by-layer strategy was adopted, i.e. a small amount of a premelted PCM was gently poured into the test tube to generate a thin solid layer at each step. The tube was cracked once the solidified sample had risen to the desired height. This cracking step was done with great care to avoid any deformation and damage to the PCM sample inside (Hu et al. Reference Hu, Zhu, Li, Tu and Fan2018). The entire sample was then easily removed from the mould, followed by cutting and shaping to produce a cylinder sample with

$T = T_{m} - 5\,^{\circ }{\rm C}$. To minimize void formation during solidification, a layer-by-layer strategy was adopted, i.e. a small amount of a premelted PCM was gently poured into the test tube to generate a thin solid layer at each step. The tube was cracked once the solidified sample had risen to the desired height. This cracking step was done with great care to avoid any deformation and damage to the PCM sample inside (Hu et al. Reference Hu, Zhu, Li, Tu and Fan2018). The entire sample was then easily removed from the mould, followed by cutting and shaping to produce a cylinder sample with ![]() $R = 6$ mm and

$R = 6$ mm and ![]() $H_{0} = 20$ or 40 mm.

$H_{0} = 20$ or 40 mm.

4.1.3. Rheological and other thermophysical properties

The dependence of the shear viscosity ![]() $\mu$ of T-X1 % and 1,6H/GX1 % on the shear rate

$\mu$ of T-X1 % and 1,6H/GX1 % on the shear rate ![]() $\dot {\gamma }$ was measured by a high-precision rotational rheometer (Anton Paar MCR102). The rheological measurements were performed at two characteristic temperatures corresponding to two superheats for both 1,6H/G-X1 % and T-X1 %. In detail, the viscosity of 1,6H/G-X1 % was measured at 42

$\dot {\gamma }$ was measured by a high-precision rotational rheometer (Anton Paar MCR102). The rheological measurements were performed at two characteristic temperatures corresponding to two superheats for both 1,6H/G-X1 % and T-X1 %. In detail, the viscosity of 1,6H/G-X1 % was measured at 42 ![]() $^\circ {\rm C}$ and 52

$^\circ {\rm C}$ and 52 ![]() $^\circ {\rm C}$ corresponding to the superheat of 5

$^\circ {\rm C}$ corresponding to the superheat of 5 ![]() $^\circ {\rm C}$ and 15

$^\circ {\rm C}$ and 15 ![]() $^\circ {\rm C}$, respectively. Similarly, the viscosity of T-X1 % was measured at 34

$^\circ {\rm C}$, respectively. Similarly, the viscosity of T-X1 % was measured at 34 ![]() $^\circ {\rm C}$ and 44

$^\circ {\rm C}$ and 44 ![]() $^\circ {\rm C}$. The results showed a minor temperature-dependent effect on viscosity.

$^\circ {\rm C}$. The results showed a minor temperature-dependent effect on viscosity.

The ![]() $\mu - \dot \gamma$ curves of T-X1 % and 1,6H/GX1 % are shown in figure 3(b), where the fitted curves based on the Carreau model are in good agreement with the experimental data, while the curves based on the power-law model only fit well over a certain segment. In addition, for the subsequent discussion of the CCM process for sugar alcohols, the rheological properties and fitted curves of inositol and dulcitol are also plotted in figure 3(b). The melting point

$\mu - \dot \gamma$ curves of T-X1 % and 1,6H/GX1 % are shown in figure 3(b), where the fitted curves based on the Carreau model are in good agreement with the experimental data, while the curves based on the power-law model only fit well over a certain segment. In addition, for the subsequent discussion of the CCM process for sugar alcohols, the rheological properties and fitted curves of inositol and dulcitol are also plotted in figure 3(b). The melting point ![]() $T_{m}$, latent heat of fusion

$T_{m}$, latent heat of fusion ![]() $L$ and specific heat capacity in liquid phase

$L$ and specific heat capacity in liquid phase ![]() $c_{{p,l}}$ of all PCMs were measured by a differential scanning calorimeter (NETZSCH 200 F3). The thermal conductivity of liquid phase PCMs was measured using a KD2 Pro thermal analyser that is based on the transient hot-line method. All fitted rheological parameters and other important thermophysical properties related to the CCM process are given in table 1.

$c_{{p,l}}$ of all PCMs were measured by a differential scanning calorimeter (NETZSCH 200 F3). The thermal conductivity of liquid phase PCMs was measured using a KD2 Pro thermal analyser that is based on the transient hot-line method. All fitted rheological parameters and other important thermophysical properties related to the CCM process are given in table 1.

