From its inception in 1946 until its acquisition by CBS in 1965, the Fender Electric Instrument Company witnessed significant transformations in popular music and U.S. culture. The period spans the last death knell of big band jazz in the late forties, the meteoric ascendancy of rock ‘n’ roll in the mid-fifties, and the first ripples of the British invasion a decade later. Fender's instruments and amplifiers became a connective tissue between all these musical scenes and epochs. During this period, the company developed the first commercially available solid body guitars—the Telecaster and Stratocaster—the first fretted electric bass, the Rhodes electric piano, and countless amplifiers that would go on to shape the sound of popular music in the second half of the twentieth century. Among Fender connoisseurs, instruments from before the company's CBS era are among the most well regarded and valuable instruments in all popular music. It is during this golden age that Fender manufactured its highly coveted “Tweed” line of amplifiers.

Nicknamed for their twill fabric coverings, amplifiers from Fender's so-called Tweed era (1948–60) have a distinctive fuzzlike overdriven sound that can be heard on many of the most celebrated records from rock history, including The Who's “We Won't Get Fooled Again,” The Eagles’ “Hotel California,” Eric Clapton's “Layla,” Crosby, Stills, Nash, & Young's “Ohio,” and countless others. From the earliest days of rock ‘n’ roll to the present, countless notable guitar players can be seen playing a Tweed amplifier at one point or another. Live photographs from the 1950s even show Elvis Presley running his vocal microphone through a Fender Tweed Bandmaster. For many contemporary guitar players, nostalgia for rock music's canonic tones has no doubt contributed to the sustained interest in Tweed-style amplifiers. Nevertheless, among the niche subset of vintage Tweed amplifier collectors, it is another group of individuals associated with the company's golden age that contributes to the prized status of these vintage amplifiers.

Inside most vintage Fender Tweed amplifiers is a piece of masking tape on which is inscribed the handwritten signature of one of the roughly half-dozen first-generation Mexican American women who hand-wired the company's most collectible instruments at its original Fullerton, California factory (see Figure 1). These builder-signed Tweed amplifiers have since become fetish objects for vintage amplifier collectors who have fabricated highly romanticized and mythological versions of several of Fender's most prolific Tweed-era female wirers. In particular, Lupe Duarte (1930–2009) and Lydia “Lily” Jaimes (1930–2015) have become two of the most well-known and well-regarded of Fender's Tweed-era employees. Since the 1990s, Tweed amp collectors have gradually elevated Duarte, especially, from an unknown factory worker into a legendary figure with a near cultlike following, such that by now her handwritten signature has become an inseparable part of the Tweed amp collecting experience.

Figure 1. “Lily” signed 1955 Fender Tweed Twin. Photo courtesy of Gary Economy.

Within online forums dedicated to vintage Fender instruments, builder signatures are prominent topics of conversation. Collectors displaying their instruments online commonly identify the builder's name associated with their vintage Tweed amplifiers, proudly touting a “Lupe” or “Lily” signature as a valuable addition to their already-rare amps. Although some guitarists have expressed a willingness to pay more for amplifiers signed by certain builders, it is more often sentimental value that guitarists seek in an amplifier signed by a recognized builder. In online forums, the participants (many of whom appear to be men with disposable income) often employ hyperbole to exaggerate the value or specialty of a Lupe-signed instrument.Footnote 1 Consider the following anecdote one guitarist shared in a Facebook group for Tweed amp collectors about his near mint condition 1956 Fender Tweed Champion, which he calls his “Champ Lupe.” His post relays a conversation he had with a repair technician in Los Angeles: “I saw a piece of masking tape inside, and I think it says ‘Leo [Fender].’ But before I got that out of my mouth, he said, ‘Don't tell me, it says “Lupe”.’ Although I kind of wanted it to say Leo, I realized [he] was right. He said, ‘Don't worry, that's a much more valuable signature.’”Footnote 2 This extraordinary declaration perfectly encapsulates the extent of Lupe Duarte's status within the Tweed amplifier collecting community.

Fender's Tweed-era amplifiers are mass-produced consumer electronic devices, which collectors now treat as singular, artlike objects, catapulting a team of once-anonymous factory workers into folk-heroes whose magical auras are thought to reside within the instruments they assembled. Whereas scholarship on instrument making has primarily studied artisanal skills like woodworking, this article takes mass production of analog electronic circuits as its focus.Footnote 3 Crucially, this article also extends the limits of typical research into consumer and collector cultures, because this is a unique instance wherein collectors have come to value the work of individual assembly line employees. This article therefore not only expands the scope of music research but also provides novel insights into the interdisciplinary research on labor history, consumerism, and cultural studies more broadly.Footnote 4

Alongside the recent resurgence in popularity of vintage hand-wired electric guitar gear, there seems to be a parallel interest in recovering the hands behind the wiring. However, with very few exceptions, collectors and historians seldom reference available biographical details about Duarte or Jaimes, of which there are few to begin with. Instead, they have largely favored heavily mythologized accounts of their technical skills and proximity to the company's golden age.Footnote 5 Because contemporary guitarists know so little about Duarte or Jaimes as people, contemporary discourses about them often inadvertently reinforce stereotypes about their Mexican and female identities, casting them as ideal laborers due to spurious stereotypes about their supposedly dexterous hands and fingers. These stereotypes are not only inaccurate, but they have been historically used to cast labor-intensive assembly work as “unskilled” and suppress wages for female workers who occupy these roles.Footnote 6

In this article, I present a history of Fender's female workers to counter the mythology and misinformation surrounding them. This article begins with a history of Fender's Tweed-era factory system, introducing the people and processes behind the company's beloved instruments. Although this period in Fender's history is among the most well documented in guitar history, there are precious few resources for understanding the perspectives of Fender's factory employees. Drawing on oral history, genealogical research, and published secondhand accounts, this article seeks to humanize Fender's mid-century instrument builders, with a special attention to the biographies and experiences of Lupe Duarte and Lydia Jaimes, while also tracking the company's shifting working conditions throughout the Tweed era.

Then, utilizing conversations with repair technicians and collectors, as well as close readings of online discourses, I describe how Fender's Tweed amplifiers have been transformed from relatively undesirable secondhand equipment into high-value collectibles. Following these discursive channels, I suggest that the contemporary interest in builder-signed Tweed amplifiers reflects a broader social process of making Fender's earliest amplifiers “vintage.” Lastly, I evaluate the persistence of gendered and racialized stereotypes about Fender's female employees being naturally equipped for labor-intensive assembly work due to their supposedly “nimble fingers.” In turn, I suggest that discourses which romanticize the labor of the women who built Fender's Tweed-era amplifiers obscure the mass-produced nature of Fender's Tweed amplifiers, overlooking the realities of the conditions under which these women worked. I offer this article as a first step toward recovering the nuances involved in labor-intensive electronics assembly work and seek to represent Fender's earliest workers with dignity and in their whole humanity. Whenever possible, I try to let Fender's employees narrate their own stories by incorporating what few firsthand accounts survive from the Tweed era.

