1. Introduction

When a drop is subjected to a high-speed gas stream, the drop can experience significant deformation or even breakup. If the stabilizing forces, including surface tension and viscous forces, are not sufficient to overcome the destabilizing inertia force, then the drop will break into a collection of child droplets of different sizes (Taylor Reference Taylor1949; Guildenbecher, López-Rivera & Sojka Reference Guildenbecher, López-Rivera and Sojka2009; Theofanous Reference Theofanous2011). The aerodynamic breakup (or aerobreakup) of drops is essential to many spray applications, such as liquid fuel injection and spray cooling, and has therefore been studied extensively in the past decades.

Though the interaction between the drop and surrounding gas in practical aerobreakup applications usually involves many complex factors, drop aerobreakup is formulated typically in a simplified configuration, i.e. an initially stationary and spherical drop is suddenly exposed to an unbounded uniform gas stream (Theofanous & Li Reference Theofanous and Li2008; Jain et al. Reference Jain, Tyagi, Prakash, Ravikrishna and Tomar2019; Marcotte & Zaleski Reference Marcotte and Zaleski2019). Then the two-phase interfacial flows that dictate the drop deformation and dynamics are fully determined by the densities and viscosities of the drop liquid and the gas, ![]() $\rho _l$,

$\rho _l$, ![]() $\mu _l$,

$\mu _l$, ![]() $\rho _g$ and

$\rho _g$ and ![]() $\mu _g$, the surface tension

$\mu _g$, the surface tension ![]() $\sigma$, the initial drop diameter

$\sigma$, the initial drop diameter ![]() $d_0$, and the gas stream velocity

$d_0$, and the gas stream velocity ![]() $U_0$. The subscripts

$U_0$. The subscripts ![]() $g$ and

$g$ and ![]() $l$ are used to denote the properties for the gas and liquid, respectively, while the subscript

$l$ are used to denote the properties for the gas and liquid, respectively, while the subscript ![]() $0$ is used to represent the initial state. The drop is considered to be far away from the free-stream boundary. Furthermore, it is assumed that the Mach number of the gas stream is significantly lower than the critical Mach number, so the compressibility effect can be neglected. Aerobreakup of drops in a supersonic gas stream (Theofanous, Li & Dinh Reference Theofanous, Li and Dinh2004; Theofanous et al. Reference Theofanous, Li, Dinh and Chang2007; Sharma et al. Reference Sharma, Singh, Rao, Kumar and Basu2021) is outside the scope of the present study. We have also considered the liquid as a Newtonian fluid and excluded the non-Newtonian effect of the drop liquids on the process (Joseph, Belanger & Beavers Reference Joseph, Belanger and Beavers1999; Theofanous, Mitkin & Ng Reference Theofanous, Mitkin and Ng2013). As a result, the present problem can be characterized fully by four independent dimensionless parameters: the Weber number

$0$ is used to represent the initial state. The drop is considered to be far away from the free-stream boundary. Furthermore, it is assumed that the Mach number of the gas stream is significantly lower than the critical Mach number, so the compressibility effect can be neglected. Aerobreakup of drops in a supersonic gas stream (Theofanous, Li & Dinh Reference Theofanous, Li and Dinh2004; Theofanous et al. Reference Theofanous, Li, Dinh and Chang2007; Sharma et al. Reference Sharma, Singh, Rao, Kumar and Basu2021) is outside the scope of the present study. We have also considered the liquid as a Newtonian fluid and excluded the non-Newtonian effect of the drop liquids on the process (Joseph, Belanger & Beavers Reference Joseph, Belanger and Beavers1999; Theofanous, Mitkin & Ng Reference Theofanous, Mitkin and Ng2013). As a result, the present problem can be characterized fully by four independent dimensionless parameters: the Weber number ![]() ${We} = \rho _g U_0^2 d_0/\sigma$, the Reynolds number

${We} = \rho _g U_0^2 d_0/\sigma$, the Reynolds number ![]() ${Re} = \rho _g U_0 d_0/\mu _g$, the Ohnesorge number

${Re} = \rho _g U_0 d_0/\mu _g$, the Ohnesorge number ![]() ${Oh} = \mu _l/\sqrt {\rho _l d_0 \sigma }$, and the gas-to-liquid density ratio

${Oh} = \mu _l/\sqrt {\rho _l d_0 \sigma }$, and the gas-to-liquid density ratio ![]() ${r}=\rho _g/\rho _l$ (Pilch & Erdman Reference Pilch and Erdman1987; Hsiang & Faeth Reference Hsiang and Faeth1992; Joseph et al. Reference Joseph, Belanger and Beavers1999; Guildenbecher et al. Reference Guildenbecher, López-Rivera and Sojka2009). Alternative dimensionless parameters can be defined based on the above four parameters, such as the gas-to-liquid viscosity ratio

${r}=\rho _g/\rho _l$ (Pilch & Erdman Reference Pilch and Erdman1987; Hsiang & Faeth Reference Hsiang and Faeth1992; Joseph et al. Reference Joseph, Belanger and Beavers1999; Guildenbecher et al. Reference Guildenbecher, López-Rivera and Sojka2009). Alternative dimensionless parameters can be defined based on the above four parameters, such as the gas-to-liquid viscosity ratio ![]() ${m}=\mu _g/\mu _l$ (Guildenbecher et al. Reference Guildenbecher, López-Rivera and Sojka2009).

${m}=\mu _g/\mu _l$ (Guildenbecher et al. Reference Guildenbecher, López-Rivera and Sojka2009).

The present study focuses on the regime of millimetre water drops in an air stream, following the recent work by Jackiw & Ashgriz (Reference Jackiw and Ashgriz2021). In this regime, the small values of ![]() $r\sim O(10^{-3})$ and

$r\sim O(10^{-3})$ and ![]() ${Oh}\sim O(10^{-3})$, and the large value of

${Oh}\sim O(10^{-3})$, and the large value of ![]() $Re\sim O(10^3)$, indicate that surface tension plays the dominant role in resisting drop breakup. The key parameter characterizing drop dynamics and morphology evolution is

$Re\sim O(10^3)$, indicate that surface tension plays the dominant role in resisting drop breakup. The key parameter characterizing drop dynamics and morphology evolution is ![]() $We\sim O(10^2)$, which is moderate. Previous experiments using shock tubes (Hinze Reference Hinze1955; Hsiang & Faeth Reference Hsiang and Faeth1995; Joseph et al. Reference Joseph, Belanger and Beavers1999; Theofanous et al. Reference Theofanous, Li and Dinh2004) and continuous jets (Liu & Reitz Reference Liu and Reitz1993; Flock et al. Reference Flock, Guildenbecher, Chen, Sojka and Bauer2012; Zhao et al. Reference Zhao, Liu, Xu, Li and Lin2013; Opfer et al. Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014; Guildenbecher et al. Reference Guildenbecher, Gao, Chen and Sojka2017; Jackiw & Ashgriz Reference Jackiw and Ashgriz2021, Reference Jackiw and Ashgriz2022) have identified different breakup modes for low-

$We\sim O(10^2)$, which is moderate. Previous experiments using shock tubes (Hinze Reference Hinze1955; Hsiang & Faeth Reference Hsiang and Faeth1995; Joseph et al. Reference Joseph, Belanger and Beavers1999; Theofanous et al. Reference Theofanous, Li and Dinh2004) and continuous jets (Liu & Reitz Reference Liu and Reitz1993; Flock et al. Reference Flock, Guildenbecher, Chen, Sojka and Bauer2012; Zhao et al. Reference Zhao, Liu, Xu, Li and Lin2013; Opfer et al. Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014; Guildenbecher et al. Reference Guildenbecher, Gao, Chen and Sojka2017; Jackiw & Ashgriz Reference Jackiw and Ashgriz2021, Reference Jackiw and Ashgriz2022) have identified different breakup modes for low-![]() ${Oh}$ drops. The critical Weber number for breakup to occur is

${Oh}$ drops. The critical Weber number for breakup to occur is ![]() ${We}_{cr}\approx 11 \pm 2$. When

${We}_{cr}\approx 11 \pm 2$. When ![]() $We< We_{cr}$, the drop will oscillate without breakup or break into a small number of large child drops due to large-amplitude nonlinear oscillations (also referred to as the vibration breakup mode). As

$We< We_{cr}$, the drop will oscillate without breakup or break into a small number of large child drops due to large-amplitude nonlinear oscillations (also referred to as the vibration breakup mode). As ![]() $We>We_{cr}$, the drop will break into a large number of child droplets. The drop morphology upon breakup varies significantly with

$We>We_{cr}$, the drop will break into a large number of child droplets. The drop morphology upon breakup varies significantly with ![]() ${We}$, from bag, bag-stem (or multi-mode), multi-bag and stripping (or sheet-thinning mode) (Hsiang & Faeth Reference Hsiang and Faeth1995; Liu & Reitz Reference Liu and Reitz1997; Guildenbecher et al. Reference Guildenbecher, López-Rivera and Sojka2009; Jackiw & Ashgriz Reference Jackiw and Ashgriz2021). When

${We}$, from bag, bag-stem (or multi-mode), multi-bag and stripping (or sheet-thinning mode) (Hsiang & Faeth Reference Hsiang and Faeth1995; Liu & Reitz Reference Liu and Reitz1997; Guildenbecher et al. Reference Guildenbecher, López-Rivera and Sojka2009; Jackiw & Ashgriz Reference Jackiw and Ashgriz2021). When ![]() ${We}$ is sufficiently large, such as

${We}$ is sufficiently large, such as ![]() $We>10^3$, it has been claimed in previous studies that the drop breaks in the catastrophic mode (Joseph et al. Reference Joseph, Belanger and Beavers1999). However, more recent high-resolution experimental diagnostics suggest that such a breakup mode does not exist (Theofanous & Li Reference Theofanous and Li2008). Different classifications of the breakup regimes have also been proposed, based on the dominant breakup mechanisms (Theofanous et al. Reference Theofanous, Li and Dinh2004). Since the bag, bag-stem and multi-bag breakup modes all involve the formation and inflation of bags, which is driven by the Rayleigh–Taylor instability, they have been reclassified as the Rayleigh–Taylor piercing mode. On the other hand, the sheet-thinning mode has been renamed the shear-induced entrainment mode, since it is driven mainly by the shear on the interface periphery.

