Published online by Cambridge University Press: 14 July 2020

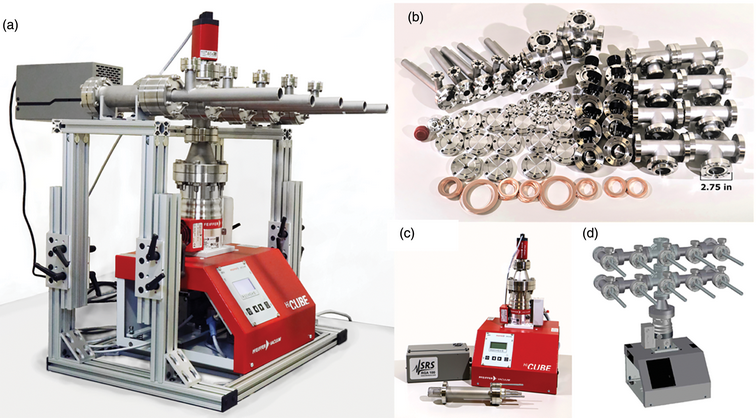

Hydrocarbon contamination plagues high-resolution and analytical electron microscopy by depositing carbonaceous layers onto surfaces during electron irradiation, which can render carefully prepared specimens useless. Increased specimen thickness degrades resolution with beam broadening alongside loss of contrast. The large inelastic cross-section of carbon hampers accurate atomic species detection. Oxygen and water molecules pose problems of lattice damage by chemically etching the specimen during imaging. These constraints on high-resolution and spectroscopic imaging demand clean, high-vacuum microscopes with dry pumps. Here, we present an open-hardware design of a high-vacuum manifold for transmission electron microscopy (TEM) holders to mitigate hydrocarbon and residual species exposure. We quantitatively show that TEM holders are inherently dirty and introduce a range of unwanted chemical species. Overnight storage in our manifold reduces contaminants by one to two orders of magnitude and promotes two to four times faster vacuum recovery. A built-in bakeout system further reduces contaminants partial pressure to below 10−10 hPa (Torr) (approximately four orders of magnitude down from ambient storage) and alleviates monolayer adsorption during a typical TEM experiment. We determine that bakeout of TEM holder with specimen held therein is the optimal cleaning method. Our high-vacuum manifold design is published with open-source blueprints, parts, and cost list.