Table 1. Fitted rheological parameters and other thermophysical properties of inositol, dulcitol, T-X1 % and 1,6H/G-X1 %.

4.2. Validation of the Carreau model and convective effect

In figure 4(a), the model predictions and experimental measurements of the instantaneous top surface height ![]() $H$(t) for T-X1 % and 1,6H/G-X1 % are shown together with three combinations of operating conditions. The solid line represents the convective model using (2.47), and the dashed line denotes the pure conduction model using (2.50). All predictions of the pure conduction model overestimate the rate of decline in height

$H$(t) for T-X1 % and 1,6H/G-X1 % are shown together with three combinations of operating conditions. The solid line represents the convective model using (2.47), and the dashed line denotes the pure conduction model using (2.50). All predictions of the pure conduction model overestimate the rate of decline in height ![]() $H$, in comparison with the experimental results. As expected, the predictions of the new model including convective effect are more accurate. There is a clear difference between the convective and conductive models when the superheat is

$H$, in comparison with the experimental results. As expected, the predictions of the new model including convective effect are more accurate. There is a clear difference between the convective and conductive models when the superheat is ![]() $30\,^{\circ }{\rm C}$, and the convective model is in better agreement with the experimental results. The convective effect is not significant at

$30\,^{\circ }{\rm C}$, and the convective model is in better agreement with the experimental results. The convective effect is not significant at ![]() $10\,^{\circ }{\rm C}$, but a non-negligible difference can still be found. Figure 4(a) also proves that the convective effect is insignificant at

$10\,^{\circ }{\rm C}$, but a non-negligible difference can still be found. Figure 4(a) also proves that the convective effect is insignificant at ![]() ${Ste} = 0.1$, while a more remarkable influence occurs at

${Ste} = 0.1$, while a more remarkable influence occurs at ![]() ${Ste} = 0.3$ or 0.4, which is consistent with the condition of

${Ste} = 0.3$ or 0.4, which is consistent with the condition of ![]() ${Ste} \ll 1$ for (2.50) as the conductive model. Additionally, it is demonstrated that, with decreasing superheat, the prediction difference between the two models becomes smaller. Especially, when

${Ste} \ll 1$ for (2.50) as the conductive model. Additionally, it is demonstrated that, with decreasing superheat, the prediction difference between the two models becomes smaller. Especially, when ![]() ${Ste} \rightarrow 0.1$, it is difficult to distinguish the difference from the height variation.

${Ste} \rightarrow 0.1$, it is difficult to distinguish the difference from the height variation.

Figure 4. (a) Comparison between the experimental results and numerical predictions of ![]() $H(t)$ over the whole process of CCM. (b) Comparison between the experimental results and numerical predictions of

$H(t)$ over the whole process of CCM. (b) Comparison between the experimental results and numerical predictions of ![]() $\delta (t)$ during the initial stage of CCM. (c) Numerical predictions of

$\delta (t)$ during the initial stage of CCM. (c) Numerical predictions of ![]() $\delta (t)$ for the whole process of CCM. (d) Transient heat flux

$\delta (t)$ for the whole process of CCM. (d) Transient heat flux ![]() $q^{\prime \prime }$ for T-X1 % and 1,6H/G-X1 %. (e) Transient equivalent heat transfer coefficient

$q^{\prime \prime }$ for T-X1 % and 1,6H/G-X1 %. (e) Transient equivalent heat transfer coefficient ![]() $h$ for T-X1 % and 1,6H/G-X1 %. Three conditions are involved for all cases with the combination of two aspect ratios (

$h$ for T-X1 % and 1,6H/G-X1 %. Three conditions are involved for all cases with the combination of two aspect ratios (![]() $A = 10/3$ or

$A = 10/3$ or ![]() $20/3$) and two degrees of superheat (

$20/3$) and two degrees of superheat (![]() $\Delta T = 10\,^{\circ }{\rm C}$ or

$\Delta T = 10\,^{\circ }{\rm C}$ or ![]() $30\,^{\circ }{\rm C}$), as denoted by [

$30\,^{\circ }{\rm C}$), as denoted by [![]() $\Delta T, A$] for each condition. Scattered points: experimental values, solid line: convection effects by (2.47), double dotted line: pure conduction assumption by (2.50), shaded patches: the scatter range of measured film thickness.

$\Delta T, A$] for each condition. Scattered points: experimental values, solid line: convection effects by (2.47), double dotted line: pure conduction assumption by (2.50), shaded patches: the scatter range of measured film thickness.