Article contents

Microstructural Characterization of Nb/Inconel 601 Interface Obtained in the Explosive Welding Process

Published online by Cambridge University Press: 28 July 2021

Abstract

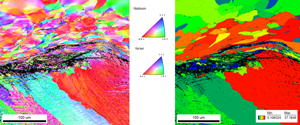

This work presents the microstructure of the cross-section of a newly developed Nb/Inconel 601 weld with particular attention paid to the continuity, morphology of the interface, and the microstructural changes within its vicinity. Both scanning (SEM) and transmission (TEM) electron microscopy techniques are excellent tools to analyze the microstructure that affects both mechanical and corrosion resistance properties of the obtained product. Grain size examination and their orientation together with the character of grain boundaries by the electron backscattered diffraction (EBSD) technique were performed followed by chemical composition determination across the interface with energy-dispersive X-ray spectroscopy (EDS) in SEM. Then, the microstructure observations of the mixed region located at the Nb/Inconel 601 interface using the TEM technique allowed its chemical and phase composition to be revealed.

- Type

- The XVIIth International Conference on Electron Microscopy (EM2020)

- Information

- Copyright

- Copyright © The Author(s), 2021. Published by Cambridge University Press on behalf of the Microscopy Society of America

References

- 1

- Cited by