Fender's Tweed Era

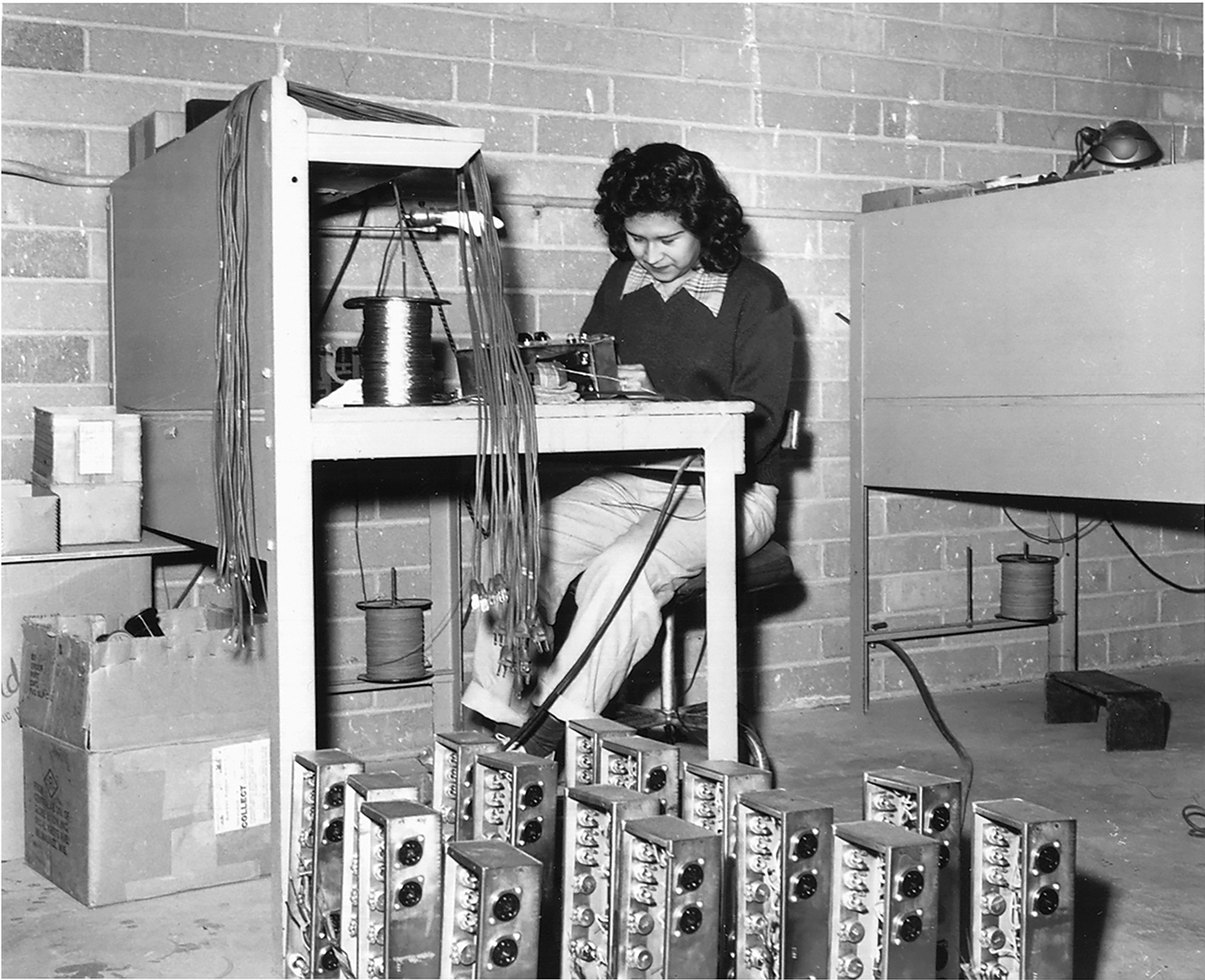

Lupe Duarte and Lydia Jaimes were both born and raised in southern California to Mexican immigrant parents (see Figures 2 and 3). Lupe Carmen Lopez Duarte first appears in the historical record in the 1940 Fullerton, California census, as “Lupi Lopez,” aged nine, and the eldest of three children.Footnote 7 In the 1930 census, the year of her birth, Duarte's parents, Louis and Jennie Lopez are listed as residing with her mother's family, along with fifteen other family members.Footnote 8 By 1940, her family had moved out on its own, and her father is recorded in the census as working as a boot black at a shoe shining parlor, although the census reports no income for the previous calendar year.

Figure 2. Lupe Duarte soldering an amplifier in the Fender factory, year unknown. Photo courtesy of Fender.

Figure 3. Lydia Jaimes assembling a Fender Telecaster in the Fender factory, year unknown. Photo courtesy of Fender.

Lydia Sanchez Jaimes first appears in the 1930 Ventura, California census as “Lidia Sanchez,” age zero.Footnote 9 Her parents, Praxedis and Napomusena Sanchez are listed as Mexican immigrants who migrated to California in 1916. A decade later, Jaimes is recorded in the 1940 Fullerton, California census as the middle of five children at 11 years old, living in Santa Paula, a majority Latino neighborhood, known colloquially as the “citrus capital of the world.”Footnote 10 Her father, Praxedis, worked as a fruit picker on a local citrus grove, but reports having been out of work for 20 weeks at the time of the 1940 census.

In the wake of the Great Depression, Mexicans living in southern California were among the hardest hit, facing unemployment rates as high as 50 percent.Footnote 11 Many of the region's Mexican women who worked during this period were teenage girls, who entered the workforce for myriad reasons, though especially to supplement their family's income for economic survival. Jaimes's daughter, Eileen Stelmark, recalls her mother's family being “poor. Really poor.”Footnote 12 Neither Jaimes's nor Duarte's mothers are listed as working at any point during their childhood, reflecting a hierarchy of labor described by historian Vicki Ruiz, in which “teenage daughters often entered the labor market first, followed by their mothers if additional income was needed.”Footnote 13 According to Stelmark, Jaimes attended Anaheim High School but did not graduate, leaving during the ninth or tenth grade. It was commonplace for young first-generation Mexican girls to leave school after the eighth grade if their labor power was required to supplement their family's income.Footnote 14 In Jaimes's case, however, Stelmark describes a clash between her mother's personality and her grandparents’ strict household that ultimately led Jaimes to run away from home when she was fifteen. Eager to make her own money and set her own rules, Jaimes stayed with extended family in Anaheim for several years, doing housework to make ends meet. According to Stelmark's recollections, “after a couple of stays with family, she was able to afford her own apartment.”Footnote 15

