1. Introduction

Since wall roughness is a common issue in engineering fluid flows, the effects of rough walls on turbulence have been studied by many researchers, as seen in review articles by Raupach, Antonia & Rajagopalan (Reference Raupach, Antonia and Rajagopalan1991), Jiménez (Reference Jiménez2004), Piomelli (Reference Piomelli2019) and Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021). The rough wall turbulence has been described often by the roughness function that depends on a representative scale, and Perry, Schofield & Joubert (Reference Perry, Schofield and Joubert1969) suggested that such roughness characteristics could be categorized into two types: k- and d-types. For the k-type roughness, the representative scale is the roughness scale, while for the d-type roughness, it is the boundary layer thickness or the pipe diameter. According to Tani (Reference Tani1987), for regularly spaced rib roughness, usually it has been considered that the demarcating ratio of the rib spacing ![]() $w$ to the rib height

$w$ to the rib height ![]() $k$ is

$k$ is ![]() $w/k=3$, and the k-type roughness is at

$w/k=3$, and the k-type roughness is at ![]() $w/k>3$, while the d-type roughness is at

$w/k>3$, while the d-type roughness is at ![]() $w/k<3$. Note that recent studies such as MacDonald et al. (Reference MacDonald, Ooi, García-Mayoral, Hutchins and Chung2018) and Xu et al. (Reference Xu, Altland, Yang and Kunz2021), however, showed that non-k-type roughness was not automatically classified as d-type roughness. Also, the direct numerical simulations (DNS) by Lee & Sung (Reference Lee and Sung2007) pointed out that there was strong turbulence interaction between inner and outer layers induced by the surface roughness. Hence the categorization may not be that simple. Anyway, in the so-called k-type rough wall turbulence, as seen in Cui, Patel & Lin (Reference Cui, Patel and Lin2003), Leonardi et al. (Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003) and Ashrafian, Andersson & Manhart (Reference Ashrafian, Andersson and Manhart2004), there are recirculation bubbles that reattach ahead of the next ribs, hence the ribs are exposed to outflows. It was also reported that the roughness function became maximum at approximately

$w/k<3$. Note that recent studies such as MacDonald et al. (Reference MacDonald, Ooi, García-Mayoral, Hutchins and Chung2018) and Xu et al. (Reference Xu, Altland, Yang and Kunz2021), however, showed that non-k-type roughness was not automatically classified as d-type roughness. Also, the direct numerical simulations (DNS) by Lee & Sung (Reference Lee and Sung2007) pointed out that there was strong turbulence interaction between inner and outer layers induced by the surface roughness. Hence the categorization may not be that simple. Anyway, in the so-called k-type rough wall turbulence, as seen in Cui, Patel & Lin (Reference Cui, Patel and Lin2003), Leonardi et al. (Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003) and Ashrafian, Andersson & Manhart (Reference Ashrafian, Andersson and Manhart2004), there are recirculation bubbles that reattach ahead of the next ribs, hence the ribs are exposed to outflows. It was also reported that the roughness function became maximum at approximately ![]() $w/k = 7$ (Flack & Schultz Reference Flack and Schultz2014). In fact, by performing DNS, Leonardi et al. (Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003) reported that the roughness function increased monotonically up to

$w/k = 7$ (Flack & Schultz Reference Flack and Schultz2014). In fact, by performing DNS, Leonardi et al. (Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003) reported that the roughness function increased monotonically up to ![]() $w/k\simeq 7$ and then maintained the level though very gradually decreased as

$w/k\simeq 7$ and then maintained the level though very gradually decreased as ![]() $w/k$ increased. In the conventional d-type roughness at

$w/k$ increased. In the conventional d-type roughness at ![]() $w/k<3$, there are stable recirculation bubbles between the ribs, and they are isolated from outflows (Cui et al. Reference Cui, Patel and Lin2003; Leonardi et al. Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003, Reference Leonardi, Orlandi, Djenidi and Antonia2004).

$w/k<3$, there are stable recirculation bubbles between the ribs, and they are isolated from outflows (Cui et al. Reference Cui, Patel and Lin2003; Leonardi et al. Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003, Reference Leonardi, Orlandi, Djenidi and Antonia2004).

As mentioned above, a significant amount of understanding of turbulence over rib-roughened surfaces has been accumulated. We, however, emphasize that the roughness elements discussed so far have been usually impermeable, but the roughness elements are sometimes recognized to be permeable, particularly in the river bed flows (e.g. Padhi et al. Reference Padhi, Penna, Dey and Gaudio2018; Shen, Yuan & Phanikumar Reference Shen, Yuan and Phanikumar2020). Some metal–foam heat exchangers also have ribbed or finned surfaces (Feng et al. Reference Feng, Li, Zhang and Lu2018; Wang et al. Reference Wang, Wang, Cai, Liu and Zhao2020). It is hence required to understand the effects of permeable rough surfaces on turbulence. The wall permeability usually increases near-wall turbulence (e.g. Lovera & Kennedy Reference Lovera and Kennedy1969; Zippe & Graf Reference Zippe and Graf1983; Manes et al. Reference Manes, Pokrajac, McEwan and Nikora2009; Pokrajac & Manes Reference Pokrajac and Manes2009; Suga et al. Reference Suga, Matsumura, Ashitaka, Tominaga and Kaneda2010), and many studies including ours (Breugem, Boersma & Uittenbogaard Reference Breugem, Boersma and Uittenbogaard2006; Manes, Poggi & Ridol Reference Manes, Poggi and Ridol2011; Suga Reference Suga2016; Suga, Nakagawa & Kaneda Reference Suga, Nakagawa and Kaneda2017; Manes et al. Reference Manes, Poggi and Ridol2011; Voermans, Ghisalberti & Ivey Reference Voermans, Ghisalberti and Ivey2017) applied the permeability Reynolds number as a measure to characterize turbulence over porous media. Here, the permeability Reynolds number is based on the square root of the permeability ![]() $K$ and the friction velocity. It is true particularly for isotropic porous media, although Rosti, Brandt & Pinelli (Reference Rosti, Brandt and Pinelli2018) and Gómez-de Segura & García-Mayoral (Reference Gómez-de Segura and García-Mayoral2019) reported numerical studies that indicated turbulent drag reduction over anisotropic porous media with high streamwise permeabilities. By particle image velocimetry (PIV) experiments for turbulence in a block-mounted channel, Suga et al. (Reference Suga, Tominaga, Mori and Kaneda2013) showed that the turbulence level over a porous square-cylinder block was lower than that over an impermeable block. We thus expect that permeable roughness increases turbulence, though its level may not exceed that over impermeable roughness. In this study, roughness with permeability is termed ‘permeable roughness’.

$K$ and the friction velocity. It is true particularly for isotropic porous media, although Rosti, Brandt & Pinelli (Reference Rosti, Brandt and Pinelli2018) and Gómez-de Segura & García-Mayoral (Reference Gómez-de Segura and García-Mayoral2019) reported numerical studies that indicated turbulent drag reduction over anisotropic porous media with high streamwise permeabilities. By particle image velocimetry (PIV) experiments for turbulence in a block-mounted channel, Suga et al. (Reference Suga, Tominaga, Mori and Kaneda2013) showed that the turbulence level over a porous square-cylinder block was lower than that over an impermeable block. We thus expect that permeable roughness increases turbulence, though its level may not exceed that over impermeable roughness. In this study, roughness with permeability is termed ‘permeable roughness’.

In the recent literature, there have been several studies for permeable roughness. Kim, Blois & Christensen (Reference Kim, Blois and Christensen2020) measured the dynamic interplay between surface and subsurface flows over rough permeable beds consisting of cubically packed spheres. Their observation indicated that the presence of bed roughness intensified the strength of flow penetration by large-scale near-surface flow structures. Since the large-scale flow structure enhances dispersion velocities, it is considered that dispersion played an important role in their results. As for numerical studies, Shen et al. (Reference Shen, Yuan and Phanikumar2020) discussed flows over sediments with rough surfaces by DNS. They reported that turbulence was affected significantly by the roughness, resulting in the modification of the penetration depth and hence the mass flux across the interface. They pointed out that the enhanced wall-normal dispersion velocity played a significant role in the enhancement of the wall-normal mixing. Stoyanova et al. (Reference Stoyanova, Wang, Sekimoto, Okano and Takagi2019) simulated to investigate turbulent drag by permeable roughness. Their results showed that an isotropic roughness structure increased the drag more than an anisotropic structure. Since isotropic roughness structures increase dispersion velocities more, it is considered that their drag increase was partly dependent on the dispersion. To the best of the authors’ knowledge, however, except for the experimental studies by the authors’ group (Okazaki et al. Reference Okazaki, Shimizu, Kuwata and Suga2020, Reference Okazaki, Takase, Kuwata and Suga2021, Reference Okazaki, Takase, Kuwata and Suga2022), there has been no study that reports systematically turbulence over rib-roughened porous walls in the literature, so far.

