1. Introduction

Wake interactions between individual horizontal axis wind turbines can reduce wind farm energy production by 10–20 % (Barthelmie et al. Reference Barthelmie, Hansen, Frandsen, Rathmann, Schepers, Schlez, Phillips, Rados, Zervos and Politis2009). Utility-scale wind turbines are controlled to maximize individual power production, rather than collective wind farm production (Boersma et al. Reference Boersma, Doekemeijer, Gebraad, Fleming, Annoni, Scholbrock, Frederik and van Wingerden2017). Individual operation entails aligning each wind turbine in the farm with the incoming wind direction. In contrast, wake steering, where individual wind turbines are intentionally yaw-misaligned with respect to the incident wind direction, has emerged as a promising strategy to reduce wake interactions and increase collective wind farm power production (e.g. Gebraad et al. Reference Gebraad, Teeuwisse, Van Wingerden, Fleming, Ruben, Marden and Pao2016; Bastankhah & Porté-Agel Reference Bastankhah and Porté-Agel2019; Kheirabadi & Nagamune Reference Kheirabadi and Nagamune2019; Zong & Porté-Agel Reference Zong and Porté-Agel2021; Howland et al. Reference Howland, Ghate, Quesada, Pena Martínez, Zhong, Larrañaga, Lele and Dabiri2022a). Maximizing collective wind farm power production through wake steering control generally involves a trade-off between the power lost by the yaw-misaligned turbines and the power gained by the downwind-waked turbines, compared to standard individual control (e.g. Fleming et al. Reference Fleming, Gebraad, Lee, van Wingerden, Johnson, Churchfield, Michalakes, Spalart and Moriarty2015). Since the power-maximizing yaw misalignment angles for wake steering control are estimated primarily using simplified analytical flow models (Gebraad et al. Reference Gebraad, Teeuwisse, Van Wingerden, Fleming, Ruben, Marden and Pao2016; Fleming et al. Reference Fleming, King, Dykes, Simley, Roadman, Scholbrock, Murphy, Lundquist, Moriarty and Fleming2019; Howland et al. Reference Howland, Quesada, Martinez, Larrañaga, Yadav, Chawla, Sivaram and Dabiri2022), it is important to accurately model the dependence of wind turbine power production and wake velocities on the yaw misalignment angle.

Wind turbine power production generally decreases as a function of an increasing yaw misalignment (![]() $\gamma$) magnitude since the component of the wind velocity that is perpendicular to the rotor decreases. Textbooks instruct that the power production of a yawed wind turbine will decrease following

$\gamma$) magnitude since the component of the wind velocity that is perpendicular to the rotor decreases. Textbooks instruct that the power production of a yawed wind turbine will decrease following ![]() $\cos ^3(\gamma )$ (Burton et al. Reference Burton, Jenkins, Sharpe and Bossanyi2011). This estimate is based on the application of classical one-dimensional momentum theory with an incoming axial freestream wind speed

$\cos ^3(\gamma )$ (Burton et al. Reference Burton, Jenkins, Sharpe and Bossanyi2011). This estimate is based on the application of classical one-dimensional momentum theory with an incoming axial freestream wind speed ![]() $u_\infty \cos (\gamma )$ perpendicular to the rotor. However, wind turbines extract power from the winds at the rotor. The wind at the rotor is affected by the velocity induced by the wind turbine. Since the induction depends on the wind turbine thrust force, and the thrust force will decrease in yaw misalignment, the induction will depend on the yaw misalignment. The

$u_\infty \cos (\gamma )$ perpendicular to the rotor. However, wind turbines extract power from the winds at the rotor. The wind at the rotor is affected by the velocity induced by the wind turbine. Since the induction depends on the wind turbine thrust force, and the thrust force will decrease in yaw misalignment, the induction will depend on the yaw misalignment. The ![]() $\cos ^3(\gamma )$ model neglects the dependence of the induction on the yaw misalignment (Micallef & Sant Reference Micallef and Sant2016). Given the error incurred by the

$\cos ^3(\gamma )$ model neglects the dependence of the induction on the yaw misalignment (Micallef & Sant Reference Micallef and Sant2016). Given the error incurred by the ![]() $\cos ^3(\gamma )$ model, most analytical wind farm power models assume that the power of a yaw-misaligned wind turbine follows

$\cos ^3(\gamma )$ model, most analytical wind farm power models assume that the power of a yaw-misaligned wind turbine follows ![]() $P_r(\gamma ) = P(\gamma )/P(\gamma =0)=\cos ^{P_p}(\gamma )$, where

$P_r(\gamma ) = P(\gamma )/P(\gamma =0)=\cos ^{P_p}(\gamma )$, where ![]() $P_p$ is an empirical, turbine-specific factor that needs to be tuned using experimental data (Dahlberg & Montgomerie Reference Dahlberg and Montgomerie2005; Gebraad et al. Reference Gebraad, Teeuwisse, Van Wingerden, Fleming, Ruben, Marden and Pao2016). However, such experiments are costly, since they require sustained operation of utility-scale wind turbines in suboptimal yaw misalignment angles (Howland et al. Reference Howland, González, Martínez, Quesada, Larranaga, Yadav, Chawla and Dabiri2020c). Further, the wide spread in

$P_p$ is an empirical, turbine-specific factor that needs to be tuned using experimental data (Dahlberg & Montgomerie Reference Dahlberg and Montgomerie2005; Gebraad et al. Reference Gebraad, Teeuwisse, Van Wingerden, Fleming, Ruben, Marden and Pao2016). However, such experiments are costly, since they require sustained operation of utility-scale wind turbines in suboptimal yaw misalignment angles (Howland et al. Reference Howland, González, Martínez, Quesada, Larranaga, Yadav, Chawla and Dabiri2020c). Further, the wide spread in ![]() $P_p$ values reported in the literature, typically

$P_p$ values reported in the literature, typically ![]() $1< P_p< 3$, suggests that the cosine model is not universal to different turbine models (Dahlberg & Montgomerie Reference Dahlberg and Montgomerie2005; Schreiber et al. Reference Schreiber, Nanos, Campagnolo and Bottasso2017; Liew, Urbán & Andersen Reference Liew, Urbán and Andersen2020; Howland et al. Reference Howland, González, Martínez, Quesada, Larranaga, Yadav, Chawla and Dabiri2020c). Accurate analytical predictions of

$1< P_p< 3$, suggests that the cosine model is not universal to different turbine models (Dahlberg & Montgomerie Reference Dahlberg and Montgomerie2005; Schreiber et al. Reference Schreiber, Nanos, Campagnolo and Bottasso2017; Liew, Urbán & Andersen Reference Liew, Urbán and Andersen2020; Howland et al. Reference Howland, González, Martínez, Quesada, Larranaga, Yadav, Chawla and Dabiri2020c). Accurate analytical predictions of ![]() $P_r(\gamma )$ remain an outstanding challenge (Hur et al. Reference Hur, Berdowski, Simao Ferreira, Boorsma and Schepers2019) – as a starting point, in this study, we focus on analytical predictions of the induction and power production of yawed actuator disks.

$P_r(\gamma )$ remain an outstanding challenge (Hur et al. Reference Hur, Berdowski, Simao Ferreira, Boorsma and Schepers2019) – as a starting point, in this study, we focus on analytical predictions of the induction and power production of yawed actuator disks.

Through analysis of an autogyro aircraft, Glauert (Reference Glauert1926) developed an equation for the area-averaged induction and the coefficient of power as a function of the yaw misalignment ![]() $\gamma$. Glauert (Reference Glauert1926) also identified that the induction of a yawed actuator disk varies over the rotor area about its mean value – this finding has been replicated in other actuator disk simulations and models (see review by Hur et al. Reference Hur, Berdowski, Simao Ferreira, Boorsma and Schepers2019). Glauert's yawed actuator disk momentum theory is commonly used in blade-element momentum (BEM) models of rotational wind turbine aerodynamics (see e.g. review by Micallef & Sant Reference Micallef and Sant2016). Using the Bernoulli equation, Shapiro, Gayme & Meneveau (Reference Shapiro, Gayme and Meneveau2018) proposed an equation for the dependence of the axial induction factor on the yaw misalignment of an actuator disk. Speakman et al. (Reference Speakman, Abkar, Martínez-Tossas and Bastankhah2021) used the axial induction equation proposed by Shapiro et al. (Reference Shapiro, Gayme and Meneveau2018) to model

$\gamma$. Glauert (Reference Glauert1926) also identified that the induction of a yawed actuator disk varies over the rotor area about its mean value – this finding has been replicated in other actuator disk simulations and models (see review by Hur et al. Reference Hur, Berdowski, Simao Ferreira, Boorsma and Schepers2019). Glauert's yawed actuator disk momentum theory is commonly used in blade-element momentum (BEM) models of rotational wind turbine aerodynamics (see e.g. review by Micallef & Sant Reference Micallef and Sant2016). Using the Bernoulli equation, Shapiro, Gayme & Meneveau (Reference Shapiro, Gayme and Meneveau2018) proposed an equation for the dependence of the axial induction factor on the yaw misalignment of an actuator disk. Speakman et al. (Reference Speakman, Abkar, Martínez-Tossas and Bastankhah2021) used the axial induction equation proposed by Shapiro et al. (Reference Shapiro, Gayme and Meneveau2018) to model ![]() $P_r(\gamma )$ for a simulation with thrust coefficient

$P_r(\gamma )$ for a simulation with thrust coefficient ![]() $0.75$, which yielded improved power predictions compared to the

$0.75$, which yielded improved power predictions compared to the ![]() $\cos ^3(\gamma )$ model, but higher predictive error than a tuned

$\cos ^3(\gamma )$ model, but higher predictive error than a tuned ![]() $\cos ^{P_p}(\gamma )$ with

$\cos ^{P_p}(\gamma )$ with ![]() $P_p$ set to

$P_p$ set to ![]() $1.88$.

$1.88$.