Jaimes and Duarte started working at Fender between 1948 and 1949 when they both would have been around 18 years old.Footnote 16 Former factory manager, Forrest White, notes in his memoir that Fender hired both women when they were “barely old enough to work.”Footnote 17 A short passage from White's memoir offers the only firsthand description of Duarte's and Jaimes's time at Fender to date. In the passage, White recalls, “Lupe and Lily had been wiring guitar small parts assemblies and amplifier chassis from day one. Their work was outstanding. When Leo [Fender] had a new project he was working on, he would have them do the wiring for him.”Footnote 18 White goes on to explain that when Fender made last minute changes to his amplifier designs, he would communicate the revisions directly to Duarte and Jaimes, causing issues in the quality control process for employees not privy to Fender's ever-changing whims.Footnote 19

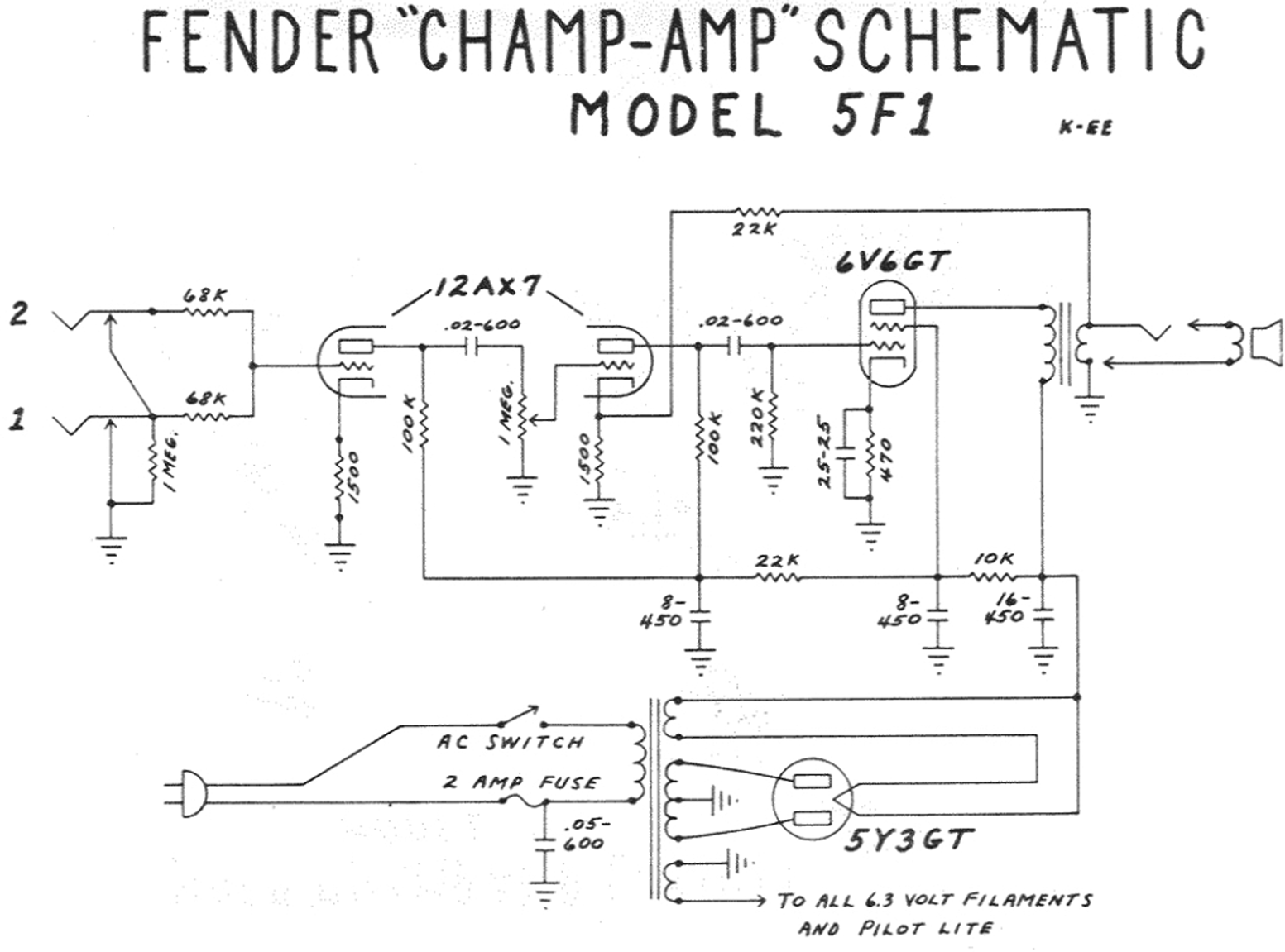

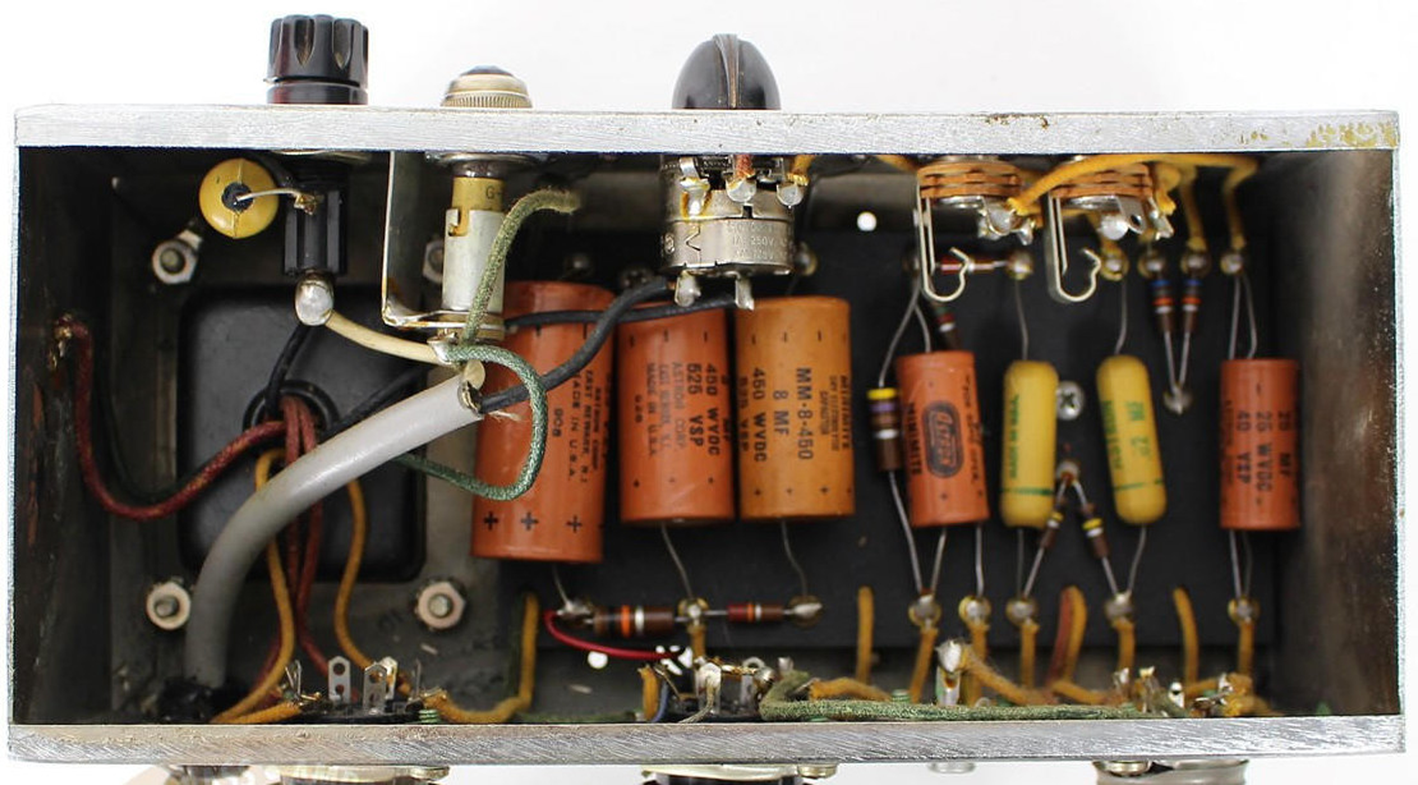

Neither Jaimes nor Duarte appear to have had any prior experience with electronics or musical instruments before being hired. During Fender's Tweed era, it was common for the company's female employees to learn multiple steps in the assembly process and fill in as needed.Footnote 20 According to White's account, Duarte and Jaimes worked in small parts assembly, installing hardware onto Fender's electric guitars, in addition to their more prominent work wiring chassis in the amplifier department. Fender's novel manufacturing processes took a Fordist approach to instrument assembly, a process that Fender maintains “quickly turned novices into experts.”Footnote 21 Fender's Tweed amplifiers were all wired by hand using either point-to-point (PTP) wiring or hand-wired circuit boards. In PTP wired circuits, the terminal of one electronic component is soldered directly to the terminal of the next using a soldering iron (see Figure 4). Fender's earliest and simplest amps, with as few as a dozen-or-so components, were all assembled with this technique. Later, and more complex, amplifier circuits were hand-wired on insulated circuit boards. Each component was anchored to a conductive stud in the board, and short wires were installed to connect the circuit's different studs. These hand-wiring techniques can be contrasted with later manufacturing processes involving printed circuit boards (PCBs), for instance, in which preprinted conductive pathways replace electrical wires and direct connections. Because each component on a PCB fits into a prefabricated hole, there is little room for variation between circuits. In hand-wired manufacturing, by contrast, although the general assortment and order of the components is predetermined by a circuit diagram, there is a degree of individual autonomy in how the blueprint is realized.

Figure 4. PTP wired 1954 Fender Tweed Champ circuit, signed by Lupe Duarte. Notice how all components are wired directly to one another by wire, or by PTP connections. Photo courtesy of Paul Trynka.