To understand the permeable roughness effect, Okazaki et al. (Reference Okazaki, Takase, Kuwata and Suga2022) summarized the PIV measurements carried out systematically for turbulent flows over rib-roughened porous walls. The cases were for regularly aligned square ribs whose spacings were ![]() $w/k=1\unicode{x2013}19$, which correspond to the condition from the d-type to k-type roughness of Perry et al. (Reference Perry, Schofield and Joubert1969) for impermeable cases. Their experiments confirmed that since the flow rate through the ribs increased as the permeability increased, the recirculation bubbles between the ribs shifted downstream and to the bottom wall. This change of the flow patterns at

$w/k=1\unicode{x2013}19$, which correspond to the condition from the d-type to k-type roughness of Perry et al. (Reference Perry, Schofield and Joubert1969) for impermeable cases. Their experiments confirmed that since the flow rate through the ribs increased as the permeability increased, the recirculation bubbles between the ribs shifted downstream and to the bottom wall. This change of the flow patterns at ![]() $w/k<3$ enhanced turbulence around the rib-top region. At

$w/k<3$ enhanced turbulence around the rib-top region. At ![]() $w/k=1$, because the permeability enhanced the transition from the d-type to k-type characteristics, the magnitude of turbulence became larger depending on the permeability. At

$w/k=1$, because the permeability enhanced the transition from the d-type to k-type characteristics, the magnitude of turbulence became larger depending on the permeability. At ![]() $w/k>3$, the increase of turbulence by the permeability became unclear since the transition to the k-type was completed. At

$w/k>3$, the increase of turbulence by the permeability became unclear since the transition to the k-type was completed. At ![]() $w/k \ge 7$, since the permeability reduced the pressure drag of the rib roughness, the turbulence level reduced slightly as the permeability increased. These trends were reflected in the profiles of drag and the equivalent sand grain roughness height. The permeability also enhanced the transition to the ‘nominally fully rough’ regime. It is, however, unknown what mechanisms are working behind the above observed trends. Also, there is no knowledge of the relation between the characteristic scales of turbulence modified by the permeable roughness.

$w/k \ge 7$, since the permeability reduced the pressure drag of the rib roughness, the turbulence level reduced slightly as the permeability increased. These trends were reflected in the profiles of drag and the equivalent sand grain roughness height. The permeability also enhanced the transition to the ‘nominally fully rough’ regime. It is, however, unknown what mechanisms are working behind the above observed trends. Also, there is no knowledge of the relation between the characteristic scales of turbulence modified by the permeable roughness.

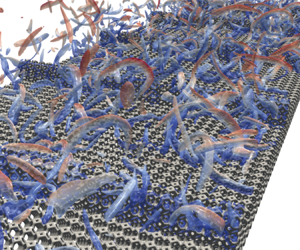

Therefore, this study discusses the effects of the permeable rib roughness on turbulence and its structure by performing DNS. We apply the multiple-relaxation-time lattice Boltzmann method (MRT LBM) (d'Humières et al. Reference d'Humières, Ginzburg, Krafczyk, Lallemand and Luo2002; Suga et al. Reference Suga, Kuwata, Takashima and Chikasue2015) to the simulation scheme. The considered flow geometry is a plane channel with a porous rib-roughened bottom wall. The bottom wall and the square ribs are made of the same porous media consisting of Kelvin cell foam structures (Thomson Reference Thomson1887). Three permeability (low, medium and high) cases are considered to construct the porous media. We focus on ![]() $w/k=1$ and 9 cases since they are representatives of d- and k-type roughness in impermeable cases. For all flow cases, the bulk Reynolds number

$w/k=1$ and 9 cases since they are representatives of d- and k-type roughness in impermeable cases. For all flow cases, the bulk Reynolds number ![]() $Re_b=U_b H/\nu$ is set at

$Re_b=U_b H/\nu$ is set at ![]() $Re_b= 5500$ where

$Re_b= 5500$ where ![]() $H$,

$H$, ![]() $\nu$ and

$\nu$ and ![]() $U_b$ are the channel height, the kinematic fluid viscosity and the bulk mean velocity for the flow region above the rib-bottom.

$U_b$ are the channel height, the kinematic fluid viscosity and the bulk mean velocity for the flow region above the rib-bottom.

2. Numerical procedure

In the LBM, which is based on the regular lattice configuration, the bounce-back treatment for fluid–solid boundaries is very simple, and the linear interpolated bounce-back scheme of Pan, Luo & Miller (Reference Pan, Luo and Miller2006) has the second-order accuracy to reproduce curved shapes (Chun & Ladd Reference Chun and Ladd2007). Since the LBM calculates temporal terms explicitly, and does not require solving the Poisson equation for the pressure field, we recognize its great advantage in parallel computations for flow fields resolved by hundreds of millions of lattice node points using general-purpose graphics processing units. Its accuracy is second order in time and space (Holdych et al. Reference Holdych, Noble, Georgiadis and Buckius2004). Accordingly, many studies including ours (e.g. Chukwudozie & Tyagi Reference Chukwudozie and Tyagi2013; Fattahi et al. Reference Fattahi, Waluga, Wohlmuth, Rü de, Manhart and Helmig2016; Kuwata & Suga Reference Kuwata and Suga2017) applied the LBM successfully to porous medium flows. The present study hence applies the LBM to simulate turbulence fields, including microscopically reproduced porous medium regions with fidelity. The presently applied three-dimensional version employs 27 discrete velocities and the multiple relaxation time for the streaming velocities and the collision operator, respectively. It is hence called the D3Q27 MRT LBM (Suga et al. Reference Suga, Kuwata, Takashima and Chikasue2015).

In the D3Q27 MRT LBM, the time evolution equation of the distribution function ![]() $f_\alpha$

$f_\alpha$ ![]() $(\alpha =0\unicode{x2013}26)$ can be written as

$(\alpha =0\unicode{x2013}26)$ can be written as

where the notation such as ![]() $\left |\,{{f}}\right \rangle$ means

$\left |\,{{f}}\right \rangle$ means ![]() $\left |\,{{f}}\right \rangle ={}^{\rm T}\!(\,f_0,\,f_1,\ldots,\,f_{26})$,

$\left |\,{{f}}\right \rangle ={}^{\rm T}\!(\,f_0,\,f_1,\ldots,\,f_{26})$, ![]() $\boldsymbol {x}$ is the position vector,

$\boldsymbol {x}$ is the position vector, ![]() $\boldsymbol {\xi }_\alpha$ is the discrete velocity, and

$\boldsymbol {\xi }_\alpha$ is the discrete velocity, and ![]() $\delta t$ is the time step. The matrix

$\delta t$ is the time step. The matrix ![]() $\boldsymbol{\mathsf{M}}$ is a

$\boldsymbol{\mathsf{M}}$ is a ![]() $27 \times 27$ matrix that linearly transforms the distribution functions to the moments as

$27 \times 27$ matrix that linearly transforms the distribution functions to the moments as ![]() $\left |{{m}}\right \rangle =\boldsymbol{\mathsf{M}}\left |\,{{f}}\right \rangle$. The collision matrix

$\left |{{m}}\right \rangle =\boldsymbol{\mathsf{M}}\left |\,{{f}}\right \rangle$. The collision matrix ![]() $\hat {\boldsymbol{\mathsf{S}}}$ is diagonal, and the equilibrium moment is

$\hat {\boldsymbol{\mathsf{S}}}$ is diagonal, and the equilibrium moment is ![]() $\left |{{m}^{{eq}}}\right \rangle =\boldsymbol{\mathsf{M}}\left |\,{{f}^{{eq}}}\right \rangle$. The local equilibrium distribution function is

$\left |{{m}^{{eq}}}\right \rangle =\boldsymbol{\mathsf{M}}\left |\,{{f}^{{eq}}}\right \rangle$. The local equilibrium distribution function is

where ![]() $w_\alpha$ is the weighting coefficient,

$w_\alpha$ is the weighting coefficient, ![]() $c_s$ is the sound speed in the LBM,

$c_s$ is the sound speed in the LBM, ![]() $\boldsymbol {u}$ is the fluid velocity, and

$\boldsymbol {u}$ is the fluid velocity, and ![]() $\rho$ is the fluid density that is expressed as the summation of constant and fluctuation parts,

$\rho$ is the fluid density that is expressed as the summation of constant and fluctuation parts, ![]() $\rho =\rho _0+\delta \rho$ (He & Luo Reference He and Luo1997). The macroscopic fluid variables such as the density, momentum and pressure are calculated by

$\rho =\rho _0+\delta \rho$ (He & Luo Reference He and Luo1997). The macroscopic fluid variables such as the density, momentum and pressure are calculated by ![]() $\rho =\sum _\alpha f_\alpha$,

$\rho =\sum _\alpha f_\alpha$, ![]() $\rho _0 u_i=\sum _\alpha \boldsymbol {\xi }_{\alpha i}\, f_\alpha$ and

$\rho _0 u_i=\sum _\alpha \boldsymbol {\xi }_{\alpha i}\, f_\alpha$ and ![]() $p=c_{s}^2 \rho$, respectively. See Appendix A for the detailed parameters, coefficients and matrices. Since we apply local mesh refinement to the porous region, the imbalance correction grid-refinement method by Kuwata & Suga (Reference Kuwata and Suga2016a) is used.

$p=c_{s}^2 \rho$, respectively. See Appendix A for the detailed parameters, coefficients and matrices. Since we apply local mesh refinement to the porous region, the imbalance correction grid-refinement method by Kuwata & Suga (Reference Kuwata and Suga2016a) is used.

3. Computational conditions

3.1. Porous structure and computational domain

The considered porous media consist of the Kelvin cells (or tetrakaidecahedrons). The Kelvin cell is a polyhedron shape that has been studied in conjunction with foams and the minimal surface area. It had been thought the best model for the space-filling shape with minimal surface area until the study of Weaire & Phelan (Reference Weaire and Phelan1994), and has been often applied as a model for regular, monodisperse ‘foam’. Since one of the aims of this study is to understand the flows over rib-roughened foam beds measured by our group (Okazaki et al. Reference Okazaki, Takase, Kuwata and Suga2022), we choose the Kelvin cells to model the foam structure applied in the experiments.

