Introduction

Shigatoxin-producing E. coli (STEC) represent a subclass of highly pathogenic E. coli strains that affect public health and are involved in foodborne outbreaks that have risen globally in recent years. Despite the fact that E. coli O157:H7 is the most common STEC serotype and accounts for the vast majority of reported cases, non-O157 outbreaks are on the rise globally (Kim et al., Reference Kim, Lee and Kim2020; Glassman et al., Reference Glassman, Ferrato and Chui2022). STEC is transmitted from healthy ruminants (the main reservoir) to humans through fecal contamination of water and dairy food. It is estimated that 11% of infections are spread via fecal–oral routes (Fahim et al., Reference Fahim, Ismael, Khalefa, Farag and Hamza2019; Ameer et al., Reference Ameer, Wasey and Salen2022). This means that milk and dairy products are potential sources of STEC infections. Mastitic infection with E. coli could be another source of milk contamination with STEC (Ombarak et al., Reference Ombarak, Hinenoya, Awasthi, Iguchi, Shima, Elbagory and Yamasaki2016; Taher et al., Reference Taher, Hemmatzadeh, Aly, Elesswy and Petrovski2020).

Human infections with STEC are characterized by a variety of symptoms, ranging from mild to bloody diarrhea (Hemorrhagic colitis). STEC infection is also associated with hemolytic uremic syndrome (HUS), in which 3% of cases developed late-stage renal disease. The incidence was three times higher in younger children (<5 years), and the mortality rate reached 2.8% (Giordano et al., Reference Giordano, Baldassarre, Palmieri, Torres, Carbone, Santangelo, Gentile, Panza, Di-Mauro, Capozza, Di-Mauro and Laforgia2019; Joseph et al., Reference Joseph, Cointe, Mariani Kurkdjian, Rafat and Hertig2020).

E. coli O157:H7 and most other STEC serotypes are acid-tolerant E. coli strains, capable of survival in a wide pH range (4.0–9.0). This explains their ability to survive in acidic environments such as fermented foods and stomach fluid. Furthermore, their low infection dose may be connected to their ability to withstand acid. One of the key reasons for compromised food safety is the acid resistance of these bacteria (Engdaw and Temesgen, Reference Engdaw and Temesgen2016; de La Pomelie et al., Reference de La Pomelie, Leroy, Talon, Ruiz, Gatellier and Santé-Lhoutellier2021). E. coli O157:H7 can produce colanic acid, which boosts the bacteria's tolerance to sublethal heat and high pH. Colanic acid plays an important role in protecting bacterial cells from stressors during preparation and preservation of fermented foods. This response, called the adaptive acid tolerance response, increases the pathogen's ability to survive the acidic conditions (Xu et al., Reference Xu, Luo, Soteyome, Lin, Xu, Mao, Su and Liu2020; Segura et al., Reference Segura, Bertin, Durand, Benbakkar and Forano2021).

Probiotics could be considered a promising solution for biocontrol of such pathogenic acid tolerant E. coli strains. Probiotics, particularly lactic acid bacteria, are known to produce bio-preservatives such as lactic acid, bacteriocins and hydrogen peroxide, which prevent the growth of both spoilage and pathogenic bacteria. Several studies have demonstrated the ability of probiotics to occupy the cellular receptors which disrupt the host-infection/toxin interactions. Furthermore, various types of probiotic bacteria can be recruited to destroy and degrade different types of toxins (Stanford et al., Reference Stanford, Bach, Baah and McAllister2014; Ghadaksaz et al., Reference Ghadaksaz, Nodoushan, Sedighian, Behzadi and Fooladi2022). The extent of probiotic protective ability against STEC infection is prospectively dependent on the used probiotic strain and its capability to modify the surrounding medium. The reduction of Shiga toxin (Stx2) production is enhanced when STEC are cultured in the presence of several Lactobacillus strains (Rahal et al., Reference Rahal, Fadlallah, Nassar, Kazzi and Matar2015).

In addition to its nutritional value, probiotic yoghurt (bio-yoghurt) plays an important role in fighting against infections. Several studies have shown that L. acidophilus has a variety of potentially health-promoting properties, including immunomodulation, lactose intolerance relief, anticancer, anticholesterolemic activity and antibacterial activity against E. coli and other food-borne pathogens (Neveen and Ahmed, Reference Neveen and Ahmed2019; Ahmed et al., Reference Ahmed, Ibrahim, Abdel-Salam and Fahim2021; Jurášková et al., Reference Jurášková, Ribeiro and Silva2022).