Any circuit schematic only notates functional relationships between components, documenting the path of electrical flow and not the spatial layout between components in an actual circuit (see Figure 5).Footnote 22 On the Fullerton factory benches, however, each amplifier's assembly was also aided by visual instructions for the spatial layout of each component (see Figures 6 and 7). Irene Vasquez, Fender's sixth-hired employee, recalls the measures the company implemented to streamline circuit assembly: “Fender was… very organized. I would wire amps and guitars, and he always had things color coordinated for us to put them together easier.”Footnote 23 Speaking of Fender's elegant instructions, Mark Baier of Victoria Amps said admiringly, “The guy who drew those schematics was the Michelangelo of electronic draftsmen.”Footnote 24

Figure 5. Fender Champ 5E1 schematic, showing functional relationships between components.

Figure 6. Fender Champ 5F1 layout. Notice the additional spatial details provided in this layout that the schematic above lacks.

Figure 7. Hand-wired Fender Champ 5F1 circuit. Notice the visual homologies between the above layout diagram and the actual layout of the components within the chassis. Also notice how components are wired to metal studs in the black circuit board, in contrast to the above PTP wired circuit. Photo courtesy of Cream City Music.

Although Fender's easy-to-follow instructions expedited the manufacturing process, there are numerous points at which an individual builder must still negotiate complex dynamics between technology, materials, and self.Footnote 25 As the editors of The Relentless Pursuit of Tone describe, the women who wound guitar pickups at Fender-contemporary Gibson in the 1950s had to contend with winding machines that frequently malfunctioned. This required them to make on-the-fly decisions about how long and how tightly to wind each pickup, resulting in worker-introduced variety between instruments from the same manufacturing line.Footnote 26 Not only would Fender's pickup wirers have been similarly responsible for making on-the-fly decisions about how long they let the machine run, but they were also tasked with repairing the fickle machines themselves. Although being able to maintain overused factory machinery can generate significant value for a company, jobs requiring such responsibilities are rarely classified as “skilled” labor.Footnote 27 Nevertheless, Fender historian Richard Smith reports that Leo Fender liked to say that “properly trained people wound [pickups] tighter—a key to Fender tone—than the machines later used in most modern factories.”Footnote 28 Likewise, in amplifier wiring roles, women like Duarte and Jaimes displayed their resourcefulness in myriad ways, including seemingly using nail polish to secure loose screws in an amplifiers’ chassis (see Figure 1). Through such idiosyncratic material traces, contemporary collectors have attempted to reconstruct each builder's individual process. Distinctive features that collectors believe they can relate back to a builder's personal style reveal each amplifier to be unique, despite their mass-produced origins.