Beyond modelling the power–yaw relationship (i.e. ![]() $P_r(\gamma )$), modelling the inviscid near-rotor wake region of a yawed actuator disk is important since inviscid models are often used as an initial condition for turbulent wake models that are used to predict wind farm power production (Frandsen et al. Reference Frandsen, Barthelmie, Pryor, Rathmann, Larsen, Højstrup and Thøgersen2006; Bastankhah & Porté-Agel Reference Bastankhah and Porté-Agel2016; Shapiro et al. Reference Shapiro, Gayme and Meneveau2018). Therefore, it is equally important to accurately model the induction and the streamwise and spanwise velocity deficits at the outlet of the inviscid near-wake region for a yawed actuator disk.

$P_r(\gamma )$), modelling the inviscid near-rotor wake region of a yawed actuator disk is important since inviscid models are often used as an initial condition for turbulent wake models that are used to predict wind farm power production (Frandsen et al. Reference Frandsen, Barthelmie, Pryor, Rathmann, Larsen, Højstrup and Thøgersen2006; Bastankhah & Porté-Agel Reference Bastankhah and Porté-Agel2016; Shapiro et al. Reference Shapiro, Gayme and Meneveau2018). Therefore, it is equally important to accurately model the induction and the streamwise and spanwise velocity deficits at the outlet of the inviscid near-wake region for a yawed actuator disk.

Finally, a line of research parallel to wake steering has investigated methods for axial induction flow control, where individual wind turbines reduce the magnitude of their wind speed wake deficits by decreasing the thrust force (Annoni et al. Reference Annoni, Gebraad, Scholbrock, Fleming and van Wingerden2016). A promising flow control methodology combines wake steering and induction control (Munters & Meyers Reference Munters and Meyers2018) – for such combined control, it is important to model the joint effect of the yaw misalignment and the wind turbine thrust coefficient on the power and wake deficit.

In this study, classical, inviscid momentum theory is extended to the yaw-misaligned actuator disk. Analytical expressions are developed for the rotor-normal induction, the streamwise velocity deficit, the spanwise velocity deficit, the thrust, and the power production of an actuator disk as a function of yaw misalignment. In § 2, a model is proposed based on a combination of momentum conservation, mass conservation and the Bernoulli equation. The model is validated against large eddy simulations (LES) of a yawed actuator disk. The numerical set-up of the LES is given in § 3, and results are provided in § 4. The model is validated against the LES in § 4.1. The dependence of the induction, velocity deficits and the power on the wind turbine thrust coefficient is presented in § 4.2. Further, in § 4.2 the model is optimized to find the thrust coefficient that maximizes power for each value of the yaw misalignment angle. In § 4.3, the induction model is used as an initial condition for a turbulent far-wake model. The implications of the developed induction–yaw model on quasi-steady wake steering and induction control are presented and discussed. Conclusions are provided in § 5.

2. Yawed actuator disk momentum theory

Our goal is to model the induction, thrust, wake deficit and deflection, and the power production of a yaw-misaligned actuator disk. For the following analysis, we assume that the flow is inviscid and frictionless. We assume that the velocity is continuous across the actuator disk, including both the streamwise and spanwise velocities, and that the pressure recovers to the incident freestream pressure away from the actuator disk. We note that the pressure recovery assumption is relevant to only the Bernoulli equation and streamwise momentum analysis. We do not apply this pressure recovery assumption to a lateral momentum balance, since it is well-known to introduce predictive error (Shapiro et al. Reference Shapiro, Gayme and Meneveau2018) due to counter-rotating vortices in the wake of yawed turbines (Howland et al. Reference Howland, Bossuyt, Martínez-Tossas, Meyers and Meneveau2016). We consider uniform inflow (in ![]() $y$ and

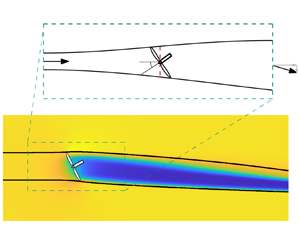

$y$ and ![]() $z$), as in standard momentum theory, and an actuator disk model (ADM) representation of the wind turbine forcing (Calaf, Meneveau & Meyers Reference Calaf, Meneveau and Meyers2010; Burton et al. Reference Burton, Jenkins, Sharpe and Bossanyi2011). The ADM is introduced in § 2.1. The lateral velocity is modelled following lifting line theory (Shapiro et al. Reference Shapiro, Gayme and Meneveau2018) (§ 2.2). The induction is modelled by combining the Bernoulli equation, conservation of mass and momentum conservation to a control volume containing the yaw-misaligned actuator disk (§ 2.3). A schematic of the yaw-misaligned actuator disk and the control volume is shown in figure 1.

$z$), as in standard momentum theory, and an actuator disk model (ADM) representation of the wind turbine forcing (Calaf, Meneveau & Meyers Reference Calaf, Meneveau and Meyers2010; Burton et al. Reference Burton, Jenkins, Sharpe and Bossanyi2011). The ADM is introduced in § 2.1. The lateral velocity is modelled following lifting line theory (Shapiro et al. Reference Shapiro, Gayme and Meneveau2018) (§ 2.2). The induction is modelled by combining the Bernoulli equation, conservation of mass and momentum conservation to a control volume containing the yaw-misaligned actuator disk (§ 2.3). A schematic of the yaw-misaligned actuator disk and the control volume is shown in figure 1.

Figure 1. Control volume for the yawed actuator disk analysis. The streamwise and spanwise directions are ![]() $x$ and

$x$ and ![]() $y$, respectively. The actuator-disk-modelled wind turbine is yaw-misaligned at angle

$y$, respectively. The actuator-disk-modelled wind turbine is yaw-misaligned at angle ![]() $\gamma$, where positive yaw misalignment is a counter-clockwise rotation viewed from above. As in classical momentum theory, we consider four stations for the analysis, and the flow variables are labelled with the corresponding station numbers as subscripts. The cross-sectional areas, streamwise velocities, spanwise velocities, pressures and mass flow rates are denoted

$\gamma$, where positive yaw misalignment is a counter-clockwise rotation viewed from above. As in classical momentum theory, we consider four stations for the analysis, and the flow variables are labelled with the corresponding station numbers as subscripts. The cross-sectional areas, streamwise velocities, spanwise velocities, pressures and mass flow rates are denoted ![]() $A$,

$A$, ![]() $u$,

$u$, ![]() $v$,

$v$, ![]() $p$ and

$p$ and ![]() $\dot {m}$, respectively. The unit vector normal to the yawed actuator disk is shown as

$\dot {m}$, respectively. The unit vector normal to the yawed actuator disk is shown as ![]() $\hat {n}$.

$\hat {n}$.

In § 2.3, we develop the equations to predict the induction, thrust, wake deficit and deflection, and the power production of a yaw-misaligned actuator disk. In § 2.4, we consider a limiting case of the developed induction model where the outlet spanwise velocity ![]() $v_4$ is negligible compared to the outlet streamwise velocity

$v_4$ is negligible compared to the outlet streamwise velocity ![]() $u_4$, i.e.

$u_4$, i.e. ![]() $|v_4| \ll u_4$.

$|v_4| \ll u_4$.

2.1. Actuator disk model

The thrust force from an actuator disk on the surrounding flow depends on the freestream rotor-normal wind speed, ![]() $\boldsymbol {u}_\infty \boldsymbol {\cdot } \hat {n}$:

$\boldsymbol {u}_\infty \boldsymbol {\cdot } \hat {n}$:

where ![]() $\rho$ is the density of the incident air,

$\rho$ is the density of the incident air, ![]() $C_T$ is the coefficient of thrust,

$C_T$ is the coefficient of thrust, ![]() $A_d={\rm \pi} D^2/4$ is the area of the rotor disk, with

$A_d={\rm \pi} D^2/4$ is the area of the rotor disk, with ![]() $D$ the wind turbine rotor diameter,

$D$ the wind turbine rotor diameter, ![]() $\hat {n}$ is the unit normal vector perpendicular to the disk, and

$\hat {n}$ is the unit normal vector perpendicular to the disk, and ![]() $\boldsymbol {u}_{\infty }$ is the freestream wind velocity vector (Sørensen Reference Sørensen2011). Wind turbines produce thrust and power based on the wind velocity at the rotor, which has been modified by induction. Thus the empirical thrust coefficient

$\boldsymbol {u}_{\infty }$ is the freestream wind velocity vector (Sørensen Reference Sørensen2011). Wind turbines produce thrust and power based on the wind velocity at the rotor, which has been modified by induction. Thus the empirical thrust coefficient ![]() $C_T$ depends on the induction. Additionally, for wind farms in the atmospheric boundary layer, it may be challenging to estimate the value of the freestream reference wind speed

$C_T$ depends on the induction. Additionally, for wind farms in the atmospheric boundary layer, it may be challenging to estimate the value of the freestream reference wind speed ![]() $u_\infty$ due to wakes of upstream turbines or heterogeneity in the background flow field. Instead, an ADM is used to model wind turbine forcing, where the thrust force scales with the rotor-normal wind speed at the disk,

$u_\infty$ due to wakes of upstream turbines or heterogeneity in the background flow field. Instead, an ADM is used to model wind turbine forcing, where the thrust force scales with the rotor-normal wind speed at the disk, ![]() $\boldsymbol {u}_d \boldsymbol {\cdot } \hat {n}$, rather than the freestream

$\boldsymbol {u}_d \boldsymbol {\cdot } \hat {n}$, rather than the freestream ![]() $\boldsymbol {u}_\infty \boldsymbol {\cdot } \hat {n}$ (Calaf et al. Reference Calaf, Meneveau and Meyers2010). The ADM thrust force then depends on a modified thrust coefficient

$\boldsymbol {u}_\infty \boldsymbol {\cdot } \hat {n}$ (Calaf et al. Reference Calaf, Meneveau and Meyers2010). The ADM thrust force then depends on a modified thrust coefficient ![]() $C_T'$ and the disk velocity (Calaf et al. Reference Calaf, Meneveau and Meyers2010):

$C_T'$ and the disk velocity (Calaf et al. Reference Calaf, Meneveau and Meyers2010):

Equation (2.2) is used in the ADM implementation in LES used for validation as well as the derivation of the analytical model.