$We>10^3$, it has been claimed in previous studies that the drop breaks in the catastrophic mode (Joseph et al. Reference Joseph, Belanger and Beavers1999). However, more recent high-resolution experimental diagnostics suggest that such a breakup mode does not exist (Theofanous & Li Reference Theofanous and Li2008). Different classifications of the breakup regimes have also been proposed, based on the dominant breakup mechanisms (Theofanous et al. Reference Theofanous, Li and Dinh2004). Since the bag, bag-stem and multi-bag breakup modes all involve the formation and inflation of bags, which is driven by the Rayleigh–Taylor instability, they have been reclassified as the Rayleigh–Taylor piercing mode. On the other hand, the sheet-thinning mode has been renamed the shear-induced entrainment mode, since it is driven mainly by the shear on the interface periphery.

The impulsive gas acceleration and continuous non-zero relative velocity between the gas and the drop induce both viscous and inviscid, steady and unsteady drag forces on the drop (Maxey & Riley Reference Maxey and Riley1983; Mei, Lawrence & Adrian Reference Mei, Lawrence and Adrian1991; Ling, Parmar & Balachandar Reference Ling, Parmar and Balachandar2013), resulting in a streamwise acceleration of the drop. As the drop deforms, the gas flow will be modulated, which in turn influences the drop deformation. Consequently, although the surrounding gas flow in the far field is steady, the drop deformation and the gas flow around the drop are highly unsteady. According to the scaling analysis (Ling et al. Reference Ling, Parmar and Balachandar2013), the ratios between the unsteady forces and the quasi-steady drag are proportional to ![]() $1/{r}$. For the present cases with

$1/{r}$. For the present cases with ![]() $r\ll 1$, the unsteady forces will have a small contribution to the overall drop acceleration. The drop dynamics are dictated by the quasi-steady drag, and the drop velocity will increase following the gas viscous time scale. For cases with a large

$r\ll 1$, the unsteady forces will have a small contribution to the overall drop acceleration. The drop dynamics are dictated by the quasi-steady drag, and the drop velocity will increase following the gas viscous time scale. For cases with a large ![]() ${r}$, such as in a pressurized gas environment, the contribution of the unsteady forces to the drop acceleration cannot be ignored (Jain et al. Reference Jain, Tyagi, Prakash, Ravikrishna and Tomar2019; Marcotte & Zaleski Reference Marcotte and Zaleski2019).

${r}$, such as in a pressurized gas environment, the contribution of the unsteady forces to the drop acceleration cannot be ignored (Jain et al. Reference Jain, Tyagi, Prakash, Ravikrishna and Tomar2019; Marcotte & Zaleski Reference Marcotte and Zaleski2019).

Aerodynamic breakup of an isolated drop involves rich physics, and the investigation of the subject is challenging for both experiments and simulations. Due to the highly unsteady flow and complex topology change, an analytical approach is generally not viable, except for limiting cases (Vanden-Broeck & Keller Reference Vanden-Broeck and Keller1980; Miksis, Vanden-Broeck & Keller Reference Miksis, Vanden-Broeck and Keller1981). Previous studies of drop aerobreakup are based on experiments. Thanks to advancements in high-speed imaging, the temporal evolution of the drop morphology can be captured clearly (Theofanous & Li Reference Theofanous and Li2008; Flock et al. Reference Flock, Guildenbecher, Chen, Sojka and Bauer2012; Opfer et al. Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014; Jackiw & Ashgriz Reference Jackiw and Ashgriz2021). With more sophisticated diagnostics, such as digital in-line holography, the velocity and size of the child droplets can also be measured (Gao et al. Reference Gao, Guildenbecher, Reu, Kulkarni, Sojka and Chen2013; Guildenbecher et al. Reference Guildenbecher, Gao, Chen and Sojka2017). However, it is still challenging to measure high-level details of the drop deformation and gas flows due to the small length and time scales involved. For example, for the bag breakup mode, it is difficult to visualize the velocity and pressure fields inside the bag and to measure directly the thickness and velocity in the bag sheet (Opfer et al. Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014). Therefore, high-fidelity interface-resolved numerical simulations that can provide these high-level details are essential to investigate drop aerobreakup (Jain et al. Reference Jain, Tyagi, Prakash, Ravikrishna and Tomar2019; Marcotte & Zaleski Reference Marcotte and Zaleski2019).

Fully-resolved simulations of drop aerobreakup are expensive if one aims to resolve all the length scales. For example, for a millimetre-sized drop that breaks in the bag mode, the bag sheet thickness reduces to tens of nanometres before the bag sheet ruptures (Williams & Davis Reference Williams and Davis1982; Burelbach, Bankoff & Davis Reference Burelbach, Bankoff and Davis1988). Previous numerical studies could afford to use a high mesh resolution for two-dimensional (2-D) axisymmetric simulations only (Han & Tryggvason Reference Han and Tryggvason1999, Reference Han and Tryggvason2001; Jing & Xu Reference Jing and Xu2010; Chang, Deng & Theofanous Reference Chang, Deng and Theofanous2013; Jalaal & Mehravaran Reference Jalaal and Mehravaran2014; Strotos et al. Reference Strotos, Malgarinos, Nikolopoulos and Gavaises2016; Stefanitsis et al. Reference Stefanitsis, Malgarinos, Strotos, Nikolopoulos, Kakaras and Gavaises2017; Jain et al. Reference Jain, Tyagi, Prakash, Ravikrishna and Tomar2019; Marcotte & Zaleski Reference Marcotte and Zaleski2019). However, as will be shown later, 2-D axisymmetric simulations will not correctly capture the bag formation in the high ![]() ${Re}$ regime since the turbulent wake and its influence on the drop deformation are not resolved faithfully. That explains why even converged 2-D simulations fail to reproduce the bag morphology observed in experiments (Marcotte & Zaleski Reference Marcotte and Zaleski2019). The mesh resolutions in previous three-dimensional (3-D) simulations are generally much lower, and are insufficient to capture the turbulent wake and the bag development (Kekesi, Amberg & Wittberg Reference Kekesi, Amberg and Wittberg2014; Jain et al. Reference Jain, Prakash, Tomar and Ravikrishna2015, Reference Jain, Tyagi, Prakash, Ravikrishna and Tomar2019; Yang et al. Reference Yang, Jia, Sun and Wang2016). There remains a significant gap between the existing simulation results and experimental data.

${Re}$ regime since the turbulent wake and its influence on the drop deformation are not resolved faithfully. That explains why even converged 2-D simulations fail to reproduce the bag morphology observed in experiments (Marcotte & Zaleski Reference Marcotte and Zaleski2019). The mesh resolutions in previous three-dimensional (3-D) simulations are generally much lower, and are insufficient to capture the turbulent wake and the bag development (Kekesi, Amberg & Wittberg Reference Kekesi, Amberg and Wittberg2014; Jain et al. Reference Jain, Prakash, Tomar and Ravikrishna2015, Reference Jain, Tyagi, Prakash, Ravikrishna and Tomar2019; Yang et al. Reference Yang, Jia, Sun and Wang2016). There remains a significant gap between the existing simulation results and experimental data.

An important motivation for the study of drop aerobreakup is to develop sub-scale models that can be used in simulations of sprays consisting of a huge number of droplets, for which it is intractable to resolve the interface of each individual drop. The cell size used for simulations of sprays in practical scales is typically much larger than the size of individual drops, therefore the drops are represented by Lagrangian point-particles (Apte, Gorokhovski & Moin Reference Apte, Gorokhovski and Moin2003; Pai & Subramaniam Reference Pai and Subramaniam2006; Balachandar Reference Balachandar2009). The drop motion, shape deformation, topology change, and heat and mass transfer between the drop and the surrounding flow need to be captured by subgrid models (O'Rourke & Amsden Reference O'Rourke and Amsden1987; Hsiang & Faeth Reference Hsiang and Faeth1992). When drop breakup occurs, one also needs to estimate the starting time and end time (Chou & Faeth Reference Chou and Faeth1998; Dai & Faeth Reference Dai and Faeth2001) and the statistics of the child droplets produced (O'Rourke & Amsden Reference O'Rourke and Amsden1987; Hsiang & Faeth Reference Hsiang and Faeth1992; Wert Reference Wert1995; Zhao et al. Reference Zhao, Liu, Xu, Li and Lin2013). For the moderate ![]() $We$ regime, the Taylor analogy breakup (TAB) model (O'Rourke & Amsden Reference O'Rourke and Amsden1987) and its subsequent variants (Tanner Reference Tanner1997; Park, Yoon & Hwang Reference Park, Yoon and Hwang2002) have been adopted widely to predict the drop deformation (the time evolution of the drop lateral radius) and the breakup time. The TAB models are based simply on the mass–spring–damper analogy, and there exist coefficients that need to be calibrated based on experimental data. Models that incorporate the flow physics have also been proposed. In the model of Villermaux & Bossa (Reference Villermaux and Bossa2009), the pressure distribution induced by the stagnation flow on the windward surface is considered as the driving force for the lateral expansion of a thin liquid disk, although the model was also extended to predict the overall drop deformation (Kulkarni & Sojka Reference Kulkarni and Sojka2014; Stefanitsis et al. Reference Stefanitsis, Strotos, Nikolopoulos, Kakaras and Gavaises2019b; Rimbert et al. Reference Rimbert, Escobar, Meignen, Hadj-Achour and Gradeck2020; Jackiw & Ashgriz Reference Jackiw and Ashgriz2021). Since the Rayleigh–Taylor instability (RTI) plays a significant role in the formation and development of bags, models based on linear RTI analysis have also been developed to predict the critical condition for the bag formation and also the number of bags to be formed in the multi-bag mode (Harper, Grube & Chang Reference Harper, Grube and Chang1972; Joseph et al. Reference Joseph, Belanger and Beavers1999; Theofanous et al. Reference Theofanous, Li and Dinh2004). For very high

