Article contents

A Feasible Surface Patterning Method for SEM-DIC: Achieving High-Resolution In Situ Mapping of Local Strain and Microstructure to Reveal the Effect of Slip Transfer on Shear Strain Near Grain Boundaries

Published online by Cambridge University Press: 16 May 2022

Abstract

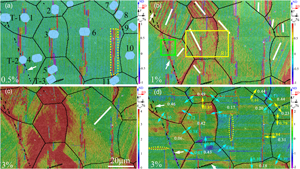

This paper exploited an alternative approach to prepare high-quality speckle patterns by uniformly dispersing nano-silica particles onto sample surfaces, helping digital image correlation (DIC) acquire the maximum spatial resolution of local strain up to 92 nm. A case study was carried out by combining this speckle pattern fabrication method with SEM-DIC and electron backscattering diffraction (EBSD). Thus, in situ mapping of local strain with ultra-high spatial resolution and microstructure in commercially pure titanium during plastic deformation could be achieved, which favored revealing the effect of slip transfer on shear strain near grain boundaries. Moreover, the slip systems could be easily identified via the combination of the SEM-DIC and EBSD techniques even though no obvious deformation trace was captured in secondary electron images. Additionally, the complex geometric compatibility factor  $( {m}^{\prime}_c)$ relating to geometric compatibility factors (mʹ) and Schmid factors was proposed to predict the shear strain (εxy) at grain boundaries.

$( {m}^{\prime}_c)$ relating to geometric compatibility factors (mʹ) and Schmid factors was proposed to predict the shear strain (εxy) at grain boundaries.

- Type

- Software and Instrumentation

- Information

- Copyright

- Copyright © The Author(s), 2022. Published by Cambridge University Press on behalf of the Microscopy Society of America

Footnotes

These authors contributed equally to this work.

References

- 2

- Cited by