Published online by Cambridge University Press: 03 December 2020

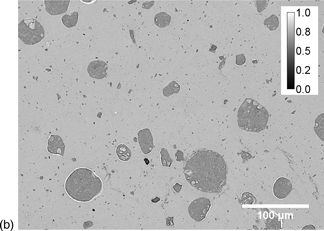

We propose a method to measure the local porosity of porous samples from scanning electron microscopy images in the backscattered electron mode. The porous samples are impregnated with a polymer resin and observed in polished cross sections. Image intensities are calibrated with intensities from pure resin and the bulk phase. The calibration model is justified with Monte Carlo simulations on perfectly homogeneous virtual samples. Uncertainties in measured porosity are given as a function of uncertainties on physical properties of the resin and the bulk phase and on measured signals. The methodology is applied to a series of heterogeneous alumina catalyst supports with varying porosities. A good agreement is found between the averaged local porosity by scanning electron microscopy and global porosity determined by mercury intrusion porosimetry. The use of local porosity statistics allowed the quantitative characterization of the porosity fluctuations of these supports that appeared to be linked with their preparation parameters.