Because of the high pathogenicity and prevalence rate of STEC in dairy products, the present study was assessed to highlight the potential role of acidophilus yoghurt (containing L. acidophilus) as a biocontrol against various pathogenic E. coli strains (Shiga toxigenic O157, non-toxigenic O157 and Shiga toxigenic non O157 [E. coli O145]) in comparison to the traditional yoghurt.

Materials and methods

Preparation of spiking strains

Three strains of E. coli were used; E. coli O157:H7 reference strain ATTCC No. (51659) obtained from Cairo MIRCEN, Faculty of Agriculture, Ain Shams University. Shiga toxigenic E. coli non O157 (O145) and non-Shiga toxigenic E. coli O157 strains previously isolated from raw milk (Fahim et al., Reference Fahim, Ghoneim, Morgan and Abdel Aal2016). E. coli strains were cultured overnight in tryptic soya broth with 0.6% yeast extract at 37°C. Cultures were diluted using 0.1% (wt/vol) peptone water (Oxoid Ltd.) to prepare a final concentration of about 5 log10 cfu/ml in the inoculated milk. The inoculation count was determined spectrophotometrically and by surface-plating onto Levine's Eosin Methylene Blue agar medium (L-EMB) (Ahmed et al., Reference Ahmed, Ibrahim, Abdel-Salam and Fahim2021).

Yoghurt preparation

For the starter culture we used freeze-dried LAB starter culture of L. delbrueckii ssp. bulgaricus and S. salivarius ssp. thermophilus (FD-DVS YC-381 – Yo-Flex®, CHR-HANSEN, Denmark). For the probiotic culture we used freeze-dried L. acidophilus (Freeze-dried culture, DVS type Lactobacillus acidophilus (La-5) CHR. HANSEN, Denmark). Yoghurt was prepared according to Al-Nabulsi et al. (Reference Al-Nabulsi, Olaimat, Osaili, Ayyash, Abushelaibi, Jaradat, Shaker, Al-Taani and Holley2016), using fresh raw whole buffalo milk obtained from a small dairy farm. Raw milk was proved to be free from inhibitory substances by the lactic acid activity test (Ahmed et al., Reference Ahmed, Darwish, Hafiz and Abd Aal2014). Milk was laboratory pasteurized at 85°C for 3 min and immediately cooled in a water bath to 43°C. The pasteurized milk was divided into two parts; the first part was prepared using yoghurt starter cultures (traditional yoghurt), while the second part was prepared using yoghurt starter culture plus L. acidophilus (1 : 1) (acidophilus yoghurt). Each culture was used as described by the manufacturer.

The prepared milk was then divided into two unequal parts; the larger part was subdivided into three aliquots which were inoculated with 105cfu/ml of the three E. coli strains individually, while the second, smaller part was left as control. The inoculated milk was distributed into sterile small plastic cups (50 ml capacity) and incubated at 43°C for 4.5–6 h in a water bath (Precision Scientific, Chicago, USA) until reaching a pH of 4.6 ± 0.1 (yoghurt formation: Ahmed et al., Reference Ahmed, Darwish, Hafiz and Abd Aal2014). Inoculated and control yoghurt samples were kept at 4°C. Samples (in triplicates) were examined at zero time (time of yoghurt formation) and after 24 h, then regularly examined every 2 d until disappearance of the inoculated strains.

Bacterial enumeration and calculation of reduction percentage

Enumeration of the inoculated microorganisms was carried out according to APHA (2004). Samples were serially diluted in 0.1% peptone water; 0.1 ml of prepared dilutions was inoculated onto duplicate plates of L-EMB and incubated at 35°C for 24–48 h. The reduction percentage was calculated as:

Log reduction of the inoculated strains = Log10 (A/B)

Percent reduction of the inoculated strains = (A–B) × 100/A

A: is the number of initial viable count

B: is the number of viable microorganisms after treatment.

Acidity determination

The titratable acidity % of yoghurt was adopted according to APHA (2004). Nine grams of yoghurt samples were transferred into a 100 ml beaker. Twice the sample weight of distilled water was added and mixed thoroughly, 0.5 ml of phenolphthalein indicator (1%) was added and then titrated with 0.1 N sodium hydroxide to the first permanent color change to faint pink (pH 8.3).

Statistical analysis

All experiments were performed in triplicate, and the mean results were calculated and analyzed statistically using SPSS Version 17.0 software. The results of traditional and acidophilus yoghurt were compared using at-test. Pearson's correlation statistical analysis was used to evaluate the correlation between acidity and the viable count of the tested strains. The results were considered significant at P-value <0.05.