$We$ regime, the Taylor analogy breakup (TAB) model (O'Rourke & Amsden Reference O'Rourke and Amsden1987) and its subsequent variants (Tanner Reference Tanner1997; Park, Yoon & Hwang Reference Park, Yoon and Hwang2002) have been adopted widely to predict the drop deformation (the time evolution of the drop lateral radius) and the breakup time. The TAB models are based simply on the mass–spring–damper analogy, and there exist coefficients that need to be calibrated based on experimental data. Models that incorporate the flow physics have also been proposed. In the model of Villermaux & Bossa (Reference Villermaux and Bossa2009), the pressure distribution induced by the stagnation flow on the windward surface is considered as the driving force for the lateral expansion of a thin liquid disk, although the model was also extended to predict the overall drop deformation (Kulkarni & Sojka Reference Kulkarni and Sojka2014; Stefanitsis et al. Reference Stefanitsis, Strotos, Nikolopoulos, Kakaras and Gavaises2019b; Rimbert et al. Reference Rimbert, Escobar, Meignen, Hadj-Achour and Gradeck2020; Jackiw & Ashgriz Reference Jackiw and Ashgriz2021). Since the Rayleigh–Taylor instability (RTI) plays a significant role in the formation and development of bags, models based on linear RTI analysis have also been developed to predict the critical condition for the bag formation and also the number of bags to be formed in the multi-bag mode (Harper, Grube & Chang Reference Harper, Grube and Chang1972; Joseph et al. Reference Joseph, Belanger and Beavers1999; Theofanous et al. Reference Theofanous, Li and Dinh2004). For very high ![]() ${We}$, the drop breaks in the stripping mode, and the corresponding breakup models are based on the shear instability (Ranger & Nicholls Reference Ranger and Nicholls1969) and the rupture of the thinning liquid sheets (Liu & Reitz Reference Liu and Reitz1997; Lee & Reitz Reference Lee and Reitz2001). Comprehensive reviews of these models have been given in previous studies (Guildenbecher et al. Reference Guildenbecher, López-Rivera and Sojka2009; Jackiw & Ashgriz Reference Jackiw and Ashgriz2021), thus are not repeated here.

${We}$, the drop breaks in the stripping mode, and the corresponding breakup models are based on the shear instability (Ranger & Nicholls Reference Ranger and Nicholls1969) and the rupture of the thinning liquid sheets (Liu & Reitz Reference Liu and Reitz1997; Lee & Reitz Reference Lee and Reitz2001). Comprehensive reviews of these models have been given in previous studies (Guildenbecher et al. Reference Guildenbecher, López-Rivera and Sojka2009; Jackiw & Ashgriz Reference Jackiw and Ashgriz2021), thus are not repeated here.

Though significant progress has been made in understanding the physics that drives the deformation and breakup of drops at moderate ![]() ${We}$, important fundamental questions remain unanswered. When

${We}$, important fundamental questions remain unanswered. When ![]() ${We}$ is just above the critical value, a single bag is formed, and the breakup starts when the bag sheet ruptures. When

${We}$ is just above the critical value, a single bag is formed, and the breakup starts when the bag sheet ruptures. When ![]() ${We}$ is very large, liquid sheets are formed at the equator and break into small droplets before a bag gets a chance to form near the centre. Between these two asymptotic limits, when

${We}$ is very large, liquid sheets are formed at the equator and break into small droplets before a bag gets a chance to form near the centre. Between these two asymptotic limits, when ![]() ${We}$ is moderate, the drop can deform to a variety of shapes before breakup occurs (Jackiw & Ashgriz Reference Jackiw and Ashgriz2021). The variation in breakup morphology is very sensitive to

${We}$ is moderate, the drop can deform to a variety of shapes before breakup occurs (Jackiw & Ashgriz Reference Jackiw and Ashgriz2021). The variation in breakup morphology is very sensitive to ![]() ${We}$ in the moderate range. As the drop is accelerated by the free stream, it experiences baroclinic torque and RTI on its windward side. Several models based on the linear stability analysis of RTI on a liquid layer of finite thickness (Mikaelian Reference Mikaelian1990, Reference Mikaelian1996) have been proposed to predict the critical Weber number (Joseph et al. Reference Joseph, Belanger and Beavers1999; Theofanous et al. Reference Theofanous, Li and Dinh2004). However, the significance of the RTI, and whether the linear stability model captures the nonlinear development of the bag and the bag morphology change from a simple axisymmetric bag to more complex shapes, remain uncertain, despite its presence on the interface (Guildenbecher et al. Reference Guildenbecher, López-Rivera and Sojka2009). It has been suggested that the Laplace pressure on the edge of the drop/disk contributes to hindering the bag formation or development (Guildenbecher et al. Reference Guildenbecher, López-Rivera and Sojka2009), yet solid evidence to support the argument remains absent.

${We}$ in the moderate range. As the drop is accelerated by the free stream, it experiences baroclinic torque and RTI on its windward side. Several models based on the linear stability analysis of RTI on a liquid layer of finite thickness (Mikaelian Reference Mikaelian1990, Reference Mikaelian1996) have been proposed to predict the critical Weber number (Joseph et al. Reference Joseph, Belanger and Beavers1999; Theofanous et al. Reference Theofanous, Li and Dinh2004). However, the significance of the RTI, and whether the linear stability model captures the nonlinear development of the bag and the bag morphology change from a simple axisymmetric bag to more complex shapes, remain uncertain, despite its presence on the interface (Guildenbecher et al. Reference Guildenbecher, López-Rivera and Sojka2009). It has been suggested that the Laplace pressure on the edge of the drop/disk contributes to hindering the bag formation or development (Guildenbecher et al. Reference Guildenbecher, López-Rivera and Sojka2009), yet solid evidence to support the argument remains absent.

The goal of the present study is to investigate the aerobreakup of an isolated drop at moderate Weber numbers through detailed interface-resolved 3-D numerical simulation. By using advanced numerical techniques, including the mass–momentum consistent volume-of-fluid method (Arrufat et al. Reference Arrufat, Crialesi-Esposito, Fuster, Ling, Malan, Pal, Scardovelli, Tryggvason and Zaleski2020; Zhang, Popinet & Ling Reference Zhang, Popinet and Ling2020), balanced-force surface tension discretization (Popinet Reference Popinet2009), and adaptive mesh refinement, we aim to resolve fully the two-phase turbulent interfacial flows involved in aerobreakup through large-scale parallel computations. The drop's initial diameter and fluid properties are kept unchanged, and the free-stream gas velocity is varied for a parametric study. Although typically the lateral radius of the drop increases monotonically in time (Flock et al. Reference Flock, Guildenbecher, Chen, Sojka and Bauer2012; Opfer et al. Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014; Jackiw & Ashgriz Reference Jackiw and Ashgriz2021), the overall deformation is a complex process consisting of different phases with distinct features. The high-level details revealed by the simulation results will be used to identify the dominant mechanisms that dictate the deformation in each phase, and also to characterize the effect of ![]() ${We}$.

${We}$.

For the range of ![]() ${We}$ considered, the drop will deform from its initial spherical shape to a forward bag with the opening facing the upstream direction. Although it is of great interest to study the rupture of thin bag sheets and the statistics of the droplets generated by the bag and rim breakups (Guildenbecher et al. Reference Guildenbecher, Gao, Chen and Sojka2017; Jackiw & Ashgriz Reference Jackiw and Ashgriz2022), the mesh resolution required to resolve fully the sheet rupture and hole formation is beyond the current available computational capability. If a liquid sheet breaks due to molecular forces, then the thickness must be reduced to tens of nanometres. For simulations of millimetre drops, a fully resolved simulation would need to cover over six orders of magnitude in length scales, which is obviously impractical even with today's computer power. Therefore, the present study will focus mainly on the drop deformation and bag formation and development before the bag sheet rupture occurs. The present simulations can be considered fully resolved and mesh-independent up to the early stage of the bag inflation, but not for the sheet rupture and child drop statistics. Nevertheless, the simulation results still provide important insights into the bag rupture mechanisms, such as the hole–hole interaction, which remain not fully understood. Since the occurrence of holes in the liquid sheet is random, ensemble averaging and statistics of multiple realizations (e.g. hole appearing locations and the number of holes) will be required to characterize fully the rupture dynamics and the statistics of the droplets formed (Mostert, Popinet & Deike Reference Mostert, Popinet and Deike2022; Tang, Adcock & Mostert Reference Tang, Adcock and Mostert2023), though such studies are outside the scope of the present work.