Assuming that the freestream wind is uniform and aligned with the ![]() $x$-direction, the freestream wind vector is

$x$-direction, the freestream wind vector is ![]() $\boldsymbol {u}_\infty = u_\infty \hat {\imath }+ 0 \hat {\jmath }$. In this study, we focus on uniform inflow, where the inflow wind

$\boldsymbol {u}_\infty = u_\infty \hat {\imath }+ 0 \hat {\jmath }$. In this study, we focus on uniform inflow, where the inflow wind ![]() $\boldsymbol {u}_\infty$ does not depend on

$\boldsymbol {u}_\infty$ does not depend on ![]() $y$ or

$y$ or ![]() $z$. This follows standard momentum theory (Burton et al. Reference Burton, Jenkins, Sharpe and Bossanyi2011), which avoids additional complexities in modelling turbine performance due to wind shear (Choukulkar et al. Reference Choukulkar, Pichugina, Clack, Calhoun, Banta, Brewer and Hardesty2016; Howland et al. Reference Howland, González, Martínez, Quesada, Larranaga, Yadav, Chawla and Dabiri2020c). However, the disk velocity may include a component in the

$z$. This follows standard momentum theory (Burton et al. Reference Burton, Jenkins, Sharpe and Bossanyi2011), which avoids additional complexities in modelling turbine performance due to wind shear (Choukulkar et al. Reference Choukulkar, Pichugina, Clack, Calhoun, Banta, Brewer and Hardesty2016; Howland et al. Reference Howland, González, Martínez, Quesada, Larranaga, Yadav, Chawla and Dabiri2020c). However, the disk velocity may include a component in the ![]() $y$-direction for yaw-misaligned turbines, and so is generally

$y$-direction for yaw-misaligned turbines, and so is generally ![]() $\boldsymbol {u}_d = u_{d}\hat {\imath } + v_{d}\hat {\jmath }$. The rotor-normal, rotor-averaged induction factor

$\boldsymbol {u}_d = u_{d}\hat {\imath } + v_{d}\hat {\jmath }$. The rotor-normal, rotor-averaged induction factor ![]() $a_n$ for a rotor with yaw misalignment angle

$a_n$ for a rotor with yaw misalignment angle ![]() $\gamma$ is defined as

$\gamma$ is defined as

In the yaw-aligned case where ![]() $\hat {n}=\hat {\imath }$, the rotor-normal induction factor

$\hat {n}=\hat {\imath }$, the rotor-normal induction factor ![]() $a_n$ reduces to the standard (streamwise) axial induction factor

$a_n$ reduces to the standard (streamwise) axial induction factor ![]() $a = 1 - u_d / u_\infty$. The thrust force written in terms of the rotor-normal induction factor is then

$a = 1 - u_d / u_\infty$. The thrust force written in terms of the rotor-normal induction factor is then

The power for the actuator disk is computed as ![]() $P = -\boldsymbol {F}_T \boldsymbol {\cdot } \boldsymbol {u}_d$.

$P = -\boldsymbol {F}_T \boldsymbol {\cdot } \boldsymbol {u}_d$.

Rotational utility-scale wind turbines produce a thrust force that depends on the velocity at the turbine (e.g. Burton et al. Reference Burton, Jenkins, Sharpe and Bossanyi2011; Sørensen Reference Sørensen2011; Howland et al. Reference Howland, González, Martínez, Quesada, Larranaga, Yadav, Chawla and Dabiri2020c) – the velocity at the turbine is lower than ![]() $u_\infty$ due to induction. Similarly, the ADM produces a thrust force that is proportional to the disk velocity, which has been modified by induction. The thrust force depends on the yaw misalignment for both utility-scale rotational wind turbines and the ADM. In the ADM,

$u_\infty$ due to induction. Similarly, the ADM produces a thrust force that is proportional to the disk velocity, which has been modified by induction. The thrust force depends on the yaw misalignment for both utility-scale rotational wind turbines and the ADM. In the ADM, ![]() $C_T^{\prime }$ is an input. If we prescribe a value of

$C_T^{\prime }$ is an input. If we prescribe a value of ![]() $C_T^{\prime }$ that does not depend on the yaw angle, then the thrust force of the ADM depends on the yaw misalignment following

$C_T^{\prime }$ that does not depend on the yaw angle, then the thrust force of the ADM depends on the yaw misalignment following ![]() $F_T(\gamma ) \propto (1-a_n)^2 \cos ^2(\gamma )$. However, since the rotor-normal induction depends on the imposed thrust force

$F_T(\gamma ) \propto (1-a_n)^2 \cos ^2(\gamma )$. However, since the rotor-normal induction depends on the imposed thrust force ![]() $F_T$, and the thrust force decreases with an increasing magnitude of yaw misalignment, we hypothesize that the induction factor will depend on

$F_T$, and the thrust force decreases with an increasing magnitude of yaw misalignment, we hypothesize that the induction factor will depend on ![]() $\gamma$ such that

$\gamma$ such that ![]() $a_n = a_n(\gamma )$.

$a_n = a_n(\gamma )$.

The derivation in §§ 2.2 and 2.3 will prescribe an ADM-type forcing where ![]() $C_T^\prime$ is an input quantity. We emphasize that the proposed analytical model can be applied for a wind turbine model for which

$C_T^\prime$ is an input quantity. We emphasize that the proposed analytical model can be applied for a wind turbine model for which ![]() $C_T^\prime$ varies as a function of the yaw misalignment. This will be demonstrated in § 4.2.

$C_T^\prime$ varies as a function of the yaw misalignment. This will be demonstrated in § 4.2.

In the model validation against LES in § 4.1, we compare the proposed model to an ADM forcing in LES where ![]() $C_T^\prime$ is a fixed quantity that does not depend on the yaw misalignment (see (2.2)). For different wind turbine models, a different form of the thrust force

$C_T^\prime$ is a fixed quantity that does not depend on the yaw misalignment (see (2.2)). For different wind turbine models, a different form of the thrust force ![]() $F_T$ may be appropriate (i.e. a form different to (2.2)). Specifically,

$F_T$ may be appropriate (i.e. a form different to (2.2)). Specifically, ![]() $C_T^\prime$ may not be a fixed quantity, and would be a required, known input to the final model form. In general for rotational turbines, the potential dependence of

$C_T^\prime$ may not be a fixed quantity, and would be a required, known input to the final model form. In general for rotational turbines, the potential dependence of ![]() $C_T^\prime$ on the yaw misalignment will depend on the turbine control strategy (i.e. the blade pitch and torque control) and the wind conditions (Howland et al. Reference Howland, González, Martínez, Quesada, Larranaga, Yadav, Chawla and Dabiri2020c). For a different form of

$C_T^\prime$ on the yaw misalignment will depend on the turbine control strategy (i.e. the blade pitch and torque control) and the wind conditions (Howland et al. Reference Howland, González, Martínez, Quesada, Larranaga, Yadav, Chawla and Dabiri2020c). For a different form of ![]() $F_T$, the quantitative model predictions would differ but the qualitative trends of the influence of yaw misalignment on the induction are expected to apply. Further discussion is included in Appendix E using wind tunnel data from Krogstad & Adaramola (Reference Krogstad and Adaramola2012), and the need for future work is highlighted in § 5.

$F_T$, the quantitative model predictions would differ but the qualitative trends of the influence of yaw misalignment on the induction are expected to apply. Further discussion is included in Appendix E using wind tunnel data from Krogstad & Adaramola (Reference Krogstad and Adaramola2012), and the need for future work is highlighted in § 5.

2.2. Lifting line spanwise velocity model with rotor-normal induction depending on yaw

Yaw-misaligned wind turbines generate a counter-rotating vortex pair that deflects and deforms the wake region into a curled wake shape (Bastankhah & Porté-Agel Reference Bastankhah and Porté-Agel2016; Howland et al. Reference Howland, Bossuyt, Martínez-Tossas, Meyers and Meneveau2016; Fleming et al. Reference Fleming, Annoni, Churchfield, Martinez-Tossas, Gruchalla, Lawson and Moriarty2018; Martínez-Tossas et al. Reference Martínez-Tossas, King, Quon, Bay, Mudafort, Hamilton, Howland and Fleming2021). The counter-rotating vortex pair rotates about a low-pressure centre. Momentum balance approaches to predict the lateral velocity in the wake of a yaw-misaligned actuator disk that neglect the influence of the lateral pressure gradient often exhibit predictive errors (Jiménez, Crespo & Migoya Reference Jiménez, Crespo and Migoya2010; Shapiro et al. Reference Shapiro, Gayme and Meneveau2018). Shapiro et al. (Reference Shapiro, Gayme and Meneveau2018) developed a model for the spanwise velocity downwind of a yaw-misaligned actuator disk. The approach uses Prandtl lifting line theory (Milne-Thomson Reference Milne-Thomson1973) to predict the spanwise velocity in the inviscid near-wake region downwind of the actuator disk. The downwash produced by the lifting line theory was presumed to be the spanwise velocity in the outlet of the streamtube enclosing the yawed actuator disk. The resulting model predicts the spanwise velocity disturbance ![]() $\delta v_0 = v_\infty - v_4 = \frac {1}{4} C_T u_\infty \cos ^2(\gamma ) \sin (\gamma )$. The model exhibited excellent predictions of the circulation at the disk hub-height (

$\delta v_0 = v_\infty - v_4 = \frac {1}{4} C_T u_\infty \cos ^2(\gamma ) \sin (\gamma )$. The model exhibited excellent predictions of the circulation at the disk hub-height (![]() $z=0$), defined as

$z=0$), defined as ![]() $\varGamma _0$ (Shapiro et al. Reference Shapiro, Gayme and Meneveau2018), over a range of yaw and thrust values. The spanwise velocity disturbance

$\varGamma _0$ (Shapiro et al. Reference Shapiro, Gayme and Meneveau2018), over a range of yaw and thrust values. The spanwise velocity disturbance ![]() $\delta v_0$ was also compared to LES. The predictions exhibited improved accuracy compared to previous models, but had a slight underprediction of

$\delta v_0$ was also compared to LES. The predictions exhibited improved accuracy compared to previous models, but had a slight underprediction of ![]() $\delta v_0$ at high yaw misalignment angles,

$\delta v_0$ at high yaw misalignment angles, ![]() $|\gamma |>20^\circ$ (Shapiro et al. Reference Shapiro, Gayme and Meneveau2018).

