No CrossRef data available.

Article contents

Plasma Focused Ion Beam Serial Sectioning as a Technique to Characterize Nonmetallic Inclusions in Superelastic Nitinol Fine Wires

Published online by Cambridge University Press: 08 December 2020

Abstract

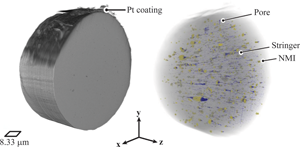

Nonmetallic inclusion (NMI) populations in superelastic (SE) Nitinol fine wires (<140 μm in diameter) were investigated by combining plasma focused ion beam (PFIB) serial sectioning with scanning electron microscopy (SEM). High purity (HP)—lower oxygen content and standard purity (SP)—higher oxygen content Nitinol wires were sectioned and imaged. The three-dimensional (3D) reconstructions provided more complete connectivity of NMIs and pores as well as information about the distribution of the features within the wire volume that is not possible with traditional two-dimensional (2D) imaging techniques. NMIs were present alone and with pores in the leading and/or trailing edges of the inclusions, in addition to stringers (i.e., fractured, elongated NMI, and intermixed with pores adjacent to each other), all of which were parallel to the wire drawing axis. The area percentages for the NMIs were 0.01% (HP Nitinol) and 0.04% (SP Nitinol), while the volume percentages measured 0.09% (HP Nitinol) and 0.47% (SP Nitinol). The combined PFIB-SEM serial sectioning approach provided the requisite resolution necessary to distinguish between NMIs and pores at micron and submicron sizes. Information gathered from this technique can be used to better inform models and predictions for fatigue lifetimes based on statistical analyses of these feature populations.

Keywords

- Type

- Materials Science Applications

- Information

- Copyright

- Copyright © The Author(s), 2020. Published by Cambridge University Press on behalf of the Microscopy Society of America