${We}$ considered, the drop will deform from its initial spherical shape to a forward bag with the opening facing the upstream direction. Although it is of great interest to study the rupture of thin bag sheets and the statistics of the droplets generated by the bag and rim breakups (Guildenbecher et al. Reference Guildenbecher, Gao, Chen and Sojka2017; Jackiw & Ashgriz Reference Jackiw and Ashgriz2022), the mesh resolution required to resolve fully the sheet rupture and hole formation is beyond the current available computational capability. If a liquid sheet breaks due to molecular forces, then the thickness must be reduced to tens of nanometres. For simulations of millimetre drops, a fully resolved simulation would need to cover over six orders of magnitude in length scales, which is obviously impractical even with today's computer power. Therefore, the present study will focus mainly on the drop deformation and bag formation and development before the bag sheet rupture occurs. The present simulations can be considered fully resolved and mesh-independent up to the early stage of the bag inflation, but not for the sheet rupture and child drop statistics. Nevertheless, the simulation results still provide important insights into the bag rupture mechanisms, such as the hole–hole interaction, which remain not fully understood. Since the occurrence of holes in the liquid sheet is random, ensemble averaging and statistics of multiple realizations (e.g. hole appearing locations and the number of holes) will be required to characterize fully the rupture dynamics and the statistics of the droplets formed (Mostert, Popinet & Deike Reference Mostert, Popinet and Deike2022; Tang, Adcock & Mostert Reference Tang, Adcock and Mostert2023), though such studies are outside the scope of the present work.

The rest of the paper will be organized as follows. Subsection 2.1 introduces the governing equations, and § 2.2 describes the numerical methods used in the present simulations. The physical parameters and simulation set-up are presented in § 2.3. Before discussing the simulation results, § 3 defines the characteristic length and time scales used to characterize the drop shape and gas flows. Grid-refinement and validation studies are presented in § 4. The simulation results identify different deformation phases, which are discussed in sequence in § 5. The effect of drop deformation on the aerodynamic drag and lift exerted on the drop is discussed in § 6. Finally, § 7 concludes the key findings of the present study.

2. Simulation methods

2.1. Governing equations

The two-phase interfacial flows are governed by the incompressible Navier–Stokes equations with surface tension,

where ![]() $\rho, u_i, p, \mu$ represent density, velocity vector, pressure and viscosity, respectively. The Dirac distribution function

$\rho, u_i, p, \mu$ represent density, velocity vector, pressure and viscosity, respectively. The Dirac distribution function ![]() $\delta _s$ is localized on the interface. The surface tension coefficient

$\delta _s$ is localized on the interface. The surface tension coefficient ![]() $\sigma$ is constant, and

$\sigma$ is constant, and ![]() $\kappa$ and

$\kappa$ and ![]() $n_i$ represent the curvature and normal vector of the interface.

$n_i$ represent the curvature and normal vector of the interface.

The gas and liquid phases are distinguished by the liquid volume fraction ![]() $c$, the evolution of which follows the advection equation

$c$, the evolution of which follows the advection equation

After spatial discretization, the cells with only liquid or gas will exhibit ![]() $c=1$ and 0, respectively, while for cells containing the gas–liquid interface,

$c=1$ and 0, respectively, while for cells containing the gas–liquid interface, ![]() $0< c<1$. The density and viscosity are both defined based on the arithmetic mean:

$0< c<1$. The density and viscosity are both defined based on the arithmetic mean:

2.2. Numerical methods

The governing equations (2.1)–(2.3) are solved using the open-source, multiphase flow solver Basilisk. The Basilisk solver uses a finite-volume method for spatial discretization. The projection method is used to incorporate the incompressibility condition. The advection equation (2.3) is solved via a geometrical volume-of-fluid (VOF) method (Scardovelli & Zaleski Reference Scardovelli and Zaleski1999). The advection of momentum across the interface is conducted consistently with the VOF advection (Arrufat et al. Reference Arrufat, Crialesi-Esposito, Fuster, Ling, Malan, Pal, Scardovelli, Tryggvason and Zaleski2020; Zhang et al. Reference Zhang, Popinet and Ling2020). The mass–momentum consistency is essential for multiphase flows with large density contrast (Zhang et al. Reference Zhang, Popinet and Ling2020). The balanced-force method is used to discretize the singular surface tension term in the momentum equation (Popinet Reference Popinet2009). The interface curvature required to calculate surface tension is computed based on the height-function method (Popinet Reference Popinet2009). The staggered-in-time discretization of the volume fraction/density and pressure leads to a formally second-order-accurate time discretization (Popinet Reference Popinet2009). An adaptive quadtree/octree mesh is used to discretize the computational domain, which allows adaptive mesh refinement in user-defined regions. The mesh adaptation is based on the wavelet estimate of the discretization errors of the liquid volume fraction and velocity (van Hooft et al. Reference van Hooft, Popinet, van Heerwaarden, van der Linden, de Roode and van de Wiel2018). The parallelization of the solver is done through a tree decomposition to guarantee high parallel performance even if a large number of levels of octree cells are used. Numerous validation studies for the Basilisk solver can be found on the Basilisk website and also in our previous studies (Sakakeeny & Ling Reference Sakakeeny and Ling2020, Reference Sakakeeny and Ling2021; Zhang et al. Reference Zhang, Popinet and Ling2020; Sakakeeny et al. Reference Sakakeeny, Deshpande, Deb, Alvarado and Ling2021).

2.3. Simulation set-up

The spherical drop is initially placed in a computational domain filled with stationary gas. We have considered both 2-D-axisymmetric and 3-D domains, as shown in figures 1(a) and 1(b), respectively. At ![]() $t=0^+$, a uniform velocity boundary condition (BC) is imposed on the left boundary of the domain, while the pressure outflow boundary condition is applied to the right boundary. Due to the incompressibility condition, the gas is suddenly accelerated to

$t=0^+$, a uniform velocity boundary condition (BC) is imposed on the left boundary of the domain, while the pressure outflow boundary condition is applied to the right boundary. Due to the incompressibility condition, the gas is suddenly accelerated to ![]() $U_0$ in an infinitesimal time (one time step in the simulation).

$U_0$ in an infinitesimal time (one time step in the simulation).

Figure 1. Schematics of the computational domains for (a) 2-D-axisymmetric and (b) 3-D simulations.

All lateral boundaries in the 3-D domain are considered as slip walls. For the 2-D domain, the bottom is the axis and the top is a slip wall. The 2-D domain is a square with edge length ![]() $l/d_0=16$, while the 3-D domain is a cube with edge length

$l/d_0=16$, while the 3-D domain is a cube with edge length ![]() $l/d_0=32$. The domain size is sufficient to resolve the wake behind the drop during the time considered. For all 2-D and 3-D simulations, the drop is initially placed

$l/d_0=32$. The domain size is sufficient to resolve the wake behind the drop during the time considered. For all 2-D and 3-D simulations, the drop is initially placed ![]() $x_0/d_0=3$ away from the inlet. In the 3-D simulations, the initial location of the drop is at the centre of the

$x_0/d_0=3$ away from the inlet. In the 3-D simulations, the initial location of the drop is at the centre of the ![]() $y$–

$y$–![]() $z$ cross-section.

$z$ cross-section.

The physical parameters used in the present simulations are chosen to be similar to the experiment of Jackiw & Ashgriz (Reference Jackiw and Ashgriz2021). The liquid and gas are water and air at room temperature, and their fluid properties are given in table 1. The initial drop diameter is fixed at ![]() $d_0=1.9$ mm. The corresponding gas-to-liquid density and viscosity ratios are thus small,

$d_0=1.9$ mm. The corresponding gas-to-liquid density and viscosity ratios are thus small, ![]() ${r}=0.0012$ and

${r}=0.0012$ and ![]() ${m}=0.018$, respectively. The Ohnesorge number

${m}=0.018$, respectively. The Ohnesorge number ![]() ${Oh}=0.0026$ is very small, indicating that the effect of liquid viscosity on drop breakup is small compared to that of surface tension, and the latter is the dominant force to resist the drop deformation/breakup induced by interaction with the gas stream. Therefore, the Weber number

${Oh}=0.0026$ is very small, indicating that the effect of liquid viscosity on drop breakup is small compared to that of surface tension, and the latter is the dominant force to resist the drop deformation/breakup induced by interaction with the gas stream. Therefore, the Weber number ![]() ${We}$ is the key dimensionless parameter that characterizes the aerobreakup dynamics. A parametric study of

${We}$ is the key dimensionless parameter that characterizes the aerobreakup dynamics. A parametric study of ![]() $We$ is performed here by varying

$We$ is performed here by varying ![]() $U_0$ from 18.7 to

$U_0$ from 18.7 to ![]() $24.0\ {\rm m}\ {\rm s}^{-1}$. The Reynolds number will vary from approximately 2400 to 3000 correspondingly. More cases were simulated, but we will focus the discussion on the five cases shown in table 2.

