Published online by Cambridge University Press: 29 January 2021

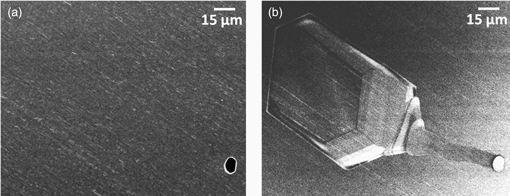

This paper presents an investigation on micropipe evolution from hexagonal voids in physical vapor transport-grown 4H-SiC single crystals using the cathodoluminescence (CL) imaging technique. Complementary techniques optical microscopy, scanning electron microscopy, and energy-dispersive spectroscopy (EDS) are also used to understand the formation mechanism of hexagonal voids along with the origin of pipes from these voids. The ability of CL to image variations along the depth of the sample provides new insights on how micropipes are attached to hexagonal voids that lie deep within the bulk single crystals. CL imaging confirms that multiple micropipes can originate from a single hexagonal void. EDS mapping shows that the inside of the micropipe walls exhibits higher levels of carbon. Investigation of the seed region by optical imaging shows that improper fixing of the seed to the crucible lid is the root cause for the formation of hexagonal voids that subsequently lead to micropipe formation.