Article contents

Effects of Cu content on the microstructure, mechanical property, and hot tearing susceptibility of die casting hypereutectic Al–22Si–0.4Mg alloy

Published online by Cambridge University Press: 02 November 2016

Abstract

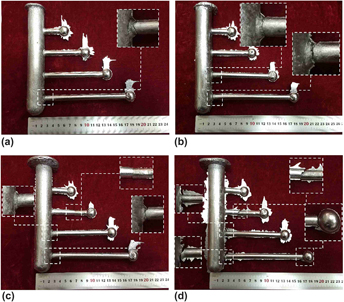

The effects of Cu content on the microstructure, mechanical property, and hot tearing susceptibility of die casting Al–22Si–0.4Mg alloy have been investigated. Different Cu contents (1.5, 2.5, 3.5, 4.5 wt%) were added in Al–22Si–0.4Mg alloy. In the as-cast microstructure, the amount, volume fraction, and average size of Al2Cu phase increase with more Cu addition. The morphology of grain boundary white Al2Cu phase turns from particle to lump. The UTS (ultimate tensile strength) of Al–22Si–xCu–0.4Mg alloy improves with Cu added, which is mainly caused by the strengthening effect of intergranular Al2Cu. The hot tearing susceptibility apparently rises with Cu content increased, which is due to longer quaternary eutectic reaction time, larger amount of residual intergranular Cu-rich liquid film spreading out over α-Al grain boundary, and higher quaternary eutectic reaction temperature. Considering both the mechanical property and hot tearing susceptibility, optimal Cu content for die casting Al–22Si–0.4Mg alloy found in this paper is 2.5 wt%.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 2

- Cited by