$|\gamma |>20^\circ$ (Shapiro et al. Reference Shapiro, Gayme and Meneveau2018).

Following § 2.1, we consider the Prandtl lifting line approach developed by Shapiro et al. (Reference Shapiro, Gayme and Meneveau2018) applied to the ADM with a prescribed ![]() $C_T^\prime$, instead of a prescribed

$C_T^\prime$, instead of a prescribed ![]() $C_T$. The spanwise velocity disturbance is

$C_T$. The spanwise velocity disturbance is

Comparing (2.5) to the model proposed by Shapiro et al. (Reference Shapiro, Gayme and Meneveau2018), ![]() $C_T^\prime$ is the input quantity and there is an additional nonlinear dependence on

$C_T^\prime$ is the input quantity and there is an additional nonlinear dependence on ![]() $a_n(\gamma )$. We note that Shapiro et al. (Reference Shapiro, Gayme and Meneveau2018) identified the influence of the yaw misalignment on the induction, and accounted for it by plotting

$a_n(\gamma )$. We note that Shapiro et al. (Reference Shapiro, Gayme and Meneveau2018) identified the influence of the yaw misalignment on the induction, and accounted for it by plotting ![]() $\delta v_0$ against

$\delta v_0$ against ![]() $C_T$, where the thrust coefficient was estimated empirically as

$C_T$, where the thrust coefficient was estimated empirically as ![]() $C_T = C_T^\prime \tilde {u}_{d}^2 / (u_\infty ^2 \cos ^2(\gamma ))$, with

$C_T = C_T^\prime \tilde {u}_{d}^2 / (u_\infty ^2 \cos ^2(\gamma ))$, with ![]() $\tilde {u}_d$ the disk velocity measured from the LES validation case. In the following subsections, we will develop a predictive model for

$\tilde {u}_d$ the disk velocity measured from the LES validation case. In the following subsections, we will develop a predictive model for ![]() $a_n(\gamma )$ that uses (2.5).

$a_n(\gamma )$ that uses (2.5).

2.3. Model for the induction of a yaw-misaligned actuator disk

To model the induction, we first apply the Bernoulli equation from stations 1 to 2 and from stations 3 to 4 within the streamtube, shown in figure 1:

\begin{equation} \left.\begin{gathered} p_1 + \tfrac{1}{2}\rho \|\boldsymbol{u}_1\|^2 = p_2 + \tfrac{1}{2}\rho \|\boldsymbol{u}_2\|^2, \\ p_3 + \tfrac{1}{2}\rho \|\boldsymbol{u}_3\|^2 = p_4 + \tfrac{1}{2}\rho \|\boldsymbol{u}_4\|^2, \end{gathered}\right\}\end{equation}

\begin{equation} \left.\begin{gathered} p_1 + \tfrac{1}{2}\rho \|\boldsymbol{u}_1\|^2 = p_2 + \tfrac{1}{2}\rho \|\boldsymbol{u}_2\|^2, \\ p_3 + \tfrac{1}{2}\rho \|\boldsymbol{u}_3\|^2 = p_4 + \tfrac{1}{2}\rho \|\boldsymbol{u}_4\|^2, \end{gathered}\right\}\end{equation}

where ![]() $\|\boldsymbol {u}_4\| = \sqrt {u_4^2 + v_4^2}$. We note that the outlet flow has non-zero components in the

$\|\boldsymbol {u}_4\| = \sqrt {u_4^2 + v_4^2}$. We note that the outlet flow has non-zero components in the ![]() $x$ (

$x$ (![]() $\hat {\imath }$) and

$\hat {\imath }$) and ![]() $y$ (

$y$ (![]() $\hat {\jmath }$) directions, denoted as

$\hat {\jmath }$) directions, denoted as ![]() $u_4$ and

$u_4$ and ![]() $v_4$, respectively (see figure 1). Assuming that the pressure recovers to the freestream at station 4 (

$v_4$, respectively (see figure 1). Assuming that the pressure recovers to the freestream at station 4 (![]() $p_1$ =

$p_1$ = ![]() $p_4 = p_\infty$) and that the velocity across the rotor disk is continuous (

$p_4 = p_\infty$) and that the velocity across the rotor disk is continuous (![]() $\boldsymbol {u}_2 = \boldsymbol {u}_3 = \boldsymbol {u}_d$), (2.6) can be combined and simplified to

$\boldsymbol {u}_2 = \boldsymbol {u}_3 = \boldsymbol {u}_d$), (2.6) can be combined and simplified to

Substituting in ![]() $\boldsymbol {u}_1 = \boldsymbol {u}_\infty$,

$\boldsymbol {u}_1 = \boldsymbol {u}_\infty$, ![]() $\boldsymbol {u}_4=u_4\hat {\imath } + v_4\hat {\jmath }$ and

$\boldsymbol {u}_4=u_4\hat {\imath } + v_4\hat {\jmath }$ and ![]() $(\,p_2 - p_3) A_d = \|\boldsymbol {F}_{T}\|$, with

$(\,p_2 - p_3) A_d = \|\boldsymbol {F}_{T}\|$, with ![]() $\boldsymbol {F}_T$ given by (2.4), this becomes

$\boldsymbol {F}_T$ given by (2.4), this becomes

Next, we apply mass conservation to the streamtube between stations 2 and 4, where ![]() $A_2=A_d$:

$A_2=A_d$:

Substituting in ![]() $\boldsymbol {u}_2=\boldsymbol {u}_d$ and the definition of

$\boldsymbol {u}_2=\boldsymbol {u}_d$ and the definition of ![]() $a_n$ in (2.3),

$a_n$ in (2.3), ![]() $\boldsymbol {u}_d \boldsymbol {\cdot } \hat {n} = (1-a_n)u_\infty \cos (\gamma )$, this simplifies to

$\boldsymbol {u}_d \boldsymbol {\cdot } \hat {n} = (1-a_n)u_\infty \cos (\gamma )$, this simplifies to

We then apply mass conservation to the two-dimensional control volume, assuming that the flow outside the disk streamtube is unperturbed at ![]() $u_\infty$:

$u_\infty$:

where ![]() $CV$ denotes the control volume (figure 1). Finally, we apply conservation of momentum to the control volume in the streamwise direction (

$CV$ denotes the control volume (figure 1). Finally, we apply conservation of momentum to the control volume in the streamwise direction (![]() $\hat {\imath }$), using the Reynolds transport theorem assuming steady-state flow:

$\hat {\imath }$), using the Reynolds transport theorem assuming steady-state flow:

where ![]() ${CS}$ is the control surface. By expanding the surface integral and combining terms, this momentum balance simplifies to

${CS}$ is the control surface. By expanding the surface integral and combining terms, this momentum balance simplifies to

Substituting (2.4), (2.10) and (2.11) into (2.13) and simplifying gives

Finally, we solve for ![]() $a_n$ in (2.8) from Bernoulli,

$a_n$ in (2.8) from Bernoulli, ![]() $u_4/u_\infty$ in (2.14) from conservation of mass and the streamwise momentum balance, and

$u_4/u_\infty$ in (2.14) from conservation of mass and the streamwise momentum balance, and ![]() $v_4/u_\infty$ in (2.5) from the lifting line spanwise velocity deficit model, resulting in a coupled nonlinear system of three equations to solve for

$v_4/u_\infty$ in (2.5) from the lifting line spanwise velocity deficit model, resulting in a coupled nonlinear system of three equations to solve for ![]() $a_n(\gamma )$,

$a_n(\gamma )$, ![]() $u_4(\gamma )$ and

$u_4(\gamma )$ and ![]() $v_4(\gamma )$:

$v_4(\gamma )$:

\begin{equation} \left.\begin{aligned} a_n(\gamma) = 1 - \dfrac{\sqrt{u_\infty^2-u_4(\gamma)^2-v_4(\gamma)^2}}{ \sqrt{C_T^\prime}\, u_\infty \cos(\gamma)},\\ \dfrac{u_4(\gamma)}{u_\infty} = 1 - \tfrac{1}{2}\,C_T^\prime \left(1-a_n(\gamma)\right) \cos^2(\gamma),\\ \dfrac{v_4(\gamma)}{u_\infty} =-\tfrac{1}{4}\,C_T^\prime \left(1-a_n(\gamma)\right)^2 \sin(\gamma) \cos^2(\gamma). \end{aligned}\right\} \end{equation}

\begin{equation} \left.\begin{aligned} a_n(\gamma) = 1 - \dfrac{\sqrt{u_\infty^2-u_4(\gamma)^2-v_4(\gamma)^2}}{ \sqrt{C_T^\prime}\, u_\infty \cos(\gamma)},\\ \dfrac{u_4(\gamma)}{u_\infty} = 1 - \tfrac{1}{2}\,C_T^\prime \left(1-a_n(\gamma)\right) \cos^2(\gamma),\\ \dfrac{v_4(\gamma)}{u_\infty} =-\tfrac{1}{4}\,C_T^\prime \left(1-a_n(\gamma)\right)^2 \sin(\gamma) \cos^2(\gamma). \end{aligned}\right\} \end{equation}

The system in (2.15) can be solved iteratively from an initial condition from standard, yaw-aligned momentum theory ![]() $a_n^0 = a = \frac {1}{2}(1-\sqrt {1-C_T})=C_T'/(C_T'+4)$ and typically converges in less than five iterations. While the system of equations in (2.15) converges quickly, it does not permit a straightforward solution. In § 2.4, we examine a limiting case of the model where the outlet spanwise velocity is neglected in the Bernoulli equation,

$a_n^0 = a = \frac {1}{2}(1-\sqrt {1-C_T})=C_T'/(C_T'+4)$ and typically converges in less than five iterations. While the system of equations in (2.15) converges quickly, it does not permit a straightforward solution. In § 2.4, we examine a limiting case of the model where the outlet spanwise velocity is neglected in the Bernoulli equation, ![]() $|v_4| \ll u_4$.

$|v_4| \ll u_4$.