A truism among electric guitar players is that two hand-wired amplifiers will sound distinct from one another, even if they contain identical circuits and components. Although guitarists have offered numerous explanations for this perceived uniqueness, the inconsistencies of the hand-wiring process permit them to attribute a circuit's idiosyncrasies to the builder by whom it was assembled.Footnote 29 One guitarist familiar with Tweed-era amplifiers insists, for instance, “if you start comparing amps built by these ladies you will come to see that they each had a style and left their unique mark. I have seen amps where the wires were pushed down very tight against the chassis others elevated, some twisted the wires tighter than others.”Footnote 30 As such, each circuit is thought to have its own individual character, intimately connected with the builder by whom it was assembled. Because Duarte's unique “style” is believed to be inscribed inside the circuits she built, all “Lupe”-signed amplifiers are also assumed to be genealogically related to one another in ways important to how guitarists invest their gear with meaning. The legibility of the hand-wiring process then resonates with Glenda Goodman's discussion of mediation in various methods of music printing:

Each form of [textual] reproduction required a tool to mediate between the human body and the surface of inscription. The degree to which that human presence is detectable on the page varies…. Manuscript foregrounds the copyist's physical self: the intimacy of the hand moving across the page is clearly evident in the quirks and care displayed by all kinds of handwriting.Footnote 31

The “quirks” and “care” inscribed by Duarte's and Jaimes's hands inside Fender's Tweed amplifiers have led some collectors to view their precious instrument as if its builder's presence still resides within. Guitarists often employ a builder's name metonymically to represent the instruments bearing their signatures, as when they say, “My ’54 Deluxe is a Lupe.”Footnote 32 Like religious relics, Fender's Tweed amplifiers are thought to preserve the essences of the heavily mythologized women who came into contact with them.

That Tweed-era instruments are signed by hand, and not only given a rubber-stamped serial number, is a further key to the imagined immediacy of Duarte's presence within the amplifiers bearing her signature.Footnote 33 Writing about the intimacy of keepsake postcards, Ceri Price notes that:

Handwriting is highly individual and that of a familiar is as immediately identifiable as a photograph. The crossings out, underlining, corrections, drawings and diagrams of the writer remain visible on the surface of the card and so the writer becomes embodied in the materiality of the postcard.Footnote 34

Many collectors now believe that each extant builder signature marks an intentional act in which a worker inscribed their presence inside an amplifier as a sign of pride in their work. Missing the signature's intended role as a tool of workplace surveillance, such misinterpretations instead align the labor-intensive work of electronics assembly with European visual art traditions, in which “the placing of a signature on a painting is a conscious act by the painter that establishes his or her presence…. [and] communicates information about the painter's relationship inward, to the painting itself: its form, subject, and even the process of its creation.”Footnote 35 Even just a cursory glance at the history of Fender's Tweed-era factory system, however, reveals a more complicated story, at times involving dangerous working conditions, belying these romanticized narratives.

Working Conditions at Fender

During the company's early years, Fender's manufacturing operations were housed in two 30′ × 60′ sheet metal buildings on Santa Fe Avenue in Fullerton, California, fabricated by the California Steel Construction Company of Los Angeles in 1946 (see Figure 8).Footnote 36 By all accounts, the buildings’ poor design contributed to both uncomfortable and dangerous working conditions.Footnote 37 Fender's sixth-hired employee, Irene Vasquez, later recalled the shortcomings of the company's earliest buildings: “The first factory was composed of corrugated metal and chain link. It was somewhat exposed to the elements. You had to walk across the street to the gas station to use the restroom.”Footnote 38 The safety standards during these early days were scandalously low, causing much dismay to the local health and safety inspectors, who engaged Fender in a prolonged game of cat and mouse trying to stop production.Footnote 39 In perhaps the most widely repeated anecdote from the Fullerton factory system, when a fire inspector visited the shop floor, he was so frightened by what he saw—highly flammable acetate containers being heated beside an open gas flame—that he hastily exited the building and called Leo Fender from a pay phone down the street.Footnote 40 Later recounting the hazards of his former workplace, Fender rarely seemed concerned, although he once admitted, “it's even dangerous just to look at a picture of a place like this.”Footnote 41

Figure 8. Fender's original Fullerton factory buildings. Photo courtesy of Fender.

More commonly, Leo Fender framed these stories as humorous. In his memoir, former plant manager Forrest White punctuates the fire inspector story by telling his readers, “I wish you could have heard [Leo Fender] laugh [when telling the story].”Footnote 42 Although there were never any fires, there were numerous workplace accidents, the most horrific of which were apparently recounted with fits of laughter from Fender. One graphic accident from 1947, which historian Richard Smith attests Fender “loved to repeat,” concerned a male employee whose genitals were pierced by a large, splintered piece of walnut hardwood sent flying by a circular saw. Smith writes that “relating this mishap as much as forty years later, Leo could hardly stop laughing.”Footnote 43 Despite abundant evidence about the conditions under which Lupe Duarte and her peers labored during the early years of Fender's Tweed era, historians tend to gloss over the bodily dangers faced by the company's earliest employees. Consider, for example, this passage from a recent Fender biography by author Ian S. Port:

Leo, of course, knew that his factory wasn't a safe environment: one employee had seen his guitar playing career ended when a punch press sliced off four fingers, and another mishandled a table saw and sent a shard of wood straight into his groin. But [at the time], there were bigger problems.Footnote 44

Port's pivotal “but” implies an acknowledgment that the health and safety of Fender's employees was a lesser priority than the company's profitability (the “bigger problem”).Footnote 45 Rather than acknowledge the fraught conditions under which Fender's Tweed-era instruments came to be, historians more commonly portray Leo Fender as a loving employer whose rapport with his workers was more paternal than anything. For instance, an unpublished resource on “Famous Fender Women” shared with me by the company prominently features an anecdote about Irene Vasquez returning to the workshop for a 2011 Gala when she reminisced fondly of her time with the company, saying “Leo was the nicest guy you could hope to meet and was like a father to me.”Footnote 46 Likewise, writing about Lupe Duarte and Lydia Jaimes in his memoir, Forrest White reckons, “Lupe and Lily both thought [Leo Fender] was the next thing to a deity. He had almost spoiled them rotten because, hey these were his kids; he had practically raised them.”Footnote 47

Undeniably, as the company expanded during the early years of the Tweed era, work conditions in the company's Fullerton factory system gradually improved. In 1952, Fender employed contractor Grady Neal to construct four new 40′ × 120′ concrete buildings on Raymond Ave in Fullerton, which, by Neal's assessment, were the strongest in the country for their size.Footnote 48 Within a year, Fender's whole production process was moved from the original sheet metal buildings into the new facilities. Between 1956 and 1958, Fender continued expansion on the Raymond Ave lot, ultimately creating nine buildings for a total of 25,000 square feet at a cost of $300,000.Footnote 49 Beyond the upgraded facilities, which afforded safer and more streamlined working conditions, the company instituted a factory-wide incentive program in 1956, through which an individual's piecework and share of the group bonus plan were tied to a quality-control plan. As Forrest White explains:

It was set up so that each operator was an inspector. So if you were on an assembly line and you did your job before it passes on to me, if it came over to me and I saw there was something wrong there that you hadn't done right, I'd say, “Hey, take it back Tony, do it right, and then I'll accept it.” So every operator was an inspector, too. And if they had to rework it, it was on their own time.Footnote 50