Results

Survival of STx and non-STx E. coli strains in traditional yoghurt

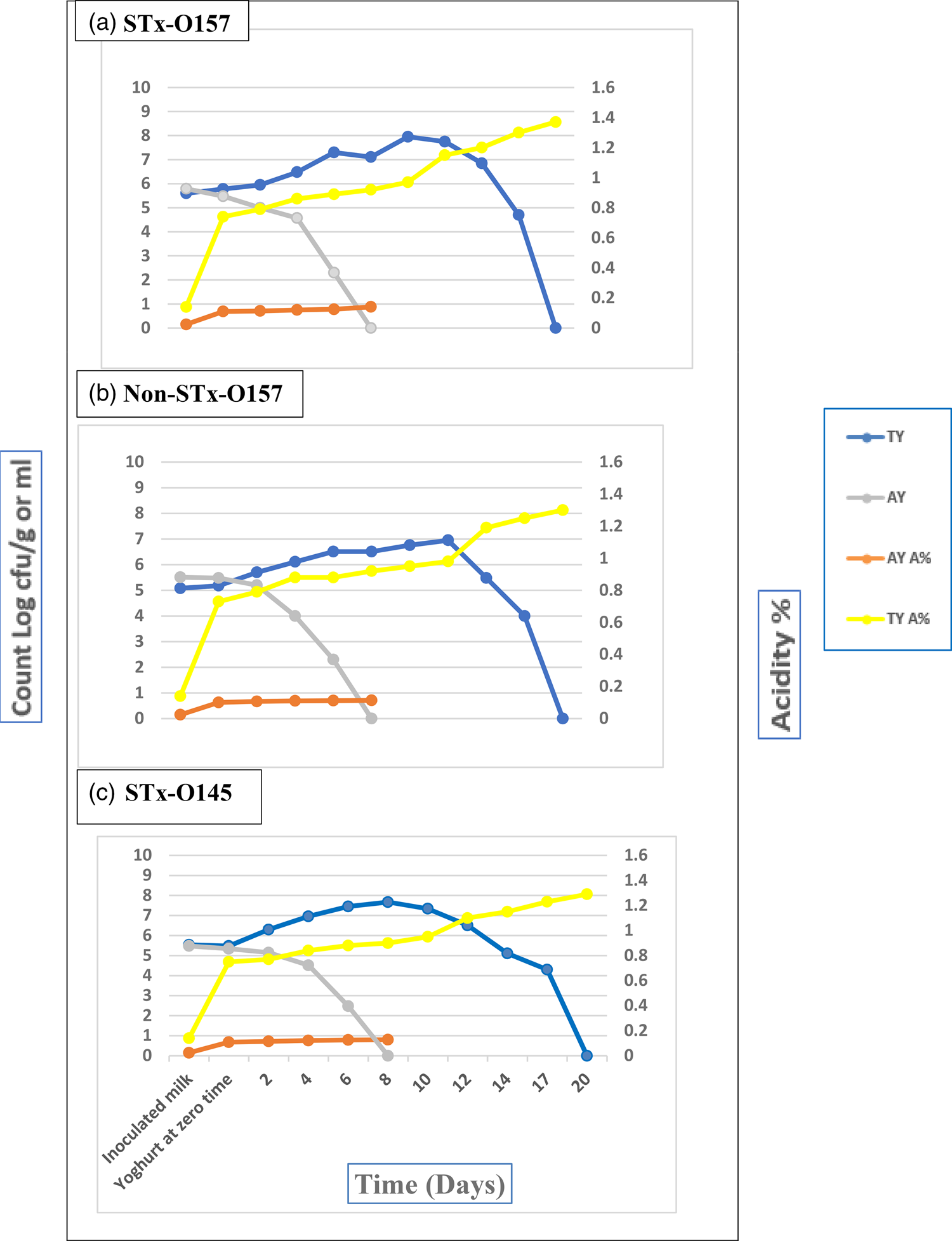

Data are presented in Fig. 1 and Table 1. The initial viable count of Shiga toxigenic E. coli O157, non-toxigenic E. coli O157 and Shiga toxigenic non O157 E. coli (O145) strains in the laboratory manufactured traditional yoghurts were 5.78, 4.69 and 5.48 log cfu/g, respectively. The count increased during the first days of storage period, while by the end of 17th day of storage, the inoculated strains count declined to 4.70, 4.00, 4.30 log cfu/g (Fig. 1), with reduction percentages of 91.67, 93.33, and 93.33%, and log reduction of 1.079, 1.176 and 1.176, respectively (Table 1).