With a solution for the normal induction factor ![]() $a_n(\gamma )$ from (2.15), the power for a yaw-misaligned actuator disk is modelled as

$a_n(\gamma )$ from (2.15), the power for a yaw-misaligned actuator disk is modelled as

As discussed in the Introduction, the dependence of wind turbine power production on the yaw misalignment is often described by the power ratio ![]() $P_r(\gamma )$ (e.g. Howland et al. Reference Howland, González, Martínez, Quesada, Larranaga, Yadav, Chawla and Dabiri2020c). The resulting model for the power ratio is

$P_r(\gamma )$ (e.g. Howland et al. Reference Howland, González, Martínez, Quesada, Larranaga, Yadav, Chawla and Dabiri2020c). The resulting model for the power ratio is

and the thrust ratio is

Given the ADM turbine representation, the thrust force scales with the rotor-averaged disk velocity (e.g. Calaf et al. Reference Calaf, Meneveau and Meyers2010). Therefore, the rotor-normal induction factor model in (2.15) is the prediction for the rotor-averaged induction factor, defined in (2.3) as ![]() $a_n$. Due to the yaw misalignment, the induction will also vary as a function of the azimuthal position about its rotor-averaged value (Glauert Reference Glauert1926). Glauert (Reference Glauert1926) modelled this

$a_n$. Due to the yaw misalignment, the induction will also vary as a function of the azimuthal position about its rotor-averaged value (Glauert Reference Glauert1926). Glauert (Reference Glauert1926) modelled this ![]() $\hat {a}_n(r,\theta ) = \left \langle a_n(r,\theta )\right \rangle _A + a_n^\prime (r,\theta )$, where

$\hat {a}_n(r,\theta ) = \left \langle a_n(r,\theta )\right \rangle _A + a_n^\prime (r,\theta )$, where ![]() $\hat {a}_n(r,\theta )$ is the rotor-normal induction depending on the radial

$\hat {a}_n(r,\theta )$ is the rotor-normal induction depending on the radial ![]() $r$ and azimuthal

$r$ and azimuthal ![]() $\theta$ position,

$\theta$ position, ![]() $\left \langle a_n(r,\theta )\right \rangle _A$ is the rotor-averaged induction (referred to as

$\left \langle a_n(r,\theta )\right \rangle _A$ is the rotor-averaged induction (referred to as ![]() $a_n$ elsewhere in the paper), and

$a_n$ elsewhere in the paper), and ![]() $a_n^\prime (r,\theta )$ is the zero-mean, azimuthally dependent deviation from the rotor-averaged induction (Hur et al. Reference Hur, Berdowski, Simao Ferreira, Boorsma and Schepers2019). The azimuthally dependent portion of the induction has been modelled empirically as

$a_n^\prime (r,\theta )$ is the zero-mean, azimuthally dependent deviation from the rotor-averaged induction (Hur et al. Reference Hur, Berdowski, Simao Ferreira, Boorsma and Schepers2019). The azimuthally dependent portion of the induction has been modelled empirically as ![]() $a_n^\prime (r,\theta ) = K_x ({r}/{R} )\sin (\theta )$, where

$a_n^\prime (r,\theta ) = K_x ({r}/{R} )\sin (\theta )$, where ![]() $R$ is the rotor radius, and

$R$ is the rotor radius, and ![]() $K_x$ is an empirical factor (Glauert Reference Glauert1926; Hur et al. Reference Hur, Berdowski, Simao Ferreira, Boorsma and Schepers2019). We note that

$K_x$ is an empirical factor (Glauert Reference Glauert1926; Hur et al. Reference Hur, Berdowski, Simao Ferreira, Boorsma and Schepers2019). We note that ![]() $a_n^\prime (r,\theta )$ averages to zero over the rotor

$a_n^\prime (r,\theta )$ averages to zero over the rotor ![]() $\left(\left \langle a_n^\prime (r,\theta )\right \rangle _A=0\right)$. Since the ADM thrust (

$\left(\left \langle a_n^\prime (r,\theta )\right \rangle _A=0\right)$. Since the ADM thrust (![]() $F_T$) and power (

$F_T$) and power (![]() $P$) depend on the rotor-averaged velocity,

$P$) depend on the rotor-averaged velocity, ![]() $a_n^\prime (r,\theta )$ will not affect

$a_n^\prime (r,\theta )$ will not affect ![]() $a_n(\gamma )$,

$a_n(\gamma )$, ![]() $F_T(\gamma )$ or

$F_T(\gamma )$ or ![]() $P(\gamma )$. For turbine models that apply thrust force unequally across the rotor, such as a blade-element (Howland et al. Reference Howland, González, Martínez, Quesada, Larranaga, Yadav, Chawla and Dabiri2020c) or actuator line (Martínez-Tossas, Churchfield & Leonardi Reference Martínez-Tossas, Churchfield and Leonardi2015) representation,

$P(\gamma )$. For turbine models that apply thrust force unequally across the rotor, such as a blade-element (Howland et al. Reference Howland, González, Martínez, Quesada, Larranaga, Yadav, Chawla and Dabiri2020c) or actuator line (Martínez-Tossas, Churchfield & Leonardi Reference Martínez-Tossas, Churchfield and Leonardi2015) representation, ![]() $a_n^\prime (r,\theta )$ can affect

$a_n^\prime (r,\theta )$ can affect ![]() $F_T(\gamma )$ and

$F_T(\gamma )$ and ![]() $P(\gamma )$, and therefore must be modelled. We suggest future research on the radial and azimuthal variations of the rotor-normal induction factor for turbines beyond the ADM.

$P(\gamma )$, and therefore must be modelled. We suggest future research on the radial and azimuthal variations of the rotor-normal induction factor for turbines beyond the ADM.

2.4. Limiting case of CV analysis with  $|v_4| \ll u_4$

$|v_4| \ll u_4$

In this subsection, we consider the limiting case where the outlet spanwise velocity from the streamtube is significantly less than the outlet streamwise velocity, ![]() $|v_4| \ll u_4$. Therefore, the outlet velocity is

$|v_4| \ll u_4$. Therefore, the outlet velocity is ![]() $\|\boldsymbol {u}_4\| = u_4$. Starting from (2.15), the rotor-normal induction is simplified as

$\|\boldsymbol {u}_4\| = u_4$. Starting from (2.15), the rotor-normal induction is simplified as

which is also the induction factor reported by Shapiro et al. (Reference Shapiro, Gayme and Meneveau2018), who assumed that the spanwise velocity disturbance appeared infinitesimally downwind of the yawed actuator disk and that it was constant in the streamtube downwind. The streamwise and spanwise velocities are

The streamwise outlet velocity ![]() $u_4(\gamma )$ can also be written in terms of the induction factor

$u_4(\gamma )$ can also be written in terms of the induction factor ![]() $a_n(\gamma )$ such that

$a_n(\gamma )$ such that ![]() $u_4(\gamma ) = u_\infty (1 - 2a_n(\gamma ))$, where

$u_4(\gamma ) = u_\infty (1 - 2a_n(\gamma ))$, where ![]() $a_n(\gamma )$ is given by (2.19). This is analogous to the outlet velocity from one-dimensional momentum

$a_n(\gamma )$ is given by (2.19). This is analogous to the outlet velocity from one-dimensional momentum ![]() $u_4(\gamma =0) = u_\infty (1-2a)$, where

$u_4(\gamma =0) = u_\infty (1-2a)$, where ![]() $a = a_n(\gamma =0)$ is again the standard axial induction factor.

$a = a_n(\gamma =0)$ is again the standard axial induction factor.

The power of the yawed actuator disk in this limiting case is

The power and thrust ratios in this limiting case are

\begin{equation} P_r(\gamma) = \left[\frac{(4+C_T^\prime) \cos(\gamma)}{4+C_T^\prime \cos^2(\gamma)}\right]^3, \quad T_r(\gamma) = \left[\frac{(4+C_T^\prime) \cos(\gamma)}{4+C_T^\prime \cos^2(\gamma)}\right]^2. \end{equation}

\begin{equation} P_r(\gamma) = \left[\frac{(4+C_T^\prime) \cos(\gamma)}{4+C_T^\prime \cos^2(\gamma)}\right]^3, \quad T_r(\gamma) = \left[\frac{(4+C_T^\prime) \cos(\gamma)}{4+C_T^\prime \cos^2(\gamma)}\right]^2. \end{equation}The power ratio model given by (2.22a) was also reported by Speakman et al. (Reference Speakman, Abkar, Martínez-Tossas and Bastankhah2021), who leveraged the streamwise induction model developed by Shapiro et al. (Reference Shapiro, Gayme and Meneveau2018) (same as (2.19)).

3. Large eddy simulation numerical set-up

Large eddy simulations are performed using an incompressible flow code PadéOps (https://github.com/FPAL-Stanford-University/PadeOps; Ghate & Lele Reference Ghate and Lele2017; Howland, Ghate & Lele Reference Howland, Ghate and Lele2020a). Fourier collocation is used in the horizontal directions and a sixth-order staggered compact finite difference scheme is used in the vertical direction (Nagarajan, Lele & Ferziger Reference Nagarajan, Lele and Ferziger2003). Time advancement uses a fourth-order strong stability preserving variant of the Runge–Kutta scheme (Gottlieb, Ketcheson & Shu Reference Gottlieb, Ketcheson and Shu2011), and the subgrid scale closure uses the sigma subfilter scale model (Nicoud et al. Reference Nicoud, Toda, Cabrit, Bose and Lee2011).