Looking back, White recounts his incentive program with pride and emphasizes the opportunities it ushered for workers to participate in the group bonus plan: “The plan was successful because the employees were happy. They were making good money.”Footnote 51 Tweed-era pickup winder Abigail Ybarra's recollections of the incentive plan were similarly positive, telling She Shreds magazine in 2017: “[There] was a time [when] we had an incentive plan and we were earning more money in Fender than in other companies around there. I remember there was this girl that came in working in the office—when she saw our checks, she transferred into the factory.”Footnote 52

Beyond economic survival, Fender's factory assembly work seems to have afforded its employees comfortable lifestyles, facilitating upward economic mobility and a transition from what Louise Tilly and Joan Scott call a wage economy to a consumer economy.Footnote 53 For young Mexican women especially, their wages presented opportunities to assimilate with their U.S. peers via entrance into consumer culture.Footnote 54 Reflecting on her mother's meticulous self-presentation, Stelmark reasons that Jaimes enjoyed working at Fender for the lifestyle it afforded: “We always had new—always had nice things, and maybe she really enjoyed that lifestyle… She always had the brand-new car… You know, she had to have the Buick or the Cadillac…. She took pride in her work, her dress, her status of having a nice home.”Footnote 55

In the first week of 1965, Leo Fender sold his company to CBS for an unprecedented $13 million, $2 million more than CBS had paid for the New York Yankees 1 year earlier. With the change of ownership came swift and forceful changes to the company's operations, including phasing out the popular incentive program and introducing cost-cutting measures throughout the company's manufacturing process. One result of these changes was a reduction in variation between instruments and amplifiers made by different employees. In light of these unpopular changes, collectors and historians have come to view the company's early days with favor, and they approach instruments and amplifiers from this period as artlike objects, denying their origins as mass-produced electronic commodities.

Making Fender's Tweed Amplifiers “Vintage”

Since the 1990s, high-end “boutique” amplifier workshops have emerged, through which Fender's pre-CBS mass-production techniques have been translated into highly labor-intensive artisanal rituals. Accordingly, contemporary builders and collectors retroactively project modern boutique values onto Fender's mid-century mass-production processes. This logic is evident, for example, in the anachronistic language of “apprenticeship,” which is regularly used to describe the company's makeshift training program.Footnote 56 What originated as mass-production techniques within an industrial factory are now highly exalted rituals with their own values of authenticity. Consider the word choice of Maricela ‘MJ’ Juarez, who has been hand-winding pickups in Seymour Duncan's boutique workshop since 1982, when describing the urgency to preserve the hand-making process: “For Seymour [Duncan] and me, the word ‘vintage’ is like a prayer your grandma taught you. The reason it's grandma's ‘prayer’ and not grandma's ‘recipe’ is because the word ‘vintage’ is holy. You have to go down to the details and keep those things as original as possible.”Footnote 57

Boutique builders study the hand-wiring of Fender's Tweed-era employees to authentically reproduce the supposed magic of a vintage Tweed amp's circuitry. Numerous workshops operate period-correct tools and machinery—sometimes the exact machines used in Fender's and Gibson's golden age factories—amounting to historically informed performances of making.Footnote 58 These performances of golden-age manufacturing values are highly meaningful to buyers, who invest as much in the builder and production process as in the instrument itself. This dynamic has been well-documented regarding wooden instruments, like violins and acoustic guitars, as Kathryn Marie Dudley explains in her ethnography of artisanal lutherie:

What we “hear” when we attend to the sound of particular instruments is more than just vibrations in the air; we are also listening to how the materials that compose them were treated in the production process—from the felling of trees to the builder's finishing touch. The more we know about that process, the more nuanced our appreciation of tone becomes.Footnote 59

The sustained interest in builder-signed Tweed amplifiers and their boutique reproductions demonstrate that this longstanding link between builder and craft object also extends to electronic commodities.

Grafting rhetorical strategies from these acoustic instrument communities, guitarists have long understood that handcrafted wooden instruments commonly improve with age, becoming not only more valuable, but indeed better sounding with each passing year.Footnote 60 Amplifiers, by contrast, rely almost wholesale on analog electronics to function, which are subject to faster cycles of obsoletion and failure. In the first few decades of the electric guitar, most professional guitarists assumed that older amplifiers were more prone to failure than newer models and therefore required more frequent and exhaustive servicing to remain functional. Common practice dictated either using a brand-new amplifier or gutting an older one and replacing its aging components with newer, more modern-sounding alternatives. Gradually, throughout the late 1980s and early 1990s, a preservationist approach to vintage amplifier repair took hold, with prominent amp technicians asserting that “if it's a good old amp, and it's been serviced and fixed, it doesn't get more reliable than that.”Footnote 61 The current landscape, in which older amplifiers are perceived as better made, better sounding, and more collectable, is the culmination of a decades-long social process of “making vintage” older amplifiers undertaken by guitarists, collectors, builders, repair technicians, historians, and journalists.Footnote 62

As collectors gradually embraced the advantages of a perfectly preserved vintage amplifier circuit, they also began to direct their attention to the ephemera and miscellanea—like builder signatures—connected with their decades-old instruments.Footnote 63 One guitarist, who blogs under the pseudonym “The Tone Hunter,” authored a step-by-step guide for using Adobe Photoshop to read faded ink on old Tweed amp tube charts, serial numbers, and builder signatures, revealing the nature of the evidence marshaled to forensically analyze vintage amplifiers. He explains: “Part of the reason we love these old amps is the historic minutia that you can glean from them.”Footnote 64 This forensic fixation on an instrument's ephemera and inscriptions, like a “Lupe” signature, supports conclusions from consumer behavior research that collectors purchase used goods, not only for their utility value, but also for their “contact histories.”Footnote 65 By emphasizing these contact histories, collectors of vintage and boutique amplifiers can cast Fender's mass-produced instruments as exceptional, artlike objects with unique contact histories, as opposed to disposable, mass-produced commodities.

Igor Kopytoff's formative research on the processual nature of commoditization describes that, in “complex societies,” consumers express a “yearning for singularization,” his term for the social process of decommoditization, or transforming a commodity into something unique and special.Footnote 66 This “making vintage” of Fender's Tweed-era amplifiers is essentially a process of singularization—diverting a mass-produced technology from its usual commodity pathways into the realm of artlike objects. Casting mid-century amplifiers as “vintage,” as opposed to “secondhand,” has facilitated the emergence of a veritable community of hobbyists, who can bond with one another and produce value by interpreting the various material traces within their instruments from this bygone golden age of guitar manufacturing. In her research on acoustic luthiers, Kathryn Marie Dudley suggests that “what fledgling builders hope to learn through lutherie's scenes of instruction… is a culturally meaningful way to be white, male, and economically self-sufficient in a postindustrial society.”Footnote 67 Likewise I contend that, through the Tweed amp object, contemporary guitarists, collectors, and boutique builders can construct their own identities—as musicians, collectors, consumers, men—in relation to an imagined builder, who, because of her anonymity and obscurity, can reflect the wide-ranging expressions of masculinity and selfhood within the Tweed amp collecting community.Footnote 68

