1. Introduction

Fluid flow separation is generally regarded as fluid detachment from a no-slip boundary. It is the root cause of several complex flow phenomena, such as vortex formation, wake flow and stall, which typically reduce engineering flow devices’ performance. For a recent survey of existing literature, we refer to (Melius, Cal & Mulleners Reference Melius, Cal and Mulleners2016; Melius, Mulleners & Cal Reference Melius, Mulleners and Cal2018; Serra, Vétel & Haller Reference Serra, Vétel and Haller2018; Le Fouest, Deparday & Mulleners Reference Le Fouest, Deparday and Mulleners2021; Deparday et al. Reference Deparday, He, Eldredge, Mulleners and Williams2022; Sudharsan, Ganapathysubramanian & Sharma Reference Sudharsan, Ganapathysubramanian and Sharma2022) and references therein, which include (Prandtl Reference Prandtl1904; Sears & Telionis Reference Sears and Telionis1971, Reference Sears and Telionis1975; Liu & Wan Reference Liu and Wan1985; Haller Reference Haller2004; Surana et al. Reference Surana, Jacobs, Grunberg and Haller2008; Wu, Ma & Zhou Reference Wu, Ma and Zhou2015). Three-dimensional (3-D) flow separation is challenging to analyse and visualize, and it has been subject to numerous studies since the mid-1950s. Inspired by dynamical systems studies by Poincaré, Legendre (Reference Legendre1956); Délery (Reference Délery2001) and Lighthill (Reference Lighthill1963) pioneered 3-D flow separation research. Several methods followed after these seminal works (Tobak & Peake Reference Tobak and Peake1982; Simpson Reference Simpson1996; Wu et al. Reference Wu, Tramel, Zhu and Yin2000). Years later, Haller and co-workers (Surana, Grunberg & Haller Reference Surana, Grunberg and Haller2006; Jacobs et al. Reference Jacobs, Surana, Peacock and Haller2007; Surana, Jacobs & Haller Reference Surana, Jacobs and Haller2007; Surana et al. Reference Surana, Jacobs, Grunberg and Haller2008) derived an exact theory of asymptotic 3-D separation in steady flows and unsteady flows with an asymptotic mean.

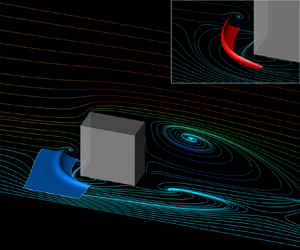

Existing techniques invariably focus on the longer-term particle dynamics, as opposed to the appearance of separation triggered by the formation of a material spike, i.e. a sharp-shaped set of fluid particles ejected from the wall. Several of these techniques rely on the notion of Lagrangian coherent structures (Haller Reference Haller2015) and their applications (Green, Rowley & Haller Reference Green, Rowley and Haller2007; Wilson, Tutkun & Cal Reference Wilson, Tutkun and Cal2013). However, the long-term behaviour in material deformation and transport is significantly different from the short-term one, which is the most relevant for early flow separation detection and control. To illustrate the difference between short-term material spikes and longer-term material ejection, figure 1(a,b) shows the evolution of material lines initially close to the wall in a steady 2-D flow analysed in detail in Serra et al. (Reference Serra, Vétel and Haller2018). While fluid particles released within the black box in (a) approach asymptotically the singular streamline (unstable manifold) emanating from the Prandtl point ![]() $p$, the birth of a material spike takes place at a different upstream location. Serra et al. (Reference Serra, Vétel and Haller2018) derived a theoretical framework to identify such a location, named the spiking point

$p$, the birth of a material spike takes place at a different upstream location. Serra et al. (Reference Serra, Vétel and Haller2018) derived a theoretical framework to identify such a location, named the spiking point ![]() $s_p$, as well as the backbone of separation (red curve) that acts as the centrepiece of the forming spike (cf. figure 1(c) and supplementary movie 1 available at https://doi.org/10.1017/jfm.2023.559) for general unsteady 2-D flows. This recent technique has proven successful in identifying the onset of flow separation in highly unsteady planar flows (Serra et al. Reference Serra, Crouzat, Simon, Vétel and Haller2020) including the flow over a wing profile at moderate Reynolds number (Klose, Serra & Jacobs Reference Klose, Serra and Jacobs2020b).

$s_p$, as well as the backbone of separation (red curve) that acts as the centrepiece of the forming spike (cf. figure 1(c) and supplementary movie 1 available at https://doi.org/10.1017/jfm.2023.559) for general unsteady 2-D flows. This recent technique has proven successful in identifying the onset of flow separation in highly unsteady planar flows (Serra et al. Reference Serra, Crouzat, Simon, Vétel and Haller2020) including the flow over a wing profile at moderate Reynolds number (Klose, Serra & Jacobs Reference Klose, Serra and Jacobs2020b).

Figure 1. (a) Streamlines of a steady 2-D flow analysed in detail in Serra et al. (Reference Serra, Vétel and Haller2018). The green dot represents the zero skin friction or Prandtl separation point. (b) Zoom of (a) in the region enclosed by the bottom right rectangle, along with the evolution of the spike visualized through the advection of material lines shown in black. (c) Backbone of separation (red curve) as defined in Serra et al. (Reference Serra, Vétel and Haller2018), along with the streamlines (blue), and material lines initially parallel to the wall (black). The red dot marks the spiking point, where the backbone connects to the wall. The time evolution of the material spike is in supplementary movie 1.

Identifying separating structures is arguably a necessary first step in the design of flow control mechanisms (Greenblatt & Wygnanski Reference Greenblatt and Wygnanski2000; You & Moin Reference You and Moin2008) that can mitigate the upwelling and breakaway from walls. Common control strategies target the asymptotic separation structures either passively (Schlichting & Gersten Reference Schlichting and Gersten2000) or actively (Cattafesta & Sheplak Reference Cattafesta and Sheplak2011). Recent efforts include optimal flow control using dynamic modes decomposition (Hemati et al. Reference Hemati, Deem, Williams, Rowley and Cattafesta2016; Taira et al. Reference Taira, Brunton, Dawson, Rowley, Colonius, McKeon, Schmidt, Gordeyev, Theofilis and Ukeiley2017) and resolvent analysis (Yeh & Taira Reference Yeh and Taira2019). None of these studies, however, explicitly control spiking, and most importantly, they target Prandtl's definition of separation. Using the asymptotic separation criterion from Haller (Reference Haller2004), Kamphuis et al. (Reference Kamphuis, Jacobs, Chen, Spedding and Hoeijmakers2018) showed that a pulsed actuation upstream of Haller's separation criterion reduces drag. Interestingly, Bhattacharjee et al. (Reference Bhattacharjee, Klose, Jacobs and Hemati2020) showed that the optimal actuator place to mitigate separation is upstream of the asymptotic separation point on an airfoil, consistent with the spiking point location (Klose et al. Reference Klose, Serra and Jacobs2020b). A 3-D theory to locate and control the material spike formation universally observed in separation experiments is still missing.

Building on Serra et al. (Reference Serra, Vétel and Haller2018), here, we propose a frame-invariant theory that identifies the origin of spike formation over a no-slip boundary in 3-D flows with arbitrary time dependence. Our technique identifies the Lagrangian centrepieces – or backbone lines and surfaces (figure 2b,c) – of separation and is also effective over short times, which are inaccessible by previous methods. Our theory is based on explicit formulas for the Lagrangian evolution of the largest principal curvature of material surfaces. The emergence of the largest principal curvature maxima (or ridge) near the boundary locates the onset of spike formation, its dimension (1-D or 2-D backbones, cf. figure 2b,c) and type. Specifically, we speak of fixed separation if the ridge emanates from the wall. Otherwise, it is a moving separation. For fixed separation, our theory discovers previously undocumented spiking points ![]() $\boldsymbol {r}_{sp}$ and spiking curves

$\boldsymbol {r}_{sp}$ and spiking curves ![]() $\gamma _{sc}$, which are distinct locations where the 1-D and 2-D backbones connect to the wall. We provide explicit formulas for the spiking points and curves using wall-based quantities. Remarkably, the spiking points and curves remain hidden from classic skin-friction line plots even in steady flows, consistent with the 2-D case (figure 1).

$\gamma _{sc}$, which are distinct locations where the 1-D and 2-D backbones connect to the wall. We provide explicit formulas for the spiking points and curves using wall-based quantities. Remarkably, the spiking points and curves remain hidden from classic skin-friction line plots even in steady flows, consistent with the 2-D case (figure 1).

Figure 2. (a) We denote the initial position of a 2-D material surface in a 3-D space by ![]() $\mathcal {M}(t_0)$. Points on the surface have coordinates

$\mathcal {M}(t_0)$. Points on the surface have coordinates ![]() $\boldsymbol {r}(\,\boldsymbol {p})$, where

$\boldsymbol {r}(\,\boldsymbol {p})$, where ![]() $\boldsymbol {p}$ contains the two independent parameters. At later times, points on the material surface

$\boldsymbol {p}$ contains the two independent parameters. At later times, points on the material surface ![]() $\mathcal {M}(t) =\boldsymbol {F}_{t_0}^{t} (\mathcal {M}(t_0))$ have coordinates

$\mathcal {M}(t) =\boldsymbol {F}_{t_0}^{t} (\mathcal {M}(t_0))$ have coordinates ![]() $\hat {\boldsymbol {r}}_{t_0}^{t}(\,\boldsymbol {p})$. At each point

$\hat {\boldsymbol {r}}_{t_0}^{t}(\,\boldsymbol {p})$. At each point ![]() $\boldsymbol {r}(\,\boldsymbol {p})$ of

$\boldsymbol {r}(\,\boldsymbol {p})$ of ![]() $\mathcal {M}(t)$,

$\mathcal {M}(t)$, ![]() $\hat {\boldsymbol {r}}_u, \hat {\boldsymbol {r}}_v$ are basis vectors for the local tangent space,

$\hat {\boldsymbol {r}}_u, \hat {\boldsymbol {r}}_v$ are basis vectors for the local tangent space, ![]() $\boldsymbol {n}_t$ is the local normal vector,

$\boldsymbol {n}_t$ is the local normal vector, ![]() $\kappa _1$ and

$\kappa _1$ and ![]() $\kappa _2$ are the principal curvatures and

$\kappa _2$ are the principal curvatures and ![]() $\boldsymbol {\zeta }_1$ and

$\boldsymbol {\zeta }_1$ and ![]() $\boldsymbol {\zeta }_2$ are the principal curvature directions (inset). (b) Sketch of possible separating spikes in 3-D flows from a no-slip boundary: 2-D backbone where

$\boldsymbol {\zeta }_2$ are the principal curvature directions (inset). (b) Sketch of possible separating spikes in 3-D flows from a no-slip boundary: 2-D backbone where ![]() $\kappa _2>\kappa _1$ or a 1-D backbone where

$\kappa _2>\kappa _1$ or a 1-D backbone where ![]() $\kappa _2 \approx \kappa _1$. (c) We define a coordinate system with

$\kappa _2 \approx \kappa _1$. (c) We define a coordinate system with ![]() $[u,v]$ parameterizing the no-slip boundary

$[u,v]$ parameterizing the no-slip boundary ![]() $\mathcal {W}$ and

$\mathcal {W}$ and ![]() $\eta$ the coordinate normal to the boundary. We define a spiking curve

$\eta$ the coordinate normal to the boundary. We define a spiking curve ![]() $\gamma _{sc}$ and spiking point

$\gamma _{sc}$ and spiking point ![]() $\boldsymbol {r}_{sp}$, as the intersection – when present – of the 2-D backbone and 1-D backbone to the no-slip boundary.

$\boldsymbol {r}_{sp}$, as the intersection – when present – of the 2-D backbone and 1-D backbone to the no-slip boundary.

This paper is organized as follows. We first develop our theoretical results in §§ 2–5. Then we give an algorithmic summary of our theory in § 6. In § 7, we illustrate our results on several examples, including steady and unsteady velocity fields that generate different flow separation structures over no-slip boundaries.