Indeed, Kelvin cells have been applied in several studies on porous medium flows, as reviewed by Kumar & Topin (Reference Kumar and Topin2017). To form the open cell structures, we apply circular cross-sectioned ligaments as illustrated in figure 1, where ![]() $D$ and

$D$ and ![]() $d$ are the unit cell height and the ligament diameter, respectively. In the present study,

$d$ are the unit cell height and the ligament diameter, respectively. In the present study, ![]() $D/d=5$ and 8.25 make porosity

$D/d=5$ and 8.25 make porosity ![]() $\varphi =0.79$ and 0.91, respectively.

$\varphi =0.79$ and 0.91, respectively.

Figure 1. Unit cell of the Kelvin cell.

Figure 2 illustrates the computational domain. The channel height ![]() $H$ is the distance between the upper wall and the surface of the porous layer. The upper wall and the very bottom of the porous layer are treated as smooth no-slip surfaces, although a symmetrical configuration is useful to obtain the drag because it balances with the pressure drop. On the other hand, in the present configuration, we can obtain the drag by the ribbed surface by subtracting the top smooth wall friction from the pressure drop. Hence we can save extra computer memory for grid points to describe a porous upper wall. It should, however, certainly be considered how the presence of the upper wall turbulence affects the flow near the bottom wall. For this issue, Leonardi et al. (Reference Leonardi, Orlandi, Djenidi and Antonia2004) compared the results of asymmetric and symmetric configurations for (solid impermeable)

$H$ is the distance between the upper wall and the surface of the porous layer. The upper wall and the very bottom of the porous layer are treated as smooth no-slip surfaces, although a symmetrical configuration is useful to obtain the drag because it balances with the pressure drop. On the other hand, in the present configuration, we can obtain the drag by the ribbed surface by subtracting the top smooth wall friction from the pressure drop. Hence we can save extra computer memory for grid points to describe a porous upper wall. It should, however, certainly be considered how the presence of the upper wall turbulence affects the flow near the bottom wall. For this issue, Leonardi et al. (Reference Leonardi, Orlandi, Djenidi and Antonia2004) compared the results of asymmetric and symmetric configurations for (solid impermeable) ![]() $w/k=3$ with

$w/k=3$ with ![]() $k/H=0.1$. Their visualizations of the two cases confirmed that the recirculation profiles between the ribs agreed well with each other. The pressure and skin friction distributions along the bottom wall also showed good agreement between the two cases. Moreover, although the maximum velocity point shifted upwards due to the roughness on the bottom wall, the normalized velocity by the wall unit showed an overlapped profile with that for the symmetry configuration, indicating that the roughness function was unaffected by the boundary condition on the upper wall.

$k/H=0.1$. Their visualizations of the two cases confirmed that the recirculation profiles between the ribs agreed well with each other. The pressure and skin friction distributions along the bottom wall also showed good agreement between the two cases. Moreover, although the maximum velocity point shifted upwards due to the roughness on the bottom wall, the normalized velocity by the wall unit showed an overlapped profile with that for the symmetry configuration, indicating that the roughness function was unaffected by the boundary condition on the upper wall.

Figure 2. Computational domain; the streamwise, wall-normal and spanwise directions are denoted as ![]() $x$-,

$x$-, ![]() $y$- and

$y$- and ![]() $z$-directions.

$z$-directions.

For the present simulations, the rib height is also fixed at ![]() $k/H=0.1$. From the viewpoint of Jiménez (Reference Jiménez2004), the ratio

$k/H=0.1$. From the viewpoint of Jiménez (Reference Jiménez2004), the ratio ![]() $H/k=10$ might not be large enough, while rib-roughened turbulent channel flow studies have often applied similar roughness scales. Indeed, Hanjalić & Launder (Reference Hanjalić and Launder1972) applied the ratios

$H/k=10$ might not be large enough, while rib-roughened turbulent channel flow studies have often applied similar roughness scales. Indeed, Hanjalić & Launder (Reference Hanjalić and Launder1972) applied the ratios ![]() $H/k=9$ and 17 for the rib-roughened channel experiments at

$H/k=9$ and 17 for the rib-roughened channel experiments at ![]() $w/k=9$. As for the DNS studies, Nagano, Hattori & Houra (Reference Nagano, Hattori and Houra2004) applied

$w/k=9$. As for the DNS studies, Nagano, Hattori & Houra (Reference Nagano, Hattori and Houra2004) applied ![]() $H/k=10\unicode{x2013}40$ for k- and d-type rib roughness, while Leonardi et al. (Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003) and Orlandi, Sassun & Leonardi (Reference Orlandi, Sassun and Leonardi2016) applied

$H/k=10\unicode{x2013}40$ for k- and d-type rib roughness, while Leonardi et al. (Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003) and Orlandi, Sassun & Leonardi (Reference Orlandi, Sassun and Leonardi2016) applied ![]() $H/k=10$ for square and triangular rib roughness. The trends of

$H/k=10$ for square and triangular rib roughness. The trends of ![]() $H/k\simeq 10$ shown in those studies, however, did not so deviate from those by large enough

$H/k\simeq 10$ shown in those studies, however, did not so deviate from those by large enough ![]() $H/k$ geometries. Furthermore, the roughness sublayer thickness was suggested to be

$H/k$ geometries. Furthermore, the roughness sublayer thickness was suggested to be ![]() $3 k$–

$3 k$–![]() $5 k$ by Raupach et al. (Reference Raupach, Antonia and Rajagopalan1991), and it was less than

$5 k$ by Raupach et al. (Reference Raupach, Antonia and Rajagopalan1991), and it was less than ![]() $5k$ by the studies of Ashrafian et al. (Reference Ashrafian, Andersson and Manhart2004) and Lee & Sung (Reference Lee and Sung2007). As discussed in Okazaki et al. (Reference Okazaki, Takase, Kuwata and Suga2022), who also applied

$5k$ by the studies of Ashrafian et al. (Reference Ashrafian, Andersson and Manhart2004) and Lee & Sung (Reference Lee and Sung2007). As discussed in Okazaki et al. (Reference Okazaki, Takase, Kuwata and Suga2022), who also applied ![]() $H/k=10$, their ratios of the equivalent boundary layer thickness to the rib height were generally larger than six, and they showed close agreement between their impermeable results and those of Burattini et al. (Reference Burattini, Leonardi, Orlandi and Antonia2008), whose ratio was

$H/k=10$, their ratios of the equivalent boundary layer thickness to the rib height were generally larger than six, and they showed close agreement between their impermeable results and those of Burattini et al. (Reference Burattini, Leonardi, Orlandi and Antonia2008), whose ratio was ![]() $H/k=21$. Since for the rib-roughened cooling passages in turbine blades the ratios are also in such a range (e.g. Iacovides & Raisee Reference Iacovides and Raisee1999), the present discussions are useful for the practical point of view. We therefore consider that

$H/k=21$. Since for the rib-roughened cooling passages in turbine blades the ratios are also in such a range (e.g. Iacovides & Raisee Reference Iacovides and Raisee1999), the present discussions are useful for the practical point of view. We therefore consider that ![]() $H/k=10$ is acceptable for discussions on rough wall turbulence, particularly for channel flow configurations.

$H/k=10$ is acceptable for discussions on rough wall turbulence, particularly for channel flow configurations.

As shown in table 1, three permeability cases: low permeable (LP), medium permeable (MP) and high permeable (HP) cases are considered for the porous media at ![]() $w/k\simeq 1$ and 9. Hereafter, cases HP1, HP9, etc. correspond to case HP at

$w/k\simeq 1$ and 9. Hereafter, cases HP1, HP9, etc. correspond to case HP at ![]() $w/k\simeq 1$, case HP at

$w/k\simeq 1$, case HP at ![]() $w/k\simeq 9$, etc., respectively. (Note that the values of

$w/k\simeq 9$, etc., respectively. (Note that the values of ![]() $w/k$ in the present study are not integers, as explained in the next paragraph.) To calculate the permeability

$w/k$ in the present study are not integers, as explained in the next paragraph.) To calculate the permeability ![]() $K$, separate computations using a unit cell with a fixed pressure drop and the periodic velocity boundary condition for each direction are carried out, as seen later, in § 3.2. Using the Darcy equation, the calculated permeabilities of LP, MP and HP cases are

$K$, separate computations using a unit cell with a fixed pressure drop and the periodic velocity boundary condition for each direction are carried out, as seen later, in § 3.2. Using the Darcy equation, the calculated permeabilities of LP, MP and HP cases are ![]() $K/H^2=1.34\times 10^{-5}$,

$K/H^2=1.34\times 10^{-5}$, ![]() $5.37\times 10^{-5}$ and

$5.37\times 10^{-5}$ and ![]() $1.10\times 10^{-4}$, respectively. Accordingly, the HP case is 8.2 times as permeable as the LP case. Since the experimentally applied foamed materials in Okazaki et al. (Reference Okazaki, Takase, Kuwata and Suga2022) had permeabilities

$1.10\times 10^{-4}$, respectively. Accordingly, the HP case is 8.2 times as permeable as the LP case. Since the experimentally applied foamed materials in Okazaki et al. (Reference Okazaki, Takase, Kuwata and Suga2022) had permeabilities ![]() $K/H^2=0.78 \times 10^{-5}\unicode{x2013} 3.7 \times 10^{-5}$, the LP case is in the range of the experimental conditions, while the other cases are more permeable than the experimentally applied media.

$K/H^2=0.78 \times 10^{-5}\unicode{x2013} 3.7 \times 10^{-5}$, the LP case is in the range of the experimental conditions, while the other cases are more permeable than the experimentally applied media.