$24.0\ {\rm m}\ {\rm s}^{-1}$. The Reynolds number will vary from approximately 2400 to 3000 correspondingly. More cases were simulated, but we will focus the discussion on the five cases shown in table 2.

Table 1. Fluid properties for simulation cases.

Table 2. Simulation cases and key parameters.

The 2-D/3-D domains are discretized by quadtree/octree meshes, which are adapted dynamically based on the wavelet estimates of the discretization errors of the liquid volume fraction and all velocity components (van Hooft et al. Reference van Hooft, Popinet, van Heerwaarden, van der Linden, de Roode and van de Wiel2018). The minimum cell size is controlled by the maximum refinement level ![]() $\mathcal {L}$, i.e.

$\mathcal {L}$, i.e. ![]() $\varDelta _{min}=l/2^{\mathcal {L}}$. For 2-D simulations,

$\varDelta _{min}=l/2^{\mathcal {L}}$. For 2-D simulations, ![]() $\mathcal {L}$ has been varied from 12 to 15, corresponding to 256 to 2048 minimum quadtree cells across the initial drop diameter, i.e.

$\mathcal {L}$ has been varied from 12 to 15, corresponding to 256 to 2048 minimum quadtree cells across the initial drop diameter, i.e. ![]() $N=d_0/\varDelta _{min}=256$ to 2048. Due to the higher computational cost for 3-D simulations, we have used a different mesh adaptation strategy. As will be shown later, the mesh resolution required to capture the early deformation of the drop is significantly lower than that required to resolve the thin liquid sheet in the bag. Therefore, we have used a maximum refinement level

$N=d_0/\varDelta _{min}=256$ to 2048. Due to the higher computational cost for 3-D simulations, we have used a different mesh adaptation strategy. As will be shown later, the mesh resolution required to capture the early deformation of the drop is significantly lower than that required to resolve the thin liquid sheet in the bag. Therefore, we have used a maximum refinement level ![]() $\mathcal {L}=12$ to 14, which is equivalent to

$\mathcal {L}=12$ to 14, which is equivalent to ![]() $N=128$ or 512 to start the simulations, for the purpose of confirming that the resolution is enough to capture the drop deformation until the bag is formed. As the bag grows and the sheet thickness decreases,

$N=128$ or 512 to start the simulations, for the purpose of confirming that the resolution is enough to capture the drop deformation until the bag is formed. As the bag grows and the sheet thickness decreases, ![]() $\mathcal {L}$ is then increased up to 16 (

$\mathcal {L}$ is then increased up to 16 (![]() $N=2048$). For the case

$N=2048$). For the case ![]() ${We}=10.9$, since a thin bag sheet is never formed,

${We}=10.9$, since a thin bag sheet is never formed, ![]() $\mathcal {L}=12$ (

$\mathcal {L}=12$ (![]() $N=256$) is used throughout the simulation.

$N=256$) is used throughout the simulation.

According to the knowledge of the authors, the current mesh resolution is significantly higher than all previous numerical studies, including both 2-D and 3-D simulations in the literature, while the domain is large enough to resolve the wake (Jain et al. Reference Jain, Tyagi, Prakash, Ravikrishna and Tomar2019; Marcotte & Zaleski Reference Marcotte and Zaleski2019). For the 3-D domain, the mesh for ![]() $N=2048$ corresponds to 16 levels of adaptively refined octree cells, which is equivalent to

$N=2048$ corresponds to 16 levels of adaptively refined octree cells, which is equivalent to ![]() $2.8\times 10^{14}$ uniform Cartesian cells. Generally, the total number of octree cells increases over time, as the drop surface area increases and the wake develops. For the case

$2.8\times 10^{14}$ uniform Cartesian cells. Generally, the total number of octree cells increases over time, as the drop surface area increases and the wake develops. For the case ![]() ${We}=15.3$, the number of octree cells reaches approximately 500 million. The high-performance tree-decomposition parallelization technique in the Basilisk solver is essential to guarantee efficient simulations using such large numbers of levels (up to 16), computational cores (up to 3584), and octree cells (up to 500 million).

${We}=15.3$, the number of octree cells reaches approximately 500 million. The high-performance tree-decomposition parallelization technique in the Basilisk solver is essential to guarantee efficient simulations using such large numbers of levels (up to 16), computational cores (up to 3584), and octree cells (up to 500 million).

For the present study, the drop diameter is 1.9 mm, and the minimum cell size for ![]() $N=2048$ is approximately

$N=2048$ is approximately ![]() $\varDelta _{min} = 0.9\ \mathrm {\mu } {\rm m}$, which is still significantly larger than the physical cutoff length scale dictated by van der Waals forces (

$\varDelta _{min} = 0.9\ \mathrm {\mu } {\rm m}$, which is still significantly larger than the physical cutoff length scale dictated by van der Waals forces (![]() ${\sim }O(10\ \text {nm})$). Therefore, the interfaces’ pinching and hole formation induced by van der Waals forces will not be captured in the simulation. The hole nucleation in the liquid sheet here is due to the numerical cutoff length, i.e. the minimum cell size

${\sim }O(10\ \text {nm})$). Therefore, the interfaces’ pinching and hole formation induced by van der Waals forces will not be captured in the simulation. The hole nucleation in the liquid sheet here is due to the numerical cutoff length, i.e. the minimum cell size ![]() $\varDelta _{min}$. When the sheet thickness is smaller than approximately

$\varDelta _{min}$. When the sheet thickness is smaller than approximately ![]() $2\varDelta _{min}$, the flow and pressure in the liquid cannot be well resolved, and the thin region of the liquid sheet represented by the VOF field will be perturbed, and numerical pinching of the interfaces will occur. The numerical breakup leads to earlier hole formation, and as a result, the bag will break at a size smaller than what was observed in experiments. Nevertheless, as indicated in previous experimental studies, holes are observed in the liquid sheet with thickness larger than the length for active molecular forces (Lhuissier & Villermaux Reference Lhuissier and Villermaux2012; Opfer et al. Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014), probably due to tiny bubbles in the liquid sheet. A more detailed discussion of the effect of mesh resolution on the bag breakup dynamics will be given later, in the results section.

$2\varDelta _{min}$, the flow and pressure in the liquid cannot be well resolved, and the thin region of the liquid sheet represented by the VOF field will be perturbed, and numerical pinching of the interfaces will occur. The numerical breakup leads to earlier hole formation, and as a result, the bag will break at a size smaller than what was observed in experiments. Nevertheless, as indicated in previous experimental studies, holes are observed in the liquid sheet with thickness larger than the length for active molecular forces (Lhuissier & Villermaux Reference Lhuissier and Villermaux2012; Opfer et al. Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014), probably due to tiny bubbles in the liquid sheet. A more detailed discussion of the effect of mesh resolution on the bag breakup dynamics will be given later, in the results section.

The 2-D simulations were run on the Baylor University cluster Kodiak using 4–36 cores (Intel Xeon Gold 6140 processor). The most refined simulation (![]() $N=2048$) takes approximately 20 days using 36 cores. The 3-D simulations were run on the TACC-Stampede2 (Intel Xeon Platinum 8160) and TACC-Frontera (Intel Xeon Platinum 8280) machines, using up to 3584 cores. The simulation time varies with cases, and the longest one takes approximately 50 days.

$N=2048$) takes approximately 20 days using 36 cores. The 3-D simulations were run on the TACC-Stampede2 (Intel Xeon Platinum 8160) and TACC-Frontera (Intel Xeon Platinum 8280) machines, using up to 3584 cores. The simulation time varies with cases, and the longest one takes approximately 50 days.

3. Parameters to characterize drop aerobreakup

Before we present and discuss the results, we will first introduce the parameters to be measured in the simulation to characterize the drop shape, dynamics and turbulent flows involved in the drop aerobreakup process.

3.1. Drop morphology

To characterize the drop shape at a given time, the maximum and minimum interfacial positions along the Cartesian coordinates were measured, i.e. ![]() $x_{max}$,

$x_{max}$, ![]() $x_{min}$,

$x_{min}$, ![]() $y_{max}$,

$y_{max}$, ![]() $y_{min}$,

$y_{min}$, ![]() $z_{max}$,

$z_{max}$, ![]() $z_{min}$, as shown in figure 2(a). Furthermore, we also measured the maximum and minimum interfacial positions along the

$z_{min}$, as shown in figure 2(a). Furthermore, we also measured the maximum and minimum interfacial positions along the ![]() $x$-axis (along the streamwise direction),

$x$-axis (along the streamwise direction), ![]() $x_{max,a}$,

$x_{max,a}$, ![]() $x_{min,a}$. Based on these measurements, several characteristic length scales can be obtained.

$x_{min,a}$. Based on these measurements, several characteristic length scales can be obtained.

(i) Length of the drop,

$L=x_{max}- x_{min}$.

$L=x_{max}- x_{min}$.(ii) Lateral radius of the drop,

$R=(y_{max}-y_{min}+z_{max}-z_{min})/4$. When the drop shape is axisymmetric, the maximum lateral radius is

$R=(y_{max}-y_{min}+z_{max}-z_{min})/4$. When the drop shape is axisymmetric, the maximum lateral radius is  $R=y_{max}=-y_{min}=z_{max}=-z_{min}$; otherwise,

$R=y_{max}=-y_{min}=z_{max}=-z_{min}$; otherwise,  $R$ is the average for the

$R$ is the average for the  $y$- and

$y$- and  $z$-directions.