2. Set-up and notation

We consider a 3-D unsteady smooth velocity field ![]() $\boldsymbol {f}(\boldsymbol {x},t)$ on a 3-D domain

$\boldsymbol {f}(\boldsymbol {x},t)$ on a 3-D domain ![]() $U$, whose trajectories satisfy

$U$, whose trajectories satisfy

We recall the customary velocity Jacobian decomposition

where ![]() $\boldsymbol {S}$ and

$\boldsymbol {S}$ and ![]() $\boldsymbol {\varOmega }$ denote the rate-of-strain and spin tensors. Trajectories

$\boldsymbol {\varOmega }$ denote the rate-of-strain and spin tensors. Trajectories ![]() $\boldsymbol {x}(t; t_0, \boldsymbol {x}_0)$ of (2.1a–d) define the flow map

$\boldsymbol {x}(t; t_0, \boldsymbol {x}_0)$ of (2.1a–d) define the flow map ![]() $\boldsymbol {F}_{t_0}^{t} (\boldsymbol {x_0})$ and the corresponding right Cauchy–Green strain tensor

$\boldsymbol {F}_{t_0}^{t} (\boldsymbol {x_0})$ and the corresponding right Cauchy–Green strain tensor ![]() $\boldsymbol {C}_{t_0}^{t}(\boldsymbol {x_0})$ that can be computed as

$\boldsymbol {C}_{t_0}^{t}(\boldsymbol {x_0})$ that can be computed as

Here, ![]() $\boldsymbol {F}_{t_0}^{t} (\boldsymbol {x}_0)$ maps an initial condition

$\boldsymbol {F}_{t_0}^{t} (\boldsymbol {x}_0)$ maps an initial condition ![]() $\boldsymbol {x}_0$ at time

$\boldsymbol {x}_0$ at time ![]() $t_0$ to its position

$t_0$ to its position ![]() $\boldsymbol {x}_t$ at time

$\boldsymbol {x}_t$ at time ![]() $t$, and

$t$, and ![]() $\boldsymbol {C}_{t_0}^{t}(\boldsymbol {x_0})$ encodes Lagrangian stretching and shearing deformations of an infinitesimal material volume in the neighbourhood of

$\boldsymbol {C}_{t_0}^{t}(\boldsymbol {x_0})$ encodes Lagrangian stretching and shearing deformations of an infinitesimal material volume in the neighbourhood of ![]() $\boldsymbol {x_0}$.

$\boldsymbol {x_0}$.

3. Curvature evolution of a material surface

To derive explicit formulas for the curvature evolution of a 2-D material surface ![]() $\mathcal {M}(t)$, we define the following parametrization (figure 2):

$\mathcal {M}(t)$, we define the following parametrization (figure 2):

\begin{align} \left.\begin{array}{c@{}}

\mathcal{M}(t_0) = \{\boldsymbol{x_0}\in U:

\boldsymbol{x_0} =\boldsymbol{r}(\,\boldsymbol{p}),

\boldsymbol{p}=[u,v]^{\top}\in V =

[u_1,u_2]\times[v_1,v_2]\subset \mathbb{R}^2\},\\

\mathcal{M}(t) = \boldsymbol{F}_{t_0}^{t}

(\mathcal{M}(t_0))= \{\boldsymbol{x_t}\in U:

\boldsymbol{x_t} =

\hat{\boldsymbol{r}}_{t_0}^{t}(\,\boldsymbol{p}) =

\boldsymbol{F}_{t_0}^{t}

(\boldsymbol{r}(\,\boldsymbol{p})), \boldsymbol{p}\in V\}.

\end{array}\right\} \end{align}

\begin{align} \left.\begin{array}{c@{}}

\mathcal{M}(t_0) = \{\boldsymbol{x_0}\in U:

\boldsymbol{x_0} =\boldsymbol{r}(\,\boldsymbol{p}),

\boldsymbol{p}=[u,v]^{\top}\in V =

[u_1,u_2]\times[v_1,v_2]\subset \mathbb{R}^2\},\\

\mathcal{M}(t) = \boldsymbol{F}_{t_0}^{t}

(\mathcal{M}(t_0))= \{\boldsymbol{x_t}\in U:

\boldsymbol{x_t} =

\hat{\boldsymbol{r}}_{t_0}^{t}(\,\boldsymbol{p}) =

\boldsymbol{F}_{t_0}^{t}

(\boldsymbol{r}(\,\boldsymbol{p})), \boldsymbol{p}\in V\}.

\end{array}\right\} \end{align}

In other words, ![]() $\boldsymbol {p}$ contains the two independent variables that uniquely specify an initial point of the material surface

$\boldsymbol {p}$ contains the two independent variables that uniquely specify an initial point of the material surface ![]() $\boldsymbol {r}(\,\boldsymbol {p})$. The coordinates of this point at time

$\boldsymbol {r}(\,\boldsymbol {p})$. The coordinates of this point at time ![]() $t$, are given by

$t$, are given by ![]() $\boldsymbol {F}_{t_0}^{t} (\boldsymbol {r}(\,\boldsymbol {p}))$, or alternatively, in compact notation, by

$\boldsymbol {F}_{t_0}^{t} (\boldsymbol {r}(\,\boldsymbol {p}))$, or alternatively, in compact notation, by ![]() $\hat {\boldsymbol {r}}_{t_0}^{t}(\,\boldsymbol {p})$.

$\hat {\boldsymbol {r}}_{t_0}^{t}(\,\boldsymbol {p})$.

At each point ![]() $\hat {\boldsymbol {r}}_{t_0}^{t}(\,\boldsymbol {p})$ on the surface, the vectors

$\hat {\boldsymbol {r}}_{t_0}^{t}(\,\boldsymbol {p})$ on the surface, the vectors ![]() $\partial _u \hat {\boldsymbol {r}}_{t_0}^{t}, \partial _v \hat {\boldsymbol {r}}_{t_0}^{t}$ define a basis for the local tangent space at

$\partial _u \hat {\boldsymbol {r}}_{t_0}^{t}, \partial _v \hat {\boldsymbol {r}}_{t_0}^{t}$ define a basis for the local tangent space at ![]() $\hat {\boldsymbol {r}}_{t_0}^{t}(\,\boldsymbol {p})$. For compactness, we will denote these vectors

$\hat {\boldsymbol {r}}_{t_0}^{t}(\,\boldsymbol {p})$. For compactness, we will denote these vectors ![]() $\boldsymbol {r}_u,\boldsymbol {r}_v$ at

$\boldsymbol {r}_u,\boldsymbol {r}_v$ at ![]() $t_0$ and

$t_0$ and ![]() $\hat {\boldsymbol {r}}_u, \hat {\boldsymbol {r}}_v$ at

$\hat {\boldsymbol {r}}_u, \hat {\boldsymbol {r}}_v$ at ![]() $t$. We can now compute a local basis for the local tangent and normal spaces at

$t$. We can now compute a local basis for the local tangent and normal spaces at ![]() $\hat {\boldsymbol {r}}_{t_0}^{t}(\,\boldsymbol {p})$ as

$\hat {\boldsymbol {r}}_{t_0}^{t}(\,\boldsymbol {p})$ as

where ![]() $\times, \vert ({\cdot }) \vert$ denote the cross-product and the vector norm, and

$\times, \vert ({\cdot }) \vert$ denote the cross-product and the vector norm, and ![]() $\boldsymbol {n}_t$ the unit vector normal to the surface.

$\boldsymbol {n}_t$ the unit vector normal to the surface.

The Weingarten map quantifies the surface curvature in different directions, and can be computed as ![]() $\boldsymbol {W}_{t_0}^t(\,\boldsymbol {p}) =({}_1\boldsymbol {\varGamma }_{t_0}^t(\,\boldsymbol {p}))^{-1}{}_2 \boldsymbol {\varGamma }_{t_0}^t(\,\boldsymbol {p})$, where

$\boldsymbol {W}_{t_0}^t(\,\boldsymbol {p}) =({}_1\boldsymbol {\varGamma }_{t_0}^t(\,\boldsymbol {p}))^{-1}{}_2 \boldsymbol {\varGamma }_{t_0}^t(\,\boldsymbol {p})$, where ![]() ${}_1\boldsymbol {\varGamma }$ and

${}_1\boldsymbol {\varGamma }$ and ![]() ${}_2\boldsymbol {\varGamma }$ are the first and second fundamental forms (e.g. Kuhnel & Hunt (Reference Kuhnel and Hunt2015) and Appendix A). The eigenvalues

${}_2\boldsymbol {\varGamma }$ are the first and second fundamental forms (e.g. Kuhnel & Hunt (Reference Kuhnel and Hunt2015) and Appendix A). The eigenvalues ![]() ${}_{2}k_{t_0}^t (\,\boldsymbol {p})\geq {}_{1}k_{t_0}^t (\,\boldsymbol {p})$ of

${}_{2}k_{t_0}^t (\,\boldsymbol {p})\geq {}_{1}k_{t_0}^t (\,\boldsymbol {p})$ of ![]() $\boldsymbol {W}_{t_0}^t(\,\boldsymbol {p})$ characterize the principal curvatures at

$\boldsymbol {W}_{t_0}^t(\,\boldsymbol {p})$ characterize the principal curvatures at ![]() $\hat {\boldsymbol {r}}_{t_0}^{t}(\,\boldsymbol {p})$ along the corresponding principal curvature directions

$\hat {\boldsymbol {r}}_{t_0}^{t}(\,\boldsymbol {p})$ along the corresponding principal curvature directions ![]() $\boldsymbol {\zeta _1}$ and

$\boldsymbol {\zeta _1}$ and ![]() $\boldsymbol {\zeta _2}$, identified by the eigenvectors of

$\boldsymbol {\zeta _2}$, identified by the eigenvectors of ![]() $\boldsymbol {W}$ (figure 2a). As a result, the time evolution of

$\boldsymbol {W}$ (figure 2a). As a result, the time evolution of ![]() $\boldsymbol {W}$ fully characterizes the curvatures of

$\boldsymbol {W}$ fully characterizes the curvatures of ![]() $\mathcal {M}(t)$. The Weingarten map of

$\mathcal {M}(t)$. The Weingarten map of ![]() $\mathcal {M}(t_0)$ is

$\mathcal {M}(t_0)$ is ![]() $\boldsymbol {W}_{t_0} = \boldsymbol {W}_{t_0}^{t_0}(\,\boldsymbol {p})$ and can be computed as

$\boldsymbol {W}_{t_0} = \boldsymbol {W}_{t_0}^{t_0}(\,\boldsymbol {p})$ and can be computed as

\begin{equation} \left.

\begin{array}{c@{}} \boldsymbol{W}_{t_0} =

({}_1\boldsymbol{\varGamma}_{t_0}(\,\boldsymbol{p}))^{-1}{}_2

\boldsymbol{\varGamma}_{t_0}(\,\boldsymbol{p}), \quad

{}_1\boldsymbol{\varGamma}_{t_0}(\,\boldsymbol{p}) =

\left(\begin{matrix}

\langle\boldsymbol{r}_u,\boldsymbol{r}_u\rangle &

\langle\boldsymbol{r}_u,\boldsymbol{r}_v\rangle\\

\langle\boldsymbol{r}_v,\boldsymbol{r}_u\rangle &

\langle\boldsymbol{r}_v,\boldsymbol{r}_v\rangle

\end{matrix}\right),\\

{}_2\boldsymbol{\varGamma}_{t_0}(\,\boldsymbol{p}) =

\left(\begin{matrix}

\langle\boldsymbol{n}_{t_0},\boldsymbol{r}_{uu}\rangle &

\langle\boldsymbol{n}_{t_0},\boldsymbol{r}_{uv}\rangle\\

\langle\boldsymbol{n}_{t_0},\boldsymbol{r}_{vu}\rangle &

\langle\boldsymbol{n}_{t_0},\boldsymbol{r}_{vv}\rangle

\end{matrix}\right)

\end{array}\right\},\end{equation}

\begin{equation} \left.

\begin{array}{c@{}} \boldsymbol{W}_{t_0} =

({}_1\boldsymbol{\varGamma}_{t_0}(\,\boldsymbol{p}))^{-1}{}_2

\boldsymbol{\varGamma}_{t_0}(\,\boldsymbol{p}), \quad

{}_1\boldsymbol{\varGamma}_{t_0}(\,\boldsymbol{p}) =

\left(\begin{matrix}

\langle\boldsymbol{r}_u,\boldsymbol{r}_u\rangle &

\langle\boldsymbol{r}_u,\boldsymbol{r}_v\rangle\\

\langle\boldsymbol{r}_v,\boldsymbol{r}_u\rangle &

\langle\boldsymbol{r}_v,\boldsymbol{r}_v\rangle

\end{matrix}\right),\\

{}_2\boldsymbol{\varGamma}_{t_0}(\,\boldsymbol{p}) =

\left(\begin{matrix}

\langle\boldsymbol{n}_{t_0},\boldsymbol{r}_{uu}\rangle &

\langle\boldsymbol{n}_{t_0},\boldsymbol{r}_{uv}\rangle\\

\langle\boldsymbol{n}_{t_0},\boldsymbol{r}_{vu}\rangle &

\langle\boldsymbol{n}_{t_0},\boldsymbol{r}_{vv}\rangle

\end{matrix}\right)

\end{array}\right\},\end{equation}

with ![]() $\langle,\rangle$ denoting the dot product and

$\langle,\rangle$ denoting the dot product and ![]() $\boldsymbol {r}_{uv} = \partial _{uv} \boldsymbol {r}$. To understand how a velocity field (2.1a–d) folds a material surface, we derive the exact map and the underlying matrix differential equation for

$\boldsymbol {r}_{uv} = \partial _{uv} \boldsymbol {r}$. To understand how a velocity field (2.1a–d) folds a material surface, we derive the exact map and the underlying matrix differential equation for ![]() $\boldsymbol {W}_{t_0}^t(\,\boldsymbol {p})$, as summarized in the following theorem.