Table 1. Computational cases: HP, MP and LP are high, medium and low permeable cases, respectively, while S are solid impermeable cases. Here, ![]() $k$,

$k$, ![]() $w$,

$w$, ![]() $\varphi$,

$\varphi$, ![]() $K$ and

$K$ and ![]() $D$ are the rib height, rib spacing, porosity, permeability and unit height of the Kelvin cell, respectively, and

$D$ are the rib height, rib spacing, porosity, permeability and unit height of the Kelvin cell, respectively, and ![]() $\varDelta ^{f}$ is the grid spacing for finer lattice regions.

$\varDelta ^{f}$ is the grid spacing for finer lattice regions.

Connecting the Kelvin cells regularly, the rib-roughened porous bed is constructed as shown in figure 3. As for the rib width, although the difference is very slight, the exact rib width is ![]() $k+d$, which is slightly larger than the rib height since this study applies Kelvin cells with fully shaped ligaments, while the ligaments of the Kelvin cell shown in figure 1 are cut in half at the surfaces of the unit box. Accordingly, the exact ratios of

$k+d$, which is slightly larger than the rib height since this study applies Kelvin cells with fully shaped ligaments, while the ligaments of the Kelvin cell shown in figure 1 are cut in half at the surfaces of the unit box. Accordingly, the exact ratios of ![]() $w/k$ are not integers, as shown in table 1. The ribs are constructed using one Kelvin cell for the HP and MP cases, while for the LP cases they consist of four cells in the streamwise wall-normal (

$w/k$ are not integers, as shown in table 1. The ribs are constructed using one Kelvin cell for the HP and MP cases, while for the LP cases they consist of four cells in the streamwise wall-normal (![]() $x$–

$x$–![]() $y$) sections, as shown in figure 3. Note that because of the open cell structure, the cross-sectional rib shapes may not look square for cases HP1 and MP1. The rib height is hence

$y$) sections, as shown in figure 3. Note that because of the open cell structure, the cross-sectional rib shapes may not look square for cases HP1 and MP1. The rib height is hence ![]() $k=D$ for both HP and MP cases. Correspondingly, the pore scales of cases HP and MP are the same as the rib height, hence for a designed porosity, they are the maximum pore size, leading to the most permeable structure with the present Kelvin cells for ribbed beds. The porosity is controlled by changing the ligament diameter

$k=D$ for both HP and MP cases. Correspondingly, the pore scales of cases HP and MP are the same as the rib height, hence for a designed porosity, they are the maximum pore size, leading to the most permeable structure with the present Kelvin cells for ribbed beds. The porosity is controlled by changing the ligament diameter ![]() $d$ in this study. Figure 3(a) also shows the origin of the coordinates used in the discussions in this study. As indicated in figure 3, the present porous layer thickness is

$d$ in this study. Figure 3(a) also shows the origin of the coordinates used in the discussions in this study. As indicated in figure 3, the present porous layer thickness is ![]() $h=k$ for case LP, while

$h=k$ for case LP, while ![]() $h=3k$ for cases HP and MP. In Appendix B, it is shown that each porous layer thickness hardly affects the turbulence characteristics over the porous bed.

$h=3k$ for cases HP and MP. In Appendix B, it is shown that each porous layer thickness hardly affects the turbulence characteristics over the porous bed.

Figure 3. Surface geometries: (a) case LP1 with origin of the coordinates, (b) case MP1, (c) case HP1.

The sizes of the computational box ![]() $L_x\times L_y\times L_z$ are listed in table 1. To resolve the porous structures and near-wall turbulence, fine lattice regions with spacings

$L_x\times L_y\times L_z$ are listed in table 1. To resolve the porous structures and near-wall turbulence, fine lattice regions with spacings ![]() $\varDelta ^f=\varDelta /2$, where

$\varDelta ^f=\varDelta /2$, where ![]() $\varDelta$ is the standard lattice spacing, are applied at the regions below 100 wall units by using the imbalance correction zonal grid refinement method of Kuwata & Suga (Reference Kuwata and Suga2016a). Then, for example, the node numbers of the finer and standard lattice regions for case HP are

$\varDelta$ is the standard lattice spacing, are applied at the regions below 100 wall units by using the imbalance correction zonal grid refinement method of Kuwata & Suga (Reference Kuwata and Suga2016a). Then, for example, the node numbers of the finer and standard lattice regions for case HP are ![]() $3299(x)\times 275(y)\times 991(z)$ and

$3299(x)\times 275(y)\times 991(z)$ and ![]() $1650(x)\times 295(y)\times 496(z)$, respectively. The corresponding total node numbers are listed in table 1. The lattice resolution for porous media for cases LP, MP and HP is maintained at

$1650(x)\times 295(y)\times 496(z)$, respectively. The corresponding total node numbers are listed in table 1. The lattice resolution for porous media for cases LP, MP and HP is maintained at ![]() $d/\varDelta ^f=8$, which is confirmed to be fine enough later, in § 3.2. The normalized lattice spacings

$d/\varDelta ^f=8$, which is confirmed to be fine enough later, in § 3.2. The normalized lattice spacings ![]() $(\varDelta ^{f})^+$ are hence always smaller than 2, and owing to the interpolated bounce-back scheme, the averaged distance of the first fluid-phase nodes from the solid parts is approximately less than one wall unit. With this resolution, it is confirmed that the solid ligament boundaries well satisfy no-slip and no-transpiration conditions by the interpolated bounce-back scheme. The present resolution is comparable to those in the previous DNS studies (Chikatamarla et al. Reference Chikatamarla, Frouzakis, Karlin, Tomboulides and Boulouchos2010; Bespalko, Pollard & Uddin Reference Bespalko, Pollard and Uddin2012; Kuwata & Suga Reference Kuwata and Suga2016b, Reference Kuwata and Suga2017). Hereafter,

$(\varDelta ^{f})^+$ are hence always smaller than 2, and owing to the interpolated bounce-back scheme, the averaged distance of the first fluid-phase nodes from the solid parts is approximately less than one wall unit. With this resolution, it is confirmed that the solid ligament boundaries well satisfy no-slip and no-transpiration conditions by the interpolated bounce-back scheme. The present resolution is comparable to those in the previous DNS studies (Chikatamarla et al. Reference Chikatamarla, Frouzakis, Karlin, Tomboulides and Boulouchos2010; Bespalko, Pollard & Uddin Reference Bespalko, Pollard and Uddin2012; Kuwata & Suga Reference Kuwata and Suga2016b, Reference Kuwata and Suga2017). Hereafter, ![]() $(\cdot )^+$ denotes a normalized value based on the friction velocity

$(\cdot )^+$ denotes a normalized value based on the friction velocity ![]() $u_*$ at the rib-top location. Pokrajac et al. (Reference Pokrajac, Finnigan, Manes, McEwan and Nikora2006) noted that there had been many discussions to determine the reference friction velocity. There were several candidates, such as the bed shear stress, the total fluid shear stress at the roughness crest, and so on. Note that the total fluid shear stress is the sum of the plane-averaged viscous, Reynolds and dispersion shear stresses. Following Finnigan (Reference Finnigan2000), Poggi et al. (Reference Poggi, Porporato, Ridolfi, Albertson and Katul2004), Jarvela (Reference Jarvela2005), Nakagawa, Tsujimoto & Shimizu (Reference Nakagawa, Tsujimoto and Shimizu1991), Pokrajac et al. (Reference Pokrajac, Finnigan, Manes, McEwan and Nikora2006), Coceal et al. (Reference Coceal, Dobre, Thomas and Belcher2007) and Burattini et al. (Reference Burattini, Leonardi, Orlandi and Antonia2008), this study defines

$u_*$ at the rib-top location. Pokrajac et al. (Reference Pokrajac, Finnigan, Manes, McEwan and Nikora2006) noted that there had been many discussions to determine the reference friction velocity. There were several candidates, such as the bed shear stress, the total fluid shear stress at the roughness crest, and so on. Note that the total fluid shear stress is the sum of the plane-averaged viscous, Reynolds and dispersion shear stresses. Following Finnigan (Reference Finnigan2000), Poggi et al. (Reference Poggi, Porporato, Ridolfi, Albertson and Katul2004), Jarvela (Reference Jarvela2005), Nakagawa, Tsujimoto & Shimizu (Reference Nakagawa, Tsujimoto and Shimizu1991), Pokrajac et al. (Reference Pokrajac, Finnigan, Manes, McEwan and Nikora2006), Coceal et al. (Reference Coceal, Dobre, Thomas and Belcher2007) and Burattini et al. (Reference Burattini, Leonardi, Orlandi and Antonia2008), this study defines ![]() $\tau _{*}$ as the total fluid shear stress at the roughness crest (rib-top location

$\tau _{*}$ as the total fluid shear stress at the roughness crest (rib-top location ![]() $y=0$). The friction velocity

$y=0$). The friction velocity ![]() $u_*$ (

$u_*$ (![]() $=\sqrt {\tau _*/\rho }$) listed in table 2 is obtained by the momentum balance, which means that the pressure drop

$=\sqrt {\tau _*/\rho }$) listed in table 2 is obtained by the momentum balance, which means that the pressure drop ![]() $\Delta p$ is balanced with the wall-shear stress at the top wall

$\Delta p$ is balanced with the wall-shear stress at the top wall ![]() $\tau _t$ and the total shear stress

$\tau _t$ and the total shear stress ![]() $\tau _*$ at

$\tau _*$ at ![]() $y=0$ as

$y=0$ as

Table 2. Calculated flow field parameters. Reynolds numbers are defined as ![]() $Re_K=K^{1/2}u_*/\nu$,