$z$-directions.(iii) Thickness of the sheet along the

$x$-axis,

$x$-axis,  $h_{a}=x_{max,a}-x_{min,a}$. At early times, when the drop shape is axisymmetric and both windward and leeward sides are convex,

$h_{a}=x_{max,a}-x_{min,a}$. At early times, when the drop shape is axisymmetric and both windward and leeward sides are convex,  $h_a=L$. At later times, when the drop deforms to a bag,

$h_a=L$. At later times, when the drop deforms to a bag,  $h_a$ represents the sheet thickness at the centre of the bag, as shown in figure 2(b).

$h_a$ represents the sheet thickness at the centre of the bag, as shown in figure 2(b).(iv) Length of the forward bag,

$L_{fb}=x_{min,a}- x_{min}$. Here, ‘forward bag’ refers to the bag with the opening facing the upstream direction.

$L_{fb}=x_{min,a}- x_{min}$. Here, ‘forward bag’ refers to the bag with the opening facing the upstream direction.

Figure 2. (a) Representative snapshot of the drop surface and velocity magnitude on the central ![]() $x$–

$x$–![]() $y$ plane, with annotations showing the characteristic length scales for the drop shape. (b) Time evolution of

$y$ plane, with annotations showing the characteristic length scales for the drop shape. (b) Time evolution of ![]() $h_a=x_{max,a}-x_{min,a}$ for

$h_a=x_{max,a}-x_{min,a}$ for ![]() ${We}=15.3$, indicating the time ranges resolved by different mesh resolutions. The horizontal lines indicate the minimum cell size for each mesh. The dimensionless variables are denoted by

${We}=15.3$, indicating the time ranges resolved by different mesh resolutions. The horizontal lines indicate the minimum cell size for each mesh. The dimensionless variables are denoted by ![]() $\hat {,}$ and defined in (3.10a–e) and (3.11).

$\hat {,}$ and defined in (3.10a–e) and (3.11).

3.2. Turbulent gas flow and drop dynamics

For the range of ![]() ${Re}$ considered, the gas flow in the wake of the drop lies in the chaotic vortex shedding or the subcritical turbulent wake regimes, according to the regime map for a solid sphere (Tiwari et al. Reference Tiwari, Pal, Bale, Minocha, Patwardhan, Nandakumar and Joshi2020b). The gas enstrophy is then used to characterize the gas turbulence, which is calculated as

${Re}$ considered, the gas flow in the wake of the drop lies in the chaotic vortex shedding or the subcritical turbulent wake regimes, according to the regime map for a solid sphere (Tiwari et al. Reference Tiwari, Pal, Bale, Minocha, Patwardhan, Nandakumar and Joshi2020b). The gas enstrophy is then used to characterize the gas turbulence, which is calculated as

where ![]() $\boldsymbol {\omega }$ is the vorticity vector, and

$\boldsymbol {\omega }$ is the vorticity vector, and ![]() $\mathbb {V}$ is the volume of the computational domain. The normalized gas enstrophy is defined as

$\mathbb {V}$ is the volume of the computational domain. The normalized gas enstrophy is defined as ![]() $\hat {\varOmega }_g=\varOmega _g d_0/U_0^2$.

$\hat {\varOmega }_g=\varOmega _g d_0/U_0^2$.

The aerodynamic drag exerted on the drop will cause the drop to accelerate along the streamwise direction. The mean velocity of the drop in the ![]() $x$-direction is calculated by integrating over all the liquid cells in the domain:

$x$-direction is calculated by integrating over all the liquid cells in the domain:

\begin{equation} u_d = \frac{\displaystyle\int cu\,{\rm d}V}{\displaystyle\int c\,{\rm d}V} . \end{equation}

\begin{equation} u_d = \frac{\displaystyle\int cu\,{\rm d}V}{\displaystyle\int c\,{\rm d}V} . \end{equation}Note that this definition is valid only before breakup occurs. Then the drag coefficient can be defined as

where ![]() $m_d$ is the mass of the drop. Here,

$m_d$ is the mass of the drop. Here, ![]() $C_D$ is defined based on the instantaneous relative velocity (

$C_D$ is defined based on the instantaneous relative velocity (![]() $U_0-u_d$), and the drop frontal area is estimated by the lateral radius (

$U_0-u_d$), and the drop frontal area is estimated by the lateral radius (![]() ${\rm \pi} R^2$). As a result, the variation of

${\rm \pi} R^2$). As a result, the variation of ![]() $C_D$ is generally not influenced by the time variation of

$C_D$ is generally not influenced by the time variation of ![]() $u_d$ and

$u_d$ and ![]() $R$.

$R$.

The asymmetric drop deformation and the turbulent wake will introduce lift on the drop. The lift coefficients in the transverse directions are defined as

where ![]() $v_d$ and

$v_d$ and ![]() $w_d$ are the mean drop velocities in the

$w_d$ are the mean drop velocities in the ![]() $y$- and

$y$- and ![]() $z$-directions, respectively, similar to

$z$-directions, respectively, similar to ![]() $u_d$.

$u_d$.

3.3. Characteristic time scales for drop deformation

The early-time deformation of the drop is driven by the pressure variation in the radial direction, which is in turn induced by the stagnation gas flow on the windward surface of the drop. The viscous and surface tension effects are secondary to the early-time deformation. Then simple scaling analysis shows that the time scale governing the drop deformation is (Ranger & Nicholls Reference Ranger and Nicholls1969; Villermaux & Bossa Reference Villermaux and Bossa2011)

The scaling ![]() $\tau _d\sim {r}^{-1/2}$ has been confirmed by the parametric study of Marcotte & Zaleski (Reference Marcotte and Zaleski2019). It was shown that the evolutions of

$\tau _d\sim {r}^{-1/2}$ has been confirmed by the parametric study of Marcotte & Zaleski (Reference Marcotte and Zaleski2019). It was shown that the evolutions of ![]() $R$ for different

$R$ for different ![]() ${r}$ collapse approximately if

${r}$ collapse approximately if ![]() $t$ is scaled by

$t$ is scaled by ![]() $\tau _d$. This time scale

$\tau _d$. This time scale ![]() $\tau _d$ was first introduced by Ranger & Nicholls (Reference Ranger and Nicholls1969) based on the drag on the drop and the resulting acceleration. However, it was shown by Marcotte & Zaleski (Reference Marcotte and Zaleski2019) that the time scale

$\tau _d$ was first introduced by Ranger & Nicholls (Reference Ranger and Nicholls1969) based on the drag on the drop and the resulting acceleration. However, it was shown by Marcotte & Zaleski (Reference Marcotte and Zaleski2019) that the time scale ![]() $\tau _d$ actually does not collapse the drop velocity for different

$\tau _d$ actually does not collapse the drop velocity for different ![]() ${r}$. In the present study,

${r}$. In the present study, ![]() ${r}$ and

${r}$ and ![]() $d_0$ are kept constant, so

$d_0$ are kept constant, so ![]() $\tau _d$ varies due to

$\tau _d$ varies due to ![]() $U_0$.

$U_0$.

The surface tension and liquid viscosity resist the drop deformation, and the corresponding time scales are

The time scale ratios are related to the key dimensionless parameters, i.e. ![]() $\tau _s/\tau _{vl}={Oh}$ and

$\tau _s/\tau _{vl}={Oh}$ and ![]() ${\tau _s}/{\tau _d} = \sqrt {We}$. For the cases considered here,

${\tau _s}/{\tau _d} = \sqrt {We}$. For the cases considered here, ![]() ${Oh}\sim O(10^{-3})$ is very small, and

${Oh}\sim O(10^{-3})$ is very small, and ![]() ${We}\sim O(10)$. As a result,

${We}\sim O(10)$. As a result, ![]() $\tau _{vl} \gg \tau _s > \tau _d$. Therefore,

$\tau _{vl} \gg \tau _s > \tau _d$. Therefore, ![]() $\tau _{vl}$ is too large to be relevant, and surface tension is the dominant resisting force. Furthermore, since

$\tau _{vl}$ is too large to be relevant, and surface tension is the dominant resisting force. Furthermore, since ![]() $\tau _s > \tau _d$, we expect the early-time drop deformation will be insensitive to

$\tau _s > \tau _d$, we expect the early-time drop deformation will be insensitive to ![]() ${We}$.

${We}$.

3.4. Characteristic time scales for drop acceleration

When a stationary drop is suddenly exposed to the free stream, it experiences an impulsive gas acceleration and a continuous non-zero relative velocity. The resulting aerodynamic drag drives the drop to move along the streamwise direction. This treatment can be considered as an approximation of the passage of a shock wave with the post-shock velocity equal to ![]() $U_0$, neglecting the compressibility effect, as discussed by Marcotte & Zaleski (Reference Marcotte and Zaleski2019).

$U_0$, neglecting the compressibility effect, as discussed by Marcotte & Zaleski (Reference Marcotte and Zaleski2019).