$\boldsymbol {W}_{t_0}^t(\,\boldsymbol {p})$, as summarized in the following theorem.

Theorem 1 Consider a smooth material surface ![]() $\mathcal {M}(t) \subset U \subseteq \mathbb {R}^3$ parametrized at

$\mathcal {M}(t) \subset U \subseteq \mathbb {R}^3$ parametrized at ![]() $t_0$ in the form

$t_0$ in the form ![]() $\boldsymbol {r}(\,\boldsymbol {p})$,

$\boldsymbol {r}(\,\boldsymbol {p})$, ![]() $\boldsymbol {p}=[u,v]^{\top }\in [u_1,u_2]\times [v_1,v_2]=V\subset \mathbb {R}^2$, and whose tangent space is spanned by

$\boldsymbol {p}=[u,v]^{\top }\in [u_1,u_2]\times [v_1,v_2]=V\subset \mathbb {R}^2$, and whose tangent space is spanned by ![]() $\boldsymbol {r}_u(\,\boldsymbol {p})$ and

$\boldsymbol {r}_u(\,\boldsymbol {p})$ and ![]() $\boldsymbol {r}_v(\,\boldsymbol {p})$. The evolution of the Weingarten map

$\boldsymbol {r}_v(\,\boldsymbol {p})$. The evolution of the Weingarten map ![]() $\boldsymbol {W}_{t_0}^t(\,\boldsymbol {p})$ of

$\boldsymbol {W}_{t_0}^t(\,\boldsymbol {p})$ of ![]() $\mathcal {M}(t)$ under the action of the flow map can be computed as

$\mathcal {M}(t)$ under the action of the flow map can be computed as

\begin{equation} \boldsymbol{W}_{t_0}^t(\,\boldsymbol{p})= \underbrace{({}_1\boldsymbol{\varGamma}_{t_0}^{t} (\,\boldsymbol{p}))^{-1}{}_1\boldsymbol{\varGamma}_{t_0}(\,\boldsymbol{p}) \frac{J_{t_0}(\,\boldsymbol{p}) {\rm det}(\boldsymbol{\nabla}\boldsymbol{F}^t_{t_0} (\boldsymbol{r}(\,\boldsymbol{p})))}{J_{t_0}^{t}(\,\boldsymbol{p})} \boldsymbol{W}_{t_0}}_{\boldsymbol{W}_I}+\underbrace{{({}_{1} \boldsymbol{\varGamma}_{t_0}^t}(\,\boldsymbol{p}))^{-1} \boldsymbol{B}_{t_0}^{t}(\,\boldsymbol{p})}_{\boldsymbol{W}_{II}}, \end{equation}

\begin{equation} \boldsymbol{W}_{t_0}^t(\,\boldsymbol{p})= \underbrace{({}_1\boldsymbol{\varGamma}_{t_0}^{t} (\,\boldsymbol{p}))^{-1}{}_1\boldsymbol{\varGamma}_{t_0}(\,\boldsymbol{p}) \frac{J_{t_0}(\,\boldsymbol{p}) {\rm det}(\boldsymbol{\nabla}\boldsymbol{F}^t_{t_0} (\boldsymbol{r}(\,\boldsymbol{p})))}{J_{t_0}^{t}(\,\boldsymbol{p})} \boldsymbol{W}_{t_0}}_{\boldsymbol{W}_I}+\underbrace{{({}_{1} \boldsymbol{\varGamma}_{t_0}^t}(\,\boldsymbol{p}))^{-1} \boldsymbol{B}_{t_0}^{t}(\,\boldsymbol{p})}_{\boldsymbol{W}_{II}}, \end{equation}where

\begin{equation} \boldsymbol{B}_{t_0}^{t}(\,\boldsymbol{p}) = \left(\begin{matrix} \langle\boldsymbol{n}_t,{\nabla}^2\boldsymbol{F}^t_{t_0} (\boldsymbol{r}(\,\boldsymbol{p}))\boldsymbol{r}_u\boldsymbol{r}_u\rangle & \langle\boldsymbol{n}_t,{\nabla}^2\boldsymbol{F}^t_{t_0} (\boldsymbol{r}(\,\boldsymbol{p}))\boldsymbol{r}_u\boldsymbol{r}_v\rangle\\ \langle\boldsymbol{n}_t,{\nabla}^2\boldsymbol{F}^t_{t_0} (\boldsymbol{r}(\,\boldsymbol{p}))\boldsymbol{r}_v\boldsymbol{r}_u\rangle & \langle\boldsymbol{n}_t,{\nabla}^2\boldsymbol{F}^t_{t_0} (\boldsymbol{r}(\,\boldsymbol{p}))\boldsymbol{r}_v\boldsymbol{r}_v\rangle \end{matrix}\right), \end{equation}

\begin{equation} \boldsymbol{B}_{t_0}^{t}(\,\boldsymbol{p}) = \left(\begin{matrix} \langle\boldsymbol{n}_t,{\nabla}^2\boldsymbol{F}^t_{t_0} (\boldsymbol{r}(\,\boldsymbol{p}))\boldsymbol{r}_u\boldsymbol{r}_u\rangle & \langle\boldsymbol{n}_t,{\nabla}^2\boldsymbol{F}^t_{t_0} (\boldsymbol{r}(\,\boldsymbol{p}))\boldsymbol{r}_u\boldsymbol{r}_v\rangle\\ \langle\boldsymbol{n}_t,{\nabla}^2\boldsymbol{F}^t_{t_0} (\boldsymbol{r}(\,\boldsymbol{p}))\boldsymbol{r}_v\boldsymbol{r}_u\rangle & \langle\boldsymbol{n}_t,{\nabla}^2\boldsymbol{F}^t_{t_0} (\boldsymbol{r}(\,\boldsymbol{p}))\boldsymbol{r}_v\boldsymbol{r}_v\rangle \end{matrix}\right), \end{equation}

where ![]() ${[{\nabla }^2\boldsymbol {F}^t_{t_0}(\boldsymbol {r} (\,\boldsymbol {p})\boldsymbol {r}_u\boldsymbol {r}_v]_i = [{\nabla }^2\boldsymbol {F}^t_{t_0}(\boldsymbol {r}) \boldsymbol {r}_{u}]_{ij} [\boldsymbol {r}_{v}]_{j}= \langle \boldsymbol {\nabla }[\boldsymbol {\nabla }\boldsymbol {F}^t_{t_0} (\boldsymbol {r})]_{ij},\boldsymbol {r}_{u}\rangle [\boldsymbol {r}_{v}]_{j}}$,

${[{\nabla }^2\boldsymbol {F}^t_{t_0}(\boldsymbol {r} (\,\boldsymbol {p})\boldsymbol {r}_u\boldsymbol {r}_v]_i = [{\nabla }^2\boldsymbol {F}^t_{t_0}(\boldsymbol {r}) \boldsymbol {r}_{u}]_{ij} [\boldsymbol {r}_{v}]_{j}= \langle \boldsymbol {\nabla }[\boldsymbol {\nabla }\boldsymbol {F}^t_{t_0} (\boldsymbol {r})]_{ij},\boldsymbol {r}_{u}\rangle [\boldsymbol {r}_{v}]_{j}}$, ![]() $J_{t_0}^{t}(\,\boldsymbol {p}) = \sqrt { {\rm det}({}_{1}\boldsymbol {\varGamma }_{t_0}^t(\,\boldsymbol {p}))}$ and

$J_{t_0}^{t}(\,\boldsymbol {p}) = \sqrt { {\rm det}({}_{1}\boldsymbol {\varGamma }_{t_0}^t(\,\boldsymbol {p}))}$ and ![]() $J_{t_0}(\,\boldsymbol {p}) = \sqrt { {\rm det}({}_{1}\boldsymbol {\varGamma }_{t_0}(\,\boldsymbol {p}))}$. Here

$J_{t_0}(\,\boldsymbol {p}) = \sqrt { {\rm det}({}_{1}\boldsymbol {\varGamma }_{t_0}(\,\boldsymbol {p}))}$. Here ![]() $[{\nabla }^2\boldsymbol {F}^t_{t_0}(\boldsymbol {r})\boldsymbol {r}_{u}]_{ij}$ represents the directional derivatives of

$[{\nabla }^2\boldsymbol {F}^t_{t_0}(\boldsymbol {r})\boldsymbol {r}_{u}]_{ij}$ represents the directional derivatives of ![]() $[\boldsymbol {\nabla }\boldsymbol {F}^t_{t_0}(\boldsymbol {r})]_{ij}$ in the direction

$[\boldsymbol {\nabla }\boldsymbol {F}^t_{t_0}(\boldsymbol {r})]_{ij}$ in the direction ![]() $\boldsymbol {r}_{u}$. We use the same notation in (3.8) and (3.9). The rate of change of the Weingarten map at

$\boldsymbol {r}_{u}$. We use the same notation in (3.8) and (3.9). The rate of change of the Weingarten map at ![]() $t_0$ is given by

$t_0$ is given by

\begin{align} \displaystyle{\dot{\boldsymbol{W}}_{t_0}(\,\boldsymbol{p})}&= \underbrace{\displaystyle{\left[\left( \boldsymbol{\nabla} \boldsymbol{\cdot}\boldsymbol{f}(\boldsymbol{r}(\,\boldsymbol{p}),t_0)- \frac{3\alpha_{t_0}(\,\boldsymbol{p})}{J_{t_0}^2(\,\boldsymbol{p})}\right) \boldsymbol{I}+\frac{2\boldsymbol{D}(\boldsymbol{p},t_0){}_1 \boldsymbol{\varGamma}_{t_0}(\,\boldsymbol{p})}{J_{t_0}^2(\,\boldsymbol{p})} \right]\boldsymbol{W}_{t_0}}}_{\dot{\boldsymbol{W}}_{I}}\nonumber\\ &\quad +\underbrace{\displaystyle{({}_1\boldsymbol{\varGamma}_{t_0} (\,\boldsymbol{p}))^{-1}\boldsymbol{M}(\boldsymbol{p},t_0)}}_{{\dot{\boldsymbol{W}}_{II}}} +\underbrace{\displaystyle{({}_1\boldsymbol{\varGamma}_{t_0}(\boldsymbol{p }))^{-1} \boldsymbol{N}_{t_0}}}_{\dot{\boldsymbol{W}}_{III}}, \end{align}

\begin{align} \displaystyle{\dot{\boldsymbol{W}}_{t_0}(\,\boldsymbol{p})}&= \underbrace{\displaystyle{\left[\left( \boldsymbol{\nabla} \boldsymbol{\cdot}\boldsymbol{f}(\boldsymbol{r}(\,\boldsymbol{p}),t_0)- \frac{3\alpha_{t_0}(\,\boldsymbol{p})}{J_{t_0}^2(\,\boldsymbol{p})}\right) \boldsymbol{I}+\frac{2\boldsymbol{D}(\boldsymbol{p},t_0){}_1 \boldsymbol{\varGamma}_{t_0}(\,\boldsymbol{p})}{J_{t_0}^2(\,\boldsymbol{p})} \right]\boldsymbol{W}_{t_0}}}_{\dot{\boldsymbol{W}}_{I}}\nonumber\\ &\quad +\underbrace{\displaystyle{({}_1\boldsymbol{\varGamma}_{t_0} (\,\boldsymbol{p}))^{-1}\boldsymbol{M}(\boldsymbol{p},t_0)}}_{{\dot{\boldsymbol{W}}_{II}}} +\underbrace{\displaystyle{({}_1\boldsymbol{\varGamma}_{t_0}(\boldsymbol{p }))^{-1} \boldsymbol{N}_{t_0}}}_{\dot{\boldsymbol{W}}_{III}}, \end{align}

where ![]() $\alpha _{t_0}(\,\boldsymbol {p}) = \langle \boldsymbol {r}_{u},\boldsymbol {S}(\boldsymbol {r} (\,\boldsymbol {p}),t_0)\boldsymbol {r}_{u}\rangle \langle \boldsymbol {r}_{v},\boldsymbol {r}_{v}\rangle +\langle \boldsymbol {r}_{v}, \boldsymbol {S}(\boldsymbol {r}(\,\boldsymbol {p}),t_0)\boldsymbol {r}_{v} \rangle \langle \boldsymbol {r}_{u},\boldsymbol {r}_{u}\rangle -2\langle \boldsymbol {r}_{u},\boldsymbol {S}(\boldsymbol {r}(\,\boldsymbol {p}), t_0) \boldsymbol {r}_{v}\rangle \langle \boldsymbol {r}_{u},\boldsymbol {r}_{v} \rangle, \boldsymbol {I}$ is the identity matrix of rank 2,