$Re_K=K^{1/2}u_*/\nu$, ![]() $Re_\tau =u_*\delta _p/\nu$, where

$Re_\tau =u_*\delta _p/\nu$, where ![]() $\delta _p$ is the equivalent boundary layer thickness on the porous wall side. The friction velocities

$\delta _p$ is the equivalent boundary layer thickness on the porous wall side. The friction velocities ![]() $u_\tau ^t$,

$u_\tau ^t$, ![]() $u_*$ and

$u_*$ and ![]() $u_\tau ^b$ are defined from the shear stresses at the top wall (

$u_\tau ^b$ are defined from the shear stresses at the top wall (![]() $\tau _t$) the rib-top location at

$\tau _t$) the rib-top location at ![]() $y=0$ (

$y=0$ (![]() $\tau _*$) and the rib foot location at

$\tau _*$) and the rib foot location at ![]() $y=-k$ (

$y=-k$ (![]() $\tau _b$), respectively. The parameters

$\tau _b$), respectively. The parameters ![]() $\kappa$,

$\kappa$, ![]() $d_0$,

$d_0$, ![]() $h_0$ and

$h_0$ and ![]() $k^*_s$, are the von Kármán constant, the zero-plane displacement, the roughness scale and the characteristic roughness height, respectively. The nominal roughness sublayer thickness is

$k^*_s$, are the von Kármán constant, the zero-plane displacement, the roughness scale and the characteristic roughness height, respectively. The nominal roughness sublayer thickness is ![]() $\delta _r$. A value normalized by

$\delta _r$. A value normalized by ![]() $u_*$ is described as

$u_*$ is described as ![]() $(\cdot )^+$.

$(\cdot )^+$.

The statistical quantities are obtained through at least 33 turnover times after the simulated variables become free from the initial conditions. Although the time step ![]() $\delta t$ is unity in the normalized lattice Boltzmann equation, depending on the present cases it is equivalent to

$\delta t$ is unity in the normalized lattice Boltzmann equation, depending on the present cases it is equivalent to ![]() $1.1\times 10^{-5}H/u_*\unicode{x2013}3.3\times 10^{-5} H/u_*$ in the physical space. Accordingly, 21 000–48 000 time steps are required for one turnover time.

$1.1\times 10^{-5}H/u_*\unicode{x2013}3.3\times 10^{-5} H/u_*$ in the physical space. Accordingly, 21 000–48 000 time steps are required for one turnover time.

3.2. Boundary conditions and validation of computational lattices

The no-slip flow boundary conditions at the ligament surfaces of the Kelvin cells are imposed by the linear interpolated bounce-back condition (Pan et al. Reference Pan, Luo and Miller2006) using the level set functions that indicate the distance from solid surfaces. At the upper and very bottom no-slip walls of the channel located at ![]() $y=0.9H$ and

$y=0.9H$ and ![]() $y=-(k+h)$, respectively, the halfway bounce-back condition is applied. The periodic flow conditions are imposed on the streamwise and spanwise directions at the computational box surfaces. A constant streamwise pressure difference is also imposed between the inlet and outlet boundaries.

$y=-(k+h)$, respectively, the halfway bounce-back condition is applied. The periodic flow conditions are imposed on the streamwise and spanwise directions at the computational box surfaces. A constant streamwise pressure difference is also imposed between the inlet and outlet boundaries.

In the preliminary discussion, we checked the effects of the lattice resolution and the computational box size. Computations using a unit cell with a fixed pressure drop and the periodic velocity boundary condition for each direction are carried out to see the lattice node dependency. Figure 4 compares profiles of the pressure gradient versus the cell Reynolds number depending on the lattice resolution. For each porosity case, the resolution ![]() $N$ corresponds to the lattice number dividing each side of the unit cell:

$N$ corresponds to the lattice number dividing each side of the unit cell: ![]() $N=D/\varDelta$, where

$N=D/\varDelta$, where ![]() $\varDelta$ is the lattice spacing. Accordingly,

$\varDelta$ is the lattice spacing. Accordingly, ![]() $d/\varDelta =8$, 16 lead to

$d/\varDelta =8$, 16 lead to ![]() $N=40$, 80 for

$N=40$, 80 for ![]() $\varphi =0.79$, while they correspond to

$\varphi =0.79$, while they correspond to ![]() $N=66$, 132 for

$N=66$, 132 for ![]() $\varphi =0.91$. It is seen that the compared profiles almost perfectly collapse onto each other, and this confirms that the lattice resolution of

$\varphi =0.91$. It is seen that the compared profiles almost perfectly collapse onto each other, and this confirms that the lattice resolution of ![]() $d/\varDelta =8$ is fine enough for the simulation around the Kelvin cells. From these computations, the permeability

$d/\varDelta =8$ is fine enough for the simulation around the Kelvin cells. From these computations, the permeability ![]() $K$ is obtained by the Darcy law that corresponds to the dotted lines in figure 4. Figure 5 compares the profile of

$K$ is obtained by the Darcy law that corresponds to the dotted lines in figure 4. Figure 5 compares the profile of ![]() $R_{uu,x_i}$ obtained with the computational box applied to each case at the location a little above

$R_{uu,x_i}$ obtained with the computational box applied to each case at the location a little above ![]() $y=k$. The definition of the two-point spatial correlation function of the velocity component

$y=k$. The definition of the two-point spatial correlation function of the velocity component ![]() $u$ is

$u$ is

\begin{equation} R_{uu, x_i} =\frac{ \overline{ u' (x_i)\,u' (x_i +\Delta x_i)}}{\overline{u'(x_i)\,u' (x_i)}}, \end{equation}

\begin{equation} R_{uu, x_i} =\frac{ \overline{ u' (x_i)\,u' (x_i +\Delta x_i)}}{\overline{u'(x_i)\,u' (x_i)}}, \end{equation}

where ![]() $\Delta x_i$ is the distance between the two locations in the

$\Delta x_i$ is the distance between the two locations in the ![]() $x_i$-direction. Here,

$x_i$-direction. Here, ![]() $(x_1, x_2, x_3)=(x,y,z)$. Figure 4(a) indicates that

$(x_1, x_2, x_3)=(x,y,z)$. Figure 4(a) indicates that ![]() $R_{uu,x}$ decays monotonically to nearly zero by

$R_{uu,x}$ decays monotonically to nearly zero by ![]() $\Delta x/H\simeq 2.0$ in each computational box. This suggests that a streamwise box length that is larger than

$\Delta x/H\simeq 2.0$ in each computational box. This suggests that a streamwise box length that is larger than ![]() $4.0H$ is satisfactory, and confirms that the length of the present box is reasonable. Since there is no obvious minimum point of each profile, coherent transverse structures are hardly detected. For the spanwise direction, figure 4(b) indicates that

$4.0H$ is satisfactory, and confirms that the length of the present box is reasonable. Since there is no obvious minimum point of each profile, coherent transverse structures are hardly detected. For the spanwise direction, figure 4(b) indicates that ![]() $R_{uu,z}$ decays to reasonably small values by

$R_{uu,z}$ decays to reasonably small values by ![]() $\Delta z/H\simeq 0.7$ in all computational boxes. The spanwise size

$\Delta z/H\simeq 0.7$ in all computational boxes. The spanwise size ![]() $1.5H$ of the present standard box is hence confirmed to be reasonable. It is then confirmed that the presently applied lattice resolutions and computational box sizes listed in table 1 are reasonable for the following discussion.

$1.5H$ of the present standard box is hence confirmed to be reasonable. It is then confirmed that the presently applied lattice resolutions and computational box sizes listed in table 1 are reasonable for the following discussion.

Figure 4. Pressure gradient versus cell Reynolds number, for (a) ![]() $\varphi =0.79$, (b)

$\varphi =0.79$, (b) ![]() $\varphi =0.91$. The cell Reynolds number is

$\varphi =0.91$. The cell Reynolds number is ![]() $Re_D=U_DD/\nu$, with the Darcy velocity

$Re_D=U_DD/\nu$, with the Darcy velocity ![]() $U_D$. The grid resolution

$U_D$. The grid resolution ![]() $N$ corresponds to the grid number for each direction. The dotted lines correspond to the Darcy law.

$N$ corresponds to the grid number for each direction. The dotted lines correspond to the Darcy law.

Figure 5. Two-point spatial correlation functions of the streamwise velocity fluctuations at ![]() $y=k$: (a) streamwise two-point correlations; (b) spanwise two-point correlations.

$y=k$: (a) streamwise two-point correlations; (b) spanwise two-point correlations.

4. Results and discussion

4.1. General flow patterns

To obtain general ideas for turbulence structures of the present simulations, figure 6 shows examples of images for the instantaneous spanwise vorticity ![]() $\omega _z^+$ distributions. Clearly, the flow image for case S1 at

$\omega _z^+$ distributions. Clearly, the flow image for case S1 at ![]() $w/k\simeq 1$ is very different from the other images, and its distribution patterns look quite symmetrical over the rib-top region in the

$w/k\simeq 1$ is very different from the other images, and its distribution patterns look quite symmetrical over the rib-top region in the ![]() $X$–

$X$–![]() $y$ plane. At

$y$ plane. At ![]() $w/k\simeq 1$ as the permeability increases, the concentration of strong vortices near the ribs becomes relaxed, and the vorticity distribution in the near-rib region tends to be similar to that in the core region for case HP1. As for

$w/k\simeq 1$ as the permeability increases, the concentration of strong vortices near the ribs becomes relaxed, and the vorticity distribution in the near-rib region tends to be similar to that in the core region for case HP1. As for ![]() $w/k\simeq 9$, strong smaller vortices near the ribs look expanded towards the core region depending on the increment of the permeability. These observations imply that turbulence levels near the ribs are large and expanded wider towards the channel centre in the permeable cases at both rib spacings.