Fig. 1. Survival over 3 weeks storage time of (a) Shiga toxigenic E. coli O157:H7, (b) Non-toxigenic E. coli O157 and (c) Shiga toxigenic non O157 E. coli (O145) in traditional (TY: blue) and acidophilous (AY: gray) yoghurts. The acidity % values are also shown in yellow (TY) and orange (AY).

Table 1. Impact of traditional and acidophilus yoghurt on the reduction rate of the tested E. coli strains

*Significant difference at P < 0.05.

The initial acidity percentage of the produced yoghurt was 0.75% in the control sample and increased during the storage period. Stx E. coli O157, non-Stx E. coli O157 and Stx E. coli O145 strains could survive for 17 d at titratable acidity of 1.30, 1.25 and 1.23%, respectively (acidity percentages were shown in online Supplementary Fig. S1). Pearson's correlation statistical analyses (data shown in online Supplementary Fig. S2) showed low negative correlations between acidity and the viable count of Stx E. coli O157 (r = −0.290), Non-StxE. coli O157 (r = −0.354) and Stx E. coli O145 (r = −0.354) in traditional yoghurt.

Survival of STx and non-STx E. coli strains in acidophilus yoghurt

Data are presented in Fig 1 and Table 1 for direct comparison with the traditional yogurts. The initial viable count of Stx E. coli O157, non-Stx E. coli O157 and Stx E. coli O145 strain in the experimental acidophilus yoghurts were 5.48, 5.48 and 5.34 log cfu/g, respectively, (Fig. 1). There was a marked decline in viable counts over the first 5 d of storage to values of 2.30, 2.30 and 2.48 log cfu/g, respectively, at the 6th day of storage, with reduction percentages of 99.93, 99.93 and 99.86%, and log reduction values of 3.176, 3.176 and 2.865, respectively (Table 1). The tested E. coli strains were completely inhibited by the end of the first week of storage.

These results emphasize that Shiga toxigenic and non-toxigenic E. coli strains could only survive in refrigerated acidophilus yoghurt for 6 d at acidity percentages of 0.78, 0.70, and 0.79%, respectively. Noticeably, negative correlations were recorded between acidity and the count of Stx E. coli O157(r = −0.634), non-Stx E. coli O157 (r = −0.487) and Stx E. coli O145 (r = −0.507). Statistical analysis (T test) showed a significant (P < 0.01) effect of acidophilus yoghurt in reducing the t(20)count of Stx E. coli O157 (3.769), Non-Stx E. coli O157 (3.392) and Stx E. coli O145 (3.595), (Table 1), compared to the traditional yoghurt.

Discussion

Despite the fact that yoghurt is a relatively safe product owing to its naturally acidic condition, STx E. coli can survive in such acidic foods. Numerous studies have stated that STEC serogroups are acid-resistant pathogens that can survive in several dairy products, including fermented ones, for several weeks to several months, thus, the safety of acidic foods like yoghurt is sometimes called into question (Bellio et al., Reference Bellio, Bianchi, Vitale, Vernetti, Gallina and Decastelli2018; Celik et al., Reference Celik, Dikici and Koluman2021).

Survival of STx and non-STx strains of E. coli in traditional yoghurt

Survival of Shiga toxigenic (STEC) and non-toxigenic E. coli strains in fermented dairy products is dependent on the type of strains and species (Fayemi and Buys, Reference Fayemi and Buys2017). For laboratory-manufactured traditional yoghurt, we observed that the viable count of three E. coli strains increased during the first days of the storage period, then remained viable for a period before declining with more than 90% reduction by the end of the 17th day of storage. These results parallel those obtained by Yilma et al. (Reference Yilma, Loiseau and Faye2015) and Celik et al. (Reference Celik, Dikici and Koluman2021) who reported the survival of Shiga toxigenic E. coli O157 and non-O157 in yoghurt. By contrast, Ahmed et al. (Reference Ahmed, Darwish, Hafiz and Abd Aal2014) could not detect E. coli in yoghurt samples at the 12th day of storage, and Fayemi and Buys (Reference Fayemi and Buys2017) reported that non-O157 E. coli strains were completely inhibited in yoghurt produced from goat milk. Moineau-Jean et al. (Reference Moineau-Jean, Guévremont, Champagne, Roy, Raymond and LaPointe2017) demonstrated that E. coli O157 count decreased by about 1.4 log cfu/g after 28 d in Greek yoghurt. This reduction of E. coli O157 and non-O157 in the presence of yoghurt starter cultures may be attributed to several factors, including the reduction of yoghurt pH, the effect of storage temperature, and the inhibitory effects of antimicrobial compounds produced by yoghurt lactic acid bacteria (Al-Nabulsi et al., Reference Al-Nabulsi, Olaimat, Osaili, Ayyash, Abushelaibi, Jaradat, Shaker, Al-Taani and Holley2016). Nevertheless, it remains the case that, in our hands, E. coli O157, non-Shiga toxigenic E. coli O157, and Shiga toxigenic E. coli O145 bacteria could all survive to some extent for 17 d in the traditional yoghurt, similar to results reported by Yakubu et al. (Reference Yakubu, Shuaibu, Ibrahim, Hassan and Nwachukwu2018) who stated that some of E. coli strains are found to be acid resistant, and can survive in fermented milk with a pH as low as 4.0.