$\alpha _{t_0}(\,\boldsymbol {p}) = \langle \boldsymbol {r}_{u},\boldsymbol {S}(\boldsymbol {r} (\,\boldsymbol {p}),t_0)\boldsymbol {r}_{u}\rangle \langle \boldsymbol {r}_{v},\boldsymbol {r}_{v}\rangle +\langle \boldsymbol {r}_{v}, \boldsymbol {S}(\boldsymbol {r}(\,\boldsymbol {p}),t_0)\boldsymbol {r}_{v} \rangle \langle \boldsymbol {r}_{u},\boldsymbol {r}_{u}\rangle -2\langle \boldsymbol {r}_{u},\boldsymbol {S}(\boldsymbol {r}(\,\boldsymbol {p}), t_0) \boldsymbol {r}_{v}\rangle \langle \boldsymbol {r}_{u},\boldsymbol {r}_{v} \rangle, \boldsymbol {I}$ is the identity matrix of rank 2,

\begin{align} \boldsymbol{D}(\boldsymbol{p},t_0) &=\left(\begin{matrix} \langle\boldsymbol{r}_v,\boldsymbol{S}(\boldsymbol{r}(\,\boldsymbol{p}),t_0) \boldsymbol{r}_v\rangle & -\langle\boldsymbol{r}_u,\boldsymbol{S} (\boldsymbol{r}(\,\boldsymbol{p}),t_0)\boldsymbol{r}_v\rangle\\ -\langle\boldsymbol{r}_u,\boldsymbol{S}(\boldsymbol{r}(\,\boldsymbol{p}),t_0) \boldsymbol{r}_v\rangle & \langle\boldsymbol{r}_u,\boldsymbol{S} (\boldsymbol{r}(\,\boldsymbol{p}),t_0)\boldsymbol{r}_u\rangle \end{matrix}\right), \end{align}

\begin{align} \boldsymbol{D}(\boldsymbol{p},t_0) &=\left(\begin{matrix} \langle\boldsymbol{r}_v,\boldsymbol{S}(\boldsymbol{r}(\,\boldsymbol{p}),t_0) \boldsymbol{r}_v\rangle & -\langle\boldsymbol{r}_u,\boldsymbol{S} (\boldsymbol{r}(\,\boldsymbol{p}),t_0)\boldsymbol{r}_v\rangle\\ -\langle\boldsymbol{r}_u,\boldsymbol{S}(\boldsymbol{r}(\,\boldsymbol{p}),t_0) \boldsymbol{r}_v\rangle & \langle\boldsymbol{r}_u,\boldsymbol{S} (\boldsymbol{r}(\,\boldsymbol{p}),t_0)\boldsymbol{r}_u\rangle \end{matrix}\right), \end{align} \begin{align} \boldsymbol{M}(\boldsymbol{p},t_0) &=\left(\begin{matrix} \langle\boldsymbol{n}_{t_0},\boldsymbol{\nabla} \boldsymbol{S} (\boldsymbol{r}(\,\boldsymbol{p}),t_0)\boldsymbol{r}_u \boldsymbol{r}_u\rangle & \langle\boldsymbol{n}_{t_0},\boldsymbol{\nabla} \boldsymbol{S}(\boldsymbol{r}(\,\boldsymbol{p}),t_0)\boldsymbol{r}_u \boldsymbol{r}_v\rangle\\ \langle\boldsymbol{n}_{t_0},\boldsymbol{\nabla} \boldsymbol{S}(\boldsymbol{r} (\,\boldsymbol{p}),t_0)\boldsymbol{r}_v\boldsymbol{r}_u\rangle & \langle \boldsymbol{n}_{t_0},\boldsymbol{\nabla} \boldsymbol{S}(\boldsymbol{r} (\,\boldsymbol{p}),t_0)\boldsymbol{r}_v\boldsymbol{r}_v\rangle \end{matrix}\right), \end{align}

\begin{align} \boldsymbol{M}(\boldsymbol{p},t_0) &=\left(\begin{matrix} \langle\boldsymbol{n}_{t_0},\boldsymbol{\nabla} \boldsymbol{S} (\boldsymbol{r}(\,\boldsymbol{p}),t_0)\boldsymbol{r}_u \boldsymbol{r}_u\rangle & \langle\boldsymbol{n}_{t_0},\boldsymbol{\nabla} \boldsymbol{S}(\boldsymbol{r}(\,\boldsymbol{p}),t_0)\boldsymbol{r}_u \boldsymbol{r}_v\rangle\\ \langle\boldsymbol{n}_{t_0},\boldsymbol{\nabla} \boldsymbol{S}(\boldsymbol{r} (\,\boldsymbol{p}),t_0)\boldsymbol{r}_v\boldsymbol{r}_u\rangle & \langle \boldsymbol{n}_{t_0},\boldsymbol{\nabla} \boldsymbol{S}(\boldsymbol{r} (\,\boldsymbol{p}),t_0)\boldsymbol{r}_v\boldsymbol{r}_v\rangle \end{matrix}\right), \end{align} \begin{align} \boldsymbol{N}(\boldsymbol{p},t_0) &= \left(\begin{matrix} \langle\boldsymbol{n}_{t_0},\boldsymbol{\nabla} \boldsymbol{\varOmega} (\boldsymbol{r}(\,\boldsymbol{p}),t_0)\boldsymbol{r}_u\boldsymbol{r}_u\rangle & \langle\boldsymbol{n}_{t_0},\boldsymbol{\nabla} \boldsymbol{\varOmega}(\boldsymbol{r} (\,\boldsymbol{p}),t_0)\boldsymbol{r}_u\boldsymbol{r}_v\rangle\\ \langle\boldsymbol{n}_{t_0},\boldsymbol{\nabla} \boldsymbol{\varOmega} (\boldsymbol{r}(\,\boldsymbol{p}),t_0)\boldsymbol{r}_v\boldsymbol{r}_u\rangle & \langle\boldsymbol{n}_{t_0},\boldsymbol{\nabla} \boldsymbol{\varOmega} (\boldsymbol{r}(\,\boldsymbol{p}),t_0)\boldsymbol{r}_v\boldsymbol{r}_v\rangle \end{matrix}\right). \end{align}

\begin{align} \boldsymbol{N}(\boldsymbol{p},t_0) &= \left(\begin{matrix} \langle\boldsymbol{n}_{t_0},\boldsymbol{\nabla} \boldsymbol{\varOmega} (\boldsymbol{r}(\,\boldsymbol{p}),t_0)\boldsymbol{r}_u\boldsymbol{r}_u\rangle & \langle\boldsymbol{n}_{t_0},\boldsymbol{\nabla} \boldsymbol{\varOmega}(\boldsymbol{r} (\,\boldsymbol{p}),t_0)\boldsymbol{r}_u\boldsymbol{r}_v\rangle\\ \langle\boldsymbol{n}_{t_0},\boldsymbol{\nabla} \boldsymbol{\varOmega} (\boldsymbol{r}(\,\boldsymbol{p}),t_0)\boldsymbol{r}_v\boldsymbol{r}_u\rangle & \langle\boldsymbol{n}_{t_0},\boldsymbol{\nabla} \boldsymbol{\varOmega} (\boldsymbol{r}(\,\boldsymbol{p}),t_0)\boldsymbol{r}_v\boldsymbol{r}_v\rangle \end{matrix}\right). \end{align}Proof. See Appendices A and B.

The term ![]() $\boldsymbol {W}_{I}$ in (3.4) describes the contribution to material folding induced by the flow if

$\boldsymbol {W}_{I}$ in (3.4) describes the contribution to material folding induced by the flow if ![]() $\mathcal {M}(t_0)$ has non-zero initial curvature

$\mathcal {M}(t_0)$ has non-zero initial curvature ![]() $\boldsymbol {W}_{t_0}$ while

$\boldsymbol {W}_{t_0}$ while ![]() $\boldsymbol {W}_{II}$ folds

$\boldsymbol {W}_{II}$ folds ![]() $\mathcal {M}(t)$ regardless of

$\mathcal {M}(t)$ regardless of ![]() $\boldsymbol {W}_{t_0}$. In

$\boldsymbol {W}_{t_0}$. In ![]() $\boldsymbol {W}_{I}$,

$\boldsymbol {W}_{I}$, ![]() $J_{t_0}^t(\,\boldsymbol {p})$ relates the area element (

$J_{t_0}^t(\,\boldsymbol {p})$ relates the area element (![]() $\textrm {d} A$) of

$\textrm {d} A$) of ![]() $\mathcal {M}(t)$ to the area element (

$\mathcal {M}(t)$ to the area element (![]() $\textrm {d}u\, \textrm {d}v$) at

$\textrm {d}u\, \textrm {d}v$) at ![]() $\boldsymbol {p}$ by

$\boldsymbol {p}$ by ![]() $\textrm {d} A = J_{t_0}^{t}(\,\boldsymbol {p})\,\textrm {d}u\,\textrm {d}v$,

$\textrm {d} A = J_{t_0}^{t}(\,\boldsymbol {p})\,\textrm {d}u\,\textrm {d}v$, ![]() $ {\rm det}(\boldsymbol {\nabla }\boldsymbol {F}^t_{t_0} (\boldsymbol {r}(\,\boldsymbol {p}))$ accounts for volume changes and the first fundamental form

$ {\rm det}(\boldsymbol {\nabla }\boldsymbol {F}^t_{t_0} (\boldsymbol {r}(\,\boldsymbol {p}))$ accounts for volume changes and the first fundamental form ![]() ${}_1\boldsymbol {\varGamma }_{t_0}(\,\boldsymbol {p})$ accounts for the shape of

${}_1\boldsymbol {\varGamma }_{t_0}(\,\boldsymbol {p})$ accounts for the shape of ![]() $\mathcal {M}(t_0)$. In

$\mathcal {M}(t_0)$. In ![]() $\boldsymbol {W}_{II}$,

$\boldsymbol {W}_{II}$, ![]() $\boldsymbol {B}_{t_0}^{t}(\,\boldsymbol {p})$ accounts for the folding of

$\boldsymbol {B}_{t_0}^{t}(\,\boldsymbol {p})$ accounts for the folding of ![]() $\mathcal {M}(t)$ described by second spatial derivatives of

$\mathcal {M}(t)$ described by second spatial derivatives of ![]() $\boldsymbol {F}^t_{t_0}$. In the short-time limit, (3.6) quantifies the rate of change of

$\boldsymbol {F}^t_{t_0}$. In the short-time limit, (3.6) quantifies the rate of change of ![]() $\boldsymbol {W}_{t_0}^t(\,\boldsymbol {p})$ at