The ADM is implemented with the regularization methodology introduced by Calaf et al. (Reference Calaf, Meneveau and Meyers2010) and further developed by Shapiro, Gayme & Meneveau (Reference Shapiro, Gayme and Meneveau2019a). The ADM forcing depends on the prescribed input of ![]() $C_T^\prime$ (see (2.2)), which is varied independently of the yaw misalignment angle. The discretized turbine thrust force

$C_T^\prime$ (see (2.2)), which is varied independently of the yaw misalignment angle. The discretized turbine thrust force ![]() $\boldsymbol {f}(\boldsymbol {x})$ is distributed in the computational domain (

$\boldsymbol {f}(\boldsymbol {x})$ is distributed in the computational domain (![]() $\boldsymbol {x}$) through an indicator function

$\boldsymbol {x}$) through an indicator function ![]() $\mathcal {R}(\boldsymbol {x})$ as

$\mathcal {R}(\boldsymbol {x})$ as

The thrust force ![]() $\boldsymbol {F}_T$ is computed with (2.2), depending on the disk velocity

$\boldsymbol {F}_T$ is computed with (2.2), depending on the disk velocity ![]() $\boldsymbol {u}_d$. The indicator function

$\boldsymbol {u}_d$. The indicator function ![]() $\mathcal {R}(\boldsymbol {x})$ is constructed from a decomposition

$\mathcal {R}(\boldsymbol {x})$ is constructed from a decomposition ![]() $\mathcal {R}(\boldsymbol {x}) = \mathcal {R}_1(x)\,\mathcal {R}_2(y, z)$ given by

$\mathcal {R}(\boldsymbol {x}) = \mathcal {R}_1(x)\,\mathcal {R}_2(y, z)$ given by

$$\begin{gather} \mathcal{R}_1(x) = \frac{1}{2s} \left[ \mathrm{erf}\left(\frac{\sqrt{6}}{\varDelta} \left(x+\frac s2\right)\right) - \mathrm{erf}\left(\frac{\sqrt{6}}{\varDelta} \left(x-\frac s2\right)\right)\right], \end{gather}$$

$$\begin{gather} \mathcal{R}_1(x) = \frac{1}{2s} \left[ \mathrm{erf}\left(\frac{\sqrt{6}}{\varDelta} \left(x+\frac s2\right)\right) - \mathrm{erf}\left(\frac{\sqrt{6}}{\varDelta} \left(x-\frac s2\right)\right)\right], \end{gather}$$

where ![]() $H(x)$ is the Heaviside function,

$H(x)$ is the Heaviside function, ![]() $\mathrm {erf}(x)$ is the error function,

$\mathrm {erf}(x)$ is the error function, ![]() $s$ is the ADM disk thickness, and

$s$ is the ADM disk thickness, and ![]() $\varDelta$ is the ADM filter width. The disk velocity

$\varDelta$ is the ADM filter width. The disk velocity ![]() $\boldsymbol {u}_d$, used in the thrust force calculation (2.2), is calculated using the indicator function such that

$\boldsymbol {u}_d$, used in the thrust force calculation (2.2), is calculated using the indicator function such that

where ![]() $\boldsymbol {u}(\boldsymbol {x})$ is the filtered velocity in the LES domain, and

$\boldsymbol {u}(\boldsymbol {x})$ is the filtered velocity in the LES domain, and ![]() $M$ is an ADM filter width-dependent correction factor (Shapiro et al. Reference Shapiro, Gayme and Meneveau2019a). Depending on the numerical implementation of the indicator function, particularly the selection of ADM filter width

$M$ is an ADM filter width-dependent correction factor (Shapiro et al. Reference Shapiro, Gayme and Meneveau2019a). Depending on the numerical implementation of the indicator function, particularly the selection of ADM filter width ![]() $\varDelta$, the ADM can underestimate the induction and therefore overestimate power production (Munters & Meyers Reference Munters and Meyers2017; Shapiro et al. Reference Shapiro, Gayme and Meneveau2019a). To alleviate this power overestimation for larger ADM filter widths, the disk velocity calculation in (3.4) uses a correction factor

$\varDelta$, the ADM can underestimate the induction and therefore overestimate power production (Munters & Meyers Reference Munters and Meyers2017; Shapiro et al. Reference Shapiro, Gayme and Meneveau2019a). To alleviate this power overestimation for larger ADM filter widths, the disk velocity calculation in (3.4) uses a correction factor ![]() $M$ derived by Shapiro et al. (Reference Shapiro, Gayme and Meneveau2019a), which depends on

$M$ derived by Shapiro et al. (Reference Shapiro, Gayme and Meneveau2019a), which depends on ![]() $C_T'$ and the ADM filter width. To compute the correction factor

$C_T'$ and the ADM filter width. To compute the correction factor ![]() $M$, the Taylor series approximation for the ADM correction factor is used (Shapiro et al. Reference Shapiro, Gayme and Meneveau2019a) such that

$M$, the Taylor series approximation for the ADM correction factor is used (Shapiro et al. Reference Shapiro, Gayme and Meneveau2019a) such that

The correction factor given by (3.5) was derived by Shapiro et al. (Reference Shapiro, Gayme and Meneveau2019a) for yaw-aligned actuator disks. For low values of ![]() $\varDelta / D$, the correction factor

$\varDelta / D$, the correction factor ![]() $M$ has a limited impact on the LES results, and the induction and power follow momentum theory (Shapiro et al. Reference Shapiro, Gayme and Meneveau2019a), but low ADM filter widths can also result in numerical oscillations in the flow field due to the ADM forcing discontinuity. For higher values of

$M$ has a limited impact on the LES results, and the induction and power follow momentum theory (Shapiro et al. Reference Shapiro, Gayme and Meneveau2019a), but low ADM filter widths can also result in numerical oscillations in the flow field due to the ADM forcing discontinuity. For higher values of ![]() $\varDelta / D$ with the correction factor implemented for a yaw-aligned ADM, the thrust force and power predicted by momentum theory are well reproduced, but the induced velocity in the LES domain does not conform to momentum theory due to the wide force smearing fundamental to the larger values of

$\varDelta / D$ with the correction factor implemented for a yaw-aligned ADM, the thrust force and power predicted by momentum theory are well reproduced, but the induced velocity in the LES domain does not conform to momentum theory due to the wide force smearing fundamental to the larger values of ![]() $\varDelta /D$ (see Appendix A, figure 10). In the results presented in § 4 where analysis of the wake flow field is required, to reduce numerical oscillations in the wake, a larger ADM filter width

$\varDelta /D$ (see Appendix A, figure 10). In the results presented in § 4 where analysis of the wake flow field is required, to reduce numerical oscillations in the wake, a larger ADM filter width ![]() $\varDelta /D = 3h/(2D)$ is used with the correction factor

$\varDelta /D = 3h/(2D)$ is used with the correction factor ![]() $M$ given by (3.5), where

$M$ given by (3.5), where ![]() $h = (\varDelta x^2 + \varDelta y^2 + \varDelta z^2)^{1/2}$. In the results presented in § 4 for which only the quantities at the actuator disk are analysed, a smaller ADM filter width of

$h = (\varDelta x^2 + \varDelta y^2 + \varDelta z^2)^{1/2}$. In the results presented in § 4 for which only the quantities at the actuator disk are analysed, a smaller ADM filter width of ![]() $\varDelta / D = 0.29 h / D = 0.032$ is used such that the correction factor is not required to reproduce the power predicted by momentum theory for the yaw-aligned ADM (see also the discussion by Shapiro et al. Reference Shapiro, Gayme and Meneveau2019a). In all cases, the ADM thickness is

$\varDelta / D = 0.29 h / D = 0.032$ is used such that the correction factor is not required to reproduce the power predicted by momentum theory for the yaw-aligned ADM (see also the discussion by Shapiro et al. Reference Shapiro, Gayme and Meneveau2019a). In all cases, the ADM thickness is ![]() $s = 3\varDelta x/2$. More discussion of the ADM numerical set-up and the interactions between the LES results and the ADM filter width and the correction factor is provided in Appendix A.

$s = 3\varDelta x/2$. More discussion of the ADM numerical set-up and the interactions between the LES results and the ADM filter width and the correction factor is provided in Appendix A.

Consistent with the model derivation (see § 2), simulations are performed with uniform inflow with zero freestream turbulence. Periodic boundary conditions are used in the lateral ![]() $y$-direction. A fringe region (Nordström, Nordin & Henningson Reference Nordström, Nordin and Henningson1999) is used in the

$y$-direction. A fringe region (Nordström, Nordin & Henningson Reference Nordström, Nordin and Henningson1999) is used in the ![]() $x$-direction to force the inflow to the desired profile with a prescribed yaw angle. All simulations are performed with a domain

$x$-direction to force the inflow to the desired profile with a prescribed yaw angle. All simulations are performed with a domain ![]() $L_x=25D$ in length, and cross-sectional size

$L_x=25D$ in length, and cross-sectional size ![]() $L_y = 20D$,

$L_y = 20D$, ![]() $L_z=10D$, with

$L_z=10D$, with ![]() $256\times 512\times 256$ grid points. A large cross-section is used to minimize the influence of blockage on the ADM, which changes as a function of turbine yaw. A single turbine is placed inside the domain at the centre of the

$256\times 512\times 256$ grid points. A large cross-section is used to minimize the influence of blockage on the ADM, which changes as a function of turbine yaw. A single turbine is placed inside the domain at the centre of the ![]() $y$–

$y$–![]() $z$ plane at a distance

$z$ plane at a distance ![]() $5D$ from the domain inlet in the

$5D$ from the domain inlet in the ![]() $x$-direction. Simulations are run for two flow-through times

$x$-direction. Simulations are run for two flow-through times ![]() $L_x/u_\infty$ to allow the turbine power output to converge, which is sufficient in these zero freestream turbulence inflow cases (Howland et al. Reference Howland, Bossuyt, Martínez-Tossas, Meyers and Meneveau2016).

$L_x/u_\infty$ to allow the turbine power output to converge, which is sufficient in these zero freestream turbulence inflow cases (Howland et al. Reference Howland, Bossuyt, Martínez-Tossas, Meyers and Meneveau2016).

4. Results

In this section, the model predictions are compared to results from LES, and the model output is explored to reveal implications for wind farm flow control. In § 4.1, the predictive model developed in § 2 is validated against LES. The dependence of the induction on the coefficient of thrust is demonstrated in the model and in LES (§ 4.1). In § 4.2, the model is optimized to find the thrust coefficients that maximize the coefficient of power as a function of the yaw misalignment angle, and the predictions are compared to LES. Finally, in § 4.3, the model is used as an initial condition for a turbulent far-wake model. The influence of the induction–yaw relationship developed in § 2 on a wake steering test case is explored.