The Myth of “Nimble Fingers”

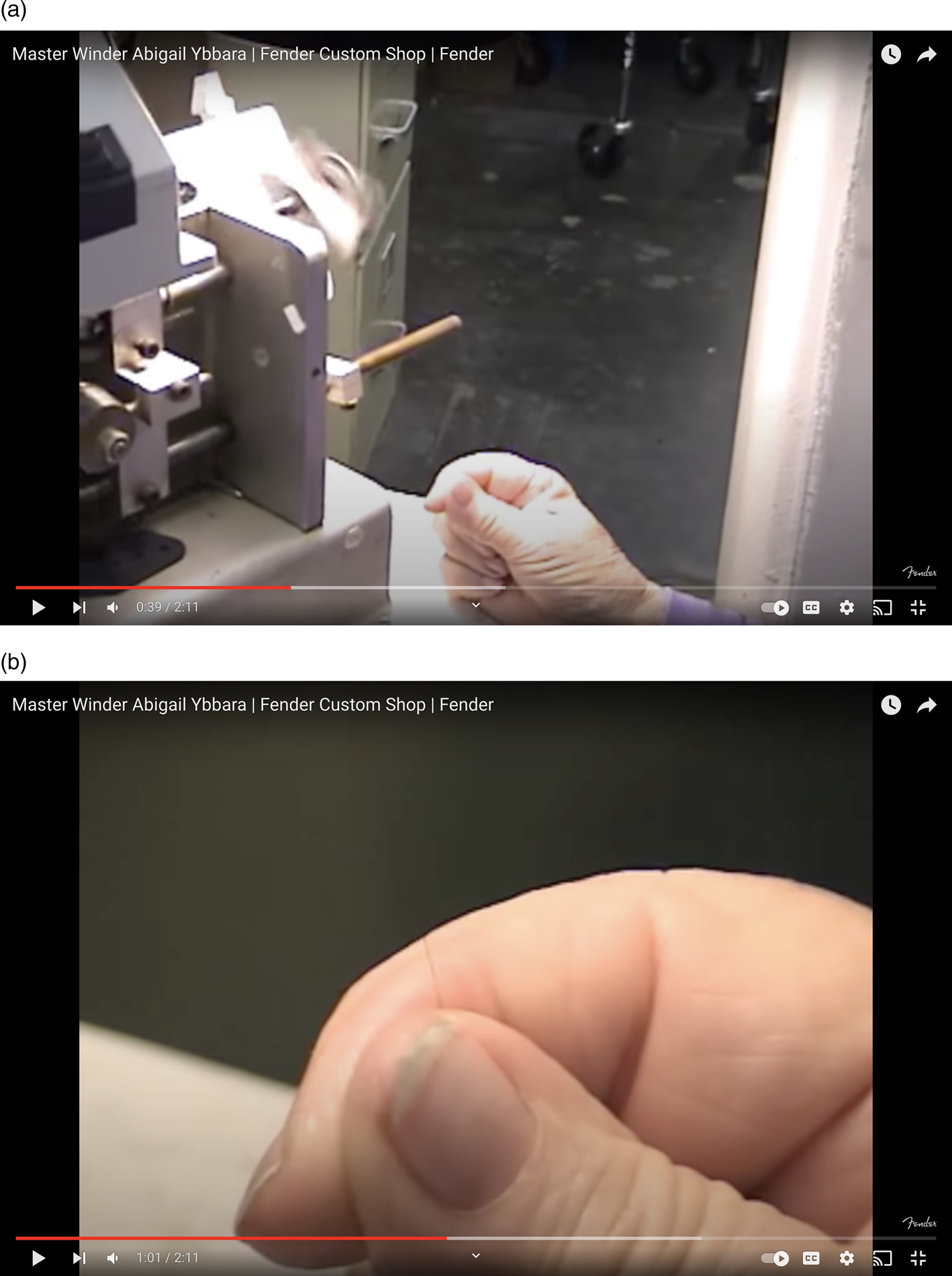

Much of the discourse surrounding Fender's Tweed amplifiers emphasizes their hand-made nature, and specifically fetishizes the hands and fingers of the women who assembled them. Consider Seymour Duncan, a legendary boutique pickup winder who learned the craft by studying Tweed-era winder Abigail Ybarra's work. For Duncan, vintage Fender pickups appear haunted by the specter of the hands that wound them: “I remember when I had to fix [Ybarra-made] pickups for people, taking the turns off, and I could just see Abigail's little hands holding the wire there, you know?”Footnote 69 To this day Fender continues to foreground the manual dexterity of its female employees in its contemporary promotional materials. A 2011 behind-the-scenes video from Fender's high-end custom shop, for example, features over-the-shoulder footage of master pickup winder, Abigail Ybarra, whose 57-year career winding pickups at Fender began during the company's Tweed-era in 1956 (see Figure 9).

Figure 9. Abigail Ybarra at her workbench, 1959. Photo courtesy of Fender.

Like Duarte and Jaimes, Abigail Ybarra (1933–) is widely known and highly regarded among Fender aficionados for her prolific career winding pickups at Fender.Footnote 70 During her time as the longest-tenured employee in the company's history, Ybarra's pickups were used by some of the most influential guitarists of all time, including Jimi Hendrix, Buddy Holly, Eric Clapton, Stevie Ray Vaughan, and countless others. As Fender's longest-tenured employee, and the company's strongest point of proximity to its bygone golden age, Ybarra has become a valuable source of institutional memory and cultural cachet for the brand. In the promotional video clip made by Fender, the camera zooms in on Ybarra's hands as she feeds a thin thread of copper wire across the spinning pickup magnet, very faintly rolling the wire between her thumb and forefinger to evenly distribute it across the length of the magnet. Periodically, Ybarra slows the spinning machine to a halt to inspect the pickup, working patiently and methodically to ensure tight and even turns.Footnote 71 The camera continues to close in on Ybarra's hands until the pickup is no longer in frame, and only her thumb and forefinger are visible (see Figures 10a and 10b). Over the duration of the 2-minute video clip, her hands are framed in close-ups for over 1 minute and 30 seconds, whereas her head and body are only visible—from behind—for fewer than a total of 30 seconds. Indeed, neither Ybarra nor the pickup seem to be the subject of the video feature. Rather, her hands, disembodied from her person, are afforded a kind of agency of their own.

Figure 10. (a and b) Extreme close-up of Abigail Ybarra's fingers from Fender promotional video. Screenshots by author.