$\boldsymbol {W}_{t_0}^t(\,\boldsymbol {p})$ at ![]() $t_0$, and elucidates which flow features contribute to the folding rate of

$t_0$, and elucidates which flow features contribute to the folding rate of ![]() $\mathcal {M}_{t_0}$. Specifically,

$\mathcal {M}_{t_0}$. Specifically, ![]() $\dot {\boldsymbol {W}}_{I}$) encodes the compressibility of

$\dot {\boldsymbol {W}}_{I}$) encodes the compressibility of ![]() $\boldsymbol {f}$ (

$\boldsymbol {f}$ (![]() $\boldsymbol {\nabla }\boldsymbol {\cdot } \boldsymbol {f}$), the stretching rate along

$\boldsymbol {\nabla }\boldsymbol {\cdot } \boldsymbol {f}$), the stretching rate along ![]() $\mathcal {M}_{t_0}$ (

$\mathcal {M}_{t_0}$ (![]() $\alpha _{t_0}(\,\boldsymbol {p})$ and

$\alpha _{t_0}(\,\boldsymbol {p})$ and ![]() $\boldsymbol {D}(\boldsymbol {p},t_0)$) and the metric properties (

$\boldsymbol {D}(\boldsymbol {p},t_0)$) and the metric properties (![]() ${}_1\varGamma _{t_0}(\,\boldsymbol {p})$), weighted by its current curvature

${}_1\varGamma _{t_0}(\,\boldsymbol {p})$), weighted by its current curvature ![]() $\boldsymbol {W}_{t_0}$;

$\boldsymbol {W}_{t_0}$; ![]() $\dot {\boldsymbol {W}}_{II}$) accounts for spatial variations of the stretching rates on

$\dot {\boldsymbol {W}}_{II}$) accounts for spatial variations of the stretching rates on ![]() $\mathcal {M}_{t_0}$ encoded in

$\mathcal {M}_{t_0}$ encoded in ![]() $\boldsymbol {\nabla }\boldsymbol {S}$; and

$\boldsymbol {\nabla }\boldsymbol {S}$; and ![]() $\dot {\boldsymbol {W}}_{III}$) accounts for spatial variations of rigid-body rotation rates on

$\dot {\boldsymbol {W}}_{III}$) accounts for spatial variations of rigid-body rotation rates on ![]() $\mathcal {M}_{t_0}$ encoded in

$\mathcal {M}_{t_0}$ encoded in ![]() $\boldsymbol {\nabla } \boldsymbol {\varOmega }$. Equations (3.4) and (3.6) have the same functional form as their 2-D analogues in Serra et al. (Reference Serra, Vétel and Haller2018) describing the folding of material curves, with the tensor

$\boldsymbol {\nabla } \boldsymbol {\varOmega }$. Equations (3.4) and (3.6) have the same functional form as their 2-D analogues in Serra et al. (Reference Serra, Vétel and Haller2018) describing the folding of material curves, with the tensor ![]() $\boldsymbol {W}_{t_0}^t$ replacing the scalar curvature

$\boldsymbol {W}_{t_0}^t$ replacing the scalar curvature ![]() $\kappa _{t_0}^t$.

$\kappa _{t_0}^t$.

Theorem 1 shows that the Lagrangian folding and the Eulerian folding rate of a material surface are caused by stretching- and rotation-based quantities. In Appendix C, we show that ![]() $\boldsymbol {W}_{t_0}^t(\,\boldsymbol {p})$ and

$\boldsymbol {W}_{t_0}^t(\,\boldsymbol {p})$ and ![]() $\dot {\boldsymbol {W}}_{t_0}^t(\,\boldsymbol {p})$ are invariant with respect to changes in the parametrization

$\dot {\boldsymbol {W}}_{t_0}^t(\,\boldsymbol {p})$ are invariant with respect to changes in the parametrization ![]() $\boldsymbol {r}(\,\boldsymbol {p})$ and time-dependent rotations and translations of the coordinate frame. Remarkably, although the spin tensor

$\boldsymbol {r}(\,\boldsymbol {p})$ and time-dependent rotations and translations of the coordinate frame. Remarkably, although the spin tensor ![]() $\boldsymbol {\varOmega }$ is not objective, its spatial variations contributing to folding (cf. (3.9)) is objective, similar to the 2-D case (Serra et al. Reference Serra, Vétel and Haller2018). We summarize these results as follows.

$\boldsymbol {\varOmega }$ is not objective, its spatial variations contributing to folding (cf. (3.9)) is objective, similar to the 2-D case (Serra et al. Reference Serra, Vétel and Haller2018). We summarize these results as follows.

Proposition 1 Denote all Euclidean coordinate changes by

where ![]() $\boldsymbol {Q}(t)\in SO(3)$ and

$\boldsymbol {Q}(t)\in SO(3)$ and ![]() $\boldsymbol {b}(t)\in \mathbb {R}^{3}$ are smooth functions of time. Here,

$\boldsymbol {b}(t)\in \mathbb {R}^{3}$ are smooth functions of time. Here, ![]() $\boldsymbol {W}_{t_0}^t(\,\boldsymbol {p})$ and

$\boldsymbol {W}_{t_0}^t(\,\boldsymbol {p})$ and ![]() $\dot {\boldsymbol {W}}_{t_0}^t(\,\boldsymbol {p})$ are independent of the parametrization

$\dot {\boldsymbol {W}}_{t_0}^t(\,\boldsymbol {p})$ are independent of the parametrization ![]() $\boldsymbol {r}(\,\boldsymbol {p})$ (3.1) and invariant under the coordinate changes in (3.10). Invariance here means

$\boldsymbol {r}(\,\boldsymbol {p})$ (3.1) and invariant under the coordinate changes in (3.10). Invariance here means ![]() $\tilde {\boldsymbol {W}}_{t_0}^t(\,\boldsymbol {p})= \boldsymbol {W}_{t_0}^t(\,\boldsymbol {p})$ and

$\tilde {\boldsymbol {W}}_{t_0}^t(\,\boldsymbol {p})= \boldsymbol {W}_{t_0}^t(\,\boldsymbol {p})$ and ![]() $\widetilde {\dot {\boldsymbol {W}}}_{t}(\,\boldsymbol {p})= \dot {\boldsymbol {W}}_{t}(\,\boldsymbol {p})$, where

$\widetilde {\dot {\boldsymbol {W}}}_{t}(\,\boldsymbol {p})= \dot {\boldsymbol {W}}_{t}(\,\boldsymbol {p})$, where ![]() $\widetilde {({\cdot })}$ denotes quantities expressed as a function of the

$\widetilde {({\cdot })}$ denotes quantities expressed as a function of the ![]() $\tilde {\boldsymbol {x}}$-coordinate, and

$\tilde {\boldsymbol {x}}$-coordinate, and ![]() $({\cdot })$ the same quantity expressed in terms of

$({\cdot })$ the same quantity expressed in terms of ![]() $\boldsymbol {x}$-coordinate.

$\boldsymbol {x}$-coordinate.

Proof. See Appendix C.

We note that the invariance of material folding in Proposition 1 is stronger than objectivity (Truesdell & Noll Reference Truesdell and Noll2004), which is required in the continuum mechanics assessment of material response and the definitions of Lagrangian and Eulerian coherent structures (Haller Reference Haller2015; Serra & Haller Reference Serra and Haller2016).

4. The Lagrangian backbone of flow separation

The onset of fluid flow separation is characterized by a distinctly folded material spike that will later separate from the boundary surface, similar to the spike formation in 2-D flows (figure 1). In three dimensions, however, the Lagrangian backbone of separation – i.e. the centrepiece of the material spike – can be one-dimensional (codimension 2) or two-dimensional (codimension 1). A 1-D backbone marks an approximately symmetric spike. In contrast, a 2-D backbone marks a ridge-like spike where folding perpendicular to the ridge is higher than the one along the ridge (cf. figure 2b).

Equipped with the exact expressions from § 3, we proceed with the definition and identification of the Lagrangian backbone of separation in three dimensions. We first define the Lagrangian change and the Eulerian rate of change of the Weingarten map as

which quantify the finite-time folding and instantaneous folding rates induced by the flow on ![]() $\mathcal {M}(t)$. We denote the eigenvalues of

$\mathcal {M}(t)$. We denote the eigenvalues of ![]() $\bar {\boldsymbol {W}}_{t_0}^{t}(\,\boldsymbol {p})$ by

$\bar {\boldsymbol {W}}_{t_0}^{t}(\,\boldsymbol {p})$ by ![]() ${}_{1}\bar {\kappa }_{t_{0}}^t(\,\boldsymbol {p})\leq {}_{2}\bar {\kappa }_{t_{0}}^t(\,\boldsymbol {p})$ and the associated eigenvectors by

${}_{1}\bar {\kappa }_{t_{0}}^t(\,\boldsymbol {p})\leq {}_{2}\bar {\kappa }_{t_{0}}^t(\,\boldsymbol {p})$ and the associated eigenvectors by ![]() $\bar {\boldsymbol {\zeta }}_1, \bar {\boldsymbol {\zeta }}_2$. Here,

$\bar {\boldsymbol {\zeta }}_1, \bar {\boldsymbol {\zeta }}_2$. Here, ![]() ${}_{2}\bar {\kappa }_{t_{0}}^t(\,\boldsymbol {p})$ quantifies the highest curvature change, i.e. the folding induced by

${}_{2}\bar {\kappa }_{t_{0}}^t(\,\boldsymbol {p})$ quantifies the highest curvature change, i.e. the folding induced by ![]() $\boldsymbol {F}_{t_0}^t$, at

$\boldsymbol {F}_{t_0}^t$, at ![]() $\boldsymbol {r}(\,\boldsymbol {p})$. By selecting normal vectors pointing towards the no-slip boundary, positive eigenvalues of

$\boldsymbol {r}(\,\boldsymbol {p})$. By selecting normal vectors pointing towards the no-slip boundary, positive eigenvalues of ![]() $\bar {\boldsymbol {W}}_{t_0}^{t}(\,\boldsymbol {p})$ mark upwelling-type deformations.

$\bar {\boldsymbol {W}}_{t_0}^{t}(\,\boldsymbol {p})$ mark upwelling-type deformations.

As aggregate curvature measures described by ![]() $\bar {\boldsymbol {W}}_{t_0}^{t}(\,\boldsymbol {p})$, we denote the Gaussian curvature change by

$\bar {\boldsymbol {W}}_{t_0}^{t}(\,\boldsymbol {p})$, we denote the Gaussian curvature change by ![]() $\bar {K}_{t_0}^t(\,\boldsymbol {p})= \det [\bar {\boldsymbol {W}}_{t_0}^{t}(\,\boldsymbol {p})]={}_{1} \bar {\kappa }_{t_{0}}^t(\,\boldsymbol {p}) {}_{2}\bar {\kappa }_{t_{0}}^t(\,\boldsymbol {p})$ and the mean curvature change by

$\bar {K}_{t_0}^t(\,\boldsymbol {p})= \det [\bar {\boldsymbol {W}}_{t_0}^{t}(\,\boldsymbol {p})]={}_{1} \bar {\kappa }_{t_{0}}^t(\,\boldsymbol {p}) {}_{2}\bar {\kappa }_{t_{0}}^t(\,\boldsymbol {p})$ and the mean curvature change by ![]() $\bar {H}_{t_0}^t(\,\boldsymbol {p})= {\textrm {Trace}[\bar {\boldsymbol {W}}_{t_0}^{t}(\,\boldsymbol {p})]}/{2}= ({{}_{1}\bar {\kappa }_{t_{0}}^t(\,\boldsymbol {p})+ {}_{2}\bar {\kappa }_{t_{0}}^t(\,\boldsymbol {p})})/{2}$. For compactness, we may denote the principal curvature changes also by

$\bar {H}_{t_0}^t(\,\boldsymbol {p})= {\textrm {Trace}[\bar {\boldsymbol {W}}_{t_0}^{t}(\,\boldsymbol {p})]}/{2}= ({{}_{1}\bar {\kappa }_{t_{0}}^t(\,\boldsymbol {p})+ {}_{2}\bar {\kappa }_{t_{0}}^t(\,\boldsymbol {p})})/{2}$. For compactness, we may denote the principal curvature changes also by ![]() $\bar {\kappa }_{1},\bar {\kappa }_{2}$, the Gaussian curvature change by

$\bar {\kappa }_{1},\bar {\kappa }_{2}$, the Gaussian curvature change by ![]() $\bar {K}$ and the mean curvature change by

$\bar {K}$ and the mean curvature change by ![]() $\bar {H}$. We note that the Gaussian curvature

$\bar {H}$. We note that the Gaussian curvature ![]() $\bar {K}$ is not a good metric to characterize the Lagrangian spike formation because in the case of flat (or approximately flat) 2-D separation ridges (e.g. figure 3),

$\bar {K}$ is not a good metric to characterize the Lagrangian spike formation because in the case of flat (or approximately flat) 2-D separation ridges (e.g. figure 3), ![]() $\bar {K} \approx 0$ on the ridge. Similarly, the mean curvature change

$\bar {K} \approx 0$ on the ridge. Similarly, the mean curvature change ![]() $\bar {H}$ is not a good metric for separation as in the case of hyperbolic-type upwelling deformations, i.e. when

$\bar {H}$ is not a good metric for separation as in the case of hyperbolic-type upwelling deformations, i.e. when ![]() $\bar {K}<0$,

$\bar {K}<0$, ![]() $\bar {H}$ can vanish on points along the separation backbone (e.g. figure 4).