$w/k\simeq 9$, strong smaller vortices near the ribs look expanded towards the core region depending on the increment of the permeability. These observations imply that turbulence levels near the ribs are large and expanded wider towards the channel centre in the permeable cases at both rib spacings.

Figure 6. Examples of snapshots for instantaneous vorticity ![]() $\omega _z^+$ distributions in streamwise–wall-normal planes. In case HP1, the vorticity distribution near the ribs and core flow region look similar. Although we see smaller pointed vortices near the ribs in case S9, vortices near the ribs look expanded towards the core flow region in cases HP1 and HP9. The origin of the streamwise axis

$\omega _z^+$ distributions in streamwise–wall-normal planes. In case HP1, the vorticity distribution near the ribs and core flow region look similar. Although we see smaller pointed vortices near the ribs in case S9, vortices near the ribs look expanded towards the core flow region in cases HP1 and HP9. The origin of the streamwise axis ![]() $X$ is set at the inlet of the computational box.

$X$ is set at the inlet of the computational box.

For the time-mean statistical flow patterns, figure 7 shows the streamlines for each case. The streamlines are presented by plotting contour lines of the stream functions calculated from spanwise-averaged time-mean velocities. Since the purpose of these plots is to show general flow patterns, the lines are drawn with arbitrary spacings. Obviously, the flow patterns in permeable cases change from those of the impermeable cases depending on the permeability. This trend is consistent with that reported by Okazaki et al. (Reference Okazaki, Takase, Kuwata and Suga2022). At ![]() $w/k\simeq 1$, as shown in figures 7(e,g), there is no obvious mean recirculation behind the ribs in cases MP1 and HP1, while it exists clearly in each cavity between the ribs in case LP1. The permeability Reynolds numbers listed in table 2 are

$w/k\simeq 1$, as shown in figures 7(e,g), there is no obvious mean recirculation behind the ribs in cases MP1 and HP1, while it exists clearly in each cavity between the ribs in case LP1. The permeability Reynolds numbers listed in table 2 are ![]() $Re_K=2.2$, 5.0 and 7.5 for cases LP1, MP1 and HP1, respectively. This implies that the mean recirculation bubbles between the ribs, which seem to be typical d-type recirculation bubbles isolated from outflows like that in case S1 and those in Cui et al. (Reference Cui, Patel and Lin2003) and Leonardi et al. (Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003, Reference Leonardi, Orlandi, Djenidi and Antonia2004), tend to vanish when

$Re_K=2.2$, 5.0 and 7.5 for cases LP1, MP1 and HP1, respectively. This implies that the mean recirculation bubbles between the ribs, which seem to be typical d-type recirculation bubbles isolated from outflows like that in case S1 and those in Cui et al. (Reference Cui, Patel and Lin2003) and Leonardi et al. (Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003, Reference Leonardi, Orlandi, Djenidi and Antonia2004), tend to vanish when ![]() $Re_K$ becomes larger. (Note that we do not mention small vortices behind ligaments of the Kelvin cells.)

$Re_K$ becomes larger. (Note that we do not mention small vortices behind ligaments of the Kelvin cells.)

Figure 7. Spanwise averaged time-mean streamlines: (a) case S1, (b) case S9, (c) case LP1, (d) case LP9, (e) case MP1, (f) case MP9, (g) case HP1, (h) case HP9. The lines are drawn with arbitrary spacings.

At ![]() $w/k\simeq 9$, in figure 7(d) it is observed that the mean recirculation flow submerges into the porous bottom layer at

$w/k\simeq 9$, in figure 7(d) it is observed that the mean recirculation flow submerges into the porous bottom layer at ![]() $4< x/k<9$ in case LP9. Compared with the flow pattern in the impermeable case shown in figure 7(b), the centre position of the recirculation shifts downstream, and the length of the recirculation bubble becomes longer. With the increased permeability the mean recirculation submerges into the porous layer in cases MP9 and HP9, as shown in figures 7(f,h), and we can observe the downward flow underneath the rib, which then goes upwards in between the ribs due to the recirculation inside the porous layer. These recirculation bubbles are exposed to outflows as in case S9 and those seen in the k-type rough wall flows of Cui et al. (Reference Cui, Patel and Lin2003), Leonardi et al. (Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003) and Ashrafian et al. (Reference Ashrafian, Andersson and Manhart2004). The observed trends of the flow patterns over the porous layers shown in figures 7(d,f,h) agree well with the experimentally reported trends by Okazaki et al. (Reference Okazaki, Shimizu, Kuwata and Suga2020). The permeability Reynolds numbers listed in table 2 are

$4< x/k<9$ in case LP9. Compared with the flow pattern in the impermeable case shown in figure 7(b), the centre position of the recirculation shifts downstream, and the length of the recirculation bubble becomes longer. With the increased permeability the mean recirculation submerges into the porous layer in cases MP9 and HP9, as shown in figures 7(f,h), and we can observe the downward flow underneath the rib, which then goes upwards in between the ribs due to the recirculation inside the porous layer. These recirculation bubbles are exposed to outflows as in case S9 and those seen in the k-type rough wall flows of Cui et al. (Reference Cui, Patel and Lin2003), Leonardi et al. (Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003) and Ashrafian et al. (Reference Ashrafian, Andersson and Manhart2004). The observed trends of the flow patterns over the porous layers shown in figures 7(d,f,h) agree well with the experimentally reported trends by Okazaki et al. (Reference Okazaki, Shimizu, Kuwata and Suga2020). The permeability Reynolds numbers listed in table 2 are ![]() $Re_K=2.7$, 5.2 and 7.5 for cases LP9, MP9 and HP9, respectively. Hence the blocking effect by the rib that keeps mean recirculation bubbles over the porous layer becomes weak, and the recirculation bubbles tend to vanish as

$Re_K=2.7$, 5.2 and 7.5 for cases LP9, MP9 and HP9, respectively. Hence the blocking effect by the rib that keeps mean recirculation bubbles over the porous layer becomes weak, and the recirculation bubbles tend to vanish as ![]() $Re_K$ increases.

$Re_K$ increases.

4.2. Statistical flow characteristics

First, figure 8 compares the present and experimental data at comparable permeability Reynolds numbers since we consider that ![]() $Re_K$ is a measure to characterize the present flow trends as discussed in the later sections. The presented profiles in figures 8(a,c) are the streamwise–spanwise plane-averaged time-mean streamwise velocities (for simplicity hereafter, mean velocities)

$Re_K$ is a measure to characterize the present flow trends as discussed in the later sections. The presented profiles in figures 8(a,c) are the streamwise–spanwise plane-averaged time-mean streamwise velocities (for simplicity hereafter, mean velocities)

normalized by the bulk mean velocity ![]() $U_b$, that is,

$U_b$, that is,

where ![]() $S$ is an

$S$ is an ![]() $x$–

$x$–![]() $z$ plane area,

$z$ plane area, ![]() $\epsilon$ is the fluid-phase ratio of the plane area,

$\epsilon$ is the fluid-phase ratio of the plane area, ![]() $\overline {(\cdot )}$ denotes a time-mean variable, and

$\overline {(\cdot )}$ denotes a time-mean variable, and ![]() $(\cdot )^f$ denotes a fluid-phase variable. A fluid-phase plane-averaged value of

$(\cdot )^f$ denotes a fluid-phase variable. A fluid-phase plane-averaged value of ![]() $\phi$ is denoted as

$\phi$ is denoted as ![]() ${\left \langle \phi \right \rangle }^{f}$, and a superficially plane-averaged value of

${\left \langle \phi \right \rangle }^{f}$, and a superficially plane-averaged value of ![]() $\phi$ is

$\phi$ is ![]() ${\langle \phi \rangle }$, hereafter. The relation between those variables is

${\langle \phi \rangle }$, hereafter. The relation between those variables is ![]() ${\langle \phi \rangle }=\epsilon {\left \langle \phi \right \rangle }^{f}$. Figures 8(b,d) indicate the plane-averaged root mean square (r.m.s.) velocities, where

${\langle \phi \rangle }=\epsilon {\left \langle \phi \right \rangle }^{f}$. Figures 8(b,d) indicate the plane-averaged root mean square (r.m.s.) velocities, where ![]() $u'_i=u_i-\bar {u}_i$, with

$u'_i=u_i-\bar {u}_i$, with ![]() $(u_1, u_2, u_3)=(u, v, w)$. Although the compared cases are representative, the shown agreement confirms that the present simulation data are useful to elucidate the turbulent flow physics which governs the rib-roughened porous wall flows studied experimentally by Okazaki et al. (Reference Okazaki, Takase, Kuwata and Suga2022).

$(u_1, u_2, u_3)=(u, v, w)$. Although the compared cases are representative, the shown agreement confirms that the present simulation data are useful to elucidate the turbulent flow physics which governs the rib-roughened porous wall flows studied experimentally by Okazaki et al. (Reference Okazaki, Takase, Kuwata and Suga2022).

Figure 8. Comparison with the experimental data of mean velocity and r.m.s. velocities: (a,b) ![]() $w/k\simeq 9$ at

$w/k\simeq 9$ at ![]() $Re_K\simeq 5$; (c,d)

$Re_K\simeq 5$; (c,d) ![]() $w/k\simeq 1$ at

$w/k\simeq 1$ at ![]() $Re_K\simeq 8$. Experimental data are from Okazaki et al. (Reference Okazaki, Takase, Kuwata and Suga2022). The experimental porous media nos 13 and 20 were metallic foam media with porosity

$Re_K\simeq 8$. Experimental data are from Okazaki et al. (Reference Okazaki, Takase, Kuwata and Suga2022). The experimental porous media nos 13 and 20 were metallic foam media with porosity ![]() $\varphi =0.95$.