Within Fender lore, the company's Latina employees are renowned for their seemingly superhuman assembly abilities. On online forums, for instance, comments occasionally entail vague allusions to the women's hands and fingers as “magic.”Footnote 72 One former employee, who worked at Fender from 1972 to 73, recalls his awe at watching the “Chicano chicks” in the wiring department in a 2002 interview for 20th Century Guitar: “They were something to behold, all chatting away while soldering so quickly, it didn't hardly seem like they were looking at the amps.”Footnote 73 This frequently invoked image of the efficient but chatty gaggle of Latina workers epitomizes a rhetorical juxtaposition between their apparently inexhaustible capacity for socializing and their almost machinelike precision and speed. By emphasizing that their quick and accurate soldering work was not hindered by their conversations, which diverted both their cognitive energy and visual focus, the women's hand movements take on a kind of mechanical autonomy. That Latina builders’ hands seemingly move without their control underscores the supposedly natural origins of this knack.

Whether knowingly or not, this discursive focus on the hands and fingers of Fender's Latina workers reproduces longstanding racist and misogynist stereotypes about Mexican women being naturally equipped for labor-intensive assembly work due to their allegedly “nimble fingers.”Footnote 74 Feminist labor historians have long noted that because Mexican women's manual skills are assumed to be a natural inheritance, their labor can be deemed unskilled, and employers can justify paying them substandard wages. Indeed, labor within Fender's Tweed-era factory system was divided along gendered lines, with young Mexican women responsible for detail-oriented, repetitive assembly jobs, like soldering amplifiers and hand-winding pickups, whereas the men were primarily responsible for woodworking and large speaker cabinet assembly. In a 2017 interview with She Shreds magazine, Abigail Ybarra explains that, “[Fender] figured that men's hands were too rough, men just wouldn't be able to handle such delicate work [like pickup winding], so it was just women [who wired electronics].”Footnote 75 Fender continues to segregate its labor force according to these gendered stereotypes, as their director of product development, Shane Nicholas, explained in an off-the-cuff observation during a video tour of their production facilities for Premier Guitar in 2011: “One of the funny things I've noticed whenever I come here is the very precise handwork is predominately done by women who have more patience and smaller hands. The bigger jobs—putting twelve- and fifteen-inch speakers in a cabinet—that's done by the guys.”Footnote 76

However pervasive these stereotypes remain, as feminist economists Diane Elson and Ruth Pearson make clear, “the famous ‘nimble fingers’ of young women are not an inheritance from their mothers in the same way that they may inherit the color of her skin or eyes.” Rather, they continue: “They are the result of the training they have received from their mothers and other female kin since early infancy in the tasks socially appropriate to woman's role [e.g., domestic sewing].”Footnote 77 They add that because this domestic training is “socially invisible and privatized, the skills it produces are attributable to nature, and the jobs that make use of it are classified as ‘unskilled’ or ‘semi-skilled.’”Footnote 78 Due to gendered and racialized stereotypes, Duarte and Jaimes are cast as ideal laborers in factory settings for their naturally “nimble fingers” and obedient demeanors, two traits spuriously believed to be genetic inheritances of all Mexican women. Because Fender's Latina employees are assumed to be naturally good at labor-intensive, detail-oriented assembly work, many guitarists attribute the quality of their vintage instruments to magical stereotypes about Mexican women, rather than the skilled work of the individual women by whom they were assembled.

Today, young women of color continue to overwhelmingly perform the majority of the labor-intensive assembly work of industrial capitalism.Footnote 79 In many cases, they do so for substandard wages and under inhospitable conditions, through which they may be subjected to bodily injury.Footnote 80 The rhetoric about their supposedly nimble fingers only serves to justify and reproduce these unacceptable conditions. Within the discourse surrounding Fender's Tweed-era amp builders, a fetishizing gaze on their hands and fingers risks reinscribing harmful stereotypes about Fender's workers and erasing the actual skills they worked to cultivate. By focusing on aspects of Fender's female employees lived experiences, I try actively to work against the stereotypes that collectors reproduce about them.

Conclusion

Fender amplifiers are a ubiquitous presence in popular music and have been much discussed within both academic and journalistic literature. This article offers novel historical insight into these celebrated instruments by centering the skills and expertise of the women responsible for assembling them. Fender's Tweed-era employees have been mythologized by collectors for their proximity to the company's golden age, but they have been wholly overlooked within discussions of rock music history and even Fender's history more specifically. As music studies gradually broadens the scope of what constitutes musical labor, I follow Lucie Vágnerová's call for historians of electronic music to “[expand] the category ‘women in sound’” to “address the factory labor of the global underclass of woman building electronics used in sound technologies.”Footnote 81 This article has shown that it is both possible and necessary to center these women, without reinscribing the same racist and misogynist logics on which industrial capitalism is predicated.

Fender's Tweed-era amplifiers have become highly mythologized collectibles, in part due to their intact builder signatures. That electric guitarists are aware of and invested in the contact histories of their mass-produced electronic equipment contradicts conventional wisdom about commodity fetishism. Rather, this case shows that not only is it possible to center individuals in histories of mass production, but that doing so is in fact often desirable to consumers and collectors.Footnote 82 For musicians, not only does this apply to wooden instruments like violins and guitars, but also to analog electronic circuits. Guitarists invest meaning in the textuality of analog circuitry and have come to read through the wires and components to imagine the people responsible for putting them together.

The histories narrated here present previously unknown information about Fender's female employees, but there is still more work to be done to better understand Duarte, Jaimes, Ybarra, and their peers as the complex individuals they were. Several years after her momentous retirement from Fender in 2013, Abigail Ybarra lamented that she missed the people at Fender the most. In the same interview, Ybarra expanded on the profound impact the Fender community had on her identity development, saying, “I found out there was a place I liked being a Latina.”Footnote 83 Although it appears that neither Duarte nor Jaimes were aware of the particular attention instruments bearing their signature started attracting in the years before they died, Jaimes's daughter notes that her mother recognized how important Fender instruments had become since her early days at the Fullerton factory. Around 2011, a few years before Jaimes passed away from cancer, she attended a local blues concert with her daughter at which she reportedly danced along and proudly pointed out the various Fender instruments on stage. When asked how her mother might react to the attention her work has received, Stelmark insists: “Oh she would be tickled pink that somebody recognized her for who she was and how she took pride in everything she did.”Footnote 84

Acknowledgments

I am deeply indebted to my colleagues at the University of Pennsylvania who offered indispensable feedback on this research throughout my studies. Many thanks to my advisors Glenda Goodman, Timothy Rommen, Jairo Moreno, my colleagues Benjamin Oyler, Larissa Johnson, Allison Brooks-Conrad, and to the reviewers and editors at the journal for their thoughtful and helpful feedback on various drafts of this article.

Competing Interest Statement

None.

Erik Broess is a visiting assisting professor in the School of Music at Boston University. He earned his PhD from the Department of Music at the University of Pennsylvania, where he researched electric guitar gear and the cultural politics of tone.