$\bar {H}$ can vanish on points along the separation backbone (e.g. figure 4).

Figure 3. Separation ridge curved in ![]() $x_1-x_2$ generated by flow described in § 7.1 over a time interval

$x_1-x_2$ generated by flow described in § 7.1 over a time interval ![]() $[0,2.5]$. (a) Mean curvature change

$[0,2.5]$. (a) Mean curvature change ![]() $\bar {H}_{0}^{2.5}$ and (b) Gaussian curvature change

$\bar {H}_{0}^{2.5}$ and (b) Gaussian curvature change ![]() $\bar {K}_{0}^{2.5}$ fields shaded on representative material surfaces at

$\bar {K}_{0}^{2.5}$ fields shaded on representative material surfaces at ![]() $t=2.5$. (c) Larger principal curvature change

$t=2.5$. (c) Larger principal curvature change ![]() ${}_2\bar {\kappa }_{0}^{2.5}$ field shaded on a material surface at

${}_2\bar {\kappa }_{0}^{2.5}$ field shaded on a material surface at ![]() $t=0$. The Lagrangian backbone of separation

$t=0$. The Lagrangian backbone of separation ![]() $\mathcal {B}(0)$ is shown in red, and the black line corresponds to the Lagrangian spiking curve

$\mathcal {B}(0)$ is shown in red, and the black line corresponds to the Lagrangian spiking curve ![]() $\gamma _{sc}$. (d,e) The Lagrangian backbone of separation

$\gamma _{sc}$. (d,e) The Lagrangian backbone of separation ![]() $\mathcal {B}(t)$ at later times in red, with the change in the larger principal curvature

$\mathcal {B}(t)$ at later times in red, with the change in the larger principal curvature ![]() ${}_2\bar {\kappa }_{0}^{2.5}$ shaded on selected material surfaces. The time evolution of panels (a–e) is available in supplementary movie 2.

${}_2\bar {\kappa }_{0}^{2.5}$ shaded on selected material surfaces. The time evolution of panels (a–e) is available in supplementary movie 2.

We observe that for either 1-D or 2-D separation backbones, high values of ![]() $\bar {\kappa }_2$ mark the material spike location. For the 2-D separation backbone,

$\bar {\kappa }_2$ mark the material spike location. For the 2-D separation backbone, ![]() $\bar {\kappa }_2$ is maximum along the principal direction

$\bar {\kappa }_2$ is maximum along the principal direction ![]() $\bar {\boldsymbol {\zeta }}_2$ (figure 2a,b). In the 1-D separation backbones, however,

$\bar {\boldsymbol {\zeta }}_2$ (figure 2a,b). In the 1-D separation backbones, however, ![]() $\bar {\kappa }_2 \cong \bar {\kappa }_1$ and

$\bar {\kappa }_2 \cong \bar {\kappa }_1$ and ![]() $\bar {\boldsymbol {\zeta }}_1, \bar {\boldsymbol {\zeta }}_2$ are not defined (figure 2a,b). In this symmetric case, maxima of

$\bar {\boldsymbol {\zeta }}_1, \bar {\boldsymbol {\zeta }}_2$ are not defined (figure 2a,b). In this symmetric case, maxima of ![]() $\bar {\kappa }_2$ mark the separation backbone. To express this coherence principle mathematically, we consider a general curved no-slip boundary (figure 2c) and a set – mathematically, a foliation – of wall-parallel material surfaces at

$\bar {\kappa }_2$ mark the separation backbone. To express this coherence principle mathematically, we consider a general curved no-slip boundary (figure 2c) and a set – mathematically, a foliation – of wall-parallel material surfaces at ![]() $t_0$ parametrized by

$t_0$ parametrized by ![]() $\boldsymbol {r}_{\eta }(\,\boldsymbol {p}), \eta \in [0,\eta _{1}], \eta _1\in \mathbb {R}^+$, where the boundary is defined as

$\boldsymbol {r}_{\eta }(\,\boldsymbol {p}), \eta \in [0,\eta _{1}], \eta _1\in \mathbb {R}^+$, where the boundary is defined as

We denote the largest principal curvature change along each layer (![]() $\eta = \textrm {const.}$) as

$\eta = \textrm {const.}$) as ![]() ${}_{2}\bar {\kappa }_{\eta }$, the Weingarten map change as

${}_{2}\bar {\kappa }_{\eta }$, the Weingarten map change as ![]() $\bar {\boldsymbol {W}}_{\eta }$ and the corresponding Gauss and mean curvature changes by

$\bar {\boldsymbol {W}}_{\eta }$ and the corresponding Gauss and mean curvature changes by ![]() $\bar {K}_{\eta },\bar {H}_{\eta }$. Following Serra et al. (Reference Serra, Vétel and Haller2018), we give the following mathematical definition.

$\bar {K}_{\eta },\bar {H}_{\eta }$. Following Serra et al. (Reference Serra, Vétel and Haller2018), we give the following mathematical definition.

Definition 1 The Lagrangian backbone ![]() $\mathcal {B}(t)$ of separation is the theoretical centrepiece of the material spike over the time interval

$\mathcal {B}(t)$ of separation is the theoretical centrepiece of the material spike over the time interval ![]() $[t_0,t_0+T]$.

$[t_0,t_0+T]$.

(a) A 1-D backbone

$\mathcal {B}(t)$ is an evolving material line whose initial position

$\mathcal {B}(t)$ is an evolving material line whose initial position  $\mathcal {B}(t_0)$ is a set of points made by positive-valued maxima of the

$\mathcal {B}(t_0)$ is a set of points made by positive-valued maxima of the  ${}_{2}\bar {\kappa }_{\eta }$ field (figure 2b). For each

${}_{2}\bar {\kappa }_{\eta }$ field (figure 2b). For each  $\eta = const.$ layer,

$\eta = const.$ layer,  $\mathcal {B}(t_0)$ is made of positive maximum points of

$\mathcal {B}(t_0)$ is made of positive maximum points of  ${}_{2}\bar {\kappa }_{\eta }$.

${}_{2}\bar {\kappa }_{\eta }$.(b) A 2-D backbone

$\mathcal {B}(t)$ is an evolving material surface whose initial position

$\mathcal {B}(t)$ is an evolving material surface whose initial position  $\mathcal {B}(t_0)$ is a positive-valued, wall-transverse ridge of

$\mathcal {B}(t_0)$ is a positive-valued, wall-transverse ridge of  ${}_{2}\bar {\kappa }_{\eta }$ (figure 2b). For each

${}_{2}\bar {\kappa }_{\eta }$ (figure 2b). For each  $\eta = const.$ layer,

$\eta = const.$ layer,  $\mathcal {B}(t_0)$ is made of positive maxima of

$\mathcal {B}(t_0)$ is made of positive maxima of  ${}_{2}\bar {\kappa }_{\eta }$ along the principal direction

${}_{2}\bar {\kappa }_{\eta }$ along the principal direction  $\bar {\boldsymbol {\zeta }}_2$.

$\bar {\boldsymbol {\zeta }}_2$.

To discern 1-D and 2-D separation backbones, we first identify the set of points ![]() $\boldsymbol {r}_{\eta }(\,\boldsymbol {p})$ on different (

$\boldsymbol {r}_{\eta }(\,\boldsymbol {p})$ on different (![]() $\eta =\textrm {const.}$) layers where

$\eta =\textrm {const.}$) layers where ![]() $2\sqrt {\vert \bar {K}_{\eta }(\,\boldsymbol {p})\vert } = \vert \bar {H}_{\eta }(\,\boldsymbol {p})\vert$. On these points,

$2\sqrt {\vert \bar {K}_{\eta }(\,\boldsymbol {p})\vert } = \vert \bar {H}_{\eta }(\,\boldsymbol {p})\vert$. On these points, ![]() $\bar {\boldsymbol {W}}_{t_0}^{t}(\,\boldsymbol {p})$ does not have distinct eigenvalues. Within this set, a 1-D separation backbone

$\bar {\boldsymbol {W}}_{t_0}^{t}(\,\boldsymbol {p})$ does not have distinct eigenvalues. Within this set, a 1-D separation backbone ![]() $\mathcal {B}(t_0)$ at

$\mathcal {B}(t_0)$ at ![]() $t_0$ is made of positive maximum points of

$t_0$ is made of positive maximum points of ![]() ${}_2\bar {\kappa }_{\eta }(\,\boldsymbol {p}):= \bar {H}_{\eta }(\,\boldsymbol {p})/2$, specified by the conditions in Proposition 2(i) left. The first condition ensures material upwelling while the second and third conditions ensure that

${}_2\bar {\kappa }_{\eta }(\,\boldsymbol {p}):= \bar {H}_{\eta }(\,\boldsymbol {p})/2$, specified by the conditions in Proposition 2(i) left. The first condition ensures material upwelling while the second and third conditions ensure that ![]() ${}_2\bar {\kappa }_{\eta }(\,\boldsymbol {p})$ is maximum, i.e. that

${}_2\bar {\kappa }_{\eta }(\,\boldsymbol {p})$ is maximum, i.e. that ![]() ${}_2\bar {\kappa }_{\eta }(\,\boldsymbol {p})$ has zero gradient and a negative definite Hessian. By contrast, 2-D separation backbones

${}_2\bar {\kappa }_{\eta }(\,\boldsymbol {p})$ has zero gradient and a negative definite Hessian. By contrast, 2-D separation backbones ![]() $\mathcal {B}(t_0)$ at

$\mathcal {B}(t_0)$ at ![]() $t_0$ are made of points

$t_0$ are made of points ![]() $\boldsymbol {r}_{\eta }(\,\boldsymbol {p})$ on different (

$\boldsymbol {r}_{\eta }(\,\boldsymbol {p})$ on different (![]() $\eta =const.$) layers where

$\eta =const.$) layers where ![]() $2\sqrt {\vert \bar {K}_{\eta }(\,\boldsymbol {p})\vert } \neq \vert \bar {H}_{\eta }(\,\boldsymbol {p})\vert$. Within this set,

$2\sqrt {\vert \bar {K}_{\eta }(\,\boldsymbol {p})\vert } \neq \vert \bar {H}_{\eta }(\,\boldsymbol {p})\vert$. Within this set, ![]() $\mathcal {B}(t_0)$ is made of positive maxima of

$\mathcal {B}(t_0)$ is made of positive maxima of ![]() ${}_{2}\bar {\kappa }_{\eta }$ along the principal direction

${}_{2}\bar {\kappa }_{\eta }$ along the principal direction ![]() $\bar {\boldsymbol {\zeta }}_2$, specified by the conditions in Proposition 2(i) right.

$\bar {\boldsymbol {\zeta }}_2$, specified by the conditions in Proposition 2(i) right.

