Published online by Cambridge University Press: 21 March 2017

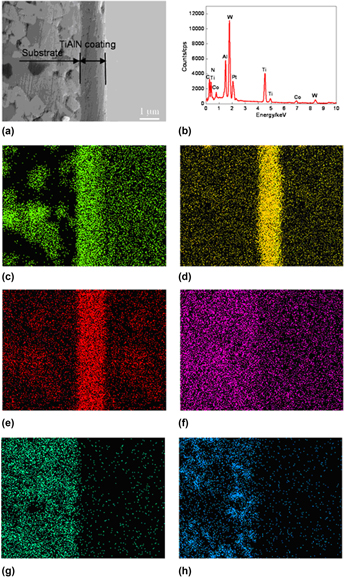

A TiAlN coating was deposited on a YT14 cemented carbide cutting tool using a cathodic arc ion plating, the surface-interface morphologies, chemical elements, phases, and microhardness of the obtained TiAlN coating were analyzed with a field emission scanning electronic microscope, energy dispersive spectrometer, X-ray diffraction, and microhardness tester, respectively, and the coating surface roughness and grain scale were characterized with a atomic force microscope. The bonding strength of the coating was measured with a scratch tester, and the friction–wear properties were investigated with a reciprocation type fiction–wear tester. The results show that the bonding strength of the coating is 54.9 N, and the coating microhardness reaches 2724 HV. The average coefficient of friction of the coating is 0.59, the wear mechanism is abrasive wear and slight brittle fracture.

Contributing Editor: Jürgen Eckert