The overall drag can be divided into quasi-steady, pressure-gradient, added-mass and Basset history forces (Maxey & Riley Reference Maxey and Riley1983; Ling et al. Reference Ling, Parmar and Balachandar2013). The last three are unsteady contributions, which are triggered mainly by the impulsive acceleration. The pressure-gradient and added-mass forces, often referred to as the inviscid unsteady forces, are active only at ![]() $t=0^+$, when the surrounding gas is suddenly accelerated from 0 to

$t=0^+$, when the surrounding gas is suddenly accelerated from 0 to ![]() $U_0$. In the simulation, this impulse spans one time step, and the integration of the impulse is

$U_0$. In the simulation, this impulse spans one time step, and the integration of the impulse is ![]() $U_0$. Therefore, the drop velocity jumps over the first time step due to the inviscid unsteady forces (including added-mass and pressure-gradient forces) as follows (Ling, Haselbacher & Balachandar Reference Ling, Haselbacher and Balachandar2011; Ling et al. Reference Ling, Parmar and Balachandar2013):

$U_0$. Therefore, the drop velocity jumps over the first time step due to the inviscid unsteady forces (including added-mass and pressure-gradient forces) as follows (Ling, Haselbacher & Balachandar Reference Ling, Haselbacher and Balachandar2011; Ling et al. Reference Ling, Parmar and Balachandar2013):

Similar estimates of the velocity jump have been proposed by Marcotte & Zaleski (Reference Marcotte and Zaleski2019) and Hadj-Achour et al. (Reference Hadj-Achour, Rimbert, Gradeck and Meignen2021). Marcotte & Zaleski (Reference Marcotte and Zaleski2019) found that the velocity jump scales with ![]() ${r}$, but the scaling coefficient

${r}$, but the scaling coefficient ![]() $1/2$ is different from the

$1/2$ is different from the ![]() $3/2$ in (3.8) since they did not include the pressure gradient force. The viscous-unsteady (Basset history) force will last for a finite period of time, characterized by the viscous-unsteady time scale

$3/2$ in (3.8) since they did not include the pressure gradient force. The viscous-unsteady (Basset history) force will last for a finite period of time, characterized by the viscous-unsteady time scale ![]() $\tau _{vu}$ (Ling et al. Reference Ling, Parmar and Balachandar2013). Due to the small value of

$\tau _{vu}$ (Ling et al. Reference Ling, Parmar and Balachandar2013). Due to the small value of ![]() ${r}$ considered here, the contributions of the unsteady forces to the increase in drop velocity are generally small (Ling et al. Reference Ling, Parmar and Balachandar2013). For cases with larger

${r}$ considered here, the contributions of the unsteady forces to the increase in drop velocity are generally small (Ling et al. Reference Ling, Parmar and Balachandar2013). For cases with larger ![]() ${r}$, additional attention to the unsteady forces will be required. For the present cases, the quasi-steady force is the dominant force that accelerates the drop. The time scale for the quasi-steady drag is referred to as the response time,

${r}$, additional attention to the unsteady forces will be required. For the present cases, the quasi-steady force is the dominant force that accelerates the drop. The time scale for the quasi-steady drag is referred to as the response time, ![]() $\tau _{qs}$. For

$\tau _{qs}$. For ![]() ${r}\ll 1$ (Ling et al. Reference Ling, Parmar and Balachandar2013),

${r}\ll 1$ (Ling et al. Reference Ling, Parmar and Balachandar2013),

where ![]() $\nu _g=\mu _g/\rho _g$, and

$\nu _g=\mu _g/\rho _g$, and ![]() $\varPhi$ is the correction factor to the Stokes drag, accounting for the effect of

$\varPhi$ is the correction factor to the Stokes drag, accounting for the effect of ![]() $Re$ and the drop shape. In the limit of zero

$Re$ and the drop shape. In the limit of zero ![]() ${Re}$ and

${Re}$ and ![]() ${We}$, the drop acts like a solid sphere in the Stokes limit, and

${We}$, the drop acts like a solid sphere in the Stokes limit, and ![]() $\varPhi =1$. For the range of

$\varPhi =1$. For the range of ![]() ${Re}$ considered here,

${Re}$ considered here, ![]() $\tau _{qs}\sim O(10^{-1}\ \textrm {s})$. As a result, drop breakup occurs on a time scale much smaller than

$\tau _{qs}\sim O(10^{-1}\ \textrm {s})$. As a result, drop breakup occurs on a time scale much smaller than ![]() $\tau _{qs}$ when the drop velocity

$\tau _{qs}$ when the drop velocity ![]() $u_d$ remains significantly lower than the free-stream velocity

$u_d$ remains significantly lower than the free-stream velocity ![]() $U_0$.

$U_0$.

Finally, we define dimensionless variables using ![]() $d_0$,

$d_0$, ![]() $U_0$ and

$U_0$ and ![]() $\rho _g$ as characteristic scales, namely

$\rho _g$ as characteristic scales, namely

Due to the focus on the drop deformation, ![]() $\tau _d$ is selected as the characteristic time scale. The dimensionless time is then defined as

$\tau _d$ is selected as the characteristic time scale. The dimensionless time is then defined as

4. Verification and validation

4.1. Grid-refinement studies

The time evolutions of the drop length ![]() $\hat {L}$ and radius

$\hat {L}$ and radius ![]() $\hat {R}$ for different mesh resolutions are shown in figure 3. The initial mesh resolutions are

$\hat {R}$ for different mesh resolutions are shown in figure 3. The initial mesh resolutions are ![]() $N=128$,

$N=128$, ![]() $256$ and

$256$ and ![]() $512$. The same mesh refinement strategy has been used for all three meshes, i.e. when the drop deforms to a bag and the bag sheet thickness decreases to approximately 4 cells, refinement level will be increased until

$512$. The same mesh refinement strategy has been used for all three meshes, i.e. when the drop deforms to a bag and the bag sheet thickness decreases to approximately 4 cells, refinement level will be increased until ![]() $N=2048$, as shown in figure 2(b). It can be seen from figure 3 that the results for

$N=2048$, as shown in figure 2(b). It can be seen from figure 3 that the results for ![]() $N=256$ and

$N=256$ and ![]() $512$ match very well. The results for

$512$ match very well. The results for ![]() $N=128$ are also similar in general, though small deviations are observed for

$N=128$ are also similar in general, though small deviations are observed for ![]() $\hat {t}>1.3$ when the forward bag forms. Therefore, one can conclude that

$\hat {t}>1.3$ when the forward bag forms. Therefore, one can conclude that ![]() $N=512$ is sufficient to yield converged results for the drop deformation until the bag ruptures, and thus is sufficient to determine the breakup criteria.

$N=512$ is sufficient to yield converged results for the drop deformation until the bag ruptures, and thus is sufficient to determine the breakup criteria.

Figure 3. Time evolutions of (a) the drop length ![]() $\hat {L}$ and (b) the drop radius

$\hat {L}$ and (b) the drop radius ![]() $\hat {R}$, for

$\hat {R}$, for ![]() $We=15.3$, obtained from the 3-D simulations. The experimental results by Opfer et al. (Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014), Flock et al. (Reference Flock, Guildenbecher, Chen, Sojka and Bauer2012) and Jackiw & Ashgriz (Reference Jackiw and Ashgriz2021) are shown for comparison.

$We=15.3$, obtained from the 3-D simulations. The experimental results by Opfer et al. (Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014), Flock et al. (Reference Flock, Guildenbecher, Chen, Sojka and Bauer2012) and Jackiw & Ashgriz (Reference Jackiw and Ashgriz2021) are shown for comparison.

In order to assess the adequacy of the mesh resolution in resolving the turbulent gas flow and its effect on the drag force, we examine the evolution of the drag coefficient ![]() $C_D$ and the gas enstrophy (see figure 4). Both

$C_D$ and the gas enstrophy (see figure 4). Both ![]() $C_D$ and

$C_D$ and ![]() $\varOmega _g$ exhibit non-monotonic behaviour due to the development of the turbulent wake and the drop deformation. The results obtained with meshes

$\varOmega _g$ exhibit non-monotonic behaviour due to the development of the turbulent wake and the drop deformation. The results obtained with meshes ![]() $N=256$ and

$N=256$ and ![]() $512$ show good agreement, with only minor discrepancies for

$512$ show good agreement, with only minor discrepancies for ![]() $\hat {t}\gtrsim 1$. Given the inherently chaotic nature of the gas flow, this level of agreement is considered satisfactory.

$\hat {t}\gtrsim 1$. Given the inherently chaotic nature of the gas flow, this level of agreement is considered satisfactory.

Figure 4. Time evolutions of (a) drag coefficient ![]() $C_D$ and (b) gas enstrophy

$C_D$ and (b) gas enstrophy ![]() $\hat {\varOmega }_g=\varOmega _g d_0/U_0^2$ for

$\hat {\varOmega }_g=\varOmega _g d_0/U_0^2$ for ![]() ${We}=15.3$. The 3-D simulation results for two different mesh resolutions,

${We}=15.3$. The 3-D simulation results for two different mesh resolutions, ![]() $N=256$ and 512, are shown. In (b), the results for

$N=256$ and 512, are shown. In (b), the results for ![]() $N=256$ were obtained by the mesh refinement

$N=256$ were obtained by the mesh refinement ![]() $\mathcal {L}=14$ without further increase, as in other cases.

$\mathcal {L}=14$ without further increase, as in other cases.