Similar to the 2-D case (Serra et al. Reference Serra, Vétel and Haller2018), in three dimensions, the points (curves) where the Lagrangian one- (two-)dimensional separation backbones connect to the wall are of particular interest for understanding whether the separation is on-wall or off-wall and for potential flow control strategies. We name these on-wall points Lagrangian spiking points ![]() $\boldsymbol {r}_{sp}$ and Lagrangian spiking curves

$\boldsymbol {r}_{sp}$ and Lagrangian spiking curves ![]() $\boldsymbol {\gamma }_{sc}$ (figure 2c). They can be identified as the intersection of

$\boldsymbol {\gamma }_{sc}$ (figure 2c). They can be identified as the intersection of ![]() $\mathcal {B}(t_0)$ with the wall

$\mathcal {B}(t_0)$ with the wall ![]() $\mathcal {W}$:

$\mathcal {W}$:

We provide below an alternative method for locating ![]() $\boldsymbol {r}_{sp}$ and

$\boldsymbol {r}_{sp}$ and ![]() $\boldsymbol {\gamma }_{sc}$ in terms of the Weingarten map. Because

$\boldsymbol {\gamma }_{sc}$ in terms of the Weingarten map. Because ![]() ${}_2\bar {\kappa }_{0}(\,\boldsymbol {p}) = 0$ on the wall,

${}_2\bar {\kappa }_{0}(\,\boldsymbol {p}) = 0$ on the wall, ![]() $\boldsymbol {r}_{sp}$ and

$\boldsymbol {r}_{sp}$ and ![]() $\boldsymbol {\gamma }_{sc}$ are distinguished wall points and lines with maximal positive

$\boldsymbol {\gamma }_{sc}$ are distinguished wall points and lines with maximal positive ![]() ${}_2\bar {\kappa }_{\eta }(\,\boldsymbol {p})$ in the limit of

${}_2\bar {\kappa }_{\eta }(\,\boldsymbol {p})$ in the limit of ![]() $\eta \rightarrow 0$. To this end, we define

$\eta \rightarrow 0$. To this end, we define ![]() $\bar {K}_{\delta \eta }(\,\boldsymbol {p}) = \textrm {det}(\bar {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p}))$ (we use the subscript

$\bar {K}_{\delta \eta }(\,\boldsymbol {p}) = \textrm {det}(\bar {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p}))$ (we use the subscript ![]() $0<\delta \eta \ll 1$ to indicate the leading-order contribution of material folding close to the wall) and

$0<\delta \eta \ll 1$ to indicate the leading-order contribution of material folding close to the wall) and ![]() $\bar {H}_{\delta \eta }(\,\boldsymbol {p}) = \textrm {Tr}(\bar {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p}))$, where

$\bar {H}_{\delta \eta }(\,\boldsymbol {p}) = \textrm {Tr}(\bar {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p}))$, where ![]() $\bar {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p})$ encodes the leading-order curvature change close to the wall. Using

$\bar {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p})$ encodes the leading-order curvature change close to the wall. Using ![]() $\bar {K}_{\delta \eta }$ and

$\bar {K}_{\delta \eta }$ and ![]() $\bar {H}_{\delta \eta }$, in Appendix D we derive explicit formulas for the Lagrangian spiking points and curves in the case of compressible and incompressible flows. The only difference between the two cases is that, in the former,

$\bar {H}_{\delta \eta }$, in Appendix D we derive explicit formulas for the Lagrangian spiking points and curves in the case of compressible and incompressible flows. The only difference between the two cases is that, in the former, ![]() $\bar {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p}):= \partial _{\eta }\bar {\boldsymbol {W}}_\eta (\,\boldsymbol {p})\vert _{\eta =0}$, while, in the latter,

$\bar {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p}):= \partial _{\eta }\bar {\boldsymbol {W}}_\eta (\,\boldsymbol {p})\vert _{\eta =0}$, while, in the latter, ![]() $\bar {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p}) := \partial _{\eta \eta }\bar {\boldsymbol {W}}_\eta (\,\boldsymbol {p})\vert _{\eta =0}$. We summarize our results for the identification of

$\bar {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p}) := \partial _{\eta \eta }\bar {\boldsymbol {W}}_\eta (\,\boldsymbol {p})\vert _{\eta =0}$. We summarize our results for the identification of ![]() $\boldsymbol {r}_{sp}$ and

$\boldsymbol {r}_{sp}$ and ![]() $\boldsymbol {\gamma }_{sc}$ in terms of Lagrangian quantities in table 1.

$\boldsymbol {\gamma }_{sc}$ in terms of Lagrangian quantities in table 1.

Table 1. Exact criteria for the Lagrangian spiking points ![]() $\boldsymbol {r}_{sp}$ and curves

$\boldsymbol {r}_{sp}$ and curves ![]() $\boldsymbol {\gamma }_{sc}$ on a no-slip boundary over the time interval

$\boldsymbol {\gamma }_{sc}$ on a no-slip boundary over the time interval ![]() $[t_0,t_0+T]$ for compressible and incompressible flows. All quantities

$[t_0,t_0+T]$ for compressible and incompressible flows. All quantities ![]() $\overline {({\cdot })}$ describe eigenvalues, eigenvectors, trace and determinant of

$\overline {({\cdot })}$ describe eigenvalues, eigenvectors, trace and determinant of ![]() $\bar {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p})$, consistent with our earlier notation.

$\bar {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p})$, consistent with our earlier notation.

In table 2, we provide exact formulas for computing ![]() $\bar {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p})$ used in the definitions of the Lagrangian spiking points and curves (table 1) in terms of on-wall Eulerian quantities for steady, time-periodic and time-aperiodic flows. The formulas in tables 1 and 2 highlight three important facts. First, in the case of steady flows, spiking points and curves are fixed, independent of

$\bar {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p})$ used in the definitions of the Lagrangian spiking points and curves (table 1) in terms of on-wall Eulerian quantities for steady, time-periodic and time-aperiodic flows. The formulas in tables 1 and 2 highlight three important facts. First, in the case of steady flows, spiking points and curves are fixed, independent of ![]() $T$, and can be computed from derivatives of the velocity field on the wall. Second, in the case of

$T$, and can be computed from derivatives of the velocity field on the wall. Second, in the case of ![]() $T_p$-periodic flows, with

$T_p$-periodic flows, with ![]() $T$ equal to any arbitrary multiple of

$T$ equal to any arbitrary multiple of ![]() $T_p$, spiking points and curves are fixed, independent of

$T_p$, spiking points and curves are fixed, independent of ![]() $t_0$, and can be computed by averaging derivatives of the velocity field on the wall over one period. Third, for general unsteady flows or time-periodic flows with

$t_0$, and can be computed by averaging derivatives of the velocity field on the wall over one period. Third, for general unsteady flows or time-periodic flows with ![]() $T\neq nT_p, n\in \mathbb {N}^+$, spiking points and curves move depending on

$T\neq nT_p, n\in \mathbb {N}^+$, spiking points and curves move depending on ![]() $t_0$ and

$t_0$ and ![]() $T$, and can be computed by averaging derivatives of the velocity field over

$T$, and can be computed by averaging derivatives of the velocity field over ![]() $[t_0,t_0+T]$. We summarize the results of this section in the following Proposition.

$[t_0,t_0+T]$. We summarize the results of this section in the following Proposition.

Table 2. Formulas for computing ![]() $\bar {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p})$ used in the definitions of the Lagrangian spiking points and curves (table 1) in terms of on-wall Eulerian quantities for steady, time-periodic and time-aperiodic flows. Here,

$\bar {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p})$ used in the definitions of the Lagrangian spiking points and curves (table 1) in terms of on-wall Eulerian quantities for steady, time-periodic and time-aperiodic flows. Here, ![]() $f_3= f_3(\boldsymbol {r}_\eta (\,\boldsymbol {p}),t)$, and derivatives are evaluated at

$f_3= f_3(\boldsymbol {r}_\eta (\,\boldsymbol {p}),t)$, and derivatives are evaluated at ![]() $\eta =0$.

$\eta =0$.

Proposition 2 Over the finite-time interval ![]() $t\in [t_0, t_0+T]$:

$t\in [t_0, t_0+T]$:

(i) The initial position

$\mathcal {B}(t_0)$ of the Lagrangian backbone of separation can be computed as the set of points

$\mathcal {B}(t_0)$ of the Lagrangian backbone of separation can be computed as the set of points  $\boldsymbol {r}_{\eta }(\,\boldsymbol {p})\in U, \boldsymbol {p}\in V, \eta \in [0,\eta _1]$ that satisfy the following conditions.

$\boldsymbol {r}_{\eta }(\,\boldsymbol {p})\in U, \boldsymbol {p}\in V, \eta \in [0,\eta _1]$ that satisfy the following conditions.

The Lagrangian spiking points

$\boldsymbol {r}_{sp}$ and curves

$\boldsymbol {r}_{sp}$ and curves  $\boldsymbol {\gamma }_{sc}$ can be computed in terms of Lagrangian quantities using the formulas in table 1, in terms of wall-based averaged Eulerian quantities using the formulas in tables 1 and 2, or as the intersection of

$\boldsymbol {\gamma }_{sc}$ can be computed in terms of Lagrangian quantities using the formulas in table 1, in terms of wall-based averaged Eulerian quantities using the formulas in tables 1 and 2, or as the intersection of  $\mathcal {B}(t_0)$ with the no-slip boundary (4.3a,b).

$\mathcal {B}(t_0)$ with the no-slip boundary (4.3a,b).(ii) Later positions

$\mathcal {B}(t)$ of the Lagrangian backbone of separation can be computed as

$\mathcal {B}(t)$ of the Lagrangian backbone of separation can be computed as  $\mathcal {B}(t):= \boldsymbol {F}_{t_0}^t(\mathcal {B}(t_0))$.

$\mathcal {B}(t):= \boldsymbol {F}_{t_0}^t(\mathcal {B}(t_0))$.(iii) The Lagrangian spiking points and curves

By Proposition 1, the Lagrangian backbone of separation is invariant under coordinate (![]() $\boldsymbol {x}$) transformations (cf. (3.10)) and changes in the parametrization (

$\boldsymbol {x}$) transformations (cf. (3.10)) and changes in the parametrization (![]() $\boldsymbol {r}(\,\boldsymbol {p})$) of initial conditions. Although the analytic formulas in tables 1 and 2 involve higher derivatives of the velocity field, the spiking point can also be identified as the intersection of

$\boldsymbol {r}(\,\boldsymbol {p})$) of initial conditions. Although the analytic formulas in tables 1 and 2 involve higher derivatives of the velocity field, the spiking point can also be identified as the intersection of ![]() $\mathcal {B}(t_0)$ with the wall (cf. (4.3a,b)) with low numerical effort. We note that, in general unsteady flows

$\mathcal {B}(t_0)$ with the wall (cf. (4.3a,b)) with low numerical effort. We note that, in general unsteady flows ![]() $\boldsymbol {f}(\boldsymbol {x},t)$, the flow map

$\boldsymbol {f}(\boldsymbol {x},t)$, the flow map ![]() $\boldsymbol {F}_{t_0}^{t_0+T}$ depends on both the initial time

$\boldsymbol {F}_{t_0}^{t_0+T}$ depends on both the initial time ![]() $t_0$ and on the Lagrangian time interval

$t_0$ and on the Lagrangian time interval ![]() $T$. Varying these two parameters enables uncovering all the separation features generated by

$T$. Varying these two parameters enables uncovering all the separation features generated by ![]() $\boldsymbol {f}(\boldsymbol {x},t)$, and their choice depends on technological limitations and the desired separation analysis. We provide two examples for selecting

$\boldsymbol {f}(\boldsymbol {x},t)$, and their choice depends on technological limitations and the desired separation analysis. We provide two examples for selecting ![]() $t_0$ or

$t_0$ or ![]() $T$ in Appendix I.

$T$ in Appendix I.

