Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Aragón, Javier

Costa, Clarinda

Coelhoso, Isabel

Mendoza, Gracia

Aguiar-Ricardo, Ana

and

Irusta, Silvia

2019.

Electrospun asymmetric membranes for wound dressing applications.

Materials Science and Engineering: C,

Vol. 103,

Issue. ,

p.

109822.

Mousavi, Seyyed Mojtaba

Zarei, Maryam

Hashemi, Seyyed Alireza

Ramakrishna, Seeram

Chiang, Wei-Hung

Lai, Chin Wei

Gholami, Ahmad

Omidifar, Navid

and

Shokripour, Mansoureh

2020.

Asymmetric Membranes: A Potential Scaffold for Wound Healing Applications.

Symmetry,

Vol. 12,

Issue. 7,

p.

1100.

Stoica, Alexandra Elena

Chircov, Cristina

and

Grumezescu, Alexandru Mihai

2020.

Nanomaterials for Wound Dressings: An Up-to-Date Overview.

Molecules,

Vol. 25,

Issue. 11,

p.

2699.

Genevro, Giovana Maria

Gomes Neto, Reginaldo Jose

Paulo, Letícia de Almeida

Lopes, Patrícia Santos

de Moraes, Mariana Agostini

and

Beppu, Marisa Masumi

2020.

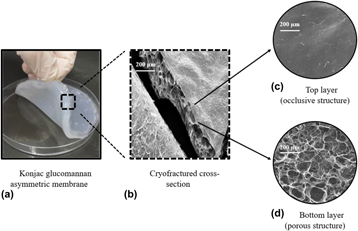

Glucomannan asymmetric membranes for wound dressing–Erratum.

Journal of Materials Research,

Vol. 35,

Issue. 2,

p.

216.

Santos, Nathalia Leal

Ragazzo, Gabriel de Oliveira

Cerri, Bianca Carreiro

Soares, Marcio Roberto

Kieckbusch, Theo Guenter

and

da Silva, Mariana Altenhofen

2020.

Physicochemical properties of konjac glucomannan/alginate films enriched with sugarcane vinasse intended for mulching applications.

International Journal of Biological Macromolecules,

Vol. 165,

Issue. ,

p.

1717.

Yang, Bo

Chen, Yushan

Li, Zhiqiang

Tang, Pengfei

Tang, Youhong

Zhang, Yaping

Nie, Xiaoqing

Fang, Cheng

Li, Xiaodong

and

Zhang, Hongping

2020.

Konjac glucomannan/polyvinyl alcohol nanofibers with enhanced skin healing properties by improving fibrinogen adsorption.

Materials Science and Engineering: C,

Vol. 110,

Issue. ,

p.

110718.

Aderibigbe, Blessing A.

2021.

Modeling and Control of Drug Delivery Systems.

p.

79.

Yaşayan, Gökçen

Alarçin, Emine

Bal-Öztürk, Ayça

and

Avci-Adali, Meltem

2022.

Bioactive Natural Products.

Vol. 74,

Issue. ,

p.

367.

Chiaoprakobkij, Nadda

Seetabhawang, Sutasinee

Okhawilai, Manunya

Uyama, Hiroshi

and

Phisalaphong, Muenduen

2022.

Multifunctional bacterial cellulose-gelatin containing mangosteen extract films with improved antibacterial and anticancer properties.

Cellulose,

Vol. 29,

Issue. 12,

p.

6811.

Yang, Li

Zhao, Quan

Guo, Zhaoyuan

Liu, Yilin

Gao, Wenxia

Pu, Yuji

and

He, Bin

2022.

Konjac glucomannan hydrogel dressing and its combination with Chinese medicine for the wound treatment.

New Journal of Chemistry,

Vol. 46,

Issue. 48,

p.

23077.

Khaliq, Touba

Sohail, Muhammad

Minhas, Muhammad Usman

Ahmed Shah, Syed

Jabeen, Nazish

Khan, Shahzeb

Hussain, Zahid

Mahmood, Arshad

Kousar, Mubeen

and

Rashid, Haroon

2022.

