No CrossRef data available.

Published online by Cambridge University Press: 03 June 2021

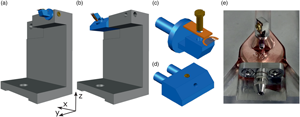

Site-specific specimen preparation for atom probe tomography (APT) is a challenging task. Small features need to be located using a suitable imaging technique and captured within a volume of less than 0.01 μm3. Correlative microscopy has shown to be helpful for target preparation as well as to gain complementary information about the material. Current strategies developed in that direction can be highly time-consuming and not always ensure the correct site extraction in complex microstructures. In this work, we present a methodology to study grain boundaries and interfaces in martensitic steels by combining electron backscattered diffraction, transmission Kikuchi diffraction (TKD), and APT. Furthermore, we include the design of a sample holder that allows to perform TKD and scanning transmission electron microscopy on the specimen during preparation without breaking the vacuum of the scanning electron microscope/focused ion beam workstation. We show a case study where a prior austenite grain boundary is traced from the bulk material to the apex of the APT specimen. The presence of contamination due to the specimen exposure to the electron beam and the use of plasma cleaning to minimize it are discussed.