$\varphi =0.95$.

Figure 9 compares the simulated mean velocity profiles. It is seen that the mean velocity increases below the rib-top position (![]() $y<0$) as the permeability increases for both

$y<0$) as the permeability increases for both ![]() $w/k\simeq 1$ and 9. Because of this increase of the flow rate at

$w/k\simeq 1$ and 9. Because of this increase of the flow rate at ![]() $y<0$, the velocity profile reduces above the rib-top region while it recovers in the upper half-region. These observed trends are consistent with those shown in the experiments by Okazaki et al. (Reference Okazaki, Takase, Kuwata and Suga2022). As for the velocity magnitudes at the rib-bottom position

$y<0$, the velocity profile reduces above the rib-top region while it recovers in the upper half-region. These observed trends are consistent with those shown in the experiments by Okazaki et al. (Reference Okazaki, Takase, Kuwata and Suga2022). As for the velocity magnitudes at the rib-bottom position ![]() $y/H=-0.1$, they are very minor even at

$y/H=-0.1$, they are very minor even at ![]() $w/k\simeq 9$ in case HP. This contrasts with the existence of substantial slip velocities at flat porous interfaces. Indeed, Suga et al. (Reference Suga, Matsumura, Ashitaka, Tominaga and Kaneda2010) and Efstathiou & Luhar (Reference Efstathiou and Luhar2018) reported that at ‘flat’ porous interfaces, there existed substantial slip velocities that were approximately 30 % of the bulk or free-stream velocity. (Interestingly, the velocity magnitudes at the rib-top position

$w/k\simeq 9$ in case HP. This contrasts with the existence of substantial slip velocities at flat porous interfaces. Indeed, Suga et al. (Reference Suga, Matsumura, Ashitaka, Tominaga and Kaneda2010) and Efstathiou & Luhar (Reference Efstathiou and Luhar2018) reported that at ‘flat’ porous interfaces, there existed substantial slip velocities that were approximately 30 % of the bulk or free-stream velocity. (Interestingly, the velocity magnitudes at the rib-top position ![]() $y=0$ are, however, close to those slip velocities.) Accordingly, although flow penetration into the porous layer at

$y=0$ are, however, close to those slip velocities.) Accordingly, although flow penetration into the porous layer at ![]() $y/H<-0.1$ is observed in permeable cases, it looks very small both at

$y/H<-0.1$ is observed in permeable cases, it looks very small both at ![]() $w/k\simeq 1$ and 9. This indicates that although streamlines are drawn inside the porous bed in figure 7, the flow rate there is negligibly small.

$w/k\simeq 1$ and 9. This indicates that although streamlines are drawn inside the porous bed in figure 7, the flow rate there is negligibly small.

Figure 9. Comparison of plane-averaged time-mean velocities: (a) streamwise mean velocities at ![]() $w/k\simeq 1$; (b) streamwise mean velocities at

$w/k\simeq 1$; (b) streamwise mean velocities at ![]() $w/k\simeq 9$.

$w/k\simeq 9$.

The profiles of the plane-averaged Reynolds shear stress (for simplicity, Reynolds shear stress hereafter) and dispersion shear stress are shown in figure 10. Here, the velocity dispersion is ![]() $\bar {\tilde {u}}_i =\bar {u}_i-{\left \langle \bar {u}_i \right \rangle }^{f}$, and the dispersion stress is defined as

$\bar {\tilde {u}}_i =\bar {u}_i-{\left \langle \bar {u}_i \right \rangle }^{f}$, and the dispersion stress is defined as

At ![]() $w/k\simeq 1$, as the permeability increases, the Reynolds shear stress around the rib increases monotonically as shown in figure 10(a). This implies that turbulence is enhanced as the permeability increases. For

$w/k\simeq 1$, as the permeability increases, the Reynolds shear stress around the rib increases monotonically as shown in figure 10(a). This implies that turbulence is enhanced as the permeability increases. For ![]() $w/k\simeq 9$, shown in figure 10(b), such a trend is seen only in the region near the rib-bottom. At the rib-top position, the Reynolds shear stress of case S9 is predominant over the other cases, while the profiles of the permeable cases look almost collapsed to a single profile. This suggests that the turbulence level over the rib at

$w/k\simeq 9$, shown in figure 10(b), such a trend is seen only in the region near the rib-bottom. At the rib-top position, the Reynolds shear stress of case S9 is predominant over the other cases, while the profiles of the permeable cases look almost collapsed to a single profile. This suggests that the turbulence level over the rib at ![]() $w/k\simeq 9$ is rather insensitive to the present permeable cases once normalized by the friction velocity. Moreover, the levels of cases HP1 and HP9 over the ribs become almost the same, and this suggests that the rib spacing becomes ineffective to affect turbulence over the ribs at a higher permeability case. As indicated in figure 9(a), in case S1, the magnitude of

$w/k\simeq 9$ is rather insensitive to the present permeable cases once normalized by the friction velocity. Moreover, the levels of cases HP1 and HP9 over the ribs become almost the same, and this suggests that the rib spacing becomes ineffective to affect turbulence over the ribs at a higher permeability case. As indicated in figure 9(a), in case S1, the magnitude of ![]() ${\langle U \rangle }/U_b$ between the ribs is close to zero, though there are locally negative velocities due to the recirculation bubbles as seen in figure 7(a). Correspondingly,

${\langle U \rangle }/U_b$ between the ribs is close to zero, though there are locally negative velocities due to the recirculation bubbles as seen in figure 7(a). Correspondingly, ![]() $-{\langle \bar {\tilde {u}} \bar {\tilde {v}} \rangle }^+$ shows a negative profile below the rib-top. As the permeability increases, however, such negative local velocities tend to disappear. Similar things take place just over the ribs in case S9. Accordingly, as the permeability increases, the dispersion shear stress changes its sign near the rib, as seen in figures 10(c,d). The penetration of the shear stress is observed until

$-{\langle \bar {\tilde {u}} \bar {\tilde {v}} \rangle }^+$ shows a negative profile below the rib-top. As the permeability increases, however, such negative local velocities tend to disappear. Similar things take place just over the ribs in case S9. Accordingly, as the permeability increases, the dispersion shear stress changes its sign near the rib, as seen in figures 10(c,d). The penetration of the shear stress is observed until ![]() $y/H\simeq -0.3$ in case HP9, unlike in the mean velocity profile. As for the dispersion stress, although its maximum magnitude is 10–20 % of that of the Reynolds shear stress, its levels inside the porous layer at

$y/H\simeq -0.3$ in case HP9, unlike in the mean velocity profile. As for the dispersion stress, although its maximum magnitude is 10–20 % of that of the Reynolds shear stress, its levels inside the porous layer at ![]() $y/H<-0.1$ become comparable or even larger than those of the Reynolds shear stress for permeable cases MP9 and HP9, as seen in figure 10(d). These trends suggest that surface mass transfer at

$y/H<-0.1$ become comparable or even larger than those of the Reynolds shear stress for permeable cases MP9 and HP9, as seen in figure 10(d). These trends suggest that surface mass transfer at ![]() $y/H<-0.1$ by turbulence and dispersion clearly increases as the increase of the permeability at

$y/H<-0.1$ by turbulence and dispersion clearly increases as the increase of the permeability at ![]() $w/k\simeq 9$.

$w/k\simeq 9$.

Figure 10. Comparison of plane-averaged Reynolds shear and dispersion shear stresses: (a) Reynolds shear stresses at ![]() $w/k\simeq 1$; (b) Reynolds shear stresses at

$w/k\simeq 1$; (b) Reynolds shear stresses at ![]() $w/k\simeq 9$; (c) dispersion stresses at

$w/k\simeq 9$; (c) dispersion stresses at ![]() $w/k\simeq 1$; (d) dispersion stresses at

$w/k\simeq 1$; (d) dispersion stresses at ![]() $w/k\simeq 9$.

$w/k\simeq 9$.