4.1. Comparison between the model and LES

The model for ![]() $P_r(\gamma )$ (2.17) is compared to LES in figure 2 for

$P_r(\gamma )$ (2.17) is compared to LES in figure 2 for ![]() $C_T^\prime =1.33$ for yaw misalignments

$C_T^\prime =1.33$ for yaw misalignments ![]() $0^\circ \leqslant \gamma \leqslant 50^\circ$. The model developed by Glauert (Reference Glauert1926), with the functional form provided in Appendix B, and the developed model in the limit

$0^\circ \leqslant \gamma \leqslant 50^\circ$. The model developed by Glauert (Reference Glauert1926), with the functional form provided in Appendix B, and the developed model in the limit ![]() $|v_4| \ll u_4$ (§ 2.4) are also shown. Finally,

$|v_4| \ll u_4$ (§ 2.4) are also shown. Finally, ![]() $\cos (\gamma )$ and

$\cos (\gamma )$ and ![]() $\cos ^3(\gamma )$ are shown for reference. The model developed in § 2.3 exhibits the lowest predictive error compared to the LES data. Neglecting the lateral velocity in the Bernoulli equation,

$\cos ^3(\gamma )$ are shown for reference. The model developed in § 2.3 exhibits the lowest predictive error compared to the LES data. Neglecting the lateral velocity in the Bernoulli equation, ![]() $|v_4| \ll u_4$ (§ 2.4), results in a consistent overprediction of the power production at all yaw misalignment angles because the portion of momentum redistributed to the spanwise velocity, which does not contribute to power, is neglected. Neglecting the lateral velocity in the Bernoulli equation (2.7) increases the predicted pressure drop, and therefore the thrust force and the power, because the energy in the spanwise velocity is not accounted for in the outlet flow.

$|v_4| \ll u_4$ (§ 2.4), results in a consistent overprediction of the power production at all yaw misalignment angles because the portion of momentum redistributed to the spanwise velocity, which does not contribute to power, is neglected. Neglecting the lateral velocity in the Bernoulli equation (2.7) increases the predicted pressure drop, and therefore the thrust force and the power, because the energy in the spanwise velocity is not accounted for in the outlet flow.

Figure 2. (a) Normalized power production for the yawed ADM wind turbine with ![]() $C_T^\prime =1.33$, normalized by the power production for a yaw-aligned ADM wind turbine (

$C_T^\prime =1.33$, normalized by the power production for a yaw-aligned ADM wind turbine (![]() $P(\gamma )/P(\gamma =0)$). The LES results are shown with green dots. The model predictions are given by the ‘Yawed CV’ curve, and the limiting case

$P(\gamma )/P(\gamma =0)$). The LES results are shown with green dots. The model predictions are given by the ‘Yawed CV’ curve, and the limiting case ![]() $|v_4| \ll u_4$ for the model is shown. For reference,

$|v_4| \ll u_4$ for the model is shown. For reference, ![]() $\cos ^3(\gamma )$ and

$\cos ^3(\gamma )$ and ![]() $\cos (\gamma )$ curves are shown in addition to the Glauert model (Appendix B). (b) Zoomed-in version of (a) to highlight the performance of different models. (c) Same as (a) with

$\cos (\gamma )$ curves are shown in addition to the Glauert model (Appendix B). (b) Zoomed-in version of (a) to highlight the performance of different models. (c) Same as (a) with ![]() $\cos (\gamma )$ on the

$\cos (\gamma )$ on the ![]() $x$-axis.

$x$-axis.

The Glauert model results in a larger power overprediction. This overprediction is expected, as discussed in Burton et al. (Reference Burton, Jenkins, Sharpe and Bossanyi2011), since the lift contributions to the thrust in the Glauert model should not contribute to power because it does not contribute to net flow through the disk. The ![]() $\cos (\gamma )$ and

$\cos (\gamma )$ and ![]() $\cos ^3(\gamma )$ curves provide upper and lower bounds, respectively, for the LES data and the model predictions. The commonly assumed

$\cos ^3(\gamma )$ curves provide upper and lower bounds, respectively, for the LES data and the model predictions. The commonly assumed ![]() $\cos ^3(\gamma )$ model (Burton et al. Reference Burton, Jenkins, Sharpe and Bossanyi2011) underpredicts the power production because the yaw misalignment reduces the thrust force, which in turn reduces the rotor-normal induction and increases the disk velocity and the power production.

$\cos ^3(\gamma )$ model (Burton et al. Reference Burton, Jenkins, Sharpe and Bossanyi2011) underpredicts the power production because the yaw misalignment reduces the thrust force, which in turn reduces the rotor-normal induction and increases the disk velocity and the power production.

The model predictions and LES results for the rotor-normal induction ![]() $a_n(\gamma )$ are shown in figure 3. As with the power production, the most accurate predictions result from the yawed CV model in § 2.3. Assuming negligible lateral velocity (§ 2.4) results in an underprediction of the induction, which therefore results in an overprediction of the disk velocity and the power production (figure 2). The Glauert model overpredicts the induction, but also overpredicts the power, likely because of the lift contributions to thrust, as mentioned previously. We note that this is the Glauert model for the rotor-averaged induction. Therefore, the model for radial and azimuthal induction variations proposed by Glauert (Reference Glauert1926) averages to zero (see § 2). The yawed CV model has increasing predictive error for the induction as a function of the yaw misalignment angle. This increasing error could be due to the assumption that the pressure recovers to freestream pressure downwind (see § 2), which was applied in the Bernoulli equation and in the streamwise momentum balance. The wake of a yaw-misaligned turbine curls due to the formation of a counter-rotating vortex pair (Howland et al. Reference Howland, Bossuyt, Martínez-Tossas, Meyers and Meneveau2016). The counter-rotating vortex pair produces a low-pressure region in the yawed turbine wake that increases in magnitude, relative to the pressure drop at the rotor, with increasing turbine yaw (Shapiro et al. Reference Shapiro, Gayme and Meneveau2018), which is not modelled in the present framework. Future work should consider incorporating a pressure model in this framework.

$a_n(\gamma )$ are shown in figure 3. As with the power production, the most accurate predictions result from the yawed CV model in § 2.3. Assuming negligible lateral velocity (§ 2.4) results in an underprediction of the induction, which therefore results in an overprediction of the disk velocity and the power production (figure 2). The Glauert model overpredicts the induction, but also overpredicts the power, likely because of the lift contributions to thrust, as mentioned previously. We note that this is the Glauert model for the rotor-averaged induction. Therefore, the model for radial and azimuthal induction variations proposed by Glauert (Reference Glauert1926) averages to zero (see § 2). The yawed CV model has increasing predictive error for the induction as a function of the yaw misalignment angle. This increasing error could be due to the assumption that the pressure recovers to freestream pressure downwind (see § 2), which was applied in the Bernoulli equation and in the streamwise momentum balance. The wake of a yaw-misaligned turbine curls due to the formation of a counter-rotating vortex pair (Howland et al. Reference Howland, Bossuyt, Martínez-Tossas, Meyers and Meneveau2016). The counter-rotating vortex pair produces a low-pressure region in the yawed turbine wake that increases in magnitude, relative to the pressure drop at the rotor, with increasing turbine yaw (Shapiro et al. Reference Shapiro, Gayme and Meneveau2018), which is not modelled in the present framework. Future work should consider incorporating a pressure model in this framework.

Figure 3. Normalized rotor-normal, rotor-averaged induction for the yawed ADM wind turbine with ![]() $C_T^\prime =1.33$. The model predictions are given by the ‘Yawed CV’ curve, and the limiting case

$C_T^\prime =1.33$. The model predictions are given by the ‘Yawed CV’ curve, and the limiting case ![]() $|v_4| \ll u_4$ for the model is shown. The Glauert model (Glauert Reference Glauert1926) for the rotor-averaged induction is provided in Appendix B.

$|v_4| \ll u_4$ for the model is shown. The Glauert model (Glauert Reference Glauert1926) for the rotor-averaged induction is provided in Appendix B.

The lateral velocity disturbance, ![]() $\delta v_0(\gamma )=v_\infty -v_4=-v_4$, is estimated from LES by averaging the lateral velocity in cross-sections of the actuator disk streamtube (Shapiro et al. Reference Shapiro, Gayme and Meneveau2018). The lateral velocity disturbance

$\delta v_0(\gamma )=v_\infty -v_4=-v_4$, is estimated from LES by averaging the lateral velocity in cross-sections of the actuator disk streamtube (Shapiro et al. Reference Shapiro, Gayme and Meneveau2018). The lateral velocity disturbance ![]() $\delta v_0(\gamma )$, estimated as the maximum of the cross-sectional averages over

$\delta v_0(\gamma )$, estimated as the maximum of the cross-sectional averages over ![]() $x$, is shown in figure 4(a) along with model predictions. The maximum value of the lateral velocity disturbance

$x$, is shown in figure 4(a) along with model predictions. The maximum value of the lateral velocity disturbance ![]() $\delta v_0(\gamma )$ generally occurs approximately

$\delta v_0(\gamma )$ generally occurs approximately ![]() $D/2$ downwind of the actuator disk wind turbine. The original

$D/2$ downwind of the actuator disk wind turbine. The original ![]() $C_T$-based model of Shapiro et al. (Reference Shapiro, Gayme and Meneveau2018) (

$C_T$-based model of Shapiro et al. (Reference Shapiro, Gayme and Meneveau2018) (![]() $\delta v_0(\gamma ) = \frac {1}{4} C_T u_\infty \cos ^2(\gamma ) \sin (\gamma )$) underpredicts the initial lateral velocity disturbance at higher yaw angles. The model developed here yields improved predictions compared to the original model by including the effect of the yaw misalignment on the induction, which the original expression based on

$\delta v_0(\gamma ) = \frac {1}{4} C_T u_\infty \cos ^2(\gamma ) \sin (\gamma )$) underpredicts the initial lateral velocity disturbance at higher yaw angles. The model developed here yields improved predictions compared to the original model by including the effect of the yaw misalignment on the induction, which the original expression based on ![]() $C_T$ does not include. Since the induction decreases with increasing magnitude of the yaw angle, the disk velocity will increase. The increase in disk velocity increases the actuator disk thrust force, partially counteracting the reduction in thrust force from yaw misalignment. The lateral velocity disturbance based on

$C_T$ does not include. Since the induction decreases with increasing magnitude of the yaw angle, the disk velocity will increase. The increase in disk velocity increases the actuator disk thrust force, partially counteracting the reduction in thrust force from yaw misalignment. The lateral velocity disturbance based on ![]() $C_T^\prime$ and

$C_T^\prime$ and ![]() $a_n(\gamma )$ will therefore be larger than a prediction from a model that assumes a fixed

$a_n(\gamma )$ will therefore be larger than a prediction from a model that assumes a fixed ![]() $C_T$ as a function of yaw

$C_T$ as a function of yaw ![]() $\gamma$.