Self-crosslinked chitosan/κ-carrageenan-based biomimetic membranes to combat diabetic burn wound infections.

International Journal of Biological Macromolecules,

Vol. 197,

Issue. ,

p.

157.

Zhou, Ning

Zheng, Shengxuan

Xie, Wanzhen

Cao, Guoyu

Wang, Lin

and

Pang, Jie

2022.

Konjac glucomannan: A review of structure, physicochemical properties, and wound dressing applications.

Journal of Applied Polymer Science,

Vol. 139,

Issue. 11,

Wegrzynowska-Drzymalska, Katarzyna

Mlynarczyk, Dariusz T.

Chelminiak-Dudkiewicz, Dorota

Kaczmarek, Halina

Goslinski, Tomasz

and

Ziegler-Borowska, Marta

2022.

Chitosan-Gelatin Films Cross-Linked with Dialdehyde Cellulose Nanocrystals as Potential Materials for Wound Dressings.

International Journal of Molecular Sciences,

Vol. 23,

Issue. 17,

p.

9700.

Paulino, Larah Gondim Santos

Avila, Luisa Bataglin

Moraes, Caroline Costa

Khan, Mohammad Rizwan

Manoharadas, Salim

dos Reis, Glaydson Simões

Dotto, Guilherme Luiz

and

da Rosa, Gabriela Silveira

2023.

Double-Layer Membranes of Chitosan and Sodium Alginate Added to Natural Olive Leaf Extract for Potential Use in Skin Lesions.

Resources,

Vol. 12,

Issue. 9,

p.

97.

Khaliq, Touba

Sohail, Muhammad

Minhas, Muhammad Usman

Mahmood, Arshad

Munir, Abubakar

Qalawlus, Aya Hamid Mohammad

Jabeen, Nazish

Kousar, Mubeen

and

Anwar, Zobia

2023.

Hyaluronic acid/alginate-based biomimetic hydrogel membranes for accelerated diabetic wound repair.

International Journal of Pharmaceutics,

Vol. 643,

Issue. ,

p.

123244.

Alves, Rafael Carvalho

Contessa, Camila Ramão

Moraes, Caroline Costa

and

Rosa, Gabriela Silveira da

2023.

Biopolymeric Membranes with Active Principle of Olive Leaves (Olea europaea L.) for Potential Topical Application.

Macromol,

Vol. 3,

Issue. 2,

p.

314.

Lopes, Laise Maia

Germiniani, Luiz Guilherme L.

Rocha Neto, João Batista Maia

Andrade, Patricia Fernanda

da Silveira, Gabriel Augusto T.

Taketa, Thiago Bezerra

Gonçalves, Maria do Carmo

and

Beppu, Marisa Masumi

2023.

Preparation and characterization of porous membranes of glucomannan and silver decorated cellulose nanocrystals for application as biomaterial.

International Journal of Biological Macromolecules,

Vol. 250,

Issue. ,

p.

126236.

Fu, Yijun

Li, Chaowei

Xue, Mengdi

Cao, Youchang

Zhang, Wei

and

Li, Dawei

2023.

Liquid handling properties of carboxymethyl modified chitosan nonwovens for medical dressings.

Journal of Molecular Structure,

Vol. 1292,

Issue. ,

p.

136118.

Firoozbahr, Meysam

Kingshott, Peter

Palombo, Enzo A.

and

Zaferanloo, Bita

2023.

Recent Advances in Using Natural Antibacterial Additives in Bioactive Wound Dressings.

Pharmaceutics,

Vol. 15,

Issue. 2,

p.

644.

Ernesto, Julia V.

Severino, Patricia

Venturini, Anna C.

Yoshida, Cristiana M. P.

da Silva, Classius F.

and

Lopes, Patricia S.

2024.

Food Packaging Materials.

p.

233.