Figures 11 and 12 indicate the simulated r.m.s. velocities and r.m.s. dispersion velocities, respectively. At ![]() $w/k\simeq 1$, the trends of the r.m.s. streamwise velocities over the rib-top position shown in figure 11(a) look different from those in the Reynolds shear stress profiles, while the other components shown in figures 11(c,e) behave similarly to the Reynolds shear stress. The streamwise component of case S1 is larger than in the other cases just above the rib, while the wall-normal and spanwise components of case S1 are smaller than in the other cases. This means that turbulence anisotropy there in case S1 is higher than that in the other cases. Turbulence anisotropy over the rib hence reduces clearly in permeable cases since the permeability weakens turbulence anisotropy near the porous interface (Breugem et al. Reference Breugem, Boersma and Uittenbogaard2006; Suga et al. Reference Suga, Matsumura, Ashitaka, Tominaga and Kaneda2010). At

$w/k\simeq 1$, the trends of the r.m.s. streamwise velocities over the rib-top position shown in figure 11(a) look different from those in the Reynolds shear stress profiles, while the other components shown in figures 11(c,e) behave similarly to the Reynolds shear stress. The streamwise component of case S1 is larger than in the other cases just above the rib, while the wall-normal and spanwise components of case S1 are smaller than in the other cases. This means that turbulence anisotropy there in case S1 is higher than that in the other cases. Turbulence anisotropy over the rib hence reduces clearly in permeable cases since the permeability weakens turbulence anisotropy near the porous interface (Breugem et al. Reference Breugem, Boersma and Uittenbogaard2006; Suga et al. Reference Suga, Matsumura, Ashitaka, Tominaga and Kaneda2010). At ![]() $w/k\simeq 9$, although there are slight discrepancies between the cases, the general trends of the cases look similar to one another. These trends over the rib are also observed in Okazaki et al. (Reference Okazaki, Shimizu, Kuwata and Suga2020). The penetration depths of permeable cases are similar to each other for

$w/k\simeq 9$, although there are slight discrepancies between the cases, the general trends of the cases look similar to one another. These trends over the rib are also observed in Okazaki et al. (Reference Okazaki, Shimizu, Kuwata and Suga2020). The penetration depths of permeable cases are similar to each other for ![]() $w/k\simeq 1$ and

$w/k\simeq 1$ and ![]() $9$ unlike in the Reynolds shear stress profiles, and the permeability enhances the r.m.s. velocities inside the porous layer at

$9$ unlike in the Reynolds shear stress profiles, and the permeability enhances the r.m.s. velocities inside the porous layer at ![]() $y/H < -0.1$. This implies that inside the porous layer, the wall-normal fluctuating energy induced by the vertical pressure fluctuation is redistributed to the other components. The r.m.s. dispersion velocities inside the porous layer at

$y/H < -0.1$. This implies that inside the porous layer, the wall-normal fluctuating energy induced by the vertical pressure fluctuation is redistributed to the other components. The r.m.s. dispersion velocities inside the porous layer at ![]() $y/H<-0.1$ shown in figure 12 at

$y/H<-0.1$ shown in figure 12 at ![]() $w/k\simeq 9$ are clearly larger than those at

$w/k\simeq 9$ are clearly larger than those at ![]() $w/k\simeq 1$, unlike the r.m.s. velocities. This trend corresponds to the mean streamlines presented in figure 7. Particularly at

$w/k\simeq 1$, unlike the r.m.s. velocities. This trend corresponds to the mean streamlines presented in figure 7. Particularly at ![]() $w/k\simeq 9$, since the mean recirculating flow with certain magnitudes of local velocities exists inside the porous layer, the r.m.s. dispersion velocities exist. While the magnitudes of the r.m.s. dispersion velocities inside the porous layer at

$w/k\simeq 9$, since the mean recirculating flow with certain magnitudes of local velocities exists inside the porous layer, the r.m.s. dispersion velocities exist. While the magnitudes of the r.m.s. dispersion velocities inside the porous layer at ![]() $w/k\simeq 9$ tend to be large in the larger permeable cases, those in cases MP9 and HP9 look similar to each other. Such a trend is also seen in the dispersion stress shown in figure 10(d). (Although there seem to be several reasons why this happens, such as the porosity and thickness of the porous layer, we do not discuss this issue further since our main focus is on the flow physics over porous rib roughness. Note that as confirmed in Appendix B, the presently applied porous layer thicknesses are enough to discuss turbulence over porous rib roughness keeping it free from the effects of the very bottom wall.) The trends observed above suggest that mass flux across the porous surface towards the inside region would be significantly larger at

$w/k\simeq 9$ tend to be large in the larger permeable cases, those in cases MP9 and HP9 look similar to each other. Such a trend is also seen in the dispersion stress shown in figure 10(d). (Although there seem to be several reasons why this happens, such as the porosity and thickness of the porous layer, we do not discuss this issue further since our main focus is on the flow physics over porous rib roughness. Note that as confirmed in Appendix B, the presently applied porous layer thicknesses are enough to discuss turbulence over porous rib roughness keeping it free from the effects of the very bottom wall.) The trends observed above suggest that mass flux across the porous surface towards the inside region would be significantly larger at ![]() $w/k\simeq 9$ than at

$w/k\simeq 9$ than at ![]() $w/k\simeq 1$, owing to the dispersion rather than turbulence.

$w/k\simeq 1$, owing to the dispersion rather than turbulence.

Figure 11. Comparison of plane-averaged r.m.s. velocities: (a) streamwise r.m.s. velocities at ![]() $w/k\simeq 1$; (b) streamwise r.m.s. velocities at

$w/k\simeq 1$; (b) streamwise r.m.s. velocities at ![]() $w/k\simeq 9$; (c) wall-normal r.m.s. velocities at

$w/k\simeq 9$; (c) wall-normal r.m.s. velocities at ![]() $w/k\simeq 1$; (d) wall-normal r.m.s. velocities at

$w/k\simeq 1$; (d) wall-normal r.m.s. velocities at ![]() $w/k\simeq 9$; (e) spanwise r.m.s. velocities at

$w/k\simeq 9$; (e) spanwise r.m.s. velocities at ![]() $w/k\simeq 1$; (f) spanwise r.m.s. velocities at

$w/k\simeq 1$; (f) spanwise r.m.s. velocities at ![]() $w/k\simeq 9$.

$w/k\simeq 9$.

Figure 12. Comparison of r.m.s. dispersion velocities: (a) streamwise components at ![]() $w/k\simeq 1$; (b) streamwise components at

$w/k\simeq 1$; (b) streamwise components at ![]() $w/k\simeq 9$; (c) wall-normal components at

$w/k\simeq 9$; (c) wall-normal components at ![]() $w/k\simeq 1$; (d) wall-normal components at

$w/k\simeq 1$; (d) wall-normal components at ![]() $w/k\simeq 9$; (e) spanwise components at

$w/k\simeq 9$; (e) spanwise components at ![]() $w/k\simeq 1$; (f) spanwise components at

$w/k\simeq 1$; (f) spanwise components at ![]() $w/k\simeq 9$.

$w/k\simeq 9$.

4.3. Drag characteristics

Corresponding to the trend of turbulence quantities observed in figures 10 and 11, the drag shows characteristic behaviours as seen in figure 13(a) that compares the data with the experiments of Okazaki et al. (Reference Okazaki, Takase, Kuwata and Suga2022). The rib-bottom drag coefficient ![]() $C_D$ corresponds to the sum of the frictional and pressure drag coefficients described by Leonardi et al. (Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003), who simulated solid impermeable cases, and their data are also included in figure 13(a). In the present study, the definition is

$C_D$ corresponds to the sum of the frictional and pressure drag coefficients described by Leonardi et al. (Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003), who simulated solid impermeable cases, and their data are also included in figure 13(a). In the present study, the definition is ![]() $C_D=2\tau _b/(\rho U_b^2)$, where the drag over the rib-bottom

$C_D=2\tau _b/(\rho U_b^2)$, where the drag over the rib-bottom ![]() $\tau _b$ is calculated by

$\tau _b$ is calculated by

since the joint integration of ![]() $\tau _b$ and the wall shear stress on the top smooth wall

$\tau _b$ and the wall shear stress on the top smooth wall ![]() $\tau _t$ balances with the integration of the pressure drop over the rib-bottom. The area over which the pressure drop is integrated is proportional to

$\tau _t$ balances with the integration of the pressure drop over the rib-bottom. The area over which the pressure drop is integrated is proportional to ![]() $H$ minus the streamwise–spanwise plane-averaged solid-phase part of the rib height:

$H$ minus the streamwise–spanwise plane-averaged solid-phase part of the rib height: ![]() $\int _{-k}^0(1-\epsilon )\,{\rm d}y$. Hence

$\int _{-k}^0(1-\epsilon )\,{\rm d}y$. Hence ![]() $C_D$ here does not include the drag by the porous bottom layer below the rib-bottom, but it includes the pressure and frictional drag through the ribs. It is seen that

$C_D$ here does not include the drag by the porous bottom layer below the rib-bottom, but it includes the pressure and frictional drag through the ribs. It is seen that ![]() $C_D$ values of the impermeable cases are in close agreement at

$C_D$ values of the impermeable cases are in close agreement at ![]() $w/k\simeq$1 and 9, while some Reynolds number effects may exist at

$w/k\simeq$1 and 9, while some Reynolds number effects may exist at ![]() $w/k\simeq 9$. In both the present and experimental studies, as the permeability (and thus

$w/k\simeq 9$. In both the present and experimental studies, as the permeability (and thus ![]() $Re_K$) increases,

$Re_K$) increases, ![]() $C_D$ increases at

$C_D$ increases at ![]() $w/k\simeq$1, although the reverse trend is seen at

$w/k\simeq$1, although the reverse trend is seen at ![]() $w/k\simeq 9$, while the differences are small between the present permeable cases. These observed trends correspond qualitatively to the changes of the permeability Reynolds number. In figure 13(b), however, we understand that the correlation between

$w/k\simeq 9$, while the differences are small between the present permeable cases. These observed trends correspond qualitatively to the changes of the permeability Reynolds number. In figure 13(b), however, we understand that the correlation between ![]() $C_D$ and

$C_D$ and ![]() $Re_K$ is not general when experimental data are cross-plotted. Note that the experimental values shown in figures 13(b,c) are somewhat dispersed, particularly at the low

$Re_K$ is not general when experimental data are cross-plotted. Note that the experimental values shown in figures 13(b,c) are somewhat dispersed, particularly at the low ![]() $Re_K$ region. As reported in the experiments for flat porous beds by Suga et al. (Reference Suga, Matsumura, Ashitaka, Tominaga and Kaneda2010) and Suga, Mori & Kaneda (Reference Suga, Mori and Kaneda2011), the slippage velocity at the porous interface and the near-wall characteristics of permeable wall turbulence change drastically in the low