Survival of Stx and non-Stx strains of E. coli in acidophilus yoghurt

We showed that the initial viable count of all three strains declined dramatically over the first 5 d of storage of acidopholus yoghurt, with reduction percentages over 99% by the 6th day of storage, and the tested E. coli strains were completely inhibited by the end of the first week of storage. Similar results were obtained by Amal et al. (Reference Amal, El Demerdash, Metwally and Shahein2016) and Ghadaksaz et al. (Reference Ghadaksaz, Nodoushan, Sedighian, Behzadi and Fooladi2022), who observed that L. acidophilus exhibits bactericidal and bacteriostatic effects against STEC strains as a result of undissociated lactic acid concentration and pH value. However, Okda et al. (Reference Okda, Abdelhamid, Fouad and El Dairouty2018) found that Lactobacillus reuteri had only a minor effect on the tested E. coli strain during the first week of storage, with a greater inhibitory effect shown at the end of the storage period.

The primary criteria for selecting a biocontrol agent include having high antagonistic activity against the pathogens, safety for human consumption, and not interfering with the nutritional and organoleptic attributes of the dairy products (Ali et al., Reference Ali, Saudi, Albrecht and Talaat2019; Fahim et al., Reference Fahim, Ahmed, Mohamed, Eman and Ahmed2021). Bio-agents, such as probiotics have the potential to exert an antagonistic effect against different strains of E. coli in addition to degrading their toxins (Puligundla and Lim, Reference Puligundla and Lim2022). In various studies, probiotics were shown to remove toxins or toxins-producing pathogens by disrupting or changing the permeability of the plasma membrane, inhibiting protein translation, or preventing the binding receptors (Murray et al., Reference Murray, Rosenthal and Pfaller2020; Ghadaksaz et al., Reference Ghadaksaz, Nodoushan, Sedighian, Behzadi and Fooladi2022).

Moreover, probiotic bacteria can be used as an alternative treatment in gastrointestinal diseases as a result of their possible therapeutic effect. L. acidophilus promotes activity against a wide range of enteropathogenic bacteria, inhibiting their growth and virulence in-vitro and in-vivo, especially when they act synergistically with the yoghurt starter culture (Minj et al., Reference Minj, Chandra, Paul and Sharma2021).

The antimicrobial impact and inhibitory effect of L. helveticus against STEC were previously reported by Bian et al. (Reference Bian, Evivie, Muhammad, Luo, Liang, Wang and Huo2016). Moreover, Dini et al. (Reference Dini, Bolla and de Urraza2016) demonstrated a positive effect of a combination of five probiotic strains (L. plantarum, Lactococcus lactis, L. kefir, Kluiveromices marxianus, and Saccharomyces bulgaricus). These findings are in line with our findings, which demonstrate the inhibitory effect of lactobacillus species against STEC strains.

These findings highlight the fact that acidophilus yoghurt has a significantly greater inhibitory effect on toxigenic and non-toxigenic E. coli strains during processing and post-processing than traditional yoghurt. This inhibitory effect may be due either to the probiotic bacteria themselves or to the antibacterial compounds they secrete, such as organic acids (lactic and acetic acids) and bacteriocins that hinder the growth of the unfavorable microorganisms.

In conclusion, we assessed the survivability of three different highly pathogenic E. coli strains in two different yoghurt types: traditional yoghurt and acidophilus yoghurt. Survivability was much less in the acidophilus yogurt, with complete inhibition of their growth by the 6th day of storage.

Supplementary material

The supplementary material for this article can be found at https://doi.org/10.1017/S0022029923000067.

Acknowledgements

We are thankful to Prof. Dr Ragaa S. Hafiz, Sabry D. Morgan and Abeer A. Awad, professors of food hygiene and control (Faculty of veterinary medicine, Cairo university), who provided expertise that greatly assisted the research.