Context

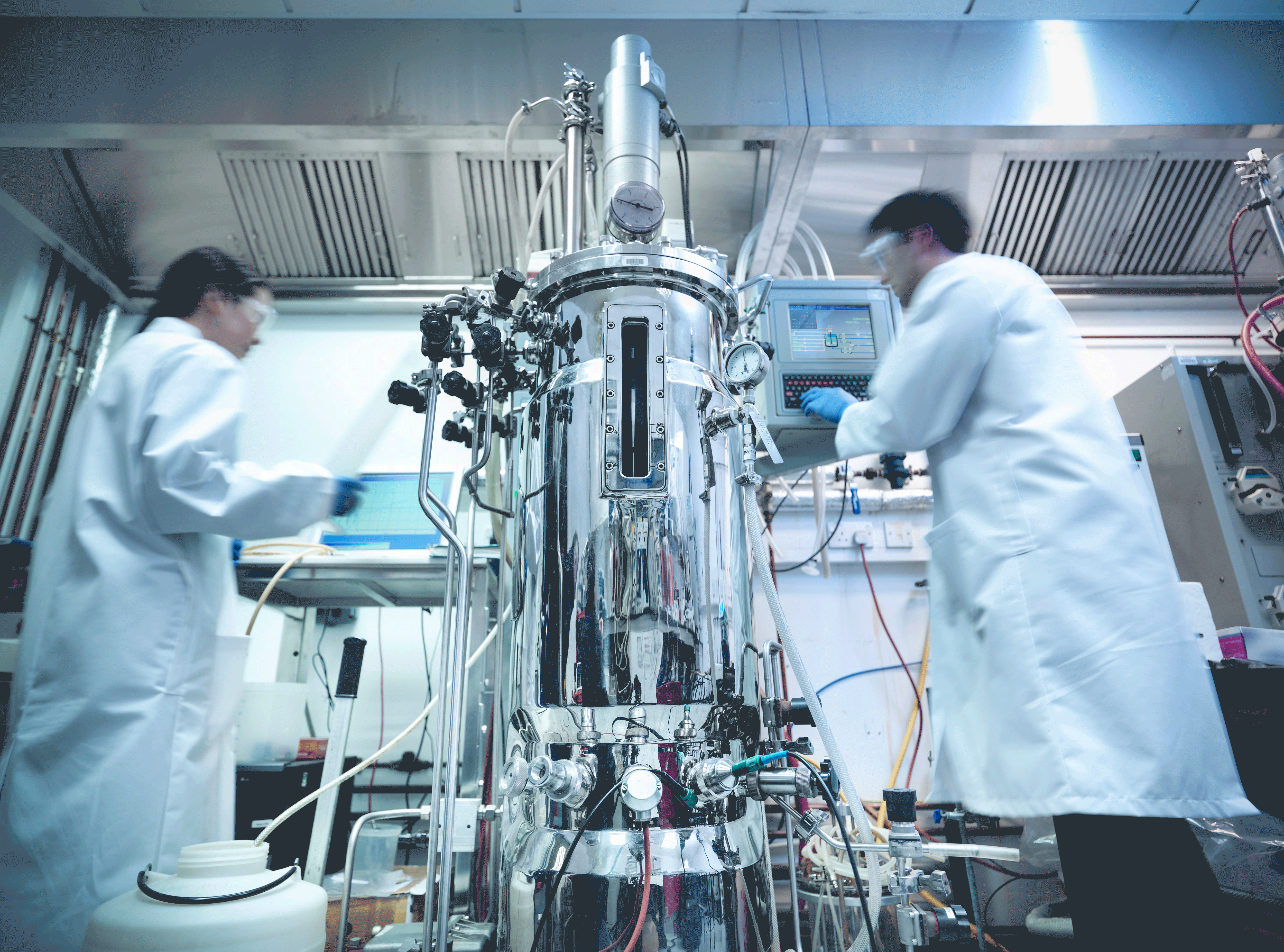

Biological manufacturing platforms open exciting opportunities to generate new materials, replace extractive processes, and perform ecosystem services through the deployment of metabolic pathways that are both found in nature and engineered. Further possibilities are generated through inter-kingdom collaborations and consortia-based pathways for manufacturing or biodegradation. In tandem, bioreactor technologies to support biocatalysis or bioconversion through novel immobilisation techniques enable flexibility in deployment. The intersection of physical, chemical and biological parameters within a novel bioreactor design will influence performance and stability in contexts beyond the sterility of the production facility. The nature and scale of new applications may invite unconventional production systems, or even consider in situ manufacturing as a potential way of disrupting centralised manufacturing and distribution processes. We may also consider how new technologies underpinning this approach could help us move beyond linear supply chains towards an embodiment of industrial ecology principles. We invite contributions that go beyond optimisation of a single pathway for product formation under conventional homogeneous conditions. Responses to this question will explicitly challenge how we currently design bioreactors through aspects of spatial distribution, connected systems or facilitating novel metabolic assemblages for multi-functional biosynthetic outputs.

Contributions

We particularly welcome highly experimental projects which seek alternatives to the existing methods of bioreactor design and metabolic engineering. We invite contributions in the following areas:

Results

-

Innovative methods of biosynthesis, bioconversion or biocatalysis supported by experimental data.

-

Examples of in situ deployments of new metabolic pathways including assessments of performance, quantitative and qualitative.

-

Appraisal of new bioreactor designs, including demonstrations of deployment in unconventional conditions.

-

Evaluation of new technologies for the scale up or intensification of bioprocesses relevant for environmental performance.

-

New metrics associated with green chemistry or biosynthesis – development of new indices to assess sustainability or quantify avoided products.

-

We also welcome null results papers that report unsuccessful experiments which may reveal fundamental limits of materials or processes.

Analysis

-

Reviews of key pathways, technologies and case studies.

-

Proposals for design and/or assessment flameworks. These can include the design of new design or modelling computational software and hardware, deployments of models such as Life Cycle Assessment for biological materials and processes.

-

Horizon scanning or ‘call to action’ articles assessing relevant emerging technologies.

Impact

-

Reviews of patents and industrial applications and interest in this area.

-

Critical evaluation of existing projects, their likely efficacy, evaluated against existing manufacturing methods.

-

Discussions on the legislative and industrial barriers to innovation.

Additional material and early outputs

We welcome a broad range of curated discussion pieces including submission of design portfolios, short polemics, position pieces, calls to action or provocations. As the question content develops, we expect this engagement to comment on the existing archive of published material.

How to contribute to this question

If you believe you can contribute to answering this Question with your research outputs find out how to submit in the Instructions for authors (https://www.cambridge.org/core/journals/research-directions-biotechnology-design/information/author-instructions/preparing-your-materials). This journal publishes Results, Analyses, Impact papers and additional content such as preprints and “grey literature”. Questions will be closed when the editors agree that enough content has been published to answer the Question so before submitting, check if this is still an active Question. If it is closed, another relevant Question may be currently open, so do review all the open Questions in your field. For any further queries check the information pages (https://www.cambridge.org/core/journals/research-directions-biotechnology-design/information/about-this-journal) or contact this email ([email protected]).

Competing interests

The author(s) declare none.