5. The Eulerian backbone of flow separation

Over an infinitesimally short-time interval, the Eulerian backbone of flow separation acts as the centrepiece of the material spike formation. We define this Eulerian concept by taking the time derivative of the Lagrangian backbone of separation and evaluating it at ![]() $T=0$. From (4.1a,b), the rate of change of

$T=0$. From (4.1a,b), the rate of change of ![]() $\bar {\boldsymbol {W}}_{t_0}^{t}(\,\boldsymbol {p})$ in the infinitesimally short time limit is

$\bar {\boldsymbol {W}}_{t_0}^{t}(\,\boldsymbol {p})$ in the infinitesimally short time limit is ![]() $\dot {\boldsymbol {W}}_{t}(\,\boldsymbol {p})$ (eq. (3.6)). Denoting by

$\dot {\boldsymbol {W}}_{t}(\,\boldsymbol {p})$ (eq. (3.6)). Denoting by ![]() ${}_{1}\dot {\kappa }_{t}(\,\boldsymbol {p})\leq {}_{2}\dot {\kappa }_{t}(\,\boldsymbol {p})$,

${}_{1}\dot {\kappa }_{t}(\,\boldsymbol {p})\leq {}_{2}\dot {\kappa }_{t}(\,\boldsymbol {p})$, ![]() $\dot {\boldsymbol {\zeta }}_1, \dot {\boldsymbol {\zeta }}_2$ the eigenvalues and eigenvectors of

$\dot {\boldsymbol {\zeta }}_1, \dot {\boldsymbol {\zeta }}_2$ the eigenvalues and eigenvectors of ![]() $\dot {\boldsymbol {W}}_{t}(\,\boldsymbol {p})$, and by

$\dot {\boldsymbol {W}}_{t}(\,\boldsymbol {p})$, and by ![]() $\dot {K}_{t}(\,\boldsymbol {p})= \det [\dot {\boldsymbol {W}}_{t}(\,\boldsymbol {p})]={}_{1}\dot {\kappa }_{t}(\,\boldsymbol {p}) {}_{2}\dot {\kappa }_{t}(\,\boldsymbol {p})$,

$\dot {K}_{t}(\,\boldsymbol {p})= \det [\dot {\boldsymbol {W}}_{t}(\,\boldsymbol {p})]={}_{1}\dot {\kappa }_{t}(\,\boldsymbol {p}) {}_{2}\dot {\kappa }_{t}(\,\boldsymbol {p})$, ![]() $\dot {H}_{t}(\,\boldsymbol {p})= {\textrm {Trace}[\dot {\boldsymbol {W}}_{t}(\,\boldsymbol {p})]}/{2}= ({{}_{1}\dot {\kappa }_{t}(\,\boldsymbol {p})+ {}_{2}\dot {\kappa }_{t}(\,\boldsymbol {p})})/{2}$ the Gaussian and mean curvature rates, we define the Eulerian backbone of separation as follows. We may omit the explicit time dependence notation for compactness.

$\dot {H}_{t}(\,\boldsymbol {p})= {\textrm {Trace}[\dot {\boldsymbol {W}}_{t}(\,\boldsymbol {p})]}/{2}= ({{}_{1}\dot {\kappa }_{t}(\,\boldsymbol {p})+ {}_{2}\dot {\kappa }_{t}(\,\boldsymbol {p})})/{2}$ the Gaussian and mean curvature rates, we define the Eulerian backbone of separation as follows. We may omit the explicit time dependence notation for compactness.

Definition 2 At a time instant ![]() $t$, the Eulerian backbone of separation

$t$, the Eulerian backbone of separation ![]() $\mathcal {B}_E(t)$ is the theoretical centrepiece of the material spike over an infinitesimally short time interval.

$\mathcal {B}_E(t)$ is the theoretical centrepiece of the material spike over an infinitesimally short time interval.

(a) A 1-D backbone

$\mathcal {B}_E(t)$ is a set of points made by positive-valued maxima of the

$\mathcal {B}_E(t)$ is a set of points made by positive-valued maxima of the  ${}_{2}\dot {\kappa }_{\eta }$ field. For each

${}_{2}\dot {\kappa }_{\eta }$ field. For each  $\eta = \textrm {const.}$ layer,

$\eta = \textrm {const.}$ layer,  $\mathcal {B}_E(t)$ is made of positive maximum points of

$\mathcal {B}_E(t)$ is made of positive maximum points of  ${}_{2}\dot {\kappa }_{\eta }$.

${}_{2}\dot {\kappa }_{\eta }$.(b) A 2-D backbone

$\mathcal {B}_E(t)$ is a positive-valued, wall-transverse ridge of

$\mathcal {B}_E(t)$ is a positive-valued, wall-transverse ridge of  ${}_{2}\dot {\kappa }_{\eta }$. For each

${}_{2}\dot {\kappa }_{\eta }$. For each  $\eta = const.$ layer,

$\eta = const.$ layer,  $\mathcal {B}_E(t)$ is made of positive maxima of

$\mathcal {B}_E(t)$ is made of positive maxima of  ${}_{2}\dot {\kappa }_{\eta }$ along the principal direction

${}_{2}\dot {\kappa }_{\eta }$ along the principal direction  $\dot {\boldsymbol {\zeta }}_2$.

$\dot {\boldsymbol {\zeta }}_2$.

Here, ![]() $\mathcal {B}_E(t)$ is a set of points where the instantaneous folding rate is positive and attains a local maximum along each

$\mathcal {B}_E(t)$ is a set of points where the instantaneous folding rate is positive and attains a local maximum along each ![]() $\eta =\textrm {const.}$ surfaces, and can be computed as described in Proposition 3.

$\eta =\textrm {const.}$ surfaces, and can be computed as described in Proposition 3.

Similar to the Lagrangian case, we define the Eulerian spiking point ![]() $\boldsymbol {r}_{spE}$ and the Eulerian spiking curve

$\boldsymbol {r}_{spE}$ and the Eulerian spiking curve ![]() $\gamma _{scE}$ as follows:

$\gamma _{scE}$ as follows:

i.e. where the Eulerian backbones of separation connects to the wall. Because ![]() $\dot {\kappa }_{t}(\,\boldsymbol {p})\equiv 0$ on the no-slip boundary,

$\dot {\kappa }_{t}(\,\boldsymbol {p})\equiv 0$ on the no-slip boundary, ![]() $\boldsymbol {r}_{spE}, \gamma _{scE}$ are distinguished points on the wall with positive maximal curvature rate in the limit of

$\boldsymbol {r}_{spE}, \gamma _{scE}$ are distinguished points on the wall with positive maximal curvature rate in the limit of ![]() $\eta \rightarrow 0$.

$\eta \rightarrow 0$.

For a flat wall, we derive analytic expressions for ![]() $\boldsymbol {r}_{spE} = \boldsymbol {r}_{\eta =0}(\boldsymbol {p}_{spE})$ and

$\boldsymbol {r}_{spE} = \boldsymbol {r}_{\eta =0}(\boldsymbol {p}_{spE})$ and ![]() $\gamma _{scE}$ (a set of

$\gamma _{scE}$ (a set of ![]() $\boldsymbol {r}_{scE} = \boldsymbol {r}_{\eta =0}(\boldsymbol {p}_{scE})$) in Appendix E, and summarize them in tables 3 and 4. For steady flows, comparing the formula of

$\boldsymbol {r}_{scE} = \boldsymbol {r}_{\eta =0}(\boldsymbol {p}_{scE})$) in Appendix E, and summarize them in tables 3 and 4. For steady flows, comparing the formula of ![]() $\boldsymbol {p}_{sp}$ and

$\boldsymbol {p}_{sp}$ and ![]() $\boldsymbol {p}_{sc}$ (cf. table 1) with the one of

$\boldsymbol {p}_{sc}$ (cf. table 1) with the one of ![]() $\boldsymbol {p}_{spE}$ and

$\boldsymbol {p}_{spE}$ and ![]() $\boldsymbol {p}_{scE}$ (cf. table 3), we obtain that the Lagrangian and the Eulerian backbones of separation connect to the wall at the same location, i.e.

$\boldsymbol {p}_{scE}$ (cf. table 3), we obtain that the Lagrangian and the Eulerian backbones of separation connect to the wall at the same location, i.e. ![]() $\boldsymbol {p}_{spE}\equiv \boldsymbol {p}_{sp}$ and

$\boldsymbol {p}_{spE}\equiv \boldsymbol {p}_{sp}$ and ![]() $\gamma _{spE}\equiv \gamma _{sp}$ (see e.g. figure 9). We summarize the results of this section in the following Proposition.

$\gamma _{spE}\equiv \gamma _{sp}$ (see e.g. figure 9). We summarize the results of this section in the following Proposition.

Proposition 3 At a time instant ![]() $t$:

$t$:

(i) The Eulerian backbone of separation

$\mathcal {B}_E(t)$ can be computed as the set of points

$\mathcal {B}_E(t)$ can be computed as the set of points  $\boldsymbol {r}_{\eta }(\,\boldsymbol {p})\in U, \, \boldsymbol {p}\in V,\, \eta \in [0,\eta _1]$ that satisfy the following conditions.

$\boldsymbol {r}_{\eta }(\,\boldsymbol {p})\in U, \, \boldsymbol {p}\in V,\, \eta \in [0,\eta _1]$ that satisfy the following conditions.

The Eulerian spiking points

$\boldsymbol {r}_{spE}$ and curves

$\boldsymbol {r}_{spE}$ and curves  $\boldsymbol {\gamma }_{scE}$ can be computed using the formulas in tables 3 and 4, or as the intersection of

$\boldsymbol {\gamma }_{scE}$ can be computed using the formulas in tables 3 and 4, or as the intersection of  $\mathcal {B}_E(t)$ with the no-slip boundary (5.1a,b).

$\mathcal {B}_E(t)$ with the no-slip boundary (5.1a,b).(ii) The Eulerian spiking point and curve coincides with the Lagrangian spiking point and curve in steady flows.

Table 3. Exact criteria determining the Eulerian spiking points ![]() $\boldsymbol {r}_{spE}$ and curves

$\boldsymbol {r}_{spE}$ and curves ![]() $\boldsymbol {\gamma }_{scE}$ on a no-slip boundary at a time instant

$\boldsymbol {\gamma }_{scE}$ on a no-slip boundary at a time instant ![]() $t$ for compressible and incompressible flows. All quantities

$t$ for compressible and incompressible flows. All quantities ![]() $\dot {\overline {({\cdot })}}$ describe eigenvalues, eigenvectors, trace and determinant of

$\dot {\overline {({\cdot })}}$ describe eigenvalues, eigenvectors, trace and determinant of ![]() $\dot {\bar {\boldsymbol {W}}}_{\delta \eta }(\,\boldsymbol {p})$, consistent with our earlier notation.

$\dot {\bar {\boldsymbol {W}}}_{\delta \eta }(\,\boldsymbol {p})$, consistent with our earlier notation.

Table 4. Formulas for computing ![]() $\dot {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p})$ used in the definitions of the Eulerian spiking points and curves (table 3) in terms of on-wall Eulerian quantities. Here,

$\dot {\boldsymbol {W}}_{\delta \eta }(\,\boldsymbol {p})$ used in the definitions of the Eulerian spiking points and curves (table 3) in terms of on-wall Eulerian quantities. Here, ![]() $f_3= f_3(\boldsymbol {r}_\eta (\,\boldsymbol {p}),t)$, and derivatives are evaluated at

$f_3= f_3(\boldsymbol {r}_\eta (\,\boldsymbol {p}),t)$, and derivatives are evaluated at ![]() $\eta = 0$ and

$\eta = 0$ and ![]() $t= t_0$.

$t= t_0$.

By Proposition 1, the Eulerian backbone of separation is objective. Following the same argument of § 4, although the analytic formulas in table 4 involve higher derivatives of the velocity field, the spiking point can also be identified with low numerical effort directly from (5.1a,b), as the intersection of ![]() $\mathcal {B}_E(t)$ with the wall.

$\mathcal {B}_E(t)$ with the wall.

6. Numerical schemes

We summarise the numerical steps necessary to locate Lagrangian and Eulerian separation backbones in a general 3-D flow.

Algorithm 1: Compute the Lagrangian backbone ![]() $\mathcal{B}(t)$ of separation (Proposition 2)

$\mathcal{B}(t)$ of separation (Proposition 2)

Algorithm 2: Compute the Eulerian backbone ![]() $\mathcal{B}_E(t)$ of separation (Proposition 3)

$\mathcal{B}_E(t)$ of separation (Proposition 3)

In §§ 7.1–7.5, we have applied Algorithms 1 and 2 using the standard ode45 function in MATLAB (2021b) with absolute and relative tolerances ![]() $10^{-6}$ to compute

$10^{-6}$ to compute ![]() $\boldsymbol {F_{t_0}^t}(\boldsymbol {x_{0}})$, and approximated spatial derivatives of