$\gamma$.

Figure 4. (a) Normalized lateral velocity deficit with ![]() $C_T^\prime =1.33$. The model predictions for the lateral velocity depending on

$C_T^\prime =1.33$. The model predictions for the lateral velocity depending on ![]() $C_T$ are shown by

$C_T$ are shown by ![]() $\delta v_0(C_T)$, where

$\delta v_0(C_T)$, where ![]() $C_T=0.75$. The model predictions for the lateral velocity depending on the induction model given by (2.15) and

$C_T=0.75$. The model predictions for the lateral velocity depending on the induction model given by (2.15) and ![]() $C_T^\prime$ are shown by

$C_T^\prime$ are shown by ![]() $\delta v_0(C_T^\prime, a_n)$. (b) Normalized streamwise velocity deficit for the yawed ADM wind turbine with

$\delta v_0(C_T^\prime, a_n)$. (b) Normalized streamwise velocity deficit for the yawed ADM wind turbine with ![]() $C_T^\prime =1.33$. The model predictions are given by the ‘Yawed CV’ curve, and the limiting case

$C_T^\prime =1.33$. The model predictions are given by the ‘Yawed CV’ curve, and the limiting case ![]() $|v_4| \ll u_4$ for the model is shown.

$|v_4| \ll u_4$ for the model is shown.

Finally, the streamwise velocity disturbance is shown in figure 4(b). The LES streamwise velocity disturbance is estimated similarly to ![]() $\delta v_0$, although the maximum value of

$\delta v_0$, although the maximum value of ![]() $\delta u_0$ generally occurs approximately

$\delta u_0$ generally occurs approximately ![]() $2D$ downwind of the actuator disk. The streamwise velocity disturbance associated with the yaw-aligned wind turbine,

$2D$ downwind of the actuator disk. The streamwise velocity disturbance associated with the yaw-aligned wind turbine, ![]() $\delta u_0/u_\infty =2a(\gamma =0)$, is shown as a reference. The streamwise velocity disturbance depends strongly on the yaw misalignment, therefore assuming

$\delta u_0/u_\infty =2a(\gamma =0)$, is shown as a reference. The streamwise velocity disturbance depends strongly on the yaw misalignment, therefore assuming ![]() $\delta u_0(\gamma \neq 0)/u_\infty =\delta u_0(\gamma =0)/u_\infty =2a(\gamma =0)$ would yield significant predictive errors in a wake model. The full model (§ 2.3) has slightly improved predictions compared to the limit of negligible lateral velocity (§ 2.4), but both model estimates overpredict the streamwise velocity disturbance at larger yaw angles.

$\delta u_0(\gamma \neq 0)/u_\infty =\delta u_0(\gamma =0)/u_\infty =2a(\gamma =0)$ would yield significant predictive errors in a wake model. The full model (§ 2.3) has slightly improved predictions compared to the limit of negligible lateral velocity (§ 2.4), but both model estimates overpredict the streamwise velocity disturbance at larger yaw angles.

The model developed in § 2 reveals that the induction ![]() $a_n$, the power

$a_n$, the power ![]() $P$ and the power ratio

$P$ and the power ratio ![]() $P_r$ all depend on both the yaw misalignment and the thrust coefficient

$P_r$ all depend on both the yaw misalignment and the thrust coefficient ![]() $C_T^\prime$. The ADM is simulated in LES over a range of yaw misalignment and

$C_T^\prime$. The ADM is simulated in LES over a range of yaw misalignment and ![]() $C_T^\prime$ values, where each pair

$C_T^\prime$ values, where each pair ![]() $(\gamma, C_T')$ represents a unique LES case. The influence of

$(\gamma, C_T')$ represents a unique LES case. The influence of ![]() $C_T^\prime$ on the power ratio

$C_T^\prime$ on the power ratio ![]() $P_r$ for the LES data and the model (2.17) is shown in figure 5(a). The coefficient of power

$P_r$ for the LES data and the model (2.17) is shown in figure 5(a). The coefficient of power ![]() $C_P$ is shown in figure 5(b). The model predictions exhibit low error, compared to the LES data, over a wide range of yaw and thrust values. We observe that the power reduction by yaw misalignment depends inherently on the value of

$C_P$ is shown in figure 5(b). The model predictions exhibit low error, compared to the LES data, over a wide range of yaw and thrust values. We observe that the power reduction by yaw misalignment depends inherently on the value of ![]() $C_T^\prime$ (figure 5a), due to the influence of the thrust coefficient

$C_T^\prime$ (figure 5a), due to the influence of the thrust coefficient ![]() $C_T^\prime$ and yaw misalignment on the induction factor

$C_T^\prime$ and yaw misalignment on the induction factor ![]() $a_n$ (figure 5c). This result suggests that the power lost due to yaw misalignment in a practical field setting will be turbine-specific, since existing turbine designs operate at a wide range of thrust coefficients (see e.g. Hansen Reference Hansen2015). Further, since the thrust coefficient depends on the operating condition and turbine controller (e.g. Ainslie Reference Ainslie1988), the power lost due to yaw misalignment will also vary in time for a given turbine design. Therefore, while an empirically tuned cosine model (

$a_n$ (figure 5c). This result suggests that the power lost due to yaw misalignment in a practical field setting will be turbine-specific, since existing turbine designs operate at a wide range of thrust coefficients (see e.g. Hansen Reference Hansen2015). Further, since the thrust coefficient depends on the operating condition and turbine controller (e.g. Ainslie Reference Ainslie1988), the power lost due to yaw misalignment will also vary in time for a given turbine design. Therefore, while an empirically tuned cosine model (![]() $\cos ^{P_p}(\gamma )$) may yield a sufficiently small error for a single turbine model and operating condition (e.g. region II operation; Pao & Johnson Reference Pao and Johnson2009), it cannot be expected to extrapolate to other wind turbine designs or control regimes. Instead, the physics-based model developed in § 2 can provide a prediction of

$\cos ^{P_p}(\gamma )$) may yield a sufficiently small error for a single turbine model and operating condition (e.g. region II operation; Pao & Johnson Reference Pao and Johnson2009), it cannot be expected to extrapolate to other wind turbine designs or control regimes. Instead, the physics-based model developed in § 2 can provide a prediction of ![]() $P_r(\gamma )$, provided that the thrust force characteristics (i.e.

$P_r(\gamma )$, provided that the thrust force characteristics (i.e. ![]() $\boldsymbol {F}_T$ or

$\boldsymbol {F}_T$ or ![]() $C_T^\prime$) are known for the turbine model of interest as a function of yaw misalignment. Future work may integrate the induction–yaw model developed in § 2 into BEM codes (e.g. FAST; Jonkman & Buhl Reference Jonkman and Buhl2005).

$C_T^\prime$) are known for the turbine model of interest as a function of yaw misalignment. Future work may integrate the induction–yaw model developed in § 2 into BEM codes (e.g. FAST; Jonkman & Buhl Reference Jonkman and Buhl2005).

Figure 5. (a) Power production for the yawed ADM wind turbine, normalized by the power production for a yaw-aligned ADM wind turbine for various values of ![]() $C_T^\prime$. (b) Coefficient of power

$C_T^\prime$. (b) Coefficient of power ![]() $C_P(\gamma )$. (c) Rotor-normal, rotor-averaged induction factor

$C_P(\gamma )$. (c) Rotor-normal, rotor-averaged induction factor ![]() $a_n(\gamma )$.

$a_n(\gamma )$.

4.2. Optimizing model power and wake deflection in yaw misalignment with  $C_T^\prime$

$C_T^\prime$

The induction and power models developed in § 2 and the results in § 4.1 indicate that the power production of a yaw-misaligned actuator disk depends on both the yaw misalignment and the local thrust coefficient ![]() $C_T^\prime$. In yaw alignment, the well-known Betz limit result estimates that the axial induction factor that maximizes the coefficient of power

$C_T^\prime$. In yaw alignment, the well-known Betz limit result estimates that the axial induction factor that maximizes the coefficient of power ![]() $C_P = 2 P / (\rho A_d u_\infty ^3)$ is

$C_P = 2 P / (\rho A_d u_\infty ^3)$ is ![]() $a=1/3$ (e.g. Burton et al. Reference Burton, Jenkins, Sharpe and Bossanyi2011), with a corresponding value of

$a=1/3$ (e.g. Burton et al. Reference Burton, Jenkins, Sharpe and Bossanyi2011), with a corresponding value of ![]() $C_T^\prime = 2$. Here, we estimate the value of

$C_T^\prime = 2$. Here, we estimate the value of ![]() $C_T^\prime$ that maximizes

$C_T^\prime$ that maximizes ![]() $C_P$ as a function of yaw misalignment value. The power produced by the actuator disk is given by (2.16). The maximum power occurs at

$C_P$ as a function of yaw misalignment value. The power produced by the actuator disk is given by (2.16). The maximum power occurs at ![]() $C_T^{\prime *}$ such that

$C_T^{\prime *}$ such that ![]() $\partial P / \partial C_T^{\prime } = 0$. Taking the derivative of (2.16) with respect to

$\partial P / \partial C_T^{\prime } = 0$. Taking the derivative of (2.16) with respect to ![]() $C_T^\prime$ yields

$C_T^\prime$ yields

For the full model ((2.15), § 2.3), ![]() $\partial a_n / \partial C_T^\prime$ does not permit a straightforward analytical solution. To result in an analytical solution, we assume the limit