4.2. Experimental validation

The simulation results obtained for the case ![]() ${We}=15.3$ are validated against available experimental data for the drop length

${We}=15.3$ are validated against available experimental data for the drop length ![]() $\hat {L}$ and radius

$\hat {L}$ and radius ![]() $\hat {R}$. Specifically, comparison is made with the experiments of Jackiw & Ashgriz (Reference Jackiw and Ashgriz2021) (water,

$\hat {R}$. Specifically, comparison is made with the experiments of Jackiw & Ashgriz (Reference Jackiw and Ashgriz2021) (water, ![]() ${We}=15.3$ and 16.0), Opfer et al. (Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014) (ethylene glycol,

${We}=15.3$ and 16.0), Opfer et al. (Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014) (ethylene glycol, ![]() ${We}=15.1$), and Flock et al. (Reference Flock, Guildenbecher, Chen, Sojka and Bauer2012) (ethyl alcohol,

${We}=15.1$), and Flock et al. (Reference Flock, Guildenbecher, Chen, Sojka and Bauer2012) (ethyl alcohol, ![]() ${We}=12.7$). The parameters employed for the present simulations are chosen to be similar to those adopted in the experiments conducted by Jackiw & Ashgriz (Reference Jackiw and Ashgriz2021) (JA). Although the dimensionless parameters for the two other experiments are not identical to those in the present study, the small values of

${We}=12.7$). The parameters employed for the present simulations are chosen to be similar to those adopted in the experiments conducted by Jackiw & Ashgriz (Reference Jackiw and Ashgriz2021) (JA). Although the dimensionless parameters for the two other experiments are not identical to those in the present study, the small values of ![]() ${Oh}$ and

${Oh}$ and ![]() ${r}$, and the large value of

${r}$, and the large value of ![]() ${Re}$, in all cases suggest that the aerobreakup dynamics for similar

${Re}$, in all cases suggest that the aerobreakup dynamics for similar ![]() ${We}$ is expected to be comparable to the present cases. Thus the experimental data serve as an important validation benchmark for the present numerical simulations.

${We}$ is expected to be comparable to the present cases. Thus the experimental data serve as an important validation benchmark for the present numerical simulations.

It can be observed from figure 3 that the simulation results for both ![]() $\hat {L}$ and

$\hat {L}$ and ![]() $\hat {R}$ exhibit remarkable agreement with the experimental data of JA and Opfer et al. (Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014) at early times. The deviations from the experimental results of Flock et al. (Reference Flock, Guildenbecher, Chen, Sojka and Bauer2012) are relatively small, given that the experimental parameters, such as

$\hat {R}$ exhibit remarkable agreement with the experimental data of JA and Opfer et al. (Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014) at early times. The deviations from the experimental results of Flock et al. (Reference Flock, Guildenbecher, Chen, Sojka and Bauer2012) are relatively small, given that the experimental parameters, such as ![]() ${We}=12.7$, do not match the present simulations exactly. The simulation results for

${We}=12.7$, do not match the present simulations exactly. The simulation results for ![]() $\hat {R}$ deviate from the JA experimental data for the same

$\hat {R}$ deviate from the JA experimental data for the same ![]() ${We}=15.3$ at approximately

${We}=15.3$ at approximately ![]() $\hat {t}=0.7$, but they match quite well with the JA experimental results for a slightly larger

$\hat {t}=0.7$, but they match quite well with the JA experimental results for a slightly larger ![]() ${We}=16$ and the other two experiments. The discrepancy may be due to the high degree of variation inherent in such experiments. Unlike the results of Opfer et al. (Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014) and Flock et al. (Reference Flock, Guildenbecher, Chen, Sojka and Bauer2012), which are averaged data for multiple experiments, those of JA correspond to single experimental runs and thus exhibit higher uncertainty. Moreover, in JA's experiment, the drop is suspended from a needle, which may significantly influence the development of the drop radius, as discussed in the appendix of their paper.

${We}=16$ and the other two experiments. The discrepancy may be due to the high degree of variation inherent in such experiments. Unlike the results of Opfer et al. (Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014) and Flock et al. (Reference Flock, Guildenbecher, Chen, Sojka and Bauer2012), which are averaged data for multiple experiments, those of JA correspond to single experimental runs and thus exhibit higher uncertainty. Moreover, in JA's experiment, the drop is suspended from a needle, which may significantly influence the development of the drop radius, as discussed in the appendix of their paper.

4.3. Limitations of 2-D axisymmetric simulations

Due to the high computational cost of 3-D simulations, 2-D axisymmetric simulations have been used widely in numerical studies of drop aerobreakup (Jain et al. Reference Jain, Tyagi, Prakash, Ravikrishna and Tomar2019; Marcotte & Zaleski Reference Marcotte and Zaleski2019; Stefanitsis et al. Reference Stefanitsis, Malgarinos, Strotos, Nikolopoulos, Kakaras and Gavaises2019a). However, previous studies for bubbles (Blanco & Magnaudet Reference Blanco and Magnaudet1995; Magnaudet & Mougin Reference Magnaudet and Mougin2007) and drops (Rimbert et al. Reference Rimbert, Escobar, Meignen, Hadj-Achour and Gradeck2020) have also indicated that 2-D axisymmetric simulations may not be sufficient to resolve the asymmetric wake when ![]() ${Re}$ and

${Re}$ and ![]() ${We}$ are not small. It remains unclear to what extent (such as time duration and ranges of

${We}$ are not small. It remains unclear to what extent (such as time duration and ranges of ![]() ${Re}$ and

${Re}$ and ![]() ${We}$) a 2-D axisymmetric simulation is valid in resolving drop aerobreakups. In the present study, we have performed both 2-D and 3-D simulations using identical numerical methods and initial/boundary conditions. Therefore, the difference between the results characterize the effect of the artificial axisymmetric constraint in the 2-D simulations on the drop.

${We}$) a 2-D axisymmetric simulation is valid in resolving drop aerobreakups. In the present study, we have performed both 2-D and 3-D simulations using identical numerical methods and initial/boundary conditions. Therefore, the difference between the results characterize the effect of the artificial axisymmetric constraint in the 2-D simulations on the drop.

The temporal evolutions of ![]() $\hat {L}$ and

$\hat {L}$ and ![]() $\hat {R}$ for both 2-D and 3-D simulations are shown in figure 5. The 2-D simulation results for two different mesh resolutions,

$\hat {R}$ for both 2-D and 3-D simulations are shown in figure 5. The 2-D simulation results for two different mesh resolutions, ![]() $N=512$ and

$N=512$ and ![]() $N=1024$, agree remarkably well, indicating that the 2-D results presented here are mesh-independent. The discrepancy between the 2-D and 3-D results is not related to the mesh resolution. The 2-D and 3-D results match very well for

$N=1024$, agree remarkably well, indicating that the 2-D results presented here are mesh-independent. The discrepancy between the 2-D and 3-D results is not related to the mesh resolution. The 2-D and 3-D results match very well for ![]() $\hat {t}\lesssim 0.5$, but the deviation grows over time. In general, the 3-D results agree much better with the experimental data. The 2-D simulation significantly underestimates the drop length compared to the 3-D simulation and experimental results, as shown in figure 5(a). This indicates that the 2-D simulations fail to capture the bag development. Significant discrepancies can also be observed in the drop velocity and drag coefficient, as shown in figures 5(c) and 5(d). For

$\hat {t}\lesssim 0.5$, but the deviation grows over time. In general, the 3-D results agree much better with the experimental data. The 2-D simulation significantly underestimates the drop length compared to the 3-D simulation and experimental results, as shown in figure 5(a). This indicates that the 2-D simulations fail to capture the bag development. Significant discrepancies can also be observed in the drop velocity and drag coefficient, as shown in figures 5(c) and 5(d). For ![]() $1\lesssim \hat {t} \lesssim 1.6$, the value of

$1\lesssim \hat {t} \lesssim 1.6$, the value of ![]() $C_D$ predicted by the 2-D simulation is only approximately half of that obtained from the 3-D simulation.

$C_D$ predicted by the 2-D simulation is only approximately half of that obtained from the 3-D simulation.

Figure 5. Comparison between 2-D-axisymmetric and 3-D simulation results for ![]() $We=15.3$, including (a) drop length

$We=15.3$, including (a) drop length ![]() $\hat {L}$, (b) drop radius

$\hat {L}$, (b) drop radius ![]() $\hat {R}$, (c) drop velocity

$\hat {R}$, (c) drop velocity ![]() $u_d$, and (d) drag coefficient

$u_d$, and (d) drag coefficient ![]() $C_D$. The experimental results by Opfer et al. (Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014), Flock et al. (Reference Flock, Guildenbecher, Chen, Sojka and Bauer2012) and Jackiw & Ashgriz (Reference Jackiw and Ashgriz2021) are shown in (a,b) for comparison.

$C_D$. The experimental results by Opfer et al. (Reference Opfer, Roisman, Venzmer, Klostermann and Tropea2014), Flock et al. (Reference Flock, Guildenbecher, Chen, Sojka and Bauer2012) and Jackiw & Ashgriz (Reference Jackiw and Ashgriz2021) are shown in (a,b) for comparison.

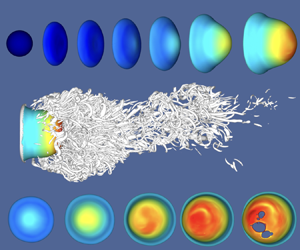

The poor prediction of the 2-D simulation is due to the fact that it cannot resolve the turbulent wake accurately. The pressure fields obtained from both 2-D and 3-D simulations are shown in figures 6(a) and 6(b), respectively. The vortical structures at different times for the 3-D simulation, visualized by the ![]() $\lambda _2$ criterion, are shown in figure 6(c) to illustrate the development of the wake. The wake is initially approximately axisymmetric and later transitions to being fully 3-D and turbulent. The artificial axisymmetric constraint in the 2-D simulation limits the azimuthal development of the wake, leading to high pressure near the leeward pole and a low-pressure region in the symmetric vortex ring, as seen in figure 6(a) at